Stress-strain curve of paper revisited - Innventia.com

Stress-strain curve of paper revisited - Innventia.com

Stress-strain curve of paper revisited - Innventia.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PAPER PHYSICS<br />

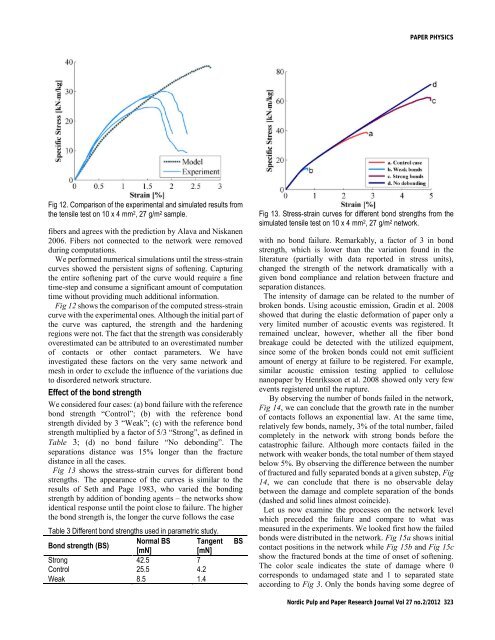

Fig 12. Comparison <strong>of</strong> the experimental and simulated results from<br />

the tensile test on 10 x 4 mm 2 , 27 g/m 2 sample.<br />

fibers and agrees with the prediction by Alava and Niskanen<br />

2006. Fibers not connected to the network were removed<br />

during <strong>com</strong>putations.<br />

We performed numerical simulations until the stress-<strong>strain</strong><br />

<strong>curve</strong>s showed the persistent signs <strong>of</strong> s<strong>of</strong>tening. Capturing<br />

the entire s<strong>of</strong>tening part <strong>of</strong> the <strong>curve</strong> would require a fine<br />

time-step and consume a significant amount <strong>of</strong> <strong>com</strong>putation<br />

time without providing much additional information.<br />

Fig 12 shows the <strong>com</strong>parison <strong>of</strong> the <strong>com</strong>puted stress-<strong>strain</strong><br />

<strong>curve</strong> with the experimental ones. Although the initial part <strong>of</strong><br />

the <strong>curve</strong> was captured, the strength and the hardening<br />

regions were not. The fact that the strength was considerably<br />

overestimated can be attributed to an overestimated number<br />

<strong>of</strong> contacts or other contact parameters. We have<br />

investigated these factors on the very same network and<br />

mesh in order to exclude the influence <strong>of</strong> the variations due<br />

to disordered network structure.<br />

Effect <strong>of</strong> the bond strength<br />

We considered four cases: (a) bond failure with the reference<br />

bond strength “Control”; (b) with the reference bond<br />

strength divided by 3 “Weak”; (c) with the reference bond<br />

strength multiplied by a factor <strong>of</strong> 5/3 “Strong”, as defined in<br />

Table 3; (d) no bond failure “No debonding”. The<br />

separations distance was 15% longer than the fracture<br />

distance in all the cases.<br />

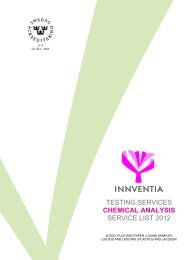

Fig 13 shows the stress-<strong>strain</strong> <strong>curve</strong>s for different bond<br />

strengths. The appearance <strong>of</strong> the <strong>curve</strong>s is similar to the<br />

results <strong>of</strong> Seth and Page 1983, who varied the bonding<br />

strength by addition <strong>of</strong> bonding agents – the networks show<br />

identical response until the point close to failure. The higher<br />

the bond strength is, the longer the <strong>curve</strong> follows the case<br />

Table 3 Different bond strengths used in parametric study.<br />

Bond strength (BS)<br />

Normal BS Tangent<br />

[mN]<br />

[mN]<br />

Strong 42.5 7<br />

Control 25.5 4.2<br />

Weak 8.5 1.4<br />

BS<br />

Fig 13. <strong>Stress</strong>-<strong>strain</strong> <strong>curve</strong>s for different bond strengths from the<br />

simulated tensile test on 10 x 4 mm 2 , 27 g/m 2 network.<br />

with no bond failure. Remarkably, a factor <strong>of</strong> 3 in bond<br />

strength, which is lower than the variation found in the<br />

literature (partially with data reported in stress units),<br />

changed the strength <strong>of</strong> the network dramatically with a<br />

given bond <strong>com</strong>pliance and relation between fracture and<br />

separation distances.<br />

The intensity <strong>of</strong> damage can be related to the number <strong>of</strong><br />

broken bonds. Using acoustic emission, Gradin et al. 2008<br />

showed that during the elastic deformation <strong>of</strong> <strong>paper</strong> only a<br />

very limited number <strong>of</strong> acoustic events was registered. It<br />

remained unclear, however, whether all the fiber bond<br />

breakage could be detected with the utilized equipment,<br />

since some <strong>of</strong> the broken bonds could not emit sufficient<br />

amount <strong>of</strong> energy at failure to be registered. For example,<br />

similar acoustic emission testing applied to cellulose<br />

nano<strong>paper</strong> by Henriksson et al. 2008 showed only very few<br />

events registered until the rupture.<br />

By observing the number <strong>of</strong> bonds failed in the network,<br />

Fig 14, we can conclude that the growth rate in the number<br />

<strong>of</strong> contacts follows an exponential law. At the same time,<br />

relatively few bonds, namely, 3% <strong>of</strong> the total number, failed<br />

<strong>com</strong>pletely in the network with strong bonds before the<br />

catastrophic failure. Although more contacts failed in the<br />

network with weaker bonds, the total number <strong>of</strong> them stayed<br />

below 5%. By observing the difference between the number<br />

<strong>of</strong> fractured and fully separated bonds at a given substep, Fig<br />

14, we can conclude that there is no observable delay<br />

between the damage and <strong>com</strong>plete separation <strong>of</strong> the bonds<br />

(dashed and solid lines almost coincide).<br />

Let us now examine the processes on the network level<br />

which preceded the failure and <strong>com</strong>pare to what was<br />

measured in the experiments. We looked first how the failed<br />

bonds were distributed in the network. Fig 15a shows initial<br />

contact positions in the network while Fig 15b and Fig 15c<br />

show the fractured bonds at the time <strong>of</strong> onset <strong>of</strong> s<strong>of</strong>tening.<br />

The color scale indicates the state <strong>of</strong> damage where 0<br />

corresponds to undamaged state and 1 to separated state<br />

according to Fig 3. Only the bonds having some degree <strong>of</strong><br />

Nordic Pulp and Paper Research Journal Vol 27 no.2/2012 323