2013 Owner's Manual - Bear Archery

2013 Owner's Manual - Bear Archery

2013 Owner's Manual - Bear Archery

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>2013</strong><br />

Owner’s <strong>Manual</strong><br />

Members of the ATA<br />

817 Maxwell Avenue • Evansville, IN 47711<br />

800-694-9494 • fax 812-467-1245<br />

www.<strong>Bear</strong><strong>Archery</strong>Products.com

Contents<br />

Important Bow Information 3-5<br />

<strong>Archery</strong> Safety & Warnings 6-7<br />

Bow Diagrams 8-10<br />

Care & Maintenance 11-12<br />

Bow/Cam Adjustments 13-30<br />

Initial Bow Setup 32-36<br />

Arrow Selection Information 37<br />

Warranties 38-39<br />

Record important bow information here<br />

and keep for future reference.<br />

Model:__________________________<br />

Weight Range:___________________<br />

Draw Length:____________________<br />

String Length:___________________<br />

Cable Length:___________________<br />

Purchased From:_________________<br />

Date Purchased:__________________<br />

Serial Number:___________________<br />

2

Congratulations! Your new <strong>Bear</strong> <strong>Archery</strong><br />

compound bow is the finest available. It has been<br />

engineered for accuracy, long life, and built with<br />

quality and pride. No other bow delivers a higher<br />

performance to value ratio than a <strong>Bear</strong>. We know<br />

how much you are going to enjoy your new bow.<br />

For this reason, we ask you read the Care and<br />

Maintenance section carefully to learn how easy it<br />

is to maintain the quality, performance, and level<br />

of satisfaction you expect from a <strong>Bear</strong> <strong>Archery</strong><br />

product.<br />

ENJOY YOUR NEW BOW!<br />

! IMPORTANT LIMB !<br />

! INFORMATION !<br />

Your new <strong>Bear</strong> <strong>Archery</strong> bow uses<br />

the latest technology in limb design. This creates<br />

a limb capable of storing optimal amounts of<br />

energy unlike any other bow in the industry. For<br />

that reason, the use of limb mounted accessories<br />

such as vibration dampeners must be restricted.<br />

These particular accessories MUST NOT<br />

BE mounted more than 2 inches from the<br />

limb pockets. Mounting limb accessories<br />

more than 2 inches away from the pockets,<br />

particularly clamping type accessories, can<br />

potentially damage the limbs and void the<br />

warranty. See the illustration below.<br />

2” MAX<br />

Limb mounted<br />

accessories CAN BE<br />

MOUNTED IN<br />

THIS REGION OF<br />

THE LIMB ONLY.<br />

3

! IMPORTANT PRESS !<br />

! INFORMATION !<br />

Due to the innovative and advanced design of<br />

your <strong>Bear</strong> <strong>Archery</strong> bow limbs, it is of the utmost<br />

importance that your bow ONLY BE<br />

PRESSED IN PROPER BOW PRESSES.<br />

Traditional style presses that use rollers to apply<br />

pressure only to the mid section of the limbs<br />

CANNOT BE USED. Only presses that are<br />

capable of applying pressure to the last 2” of the<br />

limbs should be utilized, as illustrated below<br />

!NOTE! – Limb bolts MUST be backed out 4<br />

complete turns prior to pressing a bow equipped<br />

with flare quad limbs and 3 complete turns for<br />

bows equipped with max pre-load quad limbs.<br />

DO NOT USE THIS STYLE PRESS ARMS<br />

APPROVED BOW PRESSES:<br />

For the most up to date and accurate list, please<br />

visit your local <strong>Bear</strong> <strong>Archery</strong> dealer or<br />

www.<strong>Bear</strong><strong>Archery</strong>Products.com<br />

Failure to adhere to this list of<br />

presses can result in immediate failure of the<br />

limbs, possible injury and void the<br />

manufacturer’s warranty.<br />

4

! IMPORTANT PRESS !<br />

! INFORMATION !<br />

Certain bow models<br />

require the use of fixed<br />

stops to prevent the<br />

press forces from<br />

pushing the bow out of<br />

the bottom of the press<br />

Bow press MUST only<br />

be applied to the outer<br />

2” of limb tips.<br />

Press<br />

must<br />

ONLY<br />

apply<br />

pressure<br />

to the<br />

limbs in<br />

this<br />

area.<br />

Press<br />

should be<br />

capable of<br />

adjusting<br />

to the<br />

riser’s full<br />

length<br />

5

! SAFETY FIRST !<br />

Before using this equipment, read and follow<br />

these manufacturer’s instructions carefully. If you<br />

have any questions, contact the manufacturer or<br />

a qualified dealer.<br />

Dry-firing a bow severely reduces<br />

the life expectancy of the bow and may cause<br />

immediate damage to the bow resulting in injury<br />

to yourself or others. Never dry-fire your bow!<br />

Never pull back and release the bowstring<br />

without an arrow attached to the string. Your<br />

bow is designed to transfer energy to a properly<br />

weighted arrow.<br />

Shooting underweight arrows has<br />

the same effect as dry-firing a bow and may<br />

cause serious injury. Use the proper arrow for<br />

you and your bow. If you are unsure about your<br />

arrow choice, contact your local <strong>Bear</strong> <strong>Archery</strong><br />

dealer or an arrow manufacturer.<br />

Do not use wooden or fiberglass<br />

arrows. They are not designed for use with this<br />

compound bow and may cause serious injury.<br />

Use the proper arrow for you and your bow. If<br />

you are unsure about your arrow choice, contact<br />

your archery dealer or an arrow manufacturer.<br />

Inspect your arrows and nocks<br />

regularly. Immediately discard any dented, split,<br />

splintered or otherwise damaged arrows and<br />

replace cracked or broken nocks.<br />

Do not draw your bow beyond its<br />

maximum draw length as damage to the limbs,<br />

cables and strings could occur.<br />

The use of safety glasses is recommended with<br />

any archery product.<br />

6

! SAFETY FIRST !<br />

Targets and Hunting Safety<br />

‣ Be sure of your target. Bowhunters often<br />

wear camouflage and are difficult to<br />

identify.<br />

‣ Never aim at anything you don’t intend to<br />

shoot.<br />

‣ Never point or aim a drawn bow at<br />

another person.<br />

‣ Never draw or shoot when anyone is<br />

between you and your target.<br />

‣ Never shoot at a target or object unless<br />

you are sure that it can stop your arrows.<br />

‣ Make sure the area behind and around<br />

your target is clear.<br />

‣ Before shooting, be sure that no part of<br />

the bow will strike any tree branches or<br />

other obstacles.<br />

‣ Never shoot arrows straight up in the air<br />

or in any direction where you might<br />

destroy property or endanger life.<br />

Pre-shooting checklist<br />

Are these items in good condition<br />

Properly installed In working order<br />

___ Cables<br />

___ String<br />

___ String Serving<br />

___ Loop/Nock set<br />

___ Cable Slide<br />

___ Sight<br />

___ Arrow Rest<br />

___ Arrow Nocks<br />

___ Arrow Shafts<br />

___ Set Screws<br />

7

BOW DIAGRAMS<br />

Understanding your bow and its component<br />

parts will add to your archery enjoyment.<br />

Although bows differ in performance and<br />

features, these photos represent the components<br />

available in various combinations on most<br />

models. Being familiar with this information will<br />

help you with the instructions throughout this<br />

manual. Also, you can refer to these photos when<br />

ordering parts or making technical inquiries.<br />

Weighted<br />

Axle<br />

Dampeners<br />

Flare Quad<br />

Limbs<br />

Cable with<br />

Split Yoke<br />

Limb Bolt<br />

Assembly<br />

Arc String<br />

Suppressor<br />

Cable guard<br />

Continuous<br />

String<br />

Cable Slide<br />

Arrow Rest<br />

Mounting Holes<br />

8

BOW DIAGRAMS<br />

Rocker<br />

Pivot<br />

Idler<br />

Wheel<br />

Limb<br />

Pocket<br />

Riser<br />

Sight Window and<br />

Mounting Holes<br />

Roller Cable<br />

Guard<br />

Rest Mounting Holes<br />

(Berger Hole)<br />

Grip<br />

Stabilizer<br />

Mounting<br />

Hole<br />

String<br />

Suppressor Rod<br />

String<br />

Suppressor<br />

Rubber<br />

Max Pre-Load<br />

Quad Limbs<br />

Cam<br />

Single Cam Bow<br />

9

BOW DIAGRAMS<br />

Limb<br />

Pocket<br />

Cap<br />

Limb<br />

Pocket<br />

Pivot<br />

Top<br />

Cam<br />

String<br />

Riser<br />

Buss<br />

Cable<br />

Sight Window and<br />

Mounting Holes<br />

Roller Cable<br />

Guard<br />

Rest Mounting Holes<br />

(Berger Hole)<br />

Control<br />

Cable<br />

Grip<br />

Stabilizer<br />

Mounting<br />

Hole<br />

String<br />

Suppressor Rod<br />

String<br />

Suppressor<br />

Rubber<br />

Max Pre-Load<br />

Quad Limbs<br />

Bottom Cam<br />

Hybrid Cam Bow<br />

10

CARE AND<br />

MAINTENANCE<br />

With proper care and a minimum amount of<br />

routine maintenance, your bow will be kept in<br />

top condition. However, it is still important to<br />

carefully inspect your bow on a regular basis.<br />

Cleaning<br />

Your bow should be kept clean of dust, mud and<br />

grime. Use a damp soft cotton cloth to remove<br />

dirt and moisture. Do not use solvents such as<br />

acetone or mineral spirits as they may ruin the<br />

finish.<br />

Storage and Transportation<br />

Avoid exposing your bow to temperatures over<br />

150 degrees. Excessive heat may damage your<br />

bow. Do not leave your bow unprotected in your<br />

vehicle on a hot sunny day or store in a hot attic<br />

or other hot enclosed area. Clean your bow<br />

thoroughly after each use. Never put your bow<br />

away wet or store it in a damp place. Lightly oil<br />

all steel parts (axles, mounting screws) to prevent<br />

rust. You can relax the limbs if storing for more<br />

than a year. Follow the instructions under Peak<br />

Draw Weight Adjustment in the bow adjustment<br />

section.<br />

Bow Presses<br />

Use only “double-pull” type APPROVED bow<br />

presses. A “double-pull” bow press draws your<br />

bow down at two points on the riser. Older style<br />

“single-pull” bow presses that contact the bow<br />

only in the grip area can result in bent or broken<br />

risers.<br />

To reduce unnecessary stress on the riser, back<br />

off the limb bolts 2-3 turns before placing in a<br />

press. See page 4 and/or<br />

www.<strong>Bear</strong><strong>Archery</strong>Products.com for additional<br />

bow press information.<br />

11

CARE AND<br />

MAINTENANCE<br />

Lubrication<br />

Your <strong>Bear</strong> <strong>Archery</strong> compound bow requires very<br />

little lubrication. Wipe the cable guard<br />

periodically with a dry cloth to keep the cable<br />

slide running smoothly and free of dust. Cam and<br />

idler wheel bearings do not require lubrication. If<br />

other lubrication is necessary, use white lithium<br />

grease or Teflon lubricants. Avoid excessive<br />

lubrication of any item, as this can attract dirt.<br />

On hunting bows, avoid lubricants with obvious<br />

odors.<br />

String and Synthetic Cable Maintenance<br />

Regularly apply a high quality bowstring wax to<br />

your string and synthetic cable system. Regular<br />

waxing protects your cables and strings from<br />

abrasion, wear and separation. Smear the wax<br />

into position. Then, rub it gently with your<br />

fingers or a soft piece of leather to work the wax<br />

into the strands. Replace frayed or worn<br />

bowstrings and cables immediately.<br />

•<strong>Bear</strong> <strong>Archery</strong> strongly recommends replacing<br />

the bowstring and cable annually. Please visit<br />

your local <strong>Bear</strong> <strong>Archery</strong> dealer for assistance.<br />

12

BOW ADJUSTMENTS<br />

Peak Draw Weight Adjustment<br />

<strong>Bear</strong> <strong>Archery</strong> bows have an approximate 10<br />

pound peak weight adjustment range. If your<br />

bow is equipped with limb bolt lock downs,<br />

make sure these screws (small single button head<br />

screw attached to riser through “tang”<br />

protruding from underneath the limb pocket) are<br />

loosened before making any weight adjustments.<br />

Using a 7/32” hex wrench for bows with a 3/8-<br />

16 limb bolt, and a 3/16” hex wrench for bows<br />

with a 5/16-18 limb bolt, turn the limb bolts<br />

clockwise to increase peak weight and counterclockwise<br />

to reduce peak weight. Bow weight will<br />

increase or decrease approximately two to four<br />

pounds per turn. IMPORTANT Both limb<br />

bolts must be adjusted equally. Likewise, do not<br />

turn one limb bolt more than two turns ahead of<br />

the other when making adjustments. Finally, limb<br />

bolts must never be backed out more than the<br />

specified number of full turns on bows that are<br />

equipped with max pre-load quad limbs. Also, do<br />

not back out the limb bolts more than the<br />

specified number of full turns for bows equipped<br />

with flare quad limbs unless otherwise noted.<br />

Bows with limb bolt lockdowns: After all tuning<br />

adjustments have been made; engage the limb<br />

bolt lock down screws. Screws should be snug<br />

against the limb pocket “tang”.<br />

13

BOW ADJUSTMENTS<br />

Counter-<br />

Clockwise<br />

Decreases<br />

Peak Weight<br />

Clockwise<br />

Increases<br />

Peak Weight<br />

Limb Bolt<br />

Assembly<br />

Limb Bolt<br />

Lockdown<br />

Tang &<br />

Screw<br />

Limb Bolt Adjustment<br />

Bow Max Turns<br />

Motive 4<br />

Empire 4<br />

Anarchy 4<br />

Method 4<br />

Domain 4<br />

Legion 3<br />

Encounter 3<br />

Outbreak 8<br />

Siren 3<br />

Homewrecker 3<br />

Apprentice 2 6<br />

14

CAM ADJUSTMENTS<br />

Adjusting Draw Length – H13 Synchronized<br />

Hybrid Cam System<br />

Bow model:<br />

• Motive 6<br />

• Motive 7<br />

• Method<br />

Module # Motive 6 Motive 7 Method<br />

5.5 25 1/2 26 1/2 26 1/2<br />

6 26 27 27<br />

6.5 26 1/2 27 1/2 27 1/2<br />

7 27 28 28<br />

7.5 27 1/2 28 1/2 28 1/2<br />

8 28 29 29<br />

8.5 28 1/2 29 1/2 29 1/2<br />

9 29 30 30<br />

9.5 29 1/2 30 1/2 30 1/2<br />

10 30 31 31<br />

The H13 Synchronized Hybrid cam has a rotating<br />

module for draw length adjustment. All draw length<br />

adjustments can be made without the use of a bow<br />

press. Draw length changes are made by simply<br />

rotating the modules to the desired position and<br />

moving the draw stop. To change draw length, remove<br />

the socket head cap screws from the top and bottom<br />

modules, rotate the modules to the desired<br />

positions(line up the indicator mark on the cam with<br />

the correct draw length indicator mark on the module),<br />

making sure to align the top and bottom to the same<br />

setting, and reapply the screws. Next, remove the<br />

draw stop on both the top and bottom cam and<br />

remount it in the corresponding stop locations to the<br />

draw length you selected. Such module draw length<br />

adjustments will not affect peak draw weight or timing.<br />

Modules are right and left hand specific and top<br />

and bottom specific. USE ONLY RH MODULES<br />

ON RIGHT HAND CAMS AND LH MODULES ON<br />

LH CAMS, AND ONLY USE TOP MODULES ON<br />

TOP CAMS AND BOTTOM MODULES ON<br />

BOTTOM CAMS!<br />

15

CAM ADJUSTMENTS<br />

H13 Synchronized Hybrid Cam System<br />

Axle<br />

<strong>Bear</strong>ing<br />

String<br />

Post<br />

Top Stop<br />

Control<br />

Cable<br />

Post<br />

Cam<br />

Indicator<br />

Mark<br />

Top<br />

Module<br />

Module<br />

Indicator<br />

Marks<br />

Module<br />

Mounting<br />

Screws<br />

TOP CAM (front view)<br />

Stop<br />

Mounting<br />

Screw<br />

TOP CAM (back view)<br />

16

CAM ADJUSTMENTS<br />

H13 Synchronized Hybrid Cam System<br />

Buss<br />

Cable<br />

Post<br />

Control<br />

Cable<br />

Post<br />

Bottom<br />

Stop<br />

Control<br />

Cable<br />

Track<br />

Cam<br />

Indicator<br />

Mark<br />

Module<br />

Indicator<br />

Marks<br />

Bottom<br />

Module<br />

BOTTOM CAM (front view)<br />

Control<br />

Cable<br />

Post<br />

Screw<br />

Module<br />

Mounting<br />

Screws<br />

Stop<br />

Mounting<br />

Screw<br />

BOTTOM CAM (back view)<br />

17

CAM ADJUSTMENTS<br />

H13 Synchronized Hybrid Cam System<br />

In order for the H13 Synchronized<br />

Hybrid Cam system to operate at<br />

maximum efficiency the timing<br />

needs to be set correctly. This<br />

means that the top and bottom<br />

cams roll over and hit their<br />

respective draw stops at the same<br />

time. The H13 Cam timing is set<br />

during assembly at the factory, but<br />

once the bow is broken in, or if<br />

you change strings/cables it is<br />

possible that the cam timing will<br />

need to be checked.<br />

If the H13 Cam System is out of<br />

time and the top stop hits before<br />

the bottom stop, put more twists<br />

into the control cable until both<br />

stops hit at the same time. If the<br />

H13 Cam System is out of time,<br />

and the bottom stop hits before<br />

the top stop, take twists out of the<br />

control cable until both stops hit at<br />

the same time. The high quality<br />

string materials used in your <strong>Bear</strong><br />

Bow will exhibit very little stretch<br />

and should maintain proper timing<br />

for extended periods under normal<br />

use.<br />

18

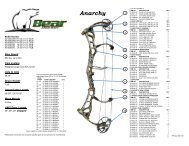

CAM ADJUSTMENTS<br />

Adjusting Draw Length – Perimeter<br />

Weighted Modular Single Cam ( ½” size<br />

module draw length adjustment)<br />

Bow model:<br />

• Anarchy<br />

Draw length Module #<br />

31.5” 9.5<br />

31” 9<br />

30.5” 8.5<br />

30” 8<br />

29.5” 7.5<br />

29” 7<br />

28.5” 6.5<br />

28” 6<br />

27.5” 5.5<br />

27” 5<br />

26.5” 4.5<br />

26” 4<br />

25.5” 3.5<br />

25” 3<br />

The perimeter weighted single cam has a modular<br />

draw length adjustment. All draw length<br />

adjustments can be made without the use of a<br />

bow press. Draw length changes are made by<br />

simply changing modules and moving the draw<br />

stop. Accessory modules are available from your<br />

local <strong>Bear</strong> <strong>Archery</strong> dealer in half-inch draw<br />

length increments. Each module is numbered,<br />

with #9.5 being the longest draw length and #3<br />

being the shortest. To change modules remove<br />

the socket head cap screws from the present<br />

module, remove that module and replace with a<br />

new module. Such module draw length<br />

adjustments will not affect peak draw weight.<br />

Modules are right and left hand specific. USE<br />

ONLY RH MODULES ON RIGHT HAND<br />

CAMS AND LH MODULES ON LH CAMS!<br />

19

Setting the TWO SIDED DRAW<br />

STOP<br />

When a module is changed, the draw stop must<br />

also be moved to the corresponding setting<br />

marked on the cam. The Anarchy has a two<br />

sided draw stop system. This system consists of<br />

a draw stop that utilizes two mounting bosses to<br />

achieve different draw stop settings. Each draw<br />

stop is marked with a 1 on one side and a ½ on<br />

the other side. These marks are used to match<br />

the stop with the desired module. If a whole<br />

number module is to be used, the draw stop<br />

must have the 1 facing out when mounted, if a<br />

half number module is to be used, the draw stop<br />

must have the ½ facing out when mounted.<br />

There is only one mounting hole in the cam for<br />

each whole and half number module set. For<br />

example, when setting a bow up with either a<br />

number 6 or a number 6 ½ module, the stop will<br />

mount in the #6 hole for both settings, but on<br />

the 6 module, the stop will read “1” facing out,<br />

and on the 6 ½ module, the stop will read “1/2”<br />

facing out. The stop will only mount in one<br />

orientation for each setting. DO NOT force the<br />

stop into the mounting hole; it will slip into the<br />

hole when the correct orientation is achieved.<br />

Example Shown:<br />

Refer to the images on the next page for<br />

additional reference.<br />

20

TWO SIDED DRAW STOP<br />

EXAMPLES<br />

#6 Module<br />

Draw Stop<br />

Position for<br />

# 6 Module<br />

#6.5 Module<br />

Draw Stop<br />

Position for<br />

#6.5 Module<br />

21

CAM ADJUSTMENTS<br />

Module number<br />

engraved in<br />

module<br />

Module<br />

Draw Stop<br />

Back View<br />

Draw<br />

Stop<br />

Screw<br />

Perimeter<br />

Weight<br />

Module<br />

Mounting<br />

Screws<br />

#9 and #9.5<br />

Draw Stop<br />

Position<br />

#8 and #8.5<br />

Draw Stop<br />

Position<br />

Front View<br />

22<br />

5, 5.5 Draw<br />

Position<br />

6, 6.5 Draw<br />

Position<br />

7, 7.5 Draw<br />

Position<br />

3, 3.5 Draw<br />

Position<br />

4, 4.5 Draw<br />

Position

CAM ADJUSTMENTS<br />

Adjusting Draw Length – Rotating Module<br />

System<br />

Bow models:<br />

• Empire<br />

• Domain<br />

• Legion<br />

• Encounter<br />

• Siren<br />

Module #<br />

Setting<br />

Empire DL Domain DL Legion DL Encounter DL Siren DL<br />

4 24 - - - -<br />

4.5 24.5 - - - -<br />

5 25 26 26 27 22<br />

5.5 25.5 26.5 26.5 27.5 22.5<br />

6 26 27 27 28 23<br />

6.5 26.5 27.5 27.5 28.5 23.5<br />

7 27 28 28 29 24<br />

7.5 27.5 28.5 28.5 29.5 24.5<br />

8 28 29 29 30 25<br />

8.5 28.5 29.5 29.5 30.5 25.5<br />

9 29 30 30 31 26<br />

9.5 29.5 30.5 30.5 31.5 26.5<br />

10 30 31 31 32 27<br />

10.5 30.5 - - - -<br />

11 31 - - - -<br />

The rotating module cam system allows the bow<br />

to be adjusted to all of its draw length positions<br />

without the use of separate individual modules<br />

and does not require a bow press for draw length<br />

adjustments at 1/2” increments. Draw length<br />

changes are made by first removing the socket<br />

head cap screws that secure the rotating module<br />

unit. Next, rotate the module until the desired<br />

module draw length module tick mark is lined up<br />

with the cam tick mark, and reinstall the screws<br />

in the corresponding holes. Such draw length<br />

adjustments will not affect peak draw weight.<br />

When the rotating module unit is repositioned to<br />

adjust draw length, the draw stop must also be<br />

moved to the corresponding setting marked on<br />

the cam.<br />

23

Module<br />

Indicator<br />

Marks<br />

CAM ADJUSTMENTS<br />

<strong>2013</strong> SINGLE CAM<br />

Rotating<br />

Module<br />

Screws<br />

String<br />

Post<br />

Cam<br />

Indicator<br />

Mark<br />

Cam<br />

String<br />

Post<br />

Front View<br />

Rotating<br />

Module<br />

Perimeter<br />

weight<br />

Cable<br />

Post<br />

Draw Stop<br />

mounting<br />

holes<br />

Draw stop<br />

Front View<br />

24

CAM ADJUSTMENTS<br />

Cable<br />

Post<br />

String<br />

Post<br />

Draw stop<br />

Rotating<br />

Module<br />

Draw length<br />

increments<br />

engraved in<br />

cam<br />

Cam<br />

Module Tick<br />

Mark<br />

Back View<br />

Rotating<br />

Module<br />

Screws<br />

Perimeter<br />

weight<br />

String<br />

Post<br />

Draw stop<br />

screws<br />

Draw stop<br />

increments<br />

MUST MATCH<br />

draw length<br />

setting<br />

Front View<br />

25

CAM ADJUSTMENTS<br />

Thread<br />

Locked<br />

Screws<br />

Siren Rotating Module Cam Back View<br />

Bolt on<br />

third track<br />

Cam<br />

The Siren rotating module cam is equipped<br />

with a bolt on third track system.<br />

DO NOT remove the third track for any<br />

reason. The screws holding this track on<br />

have been set with a thread binding agent<br />

and should never be removed. The third<br />

track is not changed during any adjustment<br />

of this cam.<br />

26

CAM ADJUSTMENTS<br />

Adjusting Draw Length – Perimeter<br />

Weighted Modular Single Cam<br />

Bow model:<br />

• Home Wrecker<br />

The perimeter weighted single cam has a<br />

modular draw length adjustment. Most<br />

draw length adjustments can be made<br />

without the use of a bow press. Draw<br />

length changes are made by simply<br />

changing modules and moving the draw<br />

stop. Accessory modules are available<br />

from your local <strong>Bear</strong> <strong>Archery</strong> dealer in<br />

one-inch draw length increments. Each<br />

module is numbered, with #10 being the<br />

longest draw length and #4 being the<br />

shortest. To change modules remove the<br />

socket head cap screws from the present<br />

module, remove that module and replace<br />

with a new module. Such module draw<br />

length adjustments will not affect peak<br />

draw weight. Modules are right and<br />

left hand specific. USE ONLY RH<br />

MODULES ON RIGHT HAND CAMS<br />

AND LH MODULES ON LH CAMS!<br />

When a module is changed, the draw<br />

stop must also be moved to the<br />

corresponding setting marked on the<br />

cam. Draw stop must be positioned so<br />

that the side marked “OUT” faces out.<br />

27

CAM ADJUSTMENTS<br />

Additionally, fine draw length<br />

adjustments of ½ inch can be made by<br />

removing the bowstring from the<br />

standard “dot” string post and<br />

reattaching it to either the “+” or “-“<br />

string posts on the cam. Moving the<br />

string to the “+” post will increase draw<br />

length by ½” and moving the string to<br />

the “-“ post will decrease draw length by<br />

½”. To make such adjustments, it is first<br />

necessary to remove tension from the<br />

harness system of the bow by<br />

compressing the bow in a bow press. A<br />

fixed or portable bow press must be<br />

used! Under NO circumstances can<br />

this relaxing of the harness system be<br />

accomplished by simply backing out<br />

limb bolts. Refer to the images on the<br />

next page for additional reference.<br />

Home Wrecker Draw Lengths<br />

Modular Single Cam Draw Length Chart<br />

String on "Dot" Post String on "+" Post String on "-" Post<br />

Module Number<br />

Draw Length Draw Length Draw Length<br />

4 22 22.5 21.5<br />

5 23 23.5 22.5<br />

6 24 24.5 23.5<br />

7 25 25.5 24.5<br />

8 26 26.5 25.5<br />

9 27 27.5 26.5<br />

10 28 28.5 27.5<br />

28

CAM ADJUSTMENTS<br />

Module<br />

number<br />

“+”<br />

Post<br />

Module<br />

Standard<br />

“dot”<br />

Post<br />

Draw Stop<br />

MUST<br />

FACE<br />

OUT<br />

Back View<br />

Standard<br />

“dot” Post<br />

“-“<br />

Post<br />

Module<br />

Mounting<br />

Screws<br />

Perimeter<br />

Weight<br />

Draw<br />

Stop<br />

Screws<br />

Front View<br />

Draw stop<br />

increments<br />

must match<br />

module<br />

number<br />

29

CAM ADJUSTMENTS<br />

Adjusting Draw Length – Rotating Modular<br />

Cam System with MultiDraw<br />

Bow model:<br />

• Apprentice 2<br />

• Outbreak<br />

The adjustable multidraw cam equipped bow can<br />

be configured to provide a draw length from 14”<br />

to 27” in 1” intervals. No bow press is required<br />

to adjust the multidraw cam system. To adjust<br />

the draw length, first remove the socket head cap<br />

screw located in the rotating module. Next rotate<br />

the module to the desired draw length and<br />

reinstall the screw in the corresponding hole. It<br />

may be necessary to pull the cable away from the<br />

module to provide clearance for the module to<br />

rotate, see the picture below. Next perform the<br />

same operation on the opposite cam. Be sure that<br />

both the top and bottom cams are set to the<br />

same draw length position. The adjustable cam<br />

operates on a sliding poundage scale where an<br />

increase in draw length also provides an increase<br />

in peak draw weight. This allows the bow to<br />

grow with the archer. The chart below shows the<br />

peak draw weight at each draw length for the 40<br />

and 50 pound peak bows.<br />

Module<br />

Mounting<br />

Screw<br />

Right or<br />

left hand<br />

designation<br />

Cam<br />

Back View<br />

Draw Length<br />

printed on<br />

module<br />

Front View<br />

30

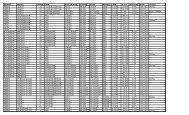

Rotating<br />

Module<br />

OUTBREAK<br />

Draw Weight vs. Draw Length Chart<br />

Module<br />

Mounting<br />

Screws<br />

Cam<br />

Cable Post<br />

String Post<br />

Draw Length<br />

60 lb<br />

Apprentice 2<br />

Draw Length [in] vs Draw Weight [lbs]<br />

Limb Bolt Bottomed<br />

50 lb<br />

Apprentice 2<br />

Outbreak<br />

60 lb<br />

Apprentice 2<br />

(6 turns)<br />

Limb Bolt Fully Backed Out<br />

50 lb<br />

Apprentice 2<br />

(6 turns)<br />

Outbreak<br />

(8 turns)<br />

15 39.5-43.5 30-34 - 21-25 14.5-18.5 -<br />

16 39.5-43.5 30-34 28-32 21-25 14.5-18.5 16-20<br />

17 39.5-43.5 30-34 28.5-32.5 21-25 14.5-18.5 16-20<br />

18 40-44 31.5-35.5 32.5-36.5 23-27 16-20 19-23<br />

19 43.5-47.5 34-38 37-41 24.5-28.5 17.5-21.5 21.5-25.5<br />

20 45.5-49.5 36.5-40.5 41-45 26-30 20-24 24.5-28.5<br />

21 48-52 39.5-43.5 45-49 28-32 21.5-25.5 27-31<br />

22 50-54 40.5-44.5 49.5-53.5 29.5-33.5 23-27 30-34<br />

23 51.5-55.5 42.5-46.5 53-57 31-35 24.5-28.5 32.5-36.5<br />

24 53-57 44-48 56.5-60.5 32.5-36.5 26-30 35-39<br />

25 55-59 46-50 59.5-63.5 34.5-38.5 28-32 37.5-41.5<br />

26 56.5-60.5 47.5-51.5 62.5-66.5 37-41 30.5-34.5 39.5-43.5<br />

27 60-64 50-54 64.5-68.5 40.5-44.5 34-38 41.5-45.5<br />

28 - 66.5-70.5 - 43.5-47.5<br />

29 - 68.5-72.5 - 45.5-49.5<br />

30 - 70-74 - 48-52<br />

31

INITIAL BOW SETUP<br />

Before you can safely and effectively shoot your<br />

bow, a number of specific initial bow setup steps<br />

must be taken. These steps can be performed on<br />

your own, if your level of expertise is adequate.<br />

Or, your local <strong>Bear</strong> <strong>Archery</strong> dealer can help you.<br />

Arrow Rest Installation & Setup<br />

Arrow rests should be installed according to the<br />

manufacturer’s specifications. The first<br />

adjustment you need to perform is setting the<br />

vertical height of your arrow rest. When properly<br />

adjusted, your arrow rest should align the<br />

centerline of the arrow with the center of the two<br />

holes used to mount the rest to the riser. To<br />

check this, place an arrow in the rest and nocked<br />

on the string. Visually confirm the center of the<br />

arrow passes directly through the center of the<br />

arrow rest mounting holes when viewed from the<br />

side. If not, adjust your rest up or down to<br />

correct.<br />

Next, the rest should be adjusted for proper<br />

“Centershot”. With an arrow in the rest and<br />

nocked on the string, firmly hold another arrow<br />

against the inside of the riser near the arrow rest<br />

mounting holes as illustrated. Look down the<br />

arrows and verify that the arrows are parallel to<br />

each other. In other words, the spacing between<br />

the two arrows should be the same along the<br />

entire length of the arrows. If not, adjust your<br />

rest side to side to correct. This is only your<br />

“initial” centershot and additional fine tuning<br />

may be required depending on your shooting<br />

style and equipment. Please refer to the images<br />

on the next page for further reference.<br />

32

INITIAL BOW SETUP<br />

Place<br />

arrow<br />

firmly<br />

against<br />

inside of<br />

riser as<br />

shown.<br />

Arrow<br />

rest<br />

should<br />

support<br />

the arrow<br />

in such a<br />

way that<br />

the<br />

arrow’s<br />

centerline<br />

passes<br />

directly<br />

through<br />

the<br />

center of<br />

the two<br />

arrow<br />

rest<br />

mounting<br />

holes.<br />

Arrows<br />

should be<br />

parallel<br />

along their<br />

entire<br />

length.<br />

33

INITIAL BOW SETUP<br />

Nocking Point and Nock Adjustment<br />

Now that the initial centershot setting is<br />

complete, you need to verify your arrow nocking<br />

point. Install the nocking point or string loop on<br />

the bowstring so that when an arrow is nocked it<br />

creates a 90 degree angle to the string. Another<br />

option is to use a process similar to the one used<br />

to determine centershot. With an arrow in the<br />

rest and nocked on the string, firmly hold<br />

another arrow against the shelf of the riser as<br />

illustrated. Look down the arrows and verify that<br />

the arrows are parallel. In other words, the<br />

spacing between the two arrows should be the<br />

same along the entire length of the arrows. If<br />

not, adjust your nocking point up or down to<br />

correct.<br />

At this time, adjust arrow fletch position to<br />

correspond with the arrow rest you are using.<br />

Such adjustments are done by simply rotating or<br />

replacing the arrow’s nock. Carefully position the<br />

nock to provide proper fletch clearance through<br />

the arrow rest. Your local <strong>Bear</strong> <strong>Archery</strong> dealer<br />

can show you how to do this or can provide the<br />

service for you. Please refer to the images on the<br />

next page for further reference.<br />

Install All Accessories<br />

After your arrow rest and nocking point are<br />

installed correctly you will need to install all other<br />

accessories such as sights, quivers, silencers, peep<br />

sights, stabilizers, etc. Before mounting ANY<br />

accessories to the limbs, Refer to page 3 for<br />

important limb information.<br />

34

INITIAL BOW SETUP<br />

90°<br />

Max<br />

Place arrow firmly<br />

against shelf of<br />

riser as shown.<br />

Arrows should<br />

be parallel<br />

along their<br />

entire length<br />

35

INITIAL BOW SETUP<br />

Sight Adjustment<br />

When first sighting in your new bow or bow<br />

sight, the key thing to remember is “Chase the<br />

arrows”. In other words if your arrows are hitting<br />

the target to the right of the bull’s-eye, move<br />

your sight to the right. If the arrows hit high on<br />

the target, raise your sight.<br />

Arrow<br />

Group<br />

In the picture above, the arrows are hitting the target<br />

high and to the right of the bull’s-eye. To correct this,<br />

adjust your sight up and to the right. Remember,<br />

“Chase the arrows.”<br />

36

ARROW SELECTION<br />

Arrow selection depends on the peak draw<br />

weight, let-off and draw length settings of your<br />

bow. Refer to arrow manufacturer’s arrow<br />

selection tables using this information. The<br />

International Bowhunters Organization (IBO)<br />

allows a minimum of five grains arrow weight<br />

per pound of peak weight. Arrow weight is the<br />

total combined weight of your arrow nock insert,<br />

and point or broadhead. To determine the<br />

lightest arrow you can safely shoot, use the<br />

following format:<br />

Peak Draw<br />

Weight (Lb)<br />

X =<br />

Multiply by<br />

5 Grains<br />

per Pound<br />

Minimum Safe<br />

Arrow Weight<br />

(Grains)<br />

Shooting arrows below these<br />

minimum weight requirements will void the<br />

warranty. Using arrows below five grains per<br />

pound of peak weight can approach dry-fire<br />

conditions and can severely reduce the life of<br />

your bow, and may cause serious injury. Contact<br />

your local <strong>Bear</strong> <strong>Archery</strong> pro shop or arrow<br />

manufacturers for arrow selection<br />

recommendations.<br />

The weight of the arrow you select can be<br />

determined as follows:<br />

1. From an arrow chart, find the weight of<br />

your arrow shaft based on the size and<br />

length.<br />

2. Add the weight of your broadhead or<br />

point.<br />

3. Add 35 grains to cover the nock, insert,<br />

and fletching. For example.<br />

Arrow<br />

400-30”<br />

240 Gr<br />

Point<br />

Mag 125<br />

(+125 Gr)<br />

Other<br />

(+35 Gr)<br />

+ + =<br />

Total<br />

Weight<br />

(=400 Gr)<br />

NOTE: It is always best to use a grain scale<br />

when available.<br />

37

<strong>Bear</strong> <strong>Archery</strong> Warranty Statement<br />

All <strong>Bear</strong> <strong>Archery</strong> compound bows are backed<br />

with a Limited Lifetime Warranty to the original<br />

owner. This warranty applies to limbs, risers, and<br />

cams. This warranty consists of the following<br />

programs:<br />

•Limbs: 100% covered at no charge for the first 5<br />

years, 50% of replacement cost after.<br />

•Risers: Lifetime Warranty.<br />

•Cams: Lifetime Warranty.<br />

Original Owner:<br />

Warranty applies only to the original owner and<br />

is not transferable. Proof of purchase may be<br />

required.<br />

Items Not Covered:<br />

Cables, strings, bearings, paint and/or film<br />

dipped finishes resulting from normal wear and<br />

tear are not included in this warranty.<br />

Damage Not Covered:<br />

Damage caused by abuse, mishandling, dry firing,<br />

alteration or modification made to original<br />

products are not covered under this warranty.<br />

The use of any bow press other than those<br />

approved by <strong>Bear</strong> <strong>Archery</strong> will void this<br />

warranty. Additionally, shooting of arrows less<br />

than 5 grains per pound of peak draw weight will<br />

void this warranty. <strong>Bear</strong> <strong>Archery</strong> reserves the<br />

right to make parts substitutions on warranty<br />

coverage at <strong>Bear</strong> <strong>Archery</strong>’s sole discretion, for<br />

any reason.<br />

Bow Warranty Registration:<br />

For this warranty to be in effect, the on-line<br />

warranty registration process must be completed<br />

at <strong>Bear</strong><strong>Archery</strong>Products.com and submitted<br />

within 30 days of purchase.<br />

Traditional Bows: 1 year Limited Warranty to<br />

the original owner.<br />

Youth Bows: 90 Day Limited Warranty to the<br />

original owner.<br />

38

<strong>Bear</strong> <strong>Archery</strong> Warranty Statement<br />

In the event a bow requires warranty service,<br />

please contact the <strong>Bear</strong> <strong>Archery</strong> Customer<br />

Department at 800-694-9494 for a return<br />

authorization (RA) number and return shipping<br />

instructions. For full warranty details, please log<br />

on to <strong>Bear</strong><strong>Archery</strong>Products.com for further<br />

information.<br />

Key Contact data:<br />

Dealer 800 Number: 800-694-9494<br />

Dealer Fax Number: 812-467-1245<br />

Web: www.<strong>Bear</strong><strong>Archery</strong>Products.com<br />

©2012 <strong>Bear</strong> <strong>Archery</strong><br />

2L-7213-13<br />

39