Stress-strain curve of paper revisited - Innventia.com

Stress-strain curve of paper revisited - Innventia.com

Stress-strain curve of paper revisited - Innventia.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PAPER PHYSICS<br />

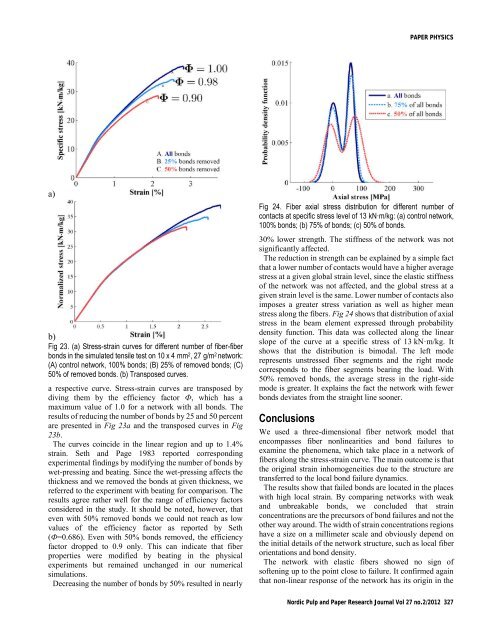

a)<br />

b)<br />

Fig 23. (a) <strong>Stress</strong>-<strong>strain</strong> <strong>curve</strong>s for different number <strong>of</strong> fiber-fiber<br />

bonds in the simulated tensile test on 10 x 4 mm 2 , 27 g/m 2 network:<br />

(A) control network, 100% bonds; (B) 25% <strong>of</strong> removed bonds; (C)<br />

50% <strong>of</strong> removed bonds. (b) Transposed <strong>curve</strong>s.<br />

a respective <strong>curve</strong>. <strong>Stress</strong>-<strong>strain</strong> <strong>curve</strong>s are transposed by<br />

diving them by the efficiency factor Ф, which has a<br />

maximum value <strong>of</strong> 1.0 for a network with all bonds. The<br />

results <strong>of</strong> reducing the number <strong>of</strong> bonds by 25 and 50 percent<br />

are presented in Fig 23a and the transposed <strong>curve</strong>s in Fig<br />

23b.<br />

The <strong>curve</strong>s coincide in the linear region and up to 1.4%<br />

<strong>strain</strong>. Seth and Page 1983 reported corresponding<br />

experimental findings by modifying the number <strong>of</strong> bonds by<br />

wet-pressing and beating. Since the wet-pressing affects the<br />

thickness and we removed the bonds at given thickness, we<br />

referred to the experiment with beating for <strong>com</strong>parison. The<br />

results agree rather well for the range <strong>of</strong> efficiency factors<br />

considered in the study. It should be noted, however, that<br />

even with 50% removed bonds we could not reach as low<br />

values <strong>of</strong> the efficiency factor as reported by Seth<br />

(Ф=0.686). Even with 50% bonds removed, the efficiency<br />

factor dropped to 0.9 only. This can indicate that fiber<br />

properties were modified by beating in the physical<br />

experiments but remained unchanged in our numerical<br />

simulations.<br />

Decreasing the number <strong>of</strong> bonds by 50% resulted in nearly<br />

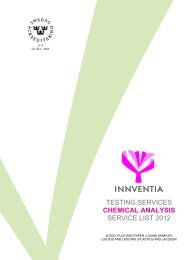

Fig 24. Fiber axial stress distribution for different number <strong>of</strong><br />

contacts at specific stress level <strong>of</strong> 13 kN·m/kg: (a) control network,<br />

100% bonds; (b) 75% <strong>of</strong> bonds; (c) 50% <strong>of</strong> bonds.<br />

30% lower strength. The stiffness <strong>of</strong> the network was not<br />

significantly affected.<br />

The reduction in strength can be explained by a simple fact<br />

that a lower number <strong>of</strong> contacts would have a higher average<br />

stress at a given global <strong>strain</strong> level, since the elastic stiffness<br />

<strong>of</strong> the network was not affected, and the global stress at a<br />

given <strong>strain</strong> level is the same. Lower number <strong>of</strong> contacts also<br />

imposes a greater stress variation as well as higher mean<br />

stress along the fibers. Fig 24 shows that distribution <strong>of</strong> axial<br />

stress in the beam element expressed through probability<br />

density function. This data was collected along the linear<br />

slope <strong>of</strong> the <strong>curve</strong> at a specific stress <strong>of</strong> 13 kN·m/kg. It<br />

shows that the distribution is bimodal. The left mode<br />

represents unstressed fiber segments and the right mode<br />

corresponds to the fiber segments bearing the load. With<br />

50% removed bonds, the average stress in the right-side<br />

mode is greater. It explains the fact the network with fewer<br />

bonds deviates from the straight line sooner.<br />

Conclusions<br />

We used a three-dimensional fiber network model that<br />

en<strong>com</strong>passes fiber nonlinearities and bond failures to<br />

examine the phenomena, which take place in a network <strong>of</strong><br />

fibers along the stress-<strong>strain</strong> <strong>curve</strong>. The main out<strong>com</strong>e is that<br />

the original <strong>strain</strong> inhomogeneities due to the structure are<br />

transferred to the local bond failure dynamics.<br />

The results show that failed bonds are located in the places<br />

with high local <strong>strain</strong>. By <strong>com</strong>paring networks with weak<br />

and unbreakable bonds, we concluded that <strong>strain</strong><br />

concentrations are the precursors <strong>of</strong> bond failures and not the<br />

other way around. The width <strong>of</strong> <strong>strain</strong> concentrations regions<br />

have a size on a millimeter scale and obviously depend on<br />

the initial details <strong>of</strong> the network structure, such as local fiber<br />

orientations and bond density.<br />

The network with elastic fibers showed no sign <strong>of</strong><br />

s<strong>of</strong>tening up to the point close to failure. It confirmed again<br />

that non-linear response <strong>of</strong> the network has its origin in the<br />

Nordic Pulp and Paper Research Journal Vol 27 no.2/2012 327