ercury/arrow

ercury/arrow

ercury/arrow

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

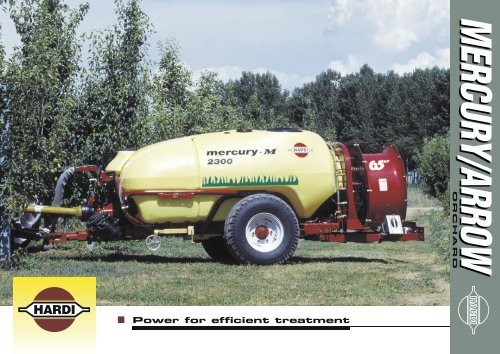

MERCURY/ARROWORCHARDPower for efficient treatment

The most extensive rangeof sprayers for protectionof fruit trees2Model Capacity Blower Pump Air kit(litres)(∅ mm)ARROW 1000ARROW 1500MERCURY 2000MERCURY 2300MERCURY 3000MERCURY 3500750 / 820820920DiaphragmF-SFDUO (DST/DHT)HEIGHT CONEMATCH*JET** Only available for MERCURY

Wide range of capacitiesHARDI’s trailed orchard sprayers are availablewith tank sizes from 1000 to 3500 litres.Wide range of air kitsYou can choose from a large variety of HARDI’sfans and cone deflectors, in order to optimize andadapt the generated air to your specific crop andworking conditions.Wide range of deflectorsThe DUO deflectors are available for all ARROWand MERCURY sprayers with axial fan. To obtainan optimum treatment of your crop with a minimumapplication rate, the choice is the verticalJET-deflector, which is available for all MERCURYsprayers.Better application performance and efficiencyThe quality and the volume of the generated airflow improve the over-all performance of themachines. You can treat at a higher forwardspeed and still obtain first-class penetration andefficiency of the application.Reliable and simpleThe design of the HARDI sprayers will meet yourdemands: A robust machine that is easy to use.High safety standardsWith the operator’s safety in mind, all areas thatare exposed to chemical products have beenplaced in the rear part of the machine.Minimised off-target applicationDrift and re-circulation of the air are kept to aminimum, thanks to the design of the air kits andnozzle placement.MERCURY MATCH working in citrus.MERCURY/ARROWDHT DUO deflector specially made for high trees with row spacing upto 6 m.3

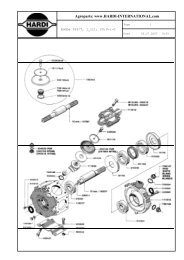

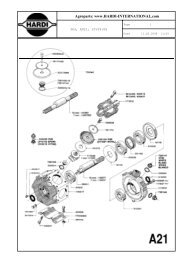

High quality componentsfor your next sprayerHARDI diaphragm pumps, theheart of the sprayerThey are designed for theapplication of plant protectionproducts and can beused for distribution ofliquid fertilizer as well.DrawbarsFour types of drawbars are available: With Ringhitch, with Fork hitch or an Articulated drawbar (standardor Heavy Duty version). All drawbars areadjustable in length.Model 363 features 6diaphragms. Volumesrange from 140 to195 l/min and pressureup to 20 bar.The 321 pump has 2 diaphragms.Output is 70l/min and the maximumpressure is 20 bar.For further protection against corrosion, themanufacturing process of the metallic partsare steel shot blasted, then treated with asynthetic priming coat and finally painted witha 2 component polyurethane paint. The chassisincorporates a jack wheel, wheel scrapersand a non-slip footstep that can be folded upwhen not used.Ring hitch drawbarFeatures• Self-priming• Able to run dry without damage• Grease lubricated crankcase• Chemical resistant diaphragms and valves• Able to rotate clockwise or anti-clockwise• Easy to service without special toolsFrameThe chassis is made of special UPN steel profilesproviding robust durability and resistanceto vibrations. The design and constructionprevent accumulation of dirt and thereby preventcorrosion.AxleThere is a wide range of fixed and adjustableaxles available for the trailed HARDI sprayers.Together with the many wheel types, theyplace the HARDI sprayers amongst the mostversatile machines in the market. The sprayercan be adapted to suit the terrain to themaximum by means of adjusting the wheeldistance. Further, the axles can be moved forwardsor backwards in order to change thecentre of gravity of the sprayer and therebyincreasemaximumstability ofthe sprayer.Fork hitch drawbarArticulated drawbar4Heavy Duty articulated drawbar

TankThe tanks are made of rotational mouldingpolyethylene, it has well-known propertiessuch as resistance to shocks and plantprotection chemicals. The smooth andBlue = Hand wash tankYellow = Main tankGreen = RinseTankrounded design optimises the performanceof the agitation system as well as easingthe tasks of filling and cleaning.Powder Mixer systemFeatures:• Capacities: from 1000 to 3500 litres• UV-resistant• Good stability as the over-all designensures a low centre of gravity• Main tank has an overcapacity of 5%,making filling a safe task• A 15 litre hand wash tank is situated atthe front, “the safe zone”• Rinse Tank and Tank Flush Nozzles forinside cleaning and rinsing the entire liquidsystem. Available only with the “Full”models• Tank contents indicators situated in thefront and on the side of the tank• Large drain valve in the sump of thetank. Remotely actuated from the topof the tank, to avoid operator exposition• Venturi agitation with high effect• Powder mixer placed in the main fillingstrainer• MERCURY sprayers have an integratedlocker for tools and spares• Smooth and rounded tank shape withoutprojections (hoses, lids, etc.) toavoid crop damage• Tank warranty - 5 years under normalworking conditionsTank Flush NozzleAir kitsThe air kits are oursecret to give youfirst-class application.Designed by aerodynamicspecialists, theair kits have better airdistribution, a lowernoise level, and lowerpower consumption.The ARROW and MERCURYsprayers can be adapted to all types ofplantation systems, thanks to HARDI’s fullrange of air kits and cone deflectors.The fans are made of aluminium and incorporatea centrifugal clutch (patented) thatassures minimum wear to the sprayer andto the tractor.MERCURY/ARROW5

The MATCH air kit incorporates six easilyadjustable air flaps for optimum direction ofthe airflow.Application systemsThe nozzle holders can be fitted with Bi-Jetsor Tri-Jets (for two or three nozzles respectively)if necessary.Nozzles1099Ceramic nozzle1299Ceramic hollow conenozzle1553Syntal hollow cone nozzle5131Syntal hollow cone nozzleMERCURY/ARROWAll nozzle holders are fitted with a non-dripvalve, that stops the liquid flow through thenozzles when pressure is below 0,5 bar.The nozzle holders in the MATCH air kit aresituated outside the air stream as a standard.In case of very dense crops, the air kit canbe delivered with the nozzle holders situatedinside the air stream for better protection.7

FConventional short fan housing with single nondripnozzle holders placed outside the air streamto avoid blocking of the outlet.The nozzles are angled towards the air stream tolet the fine droplets be mixed into the air streamand brought to the target.HEIGHT CONEThe Height Cone Deflector is designed with internalfixed channels to canalize the air upwards intwo uniform palm-shaped fans on left and rightsides of the blower unit. Very suitable for hightrees with wide canopy.SFLong fan housing with air vanes in the inlet canalizesa smooth uniform air stream to the blower,which sends up an evenly distributed air stream.Double non-drip nozzle holders angled towards thepowerful air stream, which bring the fine dropletsto the target.MATCHFor treatment of the most dense crops, where acompact, powerful sprayer is needed.With output up by 15%, superior control of dropletsis provided with 6 easily adjustable flaps atthe outlet.DUO DST/DHTStainless steel deflector that divides the topair from the blower and directs it towards bothsides. The DUO deflectors are very suitable forrow crops such as vines, apples, olives, etc. asthe height of the air stream is controllable thanksto the adjustable top deflectors.JETDesigned with internal channels that create a stronguniform air curtain. The air stream mixes with thedroplets and brings them to the target. Suitable fortall hedgerow crops such as apples and cherries.Two adjustable top deflectors, allow precise adjustmentaccording to the height of the target.MERCURY/ARROW9

CalibrationOptional extrasThe success of a plant protection treatmentdepends on three factors:1. The right choice of plant protectionchemical2. The right timing of the treatment3. The use of a sprayer that is properlycalibratedPrecision and goodspraying practice arekey factors for a goodtreatment. The timeused for adjusting andadapting the sprayer tothe desired treatmentshould be consideredas an investment inoptimising the sprayingtechnique, in order to:1. Only use the necessarydose of theplant protectionchemical2. Minimize the loss todrift3. Increase the qualityof the crop4. Reduce costsHARDI CONTROLLER 2500Spray computer for simple and easy automatic control ofthe application volume. You just concentrate on driving whileHC2500 takes care of your crop, maintaining the applicationvolume constant according to the information you have preset.HARDI MONITOR 1500Informs you of the actual application volume. Easy manualadjustment of working pressure.HARDI SONARThe electric control box is situatedin the cabin of the tractor.It is easily programmable eitherdirectly or by means of a PC. Canbe operated manually also.The ultrasonic proximity sensordetects objects within a distance of60 cm to 6 metres. The minimum/maximum range can be adjusted tosuit the actual plantation.Hydraulic brakesHARDI CONTROLLER 5500Spray computer for automatic control of the applicationvolume. The big screen with 4 line read-out gives you all theinformation you need all the time.Easy to use. Includes the function UCR (Unit Canopy Row),which gives you the opportunity to apply the spray liquid infunction of the volume of the vegetation to be treated.Wheel suspensionElectric or hydraulic regulationof the upper deflectors in DUO.10

FSFDUOHEIGHTCONEMATCHJETTechnical specificationsModel ARROW ARROW MERCURY MERCURY1000Measurements, (mm)1500 2000/2300 3000/3500Weights, (Kg)Weight 540 600 830 1070A 3630 3880 4340 4510B 1420 1470 1600 1800C *1000 1200 1450 1650Weight 560 620 850 1090A 3630 3880 4340 4510B 1420 1470 1600 1800C *1000 1200 1450 1650Weight 590 650 880 1120A 3620 3870 4340 4520B 2170 2220 2050 2170C *1000 1200 1450 1650Weight 560 620 850 1090A 3630 3880 4340 4510B 1420 1470 1600 1800C *1000 1200 1450 1650Weight 640 870 1110A 3880 4340 4510B 1470 1600 1800C 1200 1450 1650Weight 660 890 1130A 3880 4340 4510B 2330 2570 2580C 1200 1450 1650Pump characteristics* Standard axle: 1200 mmOptional axle: 1000 mmConversion from mm to inch: mm × 0,0394Measurement “A” for sprayer fi tted with drawbar with fork hitchLong drawbar with ring hitch: add 640 mmShort drawbar with ring hitch: add 155 mmArticulated drawbar: add 260 mmModel / stroke, (mm) 321/10 363/7 363/10Number of diaphragms 2 6 6Maximum revolutions, (r/min) 540 540 540Maximum pressure, ( bar ) 20 20 15Volume, ( l/min ) 70 140 194Power consumption, ( kW ) 3,0 5,4 6,2Lubrication grease grease greaseACBMERCURY/ARROW11

HARDI – A global specialist in crop protectionHARDI INTERNATIONAL A/S is an international group whosebasic idea is to satisfy the user requirements for qualityproducts ensuring efficient and responsible application ofcrop protection products.With production and development at 5 locations throughoutthe world and a worldwide distribution and service network,we maintain our global dominance through continuousresearch and development and constant focus on qualityend user needs.M I S S I O NTo promote efficient and responsible plant care in orderto support quality plant growth and food productionHARDI product developmentThroughout the development of new HARDIsprayers, all items are structurally analysedutilising state of the art engineering software.The 5 development centres throughout theworld work closely together in order to meetlocal demands and profit globally from our localpresence. All developments undergo a toughinternal testing both on test tracks and actualin-field conditions.HARDI qualityInvestments in our state of the art production facilities arecontinuous, ensuring the ongoing optimisation of productionprocesses. HARDI produces 90% of all components inorder to ensure quality and optimal performance.HARDI service and supportA key point in our distribution and salessupport is a thorough and detailed trainingof dealer and service staff. We hold alarge number of training courses on ourpremises. We use the latest technology inthe distribution of information like PC andInternet technologies. Because of our sizeand global presence with local distribution,spare parts and information can be provided anywhere inthe world.InternationalisationHARDI products are sold throughout the world in morethan 100 countries. We have factories in Denmark, France,Spain, Australia and North America. Further we have salessubsidiaries in England, Sweden, Norway, Germany and Canada.All these countries are handled by a net of highly educatedand committed dealers. Thanks to this global presencewith local distribution, you can obtain information andspare parts from HARDI anywhere in the world.HøjeTaastrup, DenmarkNørre Alslev, DenmarkSpainFranceHARDI innovationWith our focus on research anddevelopment we have registereda large amount of significantpatents. Being the trend-setterin the industry, we continue ourdedicated research in applicationtechnology.HARDI reserves the right to change the specifications without notice.Illustrations shown may include optional extras and accessories.HARDI INTERNATIONAL A /SHELGESHØJ ALLÉ 38 • DK 2630 TAASTRUP • DENMARKE-Mail: hardi@hardi-International.com • www.hardi-International.comHIA-MARKETINGGB-893831-04-2004USAAustralia