2013 Buyers' Guide 2013 Buyers' Guide - Filtration News

2013 Buyers' Guide 2013 Buyers' Guide - Filtration News

2013 Buyers' Guide 2013 Buyers' Guide - Filtration News

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

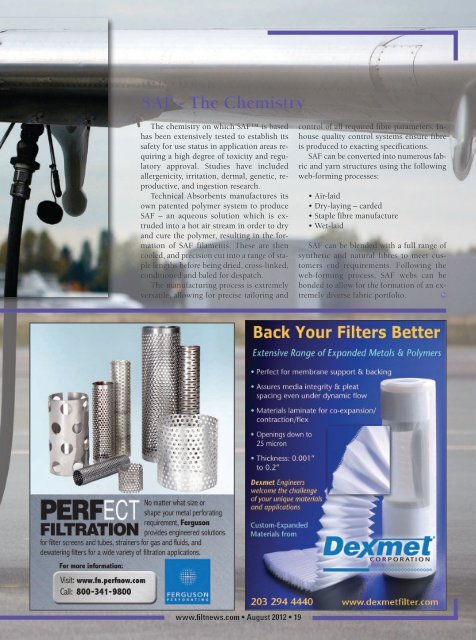

SAF - The Chemistry<br />

The chemistry on which SAF is based<br />

has been extensively tested to establish its<br />

safety for use status in application areas requiring<br />

a high degree of toxicity and regulatory<br />

approval. Studies have included<br />

allergenicity, irritation, dermal, genetic, reproductive,<br />

and ingestion research.<br />

Technical Absorbents manufactures its<br />

own patented polymer system to produce<br />

SAF – an aqueous solution which is extruded<br />

into a hot air stream in order to dry<br />

and cure the polymer, resulting in the formation<br />

of SAF filaments. These are then<br />

cooled, and precision cut into a range of staple<br />

lengths before being dried, cross-linked,<br />

conditioned and baled for despatch.<br />

The manufacturing process is extremely<br />

versatile, allowing for precise tailoring and<br />

control of all required fibre parameters. Inhouse<br />

quality control systems ensure fibre<br />

is produced to exacting specifications.<br />

SAF can be converted into numerous fabric<br />

and yarn structures using the following<br />

web-forming processes:<br />

• Air-laid<br />

• Dry-laying – carded<br />

• Staple fibre manufacture<br />

• Wet-laid<br />

SAF can be blended with a full range of<br />

synthetic and natural fibres to meet customers<br />

end requirements. Following the<br />

web-forming process, SAF webs can be<br />

bonded to allow for the formation of an extremely<br />

diverse fabric portfolio.<br />

FN<br />

www.filtnews.com • August 2012 • 19