product data - StonCor Africa

product data - StonCor Africa

product data - StonCor Africa

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

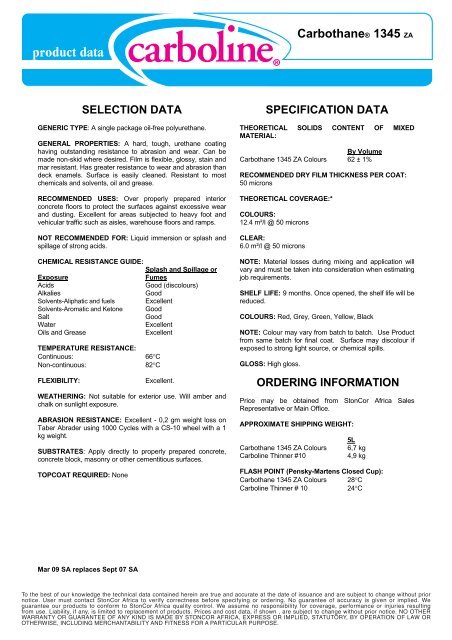

<strong>product</strong> <strong>data</strong><br />

Carbothane® 1345 ZA<br />

SELECTION DATA<br />

GENERIC TYPE: A single package oil-free polyurethane.<br />

GENERAL PROPERTIES: A hard, tough, urethane coating<br />

having outstanding resistance to abrasion and wear. Can be<br />

made non-skid where desired. Film is flexible, glossy, stain and<br />

mar resistant. Has greater resistance to wear and abrasion than<br />

deck enamels. Surface is easily cleaned. Resistant to most<br />

chemicals and solvents, oil and grease.<br />

RECOMMENDED USES: Over properly prepared interior<br />

concrete floors to protect the surfaces against excessive wear<br />

and dusting. Excellent for areas subjected to heavy foot and<br />

vehicular traffic such as aisles, warehouse floors and ramps.<br />

NOT RECOMMENDED FOR: Liquid immersion or splash and<br />

spillage of strong acids.<br />

CHEMICAL RESISTANCE GUIDE:<br />

Splash and Spillage or<br />

Exposure<br />

Fumes<br />

Acids<br />

Good (discolours)<br />

Alkalies<br />

Good<br />

Solvents-Aliphatic and fuels Excellent<br />

Solvents-Aromatic and Ketone Good<br />

Salt<br />

Good<br />

Water<br />

Excellent<br />

Oils and Grease<br />

Excellent<br />

TEMPERATURE RESISTANCE:<br />

Continuous: 66°C<br />

Non-continuous: 82°C<br />

FLEXIBILITY:<br />

Excellent.<br />

WEATHERING: Not suitable for exterior use. Will amber and<br />

chalk on sunlight exposure.<br />

ABRASION RESISTANCE: Excellent - 0,2 gm weight loss on<br />

Taber Abrader using 1000 Cycles with a CS-10 wheel with a 1<br />

kg weight.<br />

SUBSTRATES: Apply directly to properly prepared concrete,<br />

concrete block, masonry or other cementitious surfaces.<br />

TOPCOAT REQUIRED: None<br />

SPECIFICATION DATA<br />

THEORETICAL SOLIDS CONTENT OF MIXED<br />

MATERIAL:<br />

By Volume<br />

Carbothane 1345 ZA Colours 62 ± 1%<br />

RECOMMENDED DRY FILM THICKNESS PER COAT:<br />

50 microns<br />

THEORETICAL COVERAGE:*<br />

COLOURS:<br />

12.4 m²/l @ 50 microns<br />

CLEAR:<br />

6.0 m²/l @ 50 microns<br />

NOTE: Material losses during mixing and application will<br />

vary and must be taken into consideration when estimating<br />

job requirements.<br />

SHELF LIFE: 9 months. Once opened, the shelf life will be<br />

reduced.<br />

COLOURS: Red, Grey, Green, Yellow, Black<br />

NOTE: Colour may vary from batch to batch. Use Product<br />

from same batch for final coat. Surface may discolour if<br />

exposed to strong light source, or chemical spills.<br />

GLOSS: High gloss.<br />

ORDERING INFORMATION<br />

Price may be obtained from <strong>StonCor</strong> <strong>Africa</strong> Sales<br />

Representative or Main Office.<br />

APPROXIMATE SHIPPING WEIGHT:<br />

Carbothane 1345 ZA Colours<br />

Carboline Thinner #10<br />

5L<br />

6,7 kg<br />

4,9 kg<br />

FLASH POINT (Pensky-Martens Closed Cup):<br />

Carbothane 1345 ZA Colours 28°C<br />

Carboline Thinner # 10 24°C<br />

Mar 09 SA replaces Sept 07 SA<br />

To the best of our knowledge the technical <strong>data</strong> contained herein are true and accurate at the date of issuance and are subject to change without prior<br />

notice. User must contact <strong>StonCor</strong> <strong>Africa</strong> to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We<br />

guarantee our <strong>product</strong>s to conform to <strong>StonCor</strong> <strong>Africa</strong> quality control. We assume no responsibility for coverage, performance or injuries resulting<br />

from use. Liability, if any, is limited to replacement of <strong>product</strong>s. Prices and cost <strong>data</strong>, if shown , are subject to change without prior notice. NO OTHER<br />

WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY STONCOR AFRICA, EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR<br />

OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

APPLICATION INSTRUCTIONS<br />

These instructions are not intended to show <strong>product</strong> recommendations for specific service. They are issued as an aid in determining correct surface<br />

preparation, mixing instructions and application procedure. It is assumed that the proper <strong>product</strong> recommendations have been made. These<br />

instructions should be followed closely to obtain the maximum service from the materials.<br />

SURFACE PREPARATION: Remove any oil or grease from<br />

surface to be coated.<br />

Concrete floors should be at least as rough as medium grit<br />

sandpaper. The surface should be free of laitance. This can be<br />

accomplished by acid etch or mechanical abrasion. Do not coat<br />

concrete floors treated with hardening solutions unless test<br />

patch indicates satisfactory adhesion. Do not apply coating<br />

unless concrete has cured at least 28 days @ 25°C and 50%<br />

R.H.<br />

MIXING: Mix to smooth consistency before thinning. Thin 25%<br />

by volume with Carboline Thinner # 10 for first coat. Apply<br />

second coat undiluted.<br />

APPLICATION TEMPERATURES:<br />

Material<br />

Surface<br />

Normal 18-29°C 16-29°C<br />

Minimum 10°C 10°C<br />

Maximum 38°C 38°C<br />

Ambient<br />

Humidity<br />

Normal 10-32°C 35-80%<br />

Minimum 10°C 10%<br />

Maximum 43°C 90%<br />

Do not apply when the surface temperature is less than 2°C<br />

above the dew point. Special thinning and application<br />

techniques may be required above or below normal condition.<br />

SPRAY: Use adequate air volume for correct application. Hold<br />

gun 200-250 mm from the surface and at a right angle to the<br />

surface.<br />

Use a 50% overlap with each pass of the gun. On irregular<br />

surfaces, coat the edges first, making an extra pass later.<br />

NOTE: The following equipment has been found suitable,<br />

however, equivalent equipment may be substituted.<br />

CONVENTIONAL: Use a 10 mm minimum I.D. Material Hose.<br />

Mfr. & Gun Fluid Tip Air Cap<br />

Binks # 18 or # 62 63B 63PB<br />

DeVilbiss P-MBC or JGA FX (Approx. .043 ID) 704<br />

AIRLESS: Use a 10 mm minimum I.D. Material Hose.<br />

Mfr. & Gun<br />

Pump*<br />

DeVilbiss JGB-507 QFA-514<br />

Graco 205-591 President 30:1 or Bulldog 30:1<br />

Binks Model 500 Mercury 5C<br />

* Teflon packings are recommended and available from<br />

pump manufacturer.<br />

Use a 0.015" tip with 2000 psi. (138 Bar)<br />

BRUSH OR ROLLER: Brush or spread using long even<br />

full strokes. Avoid rebrushing. Rollers should be medium<br />

nap mohair or lint free lambs wool. Use slow even strokes<br />

with maximum amount of thinner to avoid air entrapment.<br />

Avoid rerolling.<br />

NON-SKID SURFACE: Broadcast Non - skid grit into the<br />

second-to-last coat of Carbothane 1345 ZA. Apply a full<br />

coat of Carbothane 1345 ZA over the silica for ease of<br />

cleaning.<br />

DRYING TIMES:<br />

Between Coats Final Cure<br />

@ 50% R.H.<br />

@ 50% R.H.<br />

12 hours 10°C 48 hours<br />

8 hours 16°C 36 hours<br />

6 hours 24°C 24 hours<br />

4 hours 32°C 18 hours<br />

NOTE: If more than 12 hours @ 25°C or equivalent time<br />

has elapsed between coats, special surface preparation<br />

will be required.<br />

CLEAN UP: Use Carboline Thinner # 10<br />

STORAGE CONDITIONS:<br />

Temperature:<br />

4-43°C<br />

Humidity: 0-95%<br />

For more detailed information please consult specific<br />

Carboline Application Guides<br />

CAUTION: MAY CONTAIN FLAMMABLE SOLVENTS. KEEP AWAY FROM SPARKS AND OPEN FLAMES. IN CONFINED AREAS WORKMEN MUST WEAR<br />

FRESH AIRLINE RESPIRATORS. HYPERSENSITIVE PERSONS SHOULD WEAR GLOVES OR USE PROTECTIVE CREAM. ALL ELECTRONIC<br />

EQUIPMENT AND INSTALLATIONS SHOULD BE MADE AND GROUNDED IN ACCORDANCE WITH THE NATIONAL ELECTRICAL CODE. IN AREAS<br />

WHERE EXPLOSION HAZARDS EXIST, WORKMEN SHOULD BE REQUIRED TO USE NONFERROUS TOOLS AND TO WEAR CONDUCTIVE<br />

AND NONSPARKING SHOES.<br />

An<br />

Company<br />

<strong>Africa</strong><br />

<strong>StonCor</strong> <strong>Africa</strong> (Pty) Ltd<br />

Co. Reg. No.: 1996/01848/07<br />

Tel No : +27 11 254 5500<br />

Website: www.stoncor.co.za<br />

E-mail: stoncorsa@stoncor.com