Stress-strain curve of paper revisited - Innventia.com

Stress-strain curve of paper revisited - Innventia.com

Stress-strain curve of paper revisited - Innventia.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PAPER PHYSICS<br />

energy cannot dissipate in highly <strong>strain</strong>ed areas by other<br />

contribute to the response <strong>of</strong> a dry network.<br />

a)<br />

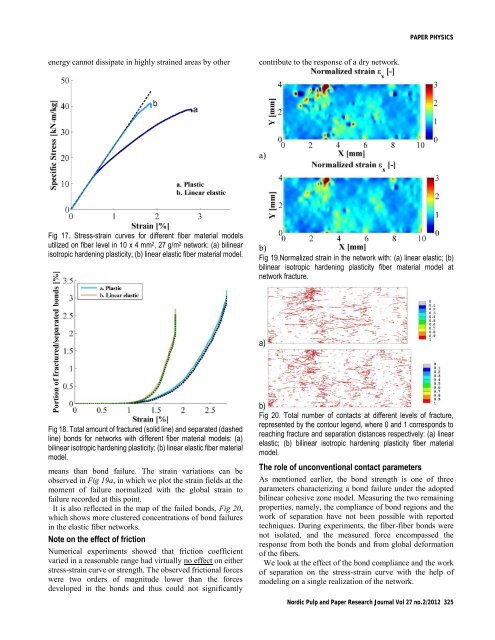

Fig 17. <strong>Stress</strong>-<strong>strain</strong> <strong>curve</strong>s for different fiber material models<br />

utilized on fiber level in 10 x 4 mm 2 , 27 g/m 2 network: (a) bilinear<br />

isotropic hardening plasticity; (b) linear elastic fiber material model.<br />

b)<br />

Fig 19.Normalized <strong>strain</strong> in the network with: (a) linear elastic; (b)<br />

bilinear isotropic hardening plasticity fiber material model at<br />

network fracture.<br />

a)<br />

Fig 18. Total amount <strong>of</strong> fractured (solid line) and separated (dashed<br />

line) bonds for networks with different fiber material models: (a)<br />

bilinear isotropic hardening plasticity; (b) linear elastic fiber material<br />

model.<br />

means than bond failure. The <strong>strain</strong> variations can be<br />

observed in Fig 19a, in which we plot the <strong>strain</strong> fields at the<br />

moment <strong>of</strong> failure normalized with the global <strong>strain</strong> to<br />

failure recorded at this point.<br />

It is also reflected in the map <strong>of</strong> the failed bonds, Fig 20,<br />

which shows more clustered concentrations <strong>of</strong> bond failures<br />

in the elastic fiber networks.<br />

Note on the effect <strong>of</strong> friction<br />

Numerical experiments showed that friction coefficient<br />

varied in a reasonable range had virtually no effect on either<br />

stress-<strong>strain</strong> <strong>curve</strong> or strength. The observed frictional forces<br />

were two orders <strong>of</strong> magnitude lower than the forces<br />

developed in the bonds and thus could not significantly<br />

b)<br />

Fig 20. Total number <strong>of</strong> contacts at different levels <strong>of</strong> fracture,<br />

represented by the contour legend, where 0 and 1 corresponds to<br />

reaching fracture and separation distances respectively: (a) linear<br />

elastic; (b) bilinear isotropic hardening plasticity fiber material<br />

model.<br />

The role <strong>of</strong> unconventional contact parameters<br />

As mentioned earlier, the bond strength is one <strong>of</strong> three<br />

parameters characterizing a bond failure under the adopted<br />

bilinear cohesive zone model. Measuring the two remaining<br />

properties, namely, the <strong>com</strong>pliance <strong>of</strong> bond regions and the<br />

work <strong>of</strong> separation have not been possible with reported<br />

techniques. During experiments, the fiber-fiber bonds were<br />

not isolated, and the measured force en<strong>com</strong>passed the<br />

response from both the bonds and from global deformation<br />

<strong>of</strong> the fibers.<br />

We look at the effect <strong>of</strong> the bond <strong>com</strong>pliance and the work<br />

<strong>of</strong> separation on the stress-<strong>strain</strong> <strong>curve</strong> with the help <strong>of</strong><br />

modeling on a single realization <strong>of</strong> the network.<br />

Nordic Pulp and Paper Research Journal Vol 27 no.2/2012 325