Master 2002-GB

Master 2002-GB

Master 2002-GB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MASTER<br />

First class spraying technology<br />

NEW

High tensile steel chassis – designed for<br />

robust use<br />

Polyethylene tank – high-impact and low<br />

centre of gravity<br />

Integrated Quick Hitch – simple and safe<br />

attachment<br />

MANIFOLD fluid system – perfect lay-out<br />

and very user friendly<br />

Rinsing equipment and safety locker –<br />

environmental advantages<br />

Outstanding boom range – to meet all field<br />

crop spraying demands<br />

Monitor or Controller – for simple and<br />

accurate spray management<br />

HARDI application technology –<br />

responsible and efficient plant care<br />

2

All key functions on the new MASTER are unsurpassed. The integrated Quick Hitch, the<br />

well-arranged MANIFOLD fluid system and the versatile boom range are some of the keyfeatures<br />

making handling a pleasure and spraying efficient.<br />

Quick Hitch<br />

The Quick Hitch (cat.II) is an<br />

integrated part of the chassis<br />

and is a valued standard feature.<br />

The Quick Hitch ensures<br />

easy and safe attachment to<br />

the tractor. To secure the<br />

sprayer attachment, the Quick<br />

Hitch is locked by safety hooks<br />

at the lower attachment points.<br />

Tank<br />

The high-impact polyethylene<br />

tank has a deep sump that<br />

ensures complete emptying of<br />

the tank. The tank design maximises<br />

liquid agitation as well as<br />

ensuring easy and efficient tank<br />

cleaning with the use of a tank<br />

flushing nozzle.<br />

A large platform ensures easy<br />

acces to the tank lid and the<br />

top-mounted suction filtre.<br />

Chassis<br />

The MASTER chassis is made<br />

in high tensile steel using stateof-the-art<br />

technology; the basis<br />

of a long lasting sprayer. The<br />

design considers operator’s<br />

safety, offers a low centre of<br />

gravity and service accessibility.<br />

Integrated support legs<br />

stabilise the sprayer safely on<br />

the ground when not in use and<br />

an optional wheel kit enables<br />

manoeuvring of the sprayer on<br />

hard level surface.<br />

MASTER<br />

3

Excellent by design,<br />

build and practical use<br />

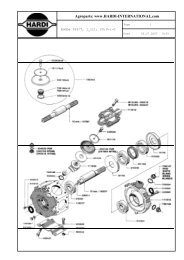

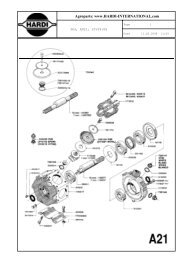

HARDI diaphragm pumps –<br />

the heart of the sprayer<br />

HARDI pumps are<br />

designed for the application<br />

of chemicals<br />

and liquid fertiliser.<br />

The diaphragms separate<br />

the liquid from the<br />

vital parts of the pump<br />

such as its bearings<br />

and crankshaft, ensuring<br />

reliable and durable<br />

operation.<br />

HARDI diaphragm pump features:<br />

• Self-priming<br />

• Able to run dry without damage<br />

• Easy to service without special tools<br />

• Grease lubricated crankcase<br />

• Chemical resistant diaphragms and<br />

valves<br />

Self-cleaning filter (optional for BK control unit)<br />

Standard fitted with an 80<br />

mesh screen (50 and 100<br />

mesh screens available). This<br />

very important safety feature<br />

minimises annoying downtime<br />

due to nozzle blockage and<br />

filters rinsing.<br />

A large and colour-coded<br />

suction filter is mounted on<br />

the main tank upper surface<br />

to allow inspection without spillage<br />

of spray liquid - even when the tank<br />

is full.<br />

MANIFOLD SYSTEM. The MANIFOLD valves operate all the<br />

fluid system functions on the sprayer; easily reached and<br />

logically incorporated into the MASTER design. A unique<br />

clamp assembly system allows servicing without special<br />

tools. Colour-coded valves and a quick-guide reference<br />

ensure easy and safe operation of the fluid system.<br />

HARDI FILLER. Chemicals are added to the main tank<br />

with safety, ease and efficiency using the HARDI FILLER<br />

(optional). FILLER wash-down and container-rinsing device<br />

are incorporated in the chemical inductor.<br />

FILLING device. Main tank FILLING device (optional) is<br />

placed below the manifold valves for ease of use from<br />

ground level.<br />

Clean water tank. An optional 15 l clean water tank for<br />

personal hygiene and a locker for safety equipment further<br />

improves the operator’s safety and his working environment.<br />

Rinsing tanks. Optional 80 l rinsing tanks (one or two) are<br />

integrated into the sprayer’s design to allow safe and efficient<br />

cleaning in the field; a very important component of<br />

good agricultural practice.<br />

EVC distribution valves.The remote controlled EVC control<br />

unit ensures quick on/off response of the sprayer and the<br />

individual distribution valves. An integral pressure equalisation<br />

feature prevents over-application when individual sections<br />

are closed. All vital parts of the EVC control unit are<br />

completely sealed off from the liquid.<br />

BK distribution valves. The unique manually operated HARDI<br />

BK control-unit features: Main on/off valve, pressure<br />

gauge, pressure filter and distribution valves with pressure<br />

equalisation. The integrated HARDI-MATIC device<br />

ensures a constant application rate regardless of speed<br />

variations within the same gear.<br />

4

Simple, solid sprayer electronics<br />

HARDI CONTROLLER 2500<br />

is a robust, simple-to-use<br />

sprayer controller.<br />

Permits automatic control<br />

of volume rate.<br />

HARDI MONITOR 1500<br />

monitors the volume<br />

applied.<br />

The HARDI CONTROLLER and MONITOR both feature:<br />

• Quick connections<br />

• Large two line readout<br />

• Display back-light<br />

• Audio/visual alarms<br />

• No batteries<br />

The equipment is easy to use and fit.<br />

Readout functions:<br />

• Volume rate being applied<br />

• Speed<br />

• Programmed and actual volume rate<br />

• Tank content<br />

• Liquid rate per minute<br />

• Active spraying swath width<br />

• Optional computer readout<br />

• One tripteller totalling covered area and<br />

volume sprayed<br />

• Eight triptellers for individual area covered<br />

and volume sprayed<br />

Optional extras:<br />

• Revolution transducer<br />

• Extra area meter transducer<br />

A versatile boom range – for the benefit of farming<br />

MASTER PRO VHY/VHZ<br />

MASTER MB<br />

MASTER HFM<br />

MASTER TWIN STREAM HAL<br />

Type of boom PRO VHY PRO VHZ HFM MB TWIN HAL<br />

Working width<br />

10 <br />

12 <br />

12,5 <br />

15 <br />

16 <br />

18 <br />

Features<br />

Adjustable trapeze <br />

Ordinary trapeze <br />

Tractor hydraulically operated Boom lift Boom lift <br />

Direct hydraulic<br />

<br />

Hydraulic boom slant Option Option Option Option<br />

Individual boom tilt<br />

<br />

Single side folding <br />

Folding 16 to 12 metre<br />

Option<br />

Spring loaded breakaway * <br />

Nozzle holder with check valve TRIPLET TRIPLET SINGLE SINGLE TRIPLET<br />

MASTER<br />

* mechanical<br />

5

PRO booms –<br />

the master<br />

of performance<br />

The PRO boom is designed and<br />

manufactured utilising our knowledge<br />

and experience as the<br />

world’s leading sprayer specialist.<br />

The boom offers every conceivable<br />

facility to meet different spraying<br />

requirements.<br />

The lattice boom structure<br />

ensures a strong<br />

and rigid boom; the<br />

basis for exact and uniform<br />

spray distribution.<br />

The nozzles, spray lines<br />

and hoses are all well<br />

protected within the<br />

boom design.<br />

6<br />

HARDI nozzles – precise and reliable<br />

HARDI supplies the a range of the highest quality nozzles<br />

for agricultural purposes. The range comprises<br />

ISO 110 ° Flat Fan nozzles, Low-Drift<br />

nozzles, INJET air inclusion nozzles, as<br />

well as 3-hole nozzles, 5-hole nozzles and<br />

foam nozzles for liquid fertilisers.<br />

TRIPLET nozzle assemblies are standard to enable quick<br />

nozzle changes with a simple rotation of the assembly. The<br />

TRIPLET features built-in non-drip check valves with a shutoff<br />

position between each nozzle location.<br />

All nozzles are developed and engineered with the most<br />

stringent focus on quality and precision. Being a manufacturer<br />

of both sprayers and nozzles, sets HARDI apart in<br />

the application technology field and further underlines the<br />

HARDI position as a sprayer specialist.<br />

A comprehensive range of nozzles for more specialised<br />

use is also available. For further nozzle information,<br />

please study the HARDI nozzle product guide or visit our<br />

homepage: www.hardi-nozzles.com

The adjustable trapeze is<br />

one of the secrets behind<br />

the superb boom performance.<br />

The trapeze can be<br />

adjusted for any field condition<br />

and spraying speed<br />

to achieve the best ride<br />

for the boom.<br />

The wheels guiding<br />

the boom lift are<br />

maintenance free.<br />

The coil-sprung<br />

boom-lift cylinder<br />

absorbs the shocks<br />

arising during high<br />

speed spraying.<br />

7

The slim line tank<br />

design combined with<br />

the compact folded<br />

PRO boom ensures<br />

optimal weight distribution<br />

and tractor<br />

stability whilst spraying<br />

and during road<br />

transport.<br />

The PRO boom is available in<br />

two versions:<br />

Tractor hydraulic outlets operate<br />

the VHY version - one<br />

single- and one double-acting<br />

outlet are required.<br />

The VHZ version is operated<br />

by direct hydraulic (DH) –<br />

one double-acting outlet is<br />

required.<br />

MASTER<br />

8

The VHZ version offers<br />

several facilities such<br />

as single-side folding<br />

and individual boom tilt.<br />

Spraying with the boom<br />

half-folded or 16 to 12<br />

m spraying widths are<br />

other unique features<br />

for the PRO-boom.<br />

Durable and reinforced boom<br />

hinges ensure a steady boom in<br />

spraying position. A spring-loaded<br />

breakaway section secures the tip<br />

of the boom.<br />

9

TWIN STREAM –<br />

unsurpassed<br />

application technique<br />

The HARDI TWIN is the most<br />

proven spraying system in the world<br />

and has demonstrably shown its<br />

reliability. Its unique form of airassistance<br />

provides magnificent<br />

drift-control, the highest fieldwork<br />

rate with benefits of notable chemical<br />

savings.<br />

10

The MASTER TWIN STREAM is the solution, when unsurpassable effectiveness,<br />

efficiency and safety is a demand.<br />

The TWIN STREAM is available<br />

in 12 and 15 m spray<br />

widths. The coil-sprung trapeze<br />

suspension ensures<br />

superb boom stability and<br />

isolates the boom from<br />

tractor movements.<br />

The angling of the aircurtain<br />

and nozzles - as<br />

well as adjustment of the<br />

air speed – are important<br />

features for minimising<br />

drift and optimising<br />

coverage. All adjustments<br />

can be remote controlled<br />

from the tractor cab.<br />

Angling of the spray<br />

ranges from ±18 degrees<br />

and the fan blower provides<br />

1500m 3 /h/m boom at<br />

speeds up to 30m/s.<br />

HARDI TWIN – advanced technology from a<br />

sprayer specialist.<br />

A conventional application technique may have<br />

to compromise between fieldwork rates and<br />

biological efficiency. Increased rates with drift<br />

reduction are possible using nozzles that produce<br />

coarse droplets, but only at the risk of<br />

losing some biological efficiency. Only HARDI<br />

TWIN enables high field work rates with fine<br />

droplet applications for maximum activity, but<br />

without the fear of drift.<br />

TWIN STREAM advantages:<br />

• Applications at higher spraying speeds<br />

• More “on time” optimal spraying hours<br />

• Lower water volume rates<br />

• Unsurpassed drift control<br />

• Effective, economic and safe plant protection<br />

product use<br />

MASTER<br />

All hydraulic functions,<br />

including the blower are<br />

driven by the tractor’s<br />

hydraulic system.<br />

Hydraulic boom slanting is<br />

optional, requiring one double-acting<br />

tractor outlet.<br />

HARDI TWIN user surveys reassure our claims:<br />

The work rate of one TWIN sprayer is equivalent<br />

to two conventional sprayers.<br />

An overall reduction of 16% pesticide used<br />

when compared to optimal conventional spraying<br />

techniques.<br />

For further details see the TWIN FACT booklet.<br />

A large number of research results are presented<br />

as well as recommendations of use.<br />

Read the booklet on our homepage:<br />

www.hardi-international.com<br />

Forward angling No angling Backward angling<br />

11

MASTER MB<br />

MASTER HFM<br />

The well-proven and very robust MB boom is available in boom widths<br />

of 10 and 12 m. The boom is manually folded with hydraulic boom<br />

height adjustment that requires one single-acting tractor outlet.<br />

The MB trapeze suspension for<br />

self-stabilisation of the boom is<br />

an important feature for optimising<br />

and improving spray distribution.<br />

Boom lock between<br />

intermediate and outer boom<br />

sections ensures optimal boom<br />

stability.<br />

The horizontal manually folded HFM boom is available in boom widths of<br />

12, 12,5 and 15 m. The 2-dimensional boom is easy to handle and the<br />

design enables single-side folding. The integrated folding and breakaway<br />

function saves weight. The boom is equipped as standard with single<br />

SNAP-FIT and diaphragm check valves.<br />

The centre section is suspended by means of a trapeze suspension and<br />

hydraulic boom height adjustment is standard. Requires a single-acting<br />

tractor outlet.<br />

Optional, hydraulic boom slant is available.<br />

An adjustable spring-loaded<br />

breakaway protects the boom<br />

from accidental collisions. Single<br />

SNAP-FIT nozzle holders with<br />

diaphragm check valves are<br />

standard on the MB booms.<br />

12

Optional extras<br />

Rinse tank<br />

Safety locker<br />

HARDI FILLER<br />

Filling device<br />

Traffic lights<br />

Specifications<br />

Tank size 800 1000 1200<br />

Pump 1303 (114 l/min) <br />

Pump 363 (183 l/min) <br />

Weight, kg<br />

PRO 12 m - 12.5 m 793 802 835<br />

PRO 15 m - 16 m 850 859 892<br />

PRO 18 m 908 917 950<br />

HAL 12 804 814 847<br />

HAL 15 893 903 936<br />

MB 10 m - 12 m 571 581 614<br />

HFM 12 m - 12.5 m 693 703 736<br />

HFM 15 734 744 777<br />

Measurments, cm A × B × C A × B × C A x B x C<br />

PRO 12 m - 12.5 m 153 × 250 × 271 153 × 250 × 271 166 × 250 × 271<br />

PRO 15 m - 16 m 153 × 250 × 271 153 × 250 × 271 166 × 250 × 271<br />

PRO 18 m 153 × 250 × 296 153 × 250 × 296 166 × 250 × 296<br />

HAL 12 190 × 260 × 271 190 × 260 × 271 203 × 260 × 271<br />

HAL 15 190 × 260 × 348 190 × 260 × 348 203 × 260 × 348<br />

MB 10 m - 12 m 135 × 240 × 250 135 × 240 × 250 148 × 250 × 230<br />

HFM 12 m - 12.5 m 145 × 262 × 250 145 × 262 × 250 158 × 262 × 205<br />

HFM 15 145 × 300 × 205 145 × 300 × 205 158 × 300 × 205<br />

MASTER<br />

In-line filters<br />

Hydraulic boom slant<br />

C<br />

A<br />

B<br />

Folding kit, from 16 to 12 m<br />

for 16 m boom<br />

Manouvering wheel kit<br />

13

HARDI – A global specialist in crop protection<br />

HARDI INTERNATIONAL A/S is an international group<br />

whose basic idea is to satisfy the user requirements for<br />

quality products ensuring efficient and responsible application<br />

of crop protection products.<br />

With production and development at 5 locations throughout<br />

the world and a worldwide distribution and service network,<br />

we maintain our global dominance through continuous<br />

research and development and constant focus on quality<br />

end user needs.<br />

M I S S I O N<br />

To promote efficient and responsible plant care in order<br />

to support quality plant growth and food production<br />

HARDI quality<br />

Investments in our state of the art production facilities are<br />

continuous, ensuring the ongoing optimisation of production<br />

processes. HARDI produces 90% of all components in<br />

order to ensure quality and optimal performance.<br />

Superb surface treatment<br />

The high technology surface treatment contains<br />

13 treatments, including a zinc-phosphate<br />

pre-treatment and powder coat painting<br />

of all major components. Together with<br />

the Delta/Magni treatment of nuts, bolts<br />

and other items, we supply high corrosion<br />

protection of our products.<br />

HøjeTaastrup, Denmark<br />

Nørre Alslev, Denmark<br />

HARDI product development<br />

Throughout the development of new HARDI<br />

sprayers, all items are structurally analysed<br />

utilising state of the art engineering software.<br />

The 5 development centres throughout the<br />

world work closely together in order to meet<br />

local demands and profit globally from our local<br />

presence. All developments undergo a tough<br />

internal testing both on test tracks and actual<br />

in-field conditions.<br />

HARDI service and support<br />

A key point in our distribution and sales support is a thorough<br />

and detailed training of dealer and service staff. We<br />

hold a large number of training courses on our premises.<br />

We use the latest technology in the distribution of information<br />

like PC and Internet technologies. Because of our size<br />

and global presence with local distribution, spare parts and<br />

information can be provided anywhere in the world.<br />

Spain<br />

France<br />

HARDI innovation<br />

With our focus on research and<br />

development we have registered<br />

a large amount of significant<br />

patents. Being the trend-setter<br />

in the industry, we continue our<br />

dedicated research in application<br />

technology.<br />

14<br />

HARDI reserves the right to change the specifications without notice.<br />

Illustrations shown may include optional extras and accessories.<br />

HARDI INTERNATIONAL A /S<br />

HELGESHØJ ALLÉ 38 • DK 2630 TAASTRUP • DENMARK<br />

E-Mail: hardi@hardi-International.com • www.hardi-International.com<br />

HIA-MARKETING<br />

<strong>GB</strong>-891811-06-<strong>2002</strong><br />

USA<br />

Australia