Standard - WEKA AG

Standard - WEKA AG

Standard - WEKA AG

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 1 of 7<br />

1. Introduction<br />

<strong>WEKA</strong> Cryogenic Valves are designed to meet the special requirements for cryogenic plants for Helium (He) or<br />

Hydrogen (H 2 ). Operating temperatures goes down to 2.2K and lower. Fluids are therefore in gas, liquid or even<br />

superfluid (HeII) state. However valves could also be used in applications with other cold liquefied gases like<br />

Neon (Ne), Nitrogen (N 2 ), Argon (Ar), Oxygen (O 2 ) etc.<br />

2. Valve Description<br />

<strong>WEKA</strong> Cryogenic Valves are available as<br />

a) Bellows sealed valves followed by a security back-up sealing and a plugged leak test port. This high quality<br />

sealing system guarantees for highest tightness and safety under pressure and vacuum conditions. Preferable<br />

it will be used for low density fluids like He and H 2 . Also for high purity gases it is recommended to use<br />

bells sealed valves.<br />

or<br />

b) Packing sealed valves with an elastomeric quad-ring for applications which have reduced requests on tightness<br />

e.g. for fluids like Nitrogen (N 2 ), Air etc. however could also be used for low density gases.<br />

Static seal to outside between valve body and bonnet and inset respectively is made with an elastomeric o-ring<br />

joint at the warm top end of the valve. O-ring joint grooves are designed for pressure and vacuum conditions.<br />

For sub-atmosphere service conditions e.g. in superfluid HeII a double o-ring joint with a guard gas connection is<br />

available.<br />

The valve seat is integrally machined into the valve body at the cold bottom end. It will be closed by a polymeric<br />

soft seal. The cardanic stem inset design guarantee seat tightness over the full temperature range. Some<br />

movement by thermal contraction of the piping could be compensated. Seal heads of valves size >= DN20 are<br />

spherical flexible joined to the inset. Smaller valves have elastically buckling spindle tubes.<br />

Seat tightness and flow control functions are cut by the design and adaptable to any specifications required.<br />

Exact tolerances of the valve bore made it possible to use for both, on/off- (digital-) and control applications. For<br />

control valves appropriate standard flow plugs with either equal- % or linear flow characteristics are available<br />

(see cat. no. 921101). Plugs with any special flow characteristics are possible on request. Digital valves will be<br />

equipped with a flow trim which assures highest possible k v -value (c v =1.16* k v value). For details regarding valve<br />

bore and travel as well as for k v - / c v -values see table ”Technical Valve Data’s”.<br />

To change either seat seal or flow plug, the stem inset is retractable through the body on the top end.<br />

Valve body and inset are a welded design with forged and tube stainless steel which guarantees a great operational<br />

reliability of service and highest possible tightness.<br />

Depending on valve size (DN) following standardised cryogenic length “h” are available. However all lengths<br />

between a minimum length, which depending on lowest service temperature and on valve size DN, up to a max.<br />

of about 2000mm or more are available. For longer length requests a special design with compensating bellows.<br />

To reduce the heat load by thermal conductivity of solids, the wall thickness for body and inset tubes are optimised<br />

regarding pressure and shut-off loads. Stem inset intersection tubes have a Perlite powder filling to prevent<br />

convective heat in-leaks.<br />

For further reduce of heat loads, a Cu-thermal flange could be brazed to body pipe to contact a cooling shield.<br />

Available are also compound valve stem insets with a vented GFK intersection tube. This design reduce the<br />

indicated heat load values (see page 7) of about 30 to 40% for valves size DN10 and greater. Available are also<br />

vented stainless steel inset tubes filled with a stainless steel or polymer netting.<br />

If there is a risk of thermo acoustic oscillations in the ring section of body and inset pipe, which is kept as small<br />

as technically possible, optional available is the fitting of a convection brake.<br />

<strong>Standard</strong> cryogenic valves are equipped with a vacuum weld-in flange for cold-box mounting from the bottom<br />

side. Flanges with greater diameter for assembling through top plate are optional available. On request possible<br />

are any other vacuum flange assembling. However valves without weld-in flange are also available as well as on<br />

request vacuum jacketed valves.<br />

L:\_Dokumentationen\Cryo_Datenblätter\_Originale\19911004-E-2002.doc

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 2 of 7<br />

The valve actuator spindle is flexible clutched on the bellows inset. This design guarantees an optimised<br />

adaptability to any functions requested and protect the valve against any inaccuracies from the actuator. A manual<br />

drive or pneumatic, electrical or hydraulic actuator could be fitted.<br />

Beside the possibility to turn the actuators in any circumferential position - in case of restricted space on cold box<br />

plates - it also allows a later modification of actuators on mounted valves to fulfil new functions.<br />

3. Valve Actuators<br />

<strong>WEKA</strong> Cryogenic Valves are supplied with manual, pneumatic or electrical actuators for on/off (digital) or control<br />

functions. Actuator control accessories like limit switches, positioner, 3/2-way solenoid valves etc. are selected<br />

according to the specified valve function.<br />

Pneumatic and electrical actuators as well as their accessories are bought from selected proven manufacturers.<br />

However, all current products, as per the customer’s request, could be assembled on request. Also available are<br />

pneumatic- or hydraulic piston drives.<br />

Actuator size and system is derived by the valve size (DN), the specified service or shut off pressure pressure,<br />

the available supply of energy (air pressure, power) and the plant control system. Also to act are specifications<br />

about actuating time, fail function in case of loss of energy supply and other restrictions like x-ray radiation's or<br />

explosion proof areas.<br />

4. Manufacturing and Quality Assurance<br />

Based on our long-standing experience in design, manufacturing and testing of Cryogenic Components we are<br />

in a position to offer you a made-to-measure solution for almost any requirement.<br />

Apart from the latest state of the art production equipment such as CAD-systems, fully integrated PPS with online<br />

BDE-system, CNC machine tools, TIG- (GTAW) welding equipment as well as He-leak tightness detector,<br />

ultra-sonic cleaning bath and separated assembling and testing rooms, we also maintain a appropriate QAsystem.<br />

The welding shop is qualified according to EN-, SVTI-, AD- and ANSI/ASME codes.<br />

<strong>WEKA</strong> Cryogenic Valves are individually He- leak tested over the valve seat and to outside, both under vacuum<br />

and pressure conditions. Valve bodies additionally are hydrostatic- or gas pressure tested. All these tests are<br />

executed, if possible, on the completely fitted valve and according to written procedures specifications.<br />

A end check of all valve function, dimensions, completeness of all accessories as well as adjusting of actuators<br />

and cleanliness of fluid contacted surfaces is carried out prior to despatch.<br />

For despatching the valves are packed in PE bags.<br />

All tests indicated above are specified in detail in the "<strong>Standard</strong> Delivery Specification for Cryogenic- and Bellows<br />

Sealed Valves"<br />

Additional tests and inspections according to customer’s request will be possible.<br />

L:\_Dokumentationen\Cryo_Datenblätter\_Originale\19911004-E-2002.doc

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 3 of 7<br />

Technical Valve Data's<br />

4.1 Valve<br />

Valve size DN<br />

(Nominal Valve Size)<br />

Valve bore / Valve travel<br />

k v s value range as control<br />

resp. digital valve<br />

(c v =1,16 * k v )<br />

i.e. different flow plugs for k v s<br />

value range, see catalogue<br />

no. 921104<br />

PN<br />

(Nominal Pressure<br />

==> max barg @ 20°C)<br />

<strong>Standard</strong><br />

Heat load to the system See page 7<br />

Size DN Dia. of valve bore Valve travel<br />

(mm)<br />

(mm)<br />

DN2 2mm / 10mm<br />

DN4 4mm / 10mm<br />

DN6 6mm / 10mm<br />

DN8 8mm / 10mm<br />

DN10 10mm / 10mm<br />

DN15 15mm / 10mm<br />

DN20 20mm / 16mm<br />

DN25 25mm / 16mm<br />

DN32 32mm / 16mm<br />

DN40-36 36mm / 20mm<br />

DN40 40mm / 32mm<br />

DN50 50mm / 32mm<br />

DN65 65mm / 32mm<br />

DN80 80mm / 40mm<br />

DN100 100mm / 50mm<br />

DN125 120mm / 65mm<br />

Size DN as control valve as digital valve<br />

DN2 0.007...0.070 lin -<br />

DN4 0.050...0.186 lin -<br />

DN6 0.09...0.80 =% 0.9 dig<br />

DN8 0.20...2.20 =% 2.5 dig<br />

DN10 0.33...2.80 =% 3 dig<br />

DN15 1.00...5.80 =% 6 dig<br />

DN20 5.3...11.0 =% 12 dig<br />

DN25 6.8...14.7 =% 15 dig<br />

DN32 12.6...21.8 =% 25-dig<br />

DN40-36 16.0...33.0 =% 35 dig<br />

DN40 20.6...43.3 =% 45 dig<br />

DN50 31.5...71.0 =% 75 dig<br />

DN65 52...98 =% 100 dig<br />

DN80 63...160 =% 170 dig<br />

DN100 ...240 =% 260 dig<br />

DN125 ...370 =% 390 dig<br />

PN25 as standard respective PN… as<br />

indicated<br />

i.e. same valve could be used as PN6, PN10,<br />

PN16 and PN 20 respectively<br />

Body and bellows are designed for 25bar, for<br />

details see specification no. 930922 (pressure<br />

load calculation)<br />

Optional on request<br />

Greater DN on request<br />

Longer travel on request, special diameter<br />

on valve bore on request e.g.<br />

Size DN Dia. of valve bore Valve travel<br />

(mm)<br />

(mm)<br />

DN150 140 / 70<br />

DN200 190 / 95<br />

DN250 240 / 120<br />

DN250spez. 270 / 135<br />

DN300 285 / 145<br />

k v s

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 4 of 7<br />

Valve Interface Connections<br />

Valve body pattern<br />

Cat. no. 911003<br />

Pipe Connection<br />

Cat. no. 911003<br />

Mounting<br />

Cryogenic length<br />

<strong>Standard</strong><br />

Angle<br />

Butt weld ends<br />

<strong>Standard</strong> weld- in flange for coldbox<br />

mounting, according to catalogue no<br />

910930 and 911031<br />

Without weld-in flange according to<br />

catatalogue No. 911104<br />

Depending on DN and service temperature,<br />

h=600, 875, 1000 and 1300mm<br />

Optional on request<br />

Globe pattern (D- or Z-shape)<br />

Y - pattern, 45°<br />

Flanges, tube fittings etc<br />

KF-flanges or any other flange<br />

according to customer’s request.<br />

Vacuum jacketed etc.<br />

all dimensions between min. h and<br />

up to max. of. ca. 2000mm<br />

4.2 Materials<br />

Body<br />

Inset<br />

<strong>Standard</strong><br />

Stainless steel code 316L i.e.<br />

DIN grades 1.4404, 1.4432 or 1.4435<br />

(DIN17440, DIN17457 and DIN 17458<br />

as well as new EN10272, EN10217<br />

and EN10216)<br />

Stainless steel code 316L i.e.<br />

Insert tube filled with Perlite powder<br />

and tight welded<br />

Optional on request<br />

Stainless steel code 321 (DIN<br />

grades 1.4541 / 1.4571) or code<br />

304L (DIN grades 1.4306/1.4307)<br />

Compound design with FWG Epoxy<br />

-glass fibre tube, vented and<br />

filled with PE-netting or ss netting.<br />

Vented stainless steel tube filled ss<br />

netting.<br />

Seat seals PTFE or PCTFE or HD-PE1000, PI, PEEK mod., Ni, Stellite 6<br />

Flow plugs CuAl10 Fe Ni5 Stainless steel polished<br />

Bonnet, union nuts<br />

Upper spindle<br />

Brass up to DN65<br />

Stainless steel grade A2 >=DN80<br />

Stainless steel grade A2/A4<br />

In stainless steel A2<br />

Static O-ring joints NBR70; FPM75 Kalrez / Chemraz etc.<br />

Stem sealing:<br />

Bellows sealed:<br />

Packing sealed:<br />

Manual drive:<br />

Stainless steel grade 316L i.e.<br />

DIN grades 1.4404 and 1.4435<br />

Security seal:<br />

= DN80 PTFE chevron packing<br />

NBR quad ring, guiding in PTFE<br />

Hand wheels and travel indication in<br />

Aluminium<br />

Yoke and legs in Stainless steel<br />

grade A2/A4<br />

FPM o-rings<br />

other packing<br />

FPM quad ring, guiding in HD-<br />

PE100<br />

L:\_Dokumentationen\Cryo_Datenblätter\_Originale\19911004-E-2002.doc

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 5 of 7<br />

5. Valve Actuators:<br />

Manual Drives:<br />

− Integral or leg design, precision drive 1/100 backlash for control functions<br />

− Manual drives with fine travel indication for control or rough indication for shut-off only<br />

− Possibility to fit switches (electromechanical or inductive) to indicate valve (end) positions<br />

− For dimensions see catalogue-no. 921029<br />

Pneumatic Actuators<br />

− Pneumatic diaphragm actuators for on/off (digital)- or control functions, max. air supply pressure depending<br />

on actuators type up to 6,0 barg respectively 4,2barg, min. air supply pressure depending on valve size, position<br />

in case of loss of air pressure or signal and service or shut-off pressure<br />

− Normally closed or normally open by spring thrust<br />

− Control valves with electropneumatic positioner, with<br />

⇒ conventional analogues positioner, signal 4-20mA<br />

or with<br />

⇒ intelligent digital positioner, signal 4-20mA with option modules for<br />

• alarms (incl. 2-off adjustable travel switches, 1-off configurable alarm outlet and 1-off binary inlet configurable<br />

for use for examples as 3/2-way solenoid valve or blocking valve)<br />

• analogues travel feedback as 4-20mA signal<br />

• HART protocol<br />

or with<br />

⇒ intelligent digital positioner for fieldbus technology, system PROFIBUS PA, with all optional as described<br />

above<br />

or with<br />

⇒ pneumatic positioner signal 0,2 - 1,0 barg, integral<br />

− Positioner will be side mounted as standard, integral conventional analogues electropneumatic and for<br />

pneumatic positioner are available on request. An optional compact mounting for the intelligent digital positioner<br />

will be available on request.<br />

− Auxiliaries like limit switches (micro, inductive- and capacitive proximity switches), 3/2 way solenoid valves<br />

and any other pneumatic air control equipment according to the valve function and customer’s request. Dimensions,<br />

specifications and materials on request<br />

Electrical Actuators<br />

− Electrical linear actuators for on/off (digital)- or control function.<br />

− Power supply 220/240V-50Hz or 110V-50Hz, 24V-DC etc.<br />

− Depending on valve function with thrust load depending limit switches, travel depending switches and travel<br />

feedback potentiometers or with integral electronically positioner signal 0/4-20mA or 0-10V and any other<br />

electrical control equipment will be available on request<br />

Other Actuators<br />

− Pneumatic piston actuators, hydraulic or fluid self-controlled actuators according to customer’s request.<br />

L:\_Dokumentationen\Cryo_Datenblätter\_Originale\19911004-E-2002.doc

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 6 of 7<br />

Heat load by thermal conductivity of solids on cryogenic valves PN25 (<strong>Standard</strong>)<br />

Heat load for any cryogenic length “h”:<br />

I<br />

L(h = )<br />

IL(h = 875,300 K − K) × 875<br />

=<br />

( W )<br />

h = <br />

h<br />

(mm)<br />

DN2, DN4, DN6 600<br />

875<br />

DN8 600<br />

875<br />

DN10 600<br />

875<br />

DN15 600<br />

875<br />

DN20 600<br />

875<br />

DN25 600<br />

875<br />

DN32 600<br />

875<br />

DN40-36 600<br />

875<br />

DN40 600<br />

875<br />

DN50 600<br />

875<br />

DN65 600<br />

875<br />

DN80 875<br />

1000<br />

DN100 875<br />

1000<br />

DN125 875<br />

1200<br />

DN150 875<br />

1200<br />

I L (300K-4K)<br />

(W)<br />

0.28<br />

0.19<br />

0.42<br />

0.29<br />

0.48<br />

0.33<br />

0.69<br />

0.47<br />

0.94<br />

0.64<br />

1.37<br />

0.94<br />

1.54<br />

1.06<br />

2.19<br />

1.50<br />

2.92<br />

2.01<br />

3.79<br />

2.60<br />

5.35<br />

3.67<br />

5.24<br />

4.58<br />

7.35<br />

6.41<br />

10.08<br />

7.24<br />

14.51<br />

10.39<br />

I L (300K-20K)<br />

(W)<br />

0.27<br />

0.19<br />

0.41<br />

0.28<br />

0.47<br />

0.32<br />

0.68<br />

0.46<br />

0.93<br />

0.63<br />

1.36<br />

0.93<br />

1.53<br />

1.05<br />

2.18<br />

1.49<br />

2.91<br />

1.99<br />

3.77<br />

2.59<br />

5.32<br />

3.65<br />

5.21<br />

4.56<br />

7.31<br />

6.37<br />

10.03<br />

7.21<br />

14.44<br />

10.34<br />

I L (300K-77K)<br />

(W)<br />

0.25<br />

0.17<br />

0.37<br />

0.26<br />

0.43<br />

0.30<br />

0.62<br />

0.42<br />

0.84<br />

0.58<br />

1.23<br />

0.84<br />

1.38<br />

0.95<br />

1.97<br />

1.35<br />

2.62<br />

2.33<br />

3.40<br />

2.33<br />

4.79<br />

3.29<br />

4.69<br />

4.11<br />

6.65<br />

5.79<br />

9.14<br />

6.56<br />

13.18<br />

9.42<br />

L:\_Dokumentationen\Cryo_Datenblätter\_Originale\19911004-E-2002.doc

<strong>WEKA</strong> <strong>AG</strong>, CH-8344 Bäretswil & CH-2300 La Chaux-de-Fonds, Switzerland<br />

Phone +41 43 833 4343 - Fax +41 43 833 4329- Schürlistrasse 8, CH-8344 Bäretswil<br />

Phone +41 32 925 97 00 - Fax +41 32 926 54 22 - Allée du Quartz 1, CH-2300 La Chaux-de-Fonds<br />

<strong>WEKA</strong> Specification no. 19911004 – <strong>WEKA</strong> Cryogenic Valves<br />

info@weka-ag.ch - www.weka-ag.ch<br />

19. September 2007 - FHo / Page 7 of 7<br />

Heat load by thermal conductivity of solids on cryogenic valves PN10<br />

h<br />

(mm)<br />

DN80 (875)<br />

1000<br />

DN100 (875)<br />

1000<br />

DN125 (875)<br />

1200<br />

DN150 (875)<br />

1200<br />

DN200 (875)<br />

1500<br />

DN250 (875)<br />

1500<br />

DN250-spez. (875)<br />

1500<br />

DN300 (875)<br />

1500<br />

I L (300K-4K)<br />

(W)<br />

(4.72)<br />

4.11<br />

(6.11)<br />

5.29<br />

(7.82)<br />

5.56<br />

(ca. 11)<br />

ca. 7.5<br />

(ca. 18)<br />

ca. 10<br />

(ca. 30)<br />

ca. 14<br />

(ca. 44)<br />

ca. 17<br />

(ca. 60)<br />

ca. 20<br />

I L (300K-20K)<br />

(W)<br />

(4.70)<br />

4.09<br />

(6.08)<br />

5.27<br />

(7.78)<br />

5.53<br />

(ca. 11)<br />

ca. 7.5<br />

(ca. 18)<br />

ca. 10<br />

(ca. 30)<br />

ca. 14<br />

(ca. 44)<br />

ca. 17<br />

(ca. 60)<br />

ca. 20<br />

I L (300K-77K)<br />

(W)<br />

(4.31)<br />

3.75<br />

(5.60)<br />

4.85<br />

(7.16)<br />

5.07<br />

(ca. 10)<br />

ca. 6.5<br />

(ca. 16)<br />

ca. 9<br />

(ca. 28)<br />

ca. 13<br />

(ca. 42)<br />

ca. 16<br />

(ca. 57)<br />

ca. 18<br />

Values above are available for the standard range of cryogenic valves. For thermal contact to shield cooling see<br />

catalogue no. 930435. Compound valve inset design with GFK intersection tube for further reduction of heat load<br />

(of about 30 to 40% depending on size of valve) on request. Values for heat load on request.<br />

L:\_Dokumentationen\Cryo_Datenblätter\_Originale\19911004-E-2002.doc

<strong>WEKA</strong> <strong>AG</strong><br />

Schürlistrasse 8, CH-8344 Bäretswil, Switzerland, Europe<br />

E-mail: info@weka-ag.ch / Tel.: ++41 (0)1 939 29 59 / Fax: ++41 (0)1 929 39 63<br />

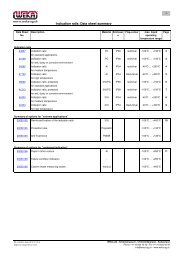

<strong>Standard</strong> Cryogenic Valve PN25, Bellows Sealed, with Pneumatic Actuator<br />

- Design pressure for body and bellows inset: PN25 resp. PN10 as indicated i.e. also possible to use as PN6, PN10, PN16 and PN20 valves respectively<br />

- With pneumatic diaphragm actuator for a shut-off pressure as indicated<br />

- Control valves with digital electropneumatic positioner (digital pneumatic with electronical control)<br />

Nominal Valve Size DN: 2 4 6 8 10 15 20 25<br />

Nominal Pressure for Valve Body /Inset PN: PN25 PN25 PN25 PN25 PN25 PN25 PN25 PN25<br />

( = nominal pipe size): 1/12" 1/8" 1/4" 3/8" 3/8" 1/2" 3/4" 1"<br />

Seat diam. (mm): 2 4 6 8 10 15 20 25<br />

Travel (mm): 10 10 10 10 10 10 16 16<br />

kv max. (m 3 /h, H 2 O, D p=1bar): (Cv = 1.16*kv, Cv in US gal/min, H 2 O, ∆p=1psi)<br />

- Control Valve:

Nominal Valve Size DN:<br />

Nominal Pressure for Valve Body /Inset PN:<br />

( = nominal pipe size):<br />

Seat diam. (mm):<br />

Travel (mm):<br />

kv max. (m 3 /h, H 2 O, D p=1bar):<br />

- Control Valve:<br />

- Digital (Shut-Off-) Valve:<br />

Valve:<br />

Dia. vacuum weld in flange, cat. No. 910930, a1 (mm):<br />

Dia. vacuum weld in flange, cat. no. 9110031, a2 (mm):<br />

Butt weld end, Dia. d*s (mm)<br />

e (mm):<br />

f (mm):<br />

Cryogenic length h (mm):<br />

Heat load 300 to 4K @ indicated length h (W):<br />

Pneumatic Diaphragm Actuator:<br />

Max. shut-off pressure (bar):<br />

Type:<br />

Dia. MA (mm):<br />

y (mm):<br />

z (mm):<br />

Control pressure min/max. for Po actuators (barg):<br />

Control pressure min/max. for Ps actuators (barg):<br />

Remarks:<br />

<strong>WEKA</strong> <strong>AG</strong><br />

Schürlistrasse 8, CH-8344 Bäretswil, Switzerland, Europe<br />

E-mail: info@weka-ag.ch / Tel.: ++41 (0)1 939 29 59 / Fax: ++41 (0)1 929 39 63<br />

<strong>Standard</strong> Cryogenic Valve PN25, Bellows Sealed, with Pneumatic Actuator<br />

- Design pressure for body and bellows inset: PN25 resp. PN10 as indicated i.e. also possible to use as PN6, PN10, PN16 and PN20 valves respectively<br />

- With pneumatic diaphragm actuator for a shut-off pressure as indicated<br />

- Control valves with digital electropneumatic positioner (digital pneumatic with electronical control)<br />

32 32 40 40 40 40 50 50<br />

PN25 = PN25 = PN25 = PN25 =<br />

1 1/4" = 1 1/2" = 1 1/2" = 2" =<br />

32 = 36 = 40 = 50 =<br />

16 = 20 = 32 = 32 =<br />

(Cv = 1.16*kv, Cv in US gal/min, H 2 O, ∆p=1psi)<br />

14.7 = 33 = 45 = 71 =<br />

15 = 35 = 50 = 75 =<br />

80 = 120 = 120 = 120 =<br />

134 = 164 = 164 = 164 =<br />

42.4*2.0 = 48.3*2.0 = 48.3*2.0 = 60.3*2.0 =<br />

80 = 100 = 100 = 100 =<br />

101 = 106 = 106 = 106 =<br />

875 = 875 = 875 = 875 =<br />

1.06 = 1.50 = 2.01 = 2.60 =<br />

Nominal Valve Size DN:<br />

Nominal Pressure for Valve Body /Inset PN:<br />

( = nominal pipe size):<br />

Seat diam. (mm):<br />

Travel (mm):<br />

kv max. (m 3 /h, H 2 O, D p=1bar):<br />

- Control Valve:<br />

- Digital (Shut-Off-) Valve:<br />

Valve:<br />

Dia. vacuum weld in flange, cat. No. 910930, a1 (mm):<br />

Dia. vacuum weld in flange, cat. no. 9110031, a2 (mm):<br />

Butt weld end, Dia. d*s (mm)<br />

e (mm):<br />

f (mm):<br />

Cryogenic length h (mm):<br />

Heat load 300 to 4K @ indicated length h (W):<br />

Pneumatic Diaphragm Actuator:<br />

Max. shut-off pressure (bar):<br />

Type:<br />

Dia. MA (mm):<br />

y (mm):<br />

z (mm):<br />

Control pressure min/max. for Po actuators (barg):<br />

Control pressure min/max. for Ps actuators (barg):<br />

Remarks:<br />

<strong>WEKA</strong> <strong>AG</strong><br />

Schürlistrasse 8, CH-8344 Bäretswil, Switzerland, Europe<br />

E-mail: info@weka-ag.ch / Tel.: ++41 (0)1 939 29 59 / Fax: ++41 (0)1 929 39 63<br />

<strong>Standard</strong> Cryogenic Valve PN25, Bellows Sealed, with Pneumatic Actuator<br />

- Design pressure for body and bellows inset: PN25 resp. PN10 as indicated i.e. also possible to use as PN6, PN10, PN16 and PN20 valves respectively<br />

- With pneumatic diaphragm actuator for a shut-off pressure as indicated<br />

- Control valves with digital electropneumatic positioner (digital pneumatic with electronical control)<br />

65 65 65 80 80 80<br />

PN25 = = PN10 PN25 =<br />

2 1/2" = = 3" 3" =<br />

65 = = 80 80 =<br />

32 = = 40 40 =<br />

(Cv = 1.16*kv, Cv in US gal/min, H 2 O, ∆p=1psi)<br />

98 = = 160 160 =<br />

100 = = 170 170 =<br />

150 = = 190 190 =<br />

200 = = 260 260 =<br />

76.1*2. = = 88.9*2.6 88.9*2.6 =<br />

125 = = 155 155 =<br />

115 = = 120 120 =<br />

875 = = 1000 1000 =<br />

3.67 = = 4.11 4.58 =<br />

Nominal Valve Size DN:<br />

Nominal Pressure for Valve Body /Inset PN:<br />

( = nominal pipe size):<br />

Seat diam. (mm):<br />

Travel (mm):<br />

kv max. (m 3 /h, H 2 O, D p=1bar):<br />

- Control Valve:<br />

- Digital (Shut-Off-) Valve:<br />

Valve:<br />

Dia. vacuum weld in flange, cat. No. 910930, a1 (mm):<br />

Dia. vacuum weld in flange, cat. no. 9110031, a2 (mm):<br />

Butt weld end, Dia. d*s (mm)<br />

e (mm):<br />

f (mm):<br />

Cryogenic length h (mm):<br />

Heat load 300 to 4K @ indicated length h (W):<br />

Pneumatic Diaphragm Actuator:<br />

Max. shut-off pressure (bar):<br />

Type:<br />

Dia. MA (mm):<br />

y (mm):<br />

z (mm):<br />

Control pressure min/max. for Po actuators (barg):<br />

Control pressure min/max. for Ps actuators (barg):<br />

Remarks:<br />

<strong>WEKA</strong> <strong>AG</strong><br />

Schürlistrasse 8, CH-8344 Bäretswil, Switzerland, Europe<br />

E-mail: info@weka-ag.ch / Tel.: ++41 (0)1 939 29 59 / Fax: ++41 (0)1 929 39 63<br />

<strong>Standard</strong> Cryogenic Valve PN25, Bellows Sealed, with Pneumatic Actuator<br />

- Design pressure for body and bellows inset: PN25 resp. PN10 as indicated i.e. also possible to use as PN6, PN10, PN16 and PN20 valves respectively<br />

- With pneumatic diaphragm actuator for a shut-off pressure as indicated<br />

- Control valves with digital electropneumatic positioner (digital pneumatic with electronical control)<br />

100 100 100 100 125 125 125<br />

PN10 PN25 = = PN10 PN25 =<br />

4" 4" = = 5" 5" =<br />

100 100 = = 120 120 =<br />

50 50 = = 65 65 =<br />

(Cv = 1.16*kv, Cv in US gal/min, H 2 O, ∆p=1psi)<br />

240 240 = = 370 370 =<br />

260 260 = = 400 400 =<br />

230 230 = = 275 275 =<br />

315 315 = = - - =<br />

114.3*2.6 114.3*2.6 = = 139.7*s 139.7*s =<br />

175 175 = = 200 200 =<br />

133 133 = = 145 145 =<br />

1000 1000 = = 1200 1200 =<br />

ca. 5.5 6.41 = = 5.56 7.24 =<br />

Nominal Valve Size DN:<br />

Nominal Pressure for Valve Body /Inset PN:<br />

( = nominal pipe size):<br />

Seat diam. (mm):<br />

Travel (mm):<br />

kv max. (m 3 /h, H 2 O, D p=1bar):<br />

- Control Valve:<br />

- Digital (Shut-Off-) Valve:<br />

Valve:<br />

Dia. vacuum weld in flange, cat. No. 910930, a1 (mm):<br />

Dia. vacuum weld in flange, cat. no. 9110031, a2 (mm):<br />

Butt weld end, Dia. d*s (mm)<br />

e (mm):<br />

f (mm):<br />

Cryogenic length h (mm):<br />

Heat load 300 to 4K @ indicated length h (W):<br />

Pneumatic Diaphragm Actuator:<br />

Max. shut-off pressure (bar):<br />

Type:<br />

Dia. MA (mm):<br />

y (mm):<br />

z (mm):<br />

Control pressure min/max. for Po actuators (barg):<br />

Control pressure min/max. for Ps actuators (barg):<br />

Remarks:<br />

<strong>WEKA</strong> <strong>AG</strong><br />

Schürlistrasse 8, CH-8344 Bäretswil, Switzerland, Europe<br />

E-mail: info@weka-ag.ch / Tel.: ++41 (0)1 939 29 59 / Fax: ++41 (0)1 929 39 63<br />

<strong>Standard</strong> Cryogenic Valve PN25, Bellows Sealed, with Pneumatic Actuator<br />

- Design pressure for body and bellows inset: PN25 resp. PN10 as indicated i.e. also possible to use as PN6, PN10, PN16 and PN20 valves respectively<br />

- With pneumatic diaphragm actuator for a shut-off pressure as indicated<br />

- Control valves with digital electropneumatic positioner (digital pneumatic with electronical control)<br />

150 150 150 150<br />

PN10 PN25 = =<br />

6" 6" = =<br />

ca. 140 ca. 140 = =<br />

ca. 70 ca. 70 = =<br />

(Cv = 1.16*kv, Cv in US gal/min, H 2 O, ∆p=1psi)<br />

ca. 550 ca. 550 = =<br />

ca. 600 ca. 600 = =<br />

ca. 325 ca. 325 = =<br />

- - = =<br />

168.3*s 168.3*s = =<br />

ca. 250 ca. 250 = =<br />

ca. 160 ca. 160 = =<br />

1200 1200 = =<br />

ca. 7.5 10.39 = =<br />

Nominal Valve Size DN:<br />

Nominal Pressure for Valve Body /Inset PN:<br />

( = nominal pipe size):<br />

Seat diam. (mm):<br />

Travel (mm):<br />

kv max. (m 3 /h, H 2 O, D p=1bar):<br />

- Control Valve:<br />

- Digital (Shut-Off-) Valve:<br />

Valve:<br />

Dia. vacuum weld in flange, cat. No. 910930, a1 (mm):<br />

Dia. vacuum weld in flange, cat. no. 9110031, a2 (mm):<br />

Butt weld end, Dia. d*s (mm)<br />

e (mm):<br />

f (mm):<br />

Cryogenic length h (mm):<br />

Heat load 300 to 4K @ indicated length h (W):<br />

Pneumatic Diaphragm Actuator:<br />

Max. shut-off pressure (bar):<br />

Type:<br />

Dia. MA (mm):<br />

y (mm):<br />

z (mm):<br />

Control pressure min/max. for Po actuators (barg):<br />

Control pressure min/max. for Ps actuators (barg):<br />

Remarks:<br />

<strong>WEKA</strong> <strong>AG</strong><br />

Schürlistrasse 8, CH-8344 Bäretswil, Switzerland, Europe<br />

E-mail: info@weka-ag.ch / Tel.: ++41 (0)1 939 29 59 / Fax: ++41 (0)1 929 39 63<br />

<strong>Standard</strong> Cryogenic Valve PN25, Bellows Sealed, with Pneumatic Actuator<br />

- Design pressure for body and bellows inset: PN25 resp. PN10 as indicated i.e. also possible to use as PN6, PN10, PN16 and PN20 valves respectively<br />

- With pneumatic diaphragm actuator for a shut-off pressure as indicated<br />

- Control valves with digital electropneumatic positioner (digital pneumatic with electronical control)<br />

200 200 250 250 250spez. 300 300<br />

PN10 PN25 PN10 PN25 PN10 PN10 PN25<br />

8" 8" 10" 10" 10" 12" 12"<br />

190 190 240 240 270 285 285<br />

95 95 120 120 135 145 145<br />

(Cv = 1.16*kv, Cv in US gal/min, H 2 O, ∆p=1psi)<br />

ca. 930 ca. 930 ca. 1550 ca. 1550 ca. 2050 ca. 2300 ca. 2300<br />

ca. 1000 ca. 1000 ca. 1650 ca. 1650 ca. 2150 ca. 2400 ca. 2400<br />

ca. 450 ca. 450 ca. 500 ca. 500 ca. 500 ca. 600 ca. 600<br />

- - - - - - -<br />

219.1*s 219.1*s 273.0*2.9 273.0*2.9 273.0*2.9 323.9*3.2 323.9*3.2<br />

ca. 300 ca. 300 ca. 400 ca. 400 ca. 400 ca. 500 ca. 500<br />

ca. 225 ca. 225 ca. 380 ca. 380 ca. 380 ca. 380 ca. 380<br />

1500 1500 1500 1500 1500 1500 1500<br />

ca. 10.0 t.b.a. ca. 14.0 t.b.a. ca. 17.0 ca. 20.0 t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a. t.b.a.<br />

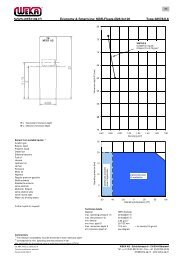

- Po=normally closed actuators / Ps=normally open actuators<br />

- Mounting in vertical direction, actuator on top (max. angle from vertical 70°, with liquid cryogens use convection brake cat. no. 930108)<br />

- Cryogenic length h according order specification, indicated length is a recommended standard for LHe service<br />

- To reduce of heat load, cryogenic length "h" could be elongated or add thermal contact according to catalogue no. 930435<br />

- For further reduce of heat load, a modified inset as compound design in ss and GFK tube is available on request<br />

- For valves in sub-atmosphere pressure conditons a He-guard space seal system to outside i.e. full double seal is available on request<br />

- Valves with a short bellows section to the vacuum envelope on request<br />

- For valves with body shape in globe pattern, Y-slanted or shifted inlet-outlet (i. e.Z-pattern) see catalogue no. 911003<br />

*1) Bigger actuators for higher shut-off pressure on request / *2) Smaller actuators for lower shut-off pressure on request<br />

All dimensions in "mm", subject to change without further notice!<br />

930219MasseP-TEV-MA.xls/Dimensions <strong>WEKA</strong> Drawing no. 930219 pages 6/8 Jan. 2000/FHo