Jarvie Journal - College of Dental Medicine - Columbia University

Jarvie Journal - College of Dental Medicine - Columbia University

Jarvie Journal - College of Dental Medicine - Columbia University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The <strong>Journal</strong> <strong>of</strong> the William <strong>Jarvie</strong> Society<br />

Evaluation <strong>of</strong> Fracture Resistance <strong>of</strong> E-Max Lithium Disilicate Customized<br />

Implant Abutments<br />

Techkouhie Hamalian 1 , Thomas Hill 2 , Anthony Randi 1*<br />

1 Postgraduate Prosthodontics, <strong>College</strong> <strong>of</strong> <strong>Dental</strong> <strong>Medicine</strong>, <strong>Columbia</strong> <strong>University</strong>, New York, NY<br />

2 Manager <strong>of</strong> Scientific Services, Research and Development, Ivoclar Vivadent, * Faculty Mentor<br />

Introduction: A recent study conducted by Sailer et al showed that the estimated 5-year survival rate<br />

<strong>of</strong> ceramic abutments on implants was 99.1%. Mechanically, zirconia (ZR) exhibits excellent fracture<br />

and chemical resistance as a result <strong>of</strong> transformation toughening. However, the mechanical shortcomings<br />

<strong>of</strong> ZR include their sensitivity to specific critical applied stress and controversial cementation protocols.<br />

The introduction <strong>of</strong> a lithium disilicate (LD) glass ceramic with 400 MPa <strong>of</strong> biaxial flexural strength<br />

(IPS e.max, Ivoclar Vivadent,) provides dentists with the option to use either conventional cementation<br />

or an adhesive bonding protocol. Therefore, this material has the potential to be used for definitive<br />

implant restorations. To date, there have been no published studies exploring the use <strong>of</strong> LD as an option<br />

to fabricate implant abutments.<br />

Objectives: The aim <strong>of</strong> this in-vitro pilot study is to evaluate the feasibility and the fracture resistance<br />

<strong>of</strong> customized LD E-max pressed abutments with E-max anterior monolithic crowns. Abutments<br />

incorporating metal inserts have shown to play a beneficial influence on the stability <strong>of</strong> ZR abutments.<br />

This study will evaluate 4 different implant connections (Branemark External hex, Nobel Replace Select,<br />

Biomet 3i, Straumann bone level).<br />

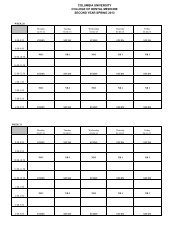

Materials and Methods: A total <strong>of</strong> 20 Abutments were tested. Machined engaging gold cylinders will<br />

be used to press the test LD groups. The null hypothesis is that pressed LD abutments will show<br />

clinically acceptable fracture resistance when compared to prefabricated ZR control abutments.<br />

Discussion: Failure modes <strong>of</strong> the ZR abutments were predominantly bending at the implant-abutment<br />

connection and screw loosening. The test LD abutments presented fractures at the cervical third level <strong>of</strong><br />

the gold cylinders, where higher concentration <strong>of</strong> tensile forces was found. Results didn’t show any<br />

debonding <strong>of</strong> the abutment-crown assembly. The intact abutment-crown interface could be explained by<br />

the chemical composition <strong>of</strong> lithium disilicate and its ability to create a strong bond. Most samples<br />

presented circumferentially around the metal insert <strong>of</strong> the gold cylinders, pressed lithium disilicate<br />

ceramics. This explains LD has the capability to flow and bond efficiently to metal.<br />

Results & Conclusions: E-Max abutments were technically possible to fabricate. LD pressed to the<br />

gold cylinders formed a strong adhesion. All test samples demonstrated adequate clinical values <strong>of</strong><br />

strength for anterior use (>300N). Plus, there were no statistical difference between the ZR and<br />

respective E-max groups (p>0.05) except for the 3i group (p