You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Lasers in Medical Manufacturing<br />

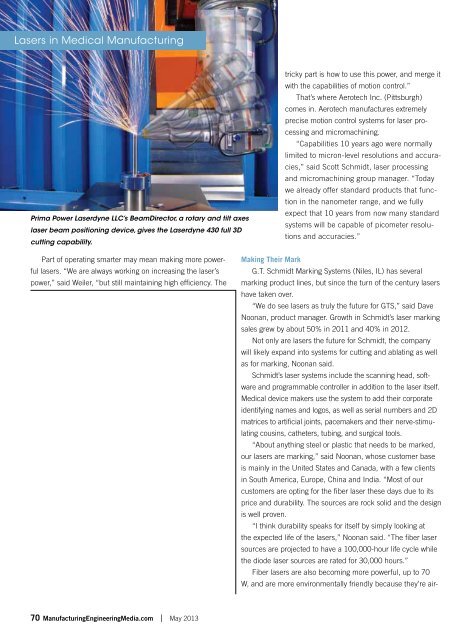

Prima Power Laserdyne LLC’s BeamDirector, a rotary and tilt axes<br />

laser beam positioning device, gives the Laserdyne 430 full 3D<br />

cutting capability.<br />

tricky part is how to use this power, and merge it<br />

with the capabilities of motion control.”<br />

That’s w<strong>here</strong> Aerotech Inc. (Pittsburgh)<br />

comes in. Aerotech manufactures extremely<br />

precise motion control systems <strong>for</strong> laser processing<br />

and micromachining.<br />

“Capabilities 10 years ago were normally<br />

limited to micron-level resolutions and accuracies,”<br />

said Scott Schmidt, laser processing<br />

and micromachining group manager. “Today<br />

we already offer standard products that function<br />

in the nanometer range, and we fully<br />

expect that 10 years from now many standard<br />

systems will be capable of picometer resolutions<br />

and accuracies.”<br />

Part of operating smarter may mean making more powerful<br />

lasers. “We are always working on increasing the laser’s<br />

power,” said Weiler, “but still maintaining high efficiency. The<br />

Making Their Mark<br />

G.T. Schmidt Marking Systems (Niles, IL) has several<br />

marking product lines, but since the turn of the century lasers<br />

have taken over.<br />

“We do see lasers as truly the future <strong>for</strong> GTS,” said Dave<br />

Noonan, product manager. Growth in Schmidt’s laser marking<br />

sales grew by about 50% in 2011 and 40% in 2012.<br />

Not only are lasers the future <strong>for</strong> Schmidt, the company<br />

will likely expand into systems <strong>for</strong> cutting and ablating as well<br />

as <strong>for</strong> marking, Noonan said.<br />

Schmidt’s laser systems include the scanning head, software<br />

and programmable controller in addition to the laser itself.<br />

Medical device makers use the system to add their corporate<br />

identifying names and logos, as well as serial numbers and 2D<br />

matrices to artificial joints, pacemakers and their nerve-stimulating<br />

cousins, catheters, tubing, and surgical tools.<br />

“About anything steel or plastic that needs to be marked,<br />

our lasers are marking,” said Noonan, whose customer base<br />

is mainly in the United States and Canada, with a few clients<br />

in South America, Europe, China and India. “Most of our<br />

customers are opting <strong>for</strong> the fiber laser these days due to its<br />

price and durability. The sources are rock solid and the design<br />

is well proven.<br />

“I think durability speaks <strong>for</strong> itself by simply looking at<br />

the expected life of the lasers,” Noonan said. “The fiber laser<br />

sources are projected to have a 100,000-hour life cycle while<br />

the diode laser sources are rated <strong>for</strong> 30,000 hours.”<br />

Fiber lasers are also becoming more powerful, up to 70<br />

W, and are more environmentally friendly because they’re air-<br />

70 ManufacturingEngineeringMedia.com | May 2013