English

English

English

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

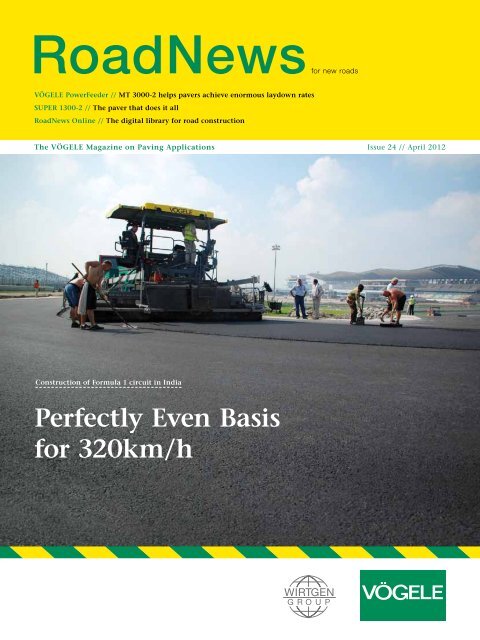

RoadNewsfor new roads<br />

VÖGELE PowerFeeder // MT 3000-2 helps pavers achieve enormous laydown rates<br />

SUPER 1300-2 // The paver that does it all<br />

RoadNews Online // The digital library for road construction<br />

The VÖGELE Magazine on Paving Applications Issue 24 // April 2012<br />

Construction of Formula 1 circuit in India<br />

Perfectly Even Basis<br />

for 320km/h

Editorial<br />

Contents // RoadNews 24<br />

Contents<br />

Top Feature...............................................................................................................................................................................<br />

Accurate paving and perfect grade and slope control // VÖGELE pavers build first Formula 1 circuit<br />

near New Delhi, India 4<br />

Technology................................................................................................................................................................................<br />

NEW!<br />

VÖGELE Multi-Cell Sonic Sensor now for extended use // Grade and slope control: One sensor for two applications 18<br />

Site Reports...............................................................................................................................................................................<br />

Feeder Technology // VÖGELE Optimize the Supply of Material<br />

High material throughput and high-quality paving // VÖGELE feeders permit daily laydown rate beyond 5,000 tonnes 10<br />

Three VÖGELE machines pave a new stretch of the B 10 Federal highway in Germany // A new SUPER 2100-2<br />

joins the strong paver team 16<br />

Traffic calming made by VÖGELE // Three pavers in action on a new bypass road 20<br />

Powerful compact paver from VÖGELE // SUPER 1300-2: The paver that does it all 26<br />

Its enormous performance is impressive // Gigantic SUPER 3000-2 paver captivates China 34<br />

Top paving quality is the decisive factor for success in<br />

road construction. Customers expect perfect results – the<br />

pavement surface, compaction and bond between layers<br />

must meet exceedingly stringent demands and ensure a<br />

long service life.<br />

Optimizing the pavers’ supply with mix using a material<br />

transfer vehicle is a major factor for achieving these goals.<br />

A feeder can significantly boost a pavement’s quality by<br />

feeding the paver with asphalt non-stop and without contact.<br />

It was this which prompted VÖGELE to develop two new<br />

machines: the PowerFeeders MT 3000-2 and MT 3000-2<br />

Offset. The first site reports prove that the machines’<br />

technical details have been perfectly tailored to meet practical<br />

requirements.<br />

Yet feeders are also immensely important in economic<br />

terms. The daily performance of an asphalt job site, for<br />

instance, can be boosted by up to 25% with a material feeder.<br />

The reason is clear: the paving process is not interrupted<br />

when using a feeder. This higher performance also<br />

significantly reduces the total time spent on site – a very<br />

important aspect in micro- and macroeconomic terms.<br />

Enjoy reading.<br />

Roland Schug<br />

NEW!<br />

VÖGELE News ........................................................................................................................................................................<br />

WIRTGEN Group Technology Days 2011 // Innovative technology thrills thousands 40<br />

RoadNews Online // The digital library for road contractors 42<br />

Tips & Tricks ...........................................................................................................................................................................<br />

Road Profiles // Points to note when paving road crowns<br />

Centre Pages<br />

Imprint RoadNews for new roads – the VÖGELE Magazine on Paving Applications | Editorial Address: Joseph-Vögele-Str. 1, 67075 Ludwigshafen,<br />

Germany, Telephone +49 (0) 621 8105 – 392, Fax +49 (0) 621 8105 – 469, E-Mail roadnews@voegele.info, Website www.voegele.info<br />

Editors: Roland Schug, Anja Sehr, Martin Hilken | Translations: Maria Weckesser | Agency: bilekjaeger, Stuttgart | Reproduction of<br />

articles is permitted after written consent. We disclaim liability for editorial submissions which have not been requested. Trademarks and<br />

registered trademarks are the property of the owners.<br />

2<br />

3

Top Feature<br />

Construction of New Racing Circuit with SUPER 1800-2<br />

Precise paving and perfect grade and slope control provide ideal conditions for Formula 1 drivers.<br />

VÖGELE Pavers<br />

Build First Formula 1 Circuit<br />

Near New Delhi, India<br />

More than 500 million people worldwide watched the first Formula 1 race in<br />

India’s history on 30 October 2011. The drivers were thrilled by the new course.<br />

The asphalt circuit with its numerous bends and the peripheral area around<br />

the new race track near New Delhi were built by machinery from VÖGELE.<br />

The SUPER 1800-2 pavers triumphed, operating reliably and achieving an<br />

outstanding evenness right from the outset.<br />

4<br />

5

Top Feature<br />

Construction of New Racing Circuit with SUPER 1800-2<br />

India // New Delhi<br />

Afghanistan<br />

Iran<br />

Pakistan<br />

New Delhi<br />

Nepal<br />

China<br />

Working with four SUPER 1800-2 pavers, the “VÖGELE team”<br />

stood out particularly through their reliability and precision<br />

on the “Buddh International Circuit”, the first Formula 1 race<br />

track in India. To build a perfectly even asphalt pavement for<br />

the drivers as they battle for milliseconds, contractor Oriental<br />

Structure Engineers LTD from New Delhi used VÖGELE pavers<br />

for the crushed-stone base followed by three layers of asphaltic<br />

concrete. A Big MultiPlex Ski was used to ensure perfect grade<br />

and slope control.<br />

Indian Ocean<br />

Job Site Details<br />

India<br />

Construction of new “Buddh International Circuit”,<br />

New Delhi, India<br />

Length of circuit:<br />

Width of circuit:<br />

Circuit areas:<br />

5.1km<br />

18 – 25m<br />

150,000m² (approx.)<br />

Peripheral areas: 600,000m 2<br />

Paving Details<br />

Pave width:<br />

Layer thickness:<br />

Material<br />

6m<br />

base course 10cm<br />

binder course 5cm<br />

surface course 4cm<br />

Base course: asphaltic concrete DGBM 40*<br />

Binder course:<br />

Surface course:<br />

special mix for racing circuits<br />

(asphaltic concrete)<br />

special mix for racing circuits<br />

(asphaltic concrete)<br />

* DGMB = “Dense-graded bituminous mixture”,<br />

Indian standard<br />

Equipment<br />

4 SUPER 1800-2<br />

with AB 600 Extending Screeds in TV Version<br />

Indian Ocean<br />

Demanding circuit<br />

A demanding circuit distinguishes this newcomer to the<br />

Formula 1 racing calendar. The 5.1km circuit with 16 bends, a<br />

road varying between 18m and 25m in width, superelevations<br />

up to 12% and gradients up to 10%, demands considerable<br />

driving skill and offers optimum conditions for breathtaking<br />

overtaking manœuvres. Oriental LTD’s experts opted for<br />

technology from VÖGELE in order to deliver top-quality<br />

paving results despite these demanding requirements. Aided<br />

by the powerful pavers, they built a two-layer crushed-stone<br />

base and paved roughly 325,000 tonnes of asphalt for the<br />

circuit and its peripheral areas in the course of the project.<br />

The requirements made on the asphalt layers were extremely<br />

high in terms of both material quality and paving accuracy.<br />

The permissible tolerances for binder content, grain mix and<br />

also evenness were far lower than those of German motorways.<br />

Minimum tolerances for the surface course<br />

Particularly stringent demands were made on the surface<br />

course. The planning engineers had reduced by half the<br />

permitted deviation of the granular material from the ideal<br />

aggregate grading curve, compared with the tolerances allowed<br />

under German regulations. What’s more, aggregate with high<br />

resistance to polishing was used for the surface course. This<br />

mix guarantees a road surface with uniform texture depth<br />

and perfect tyre grip. All aggregate for the asphalt package was<br />

hauled to the mixing plants from specially selected quarries,<br />

some of which were several hundred kilometres away. The binder,<br />

too, was modified in line with the climatic conditions prevailing<br />

in northern India to ensure an outstanding mechanical and<br />

temperature stability at all times. Overall, the planning engineers’<br />

various measures allowed the achievement of an extremely<br />

uniform pavement structure whose properties will endure for<br />

many years, despite changing climatic conditions.<br />

01 //<br />

02 //<br />

01 // The final touches: the surface course is made from<br />

a special asphalt containing aggregate with high resistance<br />

to polishing. This ensures that the road’s good grip is<br />

maintained in the long term. The surface course was paved<br />

with an AB 600 Extending Screed in TV version.<br />

02 // Dr Rainer Hart, specialist in race tracks, was full of<br />

praise for the Big MultiPlex Ski: “With this sensor technology,<br />

VÖGELE achieved an outstanding evenness”.<br />

03 // The evenness was continuously checked by the team<br />

during the paving process. Thanks to the Big MultiPlex Ski,<br />

the low tolerances specified for surface course were met<br />

right from the start when paving binder course.<br />

03 //<br />

6<br />

7

Top Feature<br />

Construction of New Racing Circuit with SUPER 1800-2<br />

The Big MultiPlex Ski was used for grade and slope control.<br />

Even long irregularities were easily levelled out with the Ski.<br />

“Thanks to the VÖGELE pavers<br />

and expert advice from WIRTGEN<br />

India, we remained safely within<br />

the extremely tight tolerances.”<br />

Pankaj Gautam, Overall Project Manager<br />

Oriental LTD<br />

Impressive top-notch laydown rates<br />

Asphalt paving extended over a period of roughly 14 months<br />

during which the work had to be interrupted temporarily,<br />

mainly on account of the monsoon rain, but also due to<br />

technical requirements associated with the project as a whole.<br />

In retrospect, however, the figures are still impressive:<br />

all in all, the VÖGELE pavers built both the roadbase<br />

and the two or three-layer asphalt pavement according to the<br />

highest technical standards over a total area of 750,000m².<br />

Top quality assured by sample mixes and test areas<br />

Quality was the most important aspect, particularly when it<br />

came to paving the asphalt for the race track. For this reason,<br />

numerous sample mixes were prepared and laid on test areas<br />

before the paving work began. The formula, mixing plant<br />

parameters and materials were perfectly matched by the team<br />

of German and Indian operators and laboratory technicians.<br />

Access roads and tangents covering several thousand square<br />

metres were built in this way. “Such sample mixes are essential<br />

for optimizing the quality of the asphalt surface course. All<br />

the various constituent parts of the asphalt, the mixing plant<br />

parameters and precision adjustment of the pavers can only be<br />

perfectly matched with one another on the basis of such tests,”<br />

explains asphalt specialist Dr Rainer Hart. He developed the<br />

concept for the race track asphalt and supervised the asphalt<br />

work from selection of the aggregate in the quarry to paving<br />

and compaction.<br />

Lower compression stress, better tyre grip<br />

On a racing circuit, the base and binder courses are very much<br />

thinner than on normal roads. This is due to the lower pressure<br />

acting on the asphalt package. Non-skid properties and evenness<br />

are far more important here. That is why the paving teams<br />

paid more and more attention to the pavement’s evenness as<br />

they worked their way up to the top of the asphalt package.<br />

And they were successful, too, for VÖGELE set new records in<br />

evenness long before the first race in India.<br />

Big MultiPlex Ski for potentially record-breaking evenness<br />

A Big MultiPlex Ski was fitted on each side of the SUPER 1800-2<br />

pavers when placing all three layers – a move which<br />

indisputably paid off, particularly when a maximum<br />

permissible tolerance of 3mm per 4m has been specified.<br />

“The evenness achieved by VÖGELE is outstanding, thanks<br />

to this sensor technology. To the greatest possible extent, the<br />

surface unevenness was less than 1mm over a distance of 4m,”<br />

says Dr Hart, who was delighted with the excellent pavement<br />

results. He has supervised the paving work on numerous<br />

Formula 1 circuits in the past.<br />

Long irregularities are levelled out<br />

The Big MultiPlex Ski uses the proven VÖGELE technology<br />

of the sonic grade sensor. Three multi-cell sonic sensors are<br />

mounted on a beam with a maximum length of 13m. They<br />

simultaneously scan a reference at several widely spaced points.<br />

NIVELTRONIC Plus ® , the VÖGELE System for Automated<br />

Grade and Slope Control, calculates a virtual reference from<br />

these picked-up values. The Big MultiPlex Ski is capable of<br />

detecting and levelling out long irregularities in the surface,<br />

such as undulations, over a maximum distance of 13m.<br />

The Ski consequently operates with greater precision than<br />

a single grade sensor. It is controlled as usual via the screed<br />

operator’s console. Variability is also assured: the individual<br />

sensors of the Big MultiPlex Ski can be moved along the beam<br />

to optimally adapt to any job site.<br />

Good work, even at very high temperatures<br />

The racing circuit near Greater Noida is only a few kilometres<br />

away from the Indian capital New Delhi. The temperatures in<br />

this region are famously high, but the VÖGELE pavers did not<br />

baulk, even at these extreme conditions. The SUPER 1800-2<br />

pavers reliably met all expectations. “Even at temperatures of<br />

more than 40 °C the pavers continued to operate faultlessly,”<br />

reports Service Technician Ralf Peter on site. Pankaj Gautam,<br />

Oriental LTD’s Overall Project Manager, also had nothing<br />

but praise for the WIRTGEN Group’s machines and team:<br />

“With their profound know-how and skilled eye, the service<br />

technicians from WIRTGEN India and VÖGELE gave us<br />

optimum support when fine-tuning the pavers.” And the<br />

result really was record-breaking: the German Formula 1 world<br />

champion Sebastian Vettel not only won the first race, but<br />

also broke the first course record with a lap time of 1:27 mins.<br />

8<br />

9

Site Report<br />

VÖGELE MT 3000-3 PowerFeeder Technology<br />

Germany<br />

North Sea<br />

Netherlands<br />

Berlin<br />

Poland<br />

Belgium<br />

Kamen<br />

Germany<br />

Czech Republic<br />

MT 3000-2<br />

POWERFEEDER<br />

TECHNOLOGY<br />

France<br />

Switzerland<br />

Austria<br />

Job Site Details<br />

Widening the A 2 motorway between “Kamener<br />

Kreuz” junction and “Bönen” exit, Germany<br />

Length of section:<br />

4km<br />

Width of section: 32 – 36m (2 x 16 – 18m)<br />

Paving Details<br />

Pave width: 7.5 – 8.5m<br />

Layer thickness: base course 18 – 22cm<br />

binder course 8.5cm<br />

surface course 2.5 – 4.5cm<br />

Material<br />

Base course: asphaltic concrete (AC 32 T S)<br />

Binder course: asphaltic concrete (AC 22 B S)<br />

Surface courses: stone mastic asphalt (SMA 8 S)<br />

mastic asphalt (MA 5 S)<br />

porous asphalt (PA 8 S)<br />

High material throughput and high-quality paving.<br />

VÖGELE Feeders<br />

Permit Daily Laydown Rate<br />

Beyond 5,000 Tonnes<br />

Equipment<br />

SUPER 1900-2 with AB 500 Extending Screed<br />

2 SUPER 2100-2 with AB 600 Extending Screeds<br />

MT 3000-2 PowerFeeder<br />

MT 1000-1 Mobile Feeder<br />

You can find a video<br />

on this construction project on the Web at:<br />

www.voegele.info<br />

> News & Media > Mediathek<br />

10<br />

11

Site Report<br />

VÖGELE MT 3000-3 PowerFeeder Technology<br />

The German A 2 motorway was widened to six lanes.<br />

Between the “Kamener Kreuz” junction and the “Bönen”<br />

exit, the MT 3000-2 PowerFeeder from VÖGELE assured a<br />

top performance and outstanding results – as continual<br />

infrared thermagrophy tests confirmed.<br />

Motorway construction projects are always a major logistics<br />

challenge. Confined conditions on the cordoned-off site,<br />

working alongside the traffic stream and high time pressure<br />

impose immense demands on both the men and their machines.<br />

For this reason, contractor Heinz Schnorpfeil Bau GmbH elected<br />

to use three VÖGELE pavers and two VÖGELE feeders – one<br />

of them the new MT 3000-2 PowerFeeder – for construction<br />

of the motorway section between the “Kamener Kreuz”<br />

junction and the “Bönen” exit. This enabled large quantities<br />

of mix to be laid in a short space of time while assuring<br />

top-quality paving. Thanks to the two material feeders,<br />

the pavers achieved a daily laydown rate beyond 5,000 tonnes<br />

of mix.<br />

The feeder set the pace<br />

Like the rest of the A 2 motorway, the 4km westbound<br />

section had to be widened to six lanes. Furthermore, on about<br />

half this stretch of road, a surface course of noise-reducing<br />

porous asphalt was paved on a sealing layer of mastic asphalt.<br />

The new VÖGELE PowerFeeder MT 3000-2 remained<br />

indispensable throughout the asphalt paving work.<br />

“The feeder set the pace when placing the base course,”<br />

explains Ralf Lauxen, Schnorpfeil’s Site Manager for asphalt.<br />

“Thick layers requiring a great deal of material – that’s where it<br />

really comes into its own, considerably speeding up the paving<br />

operations.”<br />

Non-stop paving<br />

Around 81,000 tonnes of mix were laid by the Schnorpfeil<br />

team for the base and binder courses. For the 18 to 22cm thick<br />

base and the 8.5cm thick binder course, asphaltic concrete was<br />

used. Both layers were paved in several strips up to an overall<br />

width of between 16 and 18m. Thanks to the continuous<br />

supply of mix from the feeder, the VÖGELE pavers were able<br />

to pave the material without any interruptions.<br />

Top-quality, high-speed paving<br />

When placing the surface course, three different types of<br />

mix were used: in sections where noise abatement was not<br />

required, stone mastic asphalt was paved in a 3.5cm thick<br />

layer. Before placing the low-noise surface course, a 2.5cm<br />

thick seal of mastic asphalt was paved to prevent water seeping<br />

The high performance of the VÖGELE PowerFeeder ensured<br />

a permanent, uninterrupted supply of mix.<br />

The measurements prove it:<br />

A feeder significantly boosts the job site performance<br />

A comparison of the speed of a paver working without<br />

a feeder (Fig. 1) and together with a feeder (Fig. 2) clearly<br />

demonstrates the immense importance of an uninterrupted<br />

supply of mix.<br />

Figure 1<br />

Without a feeder, regular stops often cannot be avoided –<br />

as shown in the graph in the form of repeated drops in the red<br />

curve. The average speed marked in blue comes to 2.28m/min.<br />

Figure 2<br />

The paver is continually in operation when working with<br />

the PowerFeeder MT 3000-2 Offset from VÖGELE. The red<br />

curve remains at a constantly high level. The average speed is<br />

2.83m/min. – almost 25% higher than when working without<br />

a feeder.<br />

Speed (m/min)<br />

Speed (m/min.)<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Fig. 1<br />

Working without Feeder<br />

2011−12−06−03<br />

17:00<br />

16:45<br />

16:30<br />

16:15<br />

16:00<br />

15:45<br />

15:30<br />

15:15<br />

15:00<br />

14:45<br />

14:30<br />

50 100 150 200 250 300 350 14:15<br />

Time<br />

(m)<br />

Distance (m)<br />

Time Momentary speed Average speed<br />

Current Speed<br />

Average Speed<br />

CA Konsult<br />

Speed (m/min)<br />

Speed (m/min.)<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

0<br />

Fig. 2<br />

Working together with VÖGELE PowerFeeder<br />

MT 3000-2 Offset<br />

2011−12−06−00<br />

10:15<br />

10:00<br />

09:45<br />

09:30<br />

09:15<br />

09:00<br />

08:45<br />

08:30<br />

08:15<br />

50 100 150 200 250 300 350 08:00<br />

Time<br />

(m)<br />

Distance (m)<br />

Time Momentary speed Average speed<br />

Current Speed<br />

Average Speed<br />

CA Konsult<br />

VÖGELE PowerFeeder at a Glance<br />

Cutting-edge feeder concept allows large<br />

feed lorries to be emptied in 60 seconds flat.<br />

Enormous conveying capacity up<br />

to 1,200 tonnes/h.<br />

Large range of uses guarantees high<br />

utilization of the machine.<br />

Powerful diesel heating using fuel that<br />

is constantly available, in all locations.<br />

Ideal dimensions, can therefore be<br />

transported by low-bed trailer without<br />

restrictions.<br />

Proven intuitive control with the ErgoPlus ®<br />

operating system.<br />

Measurements and graphs: C A Konsult<br />

12<br />

13

Site Report<br />

VÖGELE MT 3000-3 PowerFeeder Technology<br />

through the open pores of the noise-reducing asphalt and<br />

damaging the lower layers of the road structure. The low-noise<br />

surfacing of porous asphalt was paved with a thickness of<br />

4.5cm, achieving a high pave speed of 150m/h.<br />

MT 3000-2<br />

POWERFEEDER<br />

TECHNOLOGY<br />

A faultless surface<br />

Speed was not the only aspect – the paving quality, in particular,<br />

was another important factor. To reduce noise levels, the porous<br />

asphalt must be paved without a flaw. “Such high quality can<br />

only be achieved if the paver is permanently in motion and the<br />

paving process is not interrupted,” says Lauxen. Here too, the<br />

new VÖGELE PowerFeeder MT 3000-2 was ideal: together with<br />

its predecessor, the MT 1000-1, it guaranteed a continuous,<br />

contact-free supply of mix to the pavers placing the<br />

surface course. This prevented phenomena such as the<br />

formation of humps on restarting after a break in paving<br />

or due to jolts from feed lorries frequently encountered<br />

on job sites without a material feeder. Two SUPER 2100-2<br />

pavers and one SUPER 1900-2 worked “hot to hot” to ensure<br />

that the asphalt strips were paved with perfect joints.<br />

Uniform mix temperature<br />

However, a feeder not only assures quality on the surface,<br />

but also ensures optimum paving right down inside each<br />

layer. This is achieved by homogenizing the temperature<br />

of the mix. “A uniform mix temperature is essential for<br />

achieving uniform compaction and thus extending the<br />

service life of the road,” explains Lauxen. On the way<br />

from the mixing plant to the construction site, the asphalt<br />

in the feed lorry cools to different extents. This thermal<br />

segregation is largely overcome by the feeder by specifically<br />

remixing hotter and cooler material from the lorry in its large<br />

worm conveyors before transferring the mix to the paver.<br />

“We checked that with an infrared scanner,” says Lauxen.<br />

“The mix temperature behind the screed was absolutely<br />

uniform.”<br />

Continuing Trend:<br />

Mix Supplied by a Material Feeder<br />

The importance of using feeders for high-quality paving<br />

is being recognized in more and more countries.<br />

> In Sweden, the use of feeders is rewarded with bonus<br />

payments. The temperature behind the screed is<br />

measured and the established thermal segregation<br />

converted into “risk shares”: the lower the risk shares,<br />

the higher the bonus payment becomes.<br />

> Some public customers in the USA and Canada already<br />

stipulate that feeders must be used. Bonuses are paid<br />

in the USA for using material feeders.<br />

> In Hungary, the use of feeders for motorway jobs<br />

has been mandatory since 2002.<br />

> In Germany, a community of interests is currently<br />

being set up to promote the use of material feeders.<br />

Financial incentives and customer requirements are<br />

expected.<br />

01 //<br />

02 //<br />

01 // The MT 3000-2 is controlled via the proven<br />

ErgoPlus ® operating system from VÖGELE.<br />

02 // A top-quality surface course is needed when paving<br />

noise-reducing asphalt.<br />

03 // Three VÖGELE pavers worked “hot to hot”<br />

when placing the surface course.<br />

Totally satisfied team<br />

The entire team is totally satisfied with the new MT 3000-2<br />

PowerFeeder which has rounded off Schnorpfeil's machine<br />

park since autumn 2011. Site Manager Ralf Lauxen sums up:<br />

“It is exceedingly powerful and speeds up the paving process<br />

considerably. Without the PowerFeeder, a job like this would<br />

be impossible to achieve in this quality and within the short<br />

construction period specified.”<br />

Source:<br />

Official tendering criteria of the respective countries and regions.<br />

03 //<br />

14<br />

15

Site Report<br />

Road Construction with SUPER 2100-2<br />

As a powerful, high-performance paver which can tackle even<br />

the biggest jobs swiftly, precisely and economically, the new<br />

SUPER 2100-2 is the perfect supplement to Wolff & Müller’s<br />

fleet of machines. But Wolff & Müller were also swayed by its<br />

ease of operation. “We now only use VÖGELE pavers,” reports<br />

Site Manager Lars-Peter Schwarzer. “This is because they are so<br />

much easier to operate than other makes. Our men are glad to<br />

work with VÖGELE machines.”<br />

job site<br />

ticker<br />

Fewer rolling passes due to high compaction screeds<br />

On the B 10 job, the SUPER 2100-2 was used alternately with<br />

a SUPER 1900-2 and a SUPER 1800-2. The third paver’s task<br />

was to pave asphalt for the access and exit roads in each case.<br />

All three machines proved totally reliable. Together they placed<br />

asphaltic concrete for a 10 - 18cm thick base (AC 32 T S) and a<br />

8cm binder course (AC 18 B S). Stone mastic asphalt (SMA 11 S)<br />

was then used for the surface course. The SUPER 2100-2 and the<br />

SUPER 1900-2 were equipped with high compaction screeds,<br />

thus minimizing the number of rolling passes required. The<br />

choice of screeds and compaction options for the SUPER 2100-2<br />

is very large and includes an ideal solution for every job.<br />

On schedule thanks to VÖGELE<br />

02 //<br />

“VÖGELE pavers are so much easier<br />

to operate than other makes. Our men are<br />

glad to work with VÖGELE machines.”<br />

Lars-Peter Schwarzer, Site Manager<br />

Wolff & Müller Tief- und Strassenbau GmbH & Co. KG<br />

Three VÖGELE machines build a new stretch of the B 10 Federal highway in Germany.<br />

A New SUPER 2100-2<br />

Joins the Strong Paver Team<br />

Achieving very high laydown rates is no problem at all for<br />

the SUPER 2100-2 due to its powerful design. Although the<br />

sub-base near Süssen required extensive stabilization prior to<br />

asphalt paving and the preparatory work was delayed by the<br />

cold winter, the project was nevertheless completed earlier than<br />

scheduled. “VÖGELE’s powerful and highly reliable machines<br />

played a key role in enabling us to meet our deadline,” says<br />

Site Manager Schwarzer.<br />

03 //<br />

A newly built stretch of the B 10 Federal highway in Baden-Württemberg,<br />

Germany, relieves both the parallel A 8 motorway and the town of Süssen.<br />

For contractor Wolff & Müller Tief- und Strassenbau GmbH & Co. KG,<br />

it was the first job for their new VÖGELE paver SUPER 2100-2. The paving<br />

team was thrilled with the machine.<br />

01 // The pave width came to 9.5m. Up to 13m are<br />

possible with the SUPER 2100-2.<br />

02 // The SUPER 2100-2 achieves laydown rates<br />

up to 1,100 tonnes/h.<br />

03 // Once again, the specialists from Wolff & Müller<br />

praised the easy operation of the VÖGELE pavers.<br />

01 //<br />

16<br />

17

Technology<br />

Grade and Slope Control<br />

Multi-Cell Sonic Sensor from VÖGELE now available with extended functionality.<br />

NEW!<br />

Example 1: Big MultiPlex Ski<br />

Grade and Slope Control:<br />

One Sensor for Two Applications<br />

The Big MultiPlex Ski calculates an average from the data<br />

collected by three Multi-Cell Sonic Sensors and uses this<br />

average to create a virtual reference. Minor differences in<br />

grade and large obstacles are filtered out.<br />

The Big MultiPlex Ski levels out long irregularities<br />

in the base.<br />

The well-proven Multi-Cell Sonic<br />

Sensor from VÖGELE is now even<br />

more versatile: redesigned connectors<br />

allow it to be used for grade and<br />

slope control not only on the Big<br />

MultiPlex Ski, but also as a single<br />

sensor combined with VÖGELE<br />

NIVELTRONIC ® , the System for<br />

Automated Grade and Slope Control.<br />

1<br />

2<br />

1 Connector: Big MultiPlex Ski<br />

2 Connector: NIVELTRONIC ®<br />

Almost any base is suited for referencing, e.g.<br />

water-bound base courses, anti-freeze layers or<br />

milled surfaces.<br />

Connector<br />

for Big MultiPlex Ski at the top<br />

Modular beam<br />

up to 13m long<br />

3 Multi-Cell Sonic Sensors<br />

with 5 sensor cells each<br />

With its sophisticated technology, the Multi-Cell Sonic<br />

Sensor has already proved invaluable on many job sites.<br />

For grade control, it emits five sound cones to scan the<br />

reference. The two measured values which diverge most<br />

strongly from the specified value are filtered out and the<br />

other three used to calculate an average. These data are then<br />

transmitted to NIVELTRONIC ® for grade and slope control.<br />

Due to its versatility, the Multi-Cell Sonic Sensor can not<br />

only scan the ground (Ground Mode), but can also use<br />

a tensioned wire as a reference (Stringline Mode). It is<br />

particularly suitable for compensating short irregularities<br />

on the one hand or, in Stringline Mode, for copying<br />

a reference 1:1.<br />

Three sensors on the Big MultiPlex Ski<br />

To compensate long irregularities in the base,<br />

NIVELTRONIC ® is recommended to be used in combination<br />

with a Big MultiPlex Ski. The ski works with three<br />

Multi-Cell Sonic Sensors mounted on a beam up to 13m<br />

long. All three sensors deliver their picked up values<br />

to the Big MultiPlex Ski’s central unit which, in turn,<br />

communicates with NIVELTRONIC ® . This sensor system<br />

is ideal, above all when great evenness is required but an<br />

artificial reference is not available.<br />

Simple solution for two applications<br />

VÖGELE have now extended the Multi-Cell Sonic Sensor’s<br />

functionality and fitted it with two connectors: one<br />

serves to connect the sensor to a Big MultiPlex Ski (CAN),<br />

while the other permits the sensor’s combination with<br />

NIVELTRONIC ® (analogue). This means that, depending<br />

on requirements, one and the same sensor can be used<br />

with either the Big MultiPlex Ski or NIVELTRONIC ® , making<br />

this a worthwhile investment in two respects at once.<br />

The sensor’s integration into NIVELTRONIC ® is very easy.<br />

And just like its predecessor, this Multi-Cell Sonic Sensor,<br />

too, is available with a mounting tube.<br />

Example 2: Use as a Single Sensor<br />

The base is scanned by five sensor cells. The two most<br />

strongly diverging measurements are filtered out to<br />

ensure that unrealistic irregularities in the reference – due<br />

to tools, for example – are not included in the calculation.<br />

Compensates short irregularities in a base.<br />

Can copy a reference 1:1.<br />

The ground or a tensioned wire can be used<br />

as a reference.<br />

Connector<br />

for NIVELTRONIC ® at the side<br />

Reference sensor cell<br />

to determine the value<br />

for temperature compensation<br />

5 sensor cells<br />

for grade control<br />

18<br />

19

Site Report<br />

SUPER 1900-2, SUPER 1800-2 and SUPER 1303-2<br />

Hot<br />

to Hot<br />

Traffic calming made by VÖGELE.<br />

Three Pavers in Action<br />

on a New Bypass Road<br />

Four kilometres of road, three lanes, two passing places and two bridges:<br />

contractor Matthäi relied on machine technology from VÖGELE for<br />

placing the surface course on the new stretch of the B 442 Federal road<br />

near Eimbeckhausen in Lower Saxony, Germany.<br />

20<br />

21

Tips & Tricks from p racT ical a pplicaT ions<br />

18<br />

roadnews 24<br />

points to note<br />

When paving road crowns<br />

Positive and negative crowns from -1% to +3% can be paved as<br />

standard with the VÖGELE AB 500 and AB 600 Extending Screeds,<br />

as well as with the SB 250 and SB 300 Fixed-Width Screeds.<br />

A simple retrofitting is all it takes to increase the range for crowns<br />

from -2.5% to +5%. Despite this, a number of details must be taken<br />

into account in order to obtain perfect results at all times.<br />

andré felchner, Head of applications Technology at VÖGElE, Germany, provides “Tips & Tricks from practical<br />

applications”. He is an expert in both practical applications and paver technology and also conveys his<br />

knowledge to paving teams from all over the world in VÖGElE training courses and workshops.<br />

crowns serve a number of very different purposes. positive crowns are produced in road construction every<br />

day, as they allow rainwater to drain off rapidly. negative crowns, on the other hand, are used to guide the<br />

water, for instance if a gutter or drain is required on large open squares.<br />

positive crown<br />

negative crown

Tips & Tricks from p racT ical a pplicaT ions<br />

Tips & Tricks from p racT ical a pplicaT ions<br />

18<br />

roadnews 24<br />

18<br />

roadnews 24<br />

Tip 1:<br />

look at the Transverse Grade<br />

Tip 2:<br />

save paving material by increasing the amount of crown<br />

it would be really simple if the transverse grade of a road were always horizontal. Unfortunately, that<br />

is very rarely the case (see fig. 1). a road with a cross slope frequently causes irritation among users.<br />

This is because, when the work is complete, different slope angles are measured on each side of the<br />

crown point even when the amount of crown has been set correctly (see fig. 2).<br />

it may sound banal, but knowing that different transverse grades prevail in practice is crucial<br />

to correct paving.<br />

setting a larger crown is particularly advantageous when rehabilitating a worn road pavement.<br />

Example from practice: the authority letting the road rehabilitation contract specifies a layer thickness<br />

of 4cm. The contractor, however, works with a standard crown of 3%. figure 3 shows that under these<br />

conditions much more material than required needs placing. The extra costs have to be borne by the<br />

contractor.<br />

in figure 4 we see that the extra amount of material required is far less when working with a larger<br />

crown of 5%.<br />

figure 1: Transverse grade is horizontal<br />

a horizontal transverse grade is normally encountered when building a new road.<br />

u The required crown is set (in this case 3%).<br />

u Paving is carried out as usual.<br />

result: A slope of 3% is measured on each side of the crown point when the work is complete.<br />

figure 3: conventional crown with a slope of 3%<br />

crown 3%<br />

0%<br />

3%<br />

required layer thickness 4cm<br />

Extra amount of material<br />

3%<br />

crown 3%<br />

0%<br />

3%<br />

3%<br />

figure 4: larger crown with a slope of 5%<br />

figure 2: Transverse grade with a slope<br />

required layer thickness 4cm<br />

Transverse grades with a slope are most commonly found in practice, for instance when rehabilitating<br />

road pavements.<br />

u The required crown is set (in this case 3%).<br />

u Paving is carried out as usual.<br />

0%<br />

5%<br />

crown 5%<br />

Extra amount of material<br />

5%<br />

result: After paving, 4% are measured on the left and 2% on the right.<br />

reason: Due to the sloping transverse grade of the crown, different slope angles result on the left<br />

and right of the crown point.<br />

0%<br />

4%<br />

crown 3%<br />

2%<br />

Tip: make use of the option of a larger crown, for it tangibly improves the efficient use of paving<br />

material and makes the paving process particularly economical!

Tips & Tricks from p racT ical a pplicaT ions<br />

simple retrofitting<br />

a larger crown can be selected as optional equipment when ordering a new paver. But pavers which are<br />

18<br />

roadnews 24<br />

already in use can be easily retrofitted, too. four parts are all that is needed to increase the paver’s range of<br />

possible crowns from -1% to +3% to a range from -2.5% to +5%.<br />

HOT<br />

TO HOT<br />

SUPER 1900-2, SUPER 1800-2 and SUPER 1303-2<br />

“Hot to Hot” for Perfect Joints<br />

Perfect joints and carefully shaped pavement<br />

edges are crucial for a long service life of a road,<br />

as well as for road safety and ride comfort. Joints<br />

with the best interlocking properties and reliable<br />

bonding are achieved when paving “hot to hot”<br />

with two or more pavers working in echelon.<br />

The following must be observed:<br />

When paving multiple strips – be it<br />

“hot to hot” or “hot to cold” – the pavers<br />

should work with an overlap of 2 to 3cm.<br />

And the subsequent compaction by rolling<br />

must be considered.<br />

The pavers should work as close together<br />

as possible (maximum distance = length<br />

of paver).<br />

01<br />

02<br />

Adapter plate for a crown of -2.5% Adapter plate for a crown of -2.5%<br />

01 //<br />

01 // Paving wearing course “hot to hot” guaranteed<br />

perfect longitudinal joints.<br />

02 // The ergonomically designed and clearly arranged<br />

ErgoPlus ® paver operator’s consoles made operation<br />

of the pavers particularly easy.<br />

Short Distance<br />

03<br />

04<br />

Screed arm guide plate for a crown of +5%<br />

Extended scale<br />

Overlap of 2 – 3cm<br />

01<br />

04<br />

For more information about the perfect paving of<br />

longitudinal joints please refer to the “Tips & Tricks”<br />

in RoadNews 18 or to RoadNews Online, the new<br />

digital library for road contractors. You can find this<br />

on our homepage www.voegele.info.<br />

02 //<br />

02 03<br />

23

Site Report<br />

SUPER 1900-2, SUPER 1800-2 and SUPER 1303-2<br />

01 // 02 //<br />

03 //<br />

Extending screeds with bolt-on extensions<br />

Most of the asphalt work was undertaken by a SUPER 1900-2<br />

and a SUPER 1800-2. These two versatile, high-performance<br />

tracked pavers can be used for a large variety of jobs – motorways,<br />

country roads, squares and roundabouts – making them<br />

eminently suitable to meet all the challenges of this particular<br />

job site. In Eimbeckhausen, both machines came with an<br />

AB 500 Extending Screed in TP1 version. Bolt-on extensions<br />

were fitted for a maximum pave width of 6.5m. As a result,<br />

asphalt for the wearing course could be paved on the 11.5m<br />

wide roadway and the 12.5m wide bridge decks without<br />

a need for conversion. On some stretches, a third machine<br />

came into play: a wheeled SUPER 1303-2 combined with an<br />

AB 340 Extending Screed in TV version was used for surfacing<br />

the passing places.<br />

Big MultiPlex Ski for grade and slope control<br />

To ensure precise grade and slope control when paving wearing<br />

course – another crucial requirement for a top-quality road –<br />

the SUPER 1800-2 and SUPER 1900-2 were fitted with a<br />

Big MultiPlex Ski. The ski’s sonic sensors scanned the new<br />

binder course and transmitted their picked-up values to<br />

NIVELTRONIC Plus ® , the System for Automated Grade and<br />

Slope Control. The admitted tolerance for the specified surface<br />

accuracy was 4mm in a longitudinal direction over a length of<br />

4m – a requirement easily met with the sophisticated VÖGELE<br />

technology. Summing up, Site Manager Gattkowski could not<br />

have been more positive: “Layer thickness, compaction and<br />

bond of layers – everything was perfect. We are totally satisfied<br />

with the finished pavement.”<br />

Generously dimensioned workplace<br />

The easy operation of the three machines was pivotal in<br />

ensuring that the entire project went off so smoothly. All<br />

pavers of the “dash 2” generation from VÖGELE come with<br />

the proven, intuitive ErgoPlus ® operating system. This system<br />

not only encompasses the clearly arranged paver operator’s<br />

console and the two screed consoles, but also a perfectly<br />

designed operator platform. “The paver operator’s workplace<br />

is very generously dimensioned,” said Gattkowski. Thanks to<br />

this user-oriented design, full concentration is always assured,<br />

even when working under high pressure.<br />

01 // HAMM tandem rollers were on the scene for final<br />

compaction and contributed substantially to the asphalt<br />

pavement’s high quality.<br />

02 // The binder course was scanned by a Big MultiPlex Ski<br />

for grade and slope control.<br />

03 // Due to the outstanding quality of the asphalt layers,<br />

the new bypass road can handle high traffic loads without<br />

difficulty.<br />

04 // An optimum head of mix in front of the screed at all<br />

times due to large augers installed in the VÖGELE pavers.<br />

“Layer thickness, compaction<br />

and bond of layers – everything<br />

was perfect. We are totally satisfied<br />

with the resultant pavement.”<br />

Jörg Gattkowski, Site Manager<br />

04 //<br />

Contractor Matthäi<br />

24<br />

25

Site Report<br />

Pavement Rehabilitation and New Construction with SUPER 1300-2<br />

Germany<br />

North Sea<br />

Netherlands<br />

Berlin<br />

Poland<br />

Heilbronn<br />

3 rd Job Site<br />

Building Asphalt Tracks<br />

Requirement: Versatility<br />

Belgium<br />

Germany<br />

Czech Republic<br />

France<br />

Stuttgart<br />

Karlsruhe<br />

A 81<br />

Switzerland<br />

Austria<br />

The powerful compact paver from VÖGELE<br />

proves its value on very different job sites in Germany.<br />

SUPER 1300-2:<br />

The Paver<br />

That Does It All<br />

1 st Job Site<br />

Construction of Diversion Lane<br />

A 8<br />

Stuttgart<br />

A 8<br />

The versatile compact paver<br />

SUPER 1300-2 has proven its value<br />

in very different paving situations,<br />

as the following three job sites<br />

illustrate. It owes its success to the<br />

well-thought-out design, combining<br />

slim outer dimensions with a high<br />

performance. The paver can handle<br />

pave widths up to 5m and place up to<br />

350 tonnes of mix per hour. It is also<br />

sufficiently compact to manœuvre<br />

easily on confined sites and is simple<br />

to transport, too.<br />

Requirement: Performance<br />

A 81<br />

2 nd Job Site<br />

Rehabilitation of Access Road<br />

Requirement: Compact Design<br />

Ulm<br />

26<br />

27

Site Report<br />

Pavement Rehabilitation and New Construction with SUPER 1300-2<br />

1 st Job Site<br />

Construction of Diversion Lane<br />

Requirement: Performance<br />

Job Site Details<br />

Construction of new lane diverting traffic<br />

on the A8 motorway, Germany<br />

The A 8 is one of Germany’s very heavily trafficked motorways.<br />

And its enormous traffic load is increasing continuously.<br />

At present, the A8 is being widened to six lanes between the<br />

“Karlsbad” and “Pforzheim-West” junctions. To avoid disruptions<br />

to traffic during the construction work, one lane of westbound<br />

traffic from Stuttgart to Karlsruhe was moved to the other side<br />

of the motorway in a contraflow system. Contractor Martin<br />

Paschmann Asphaltbau GmbH built a new lane for the purpose<br />

on the central reservation using a SUPER 1300-2 from VÖGELE.<br />

The SUPER 1300-2 excels itself on the A8<br />

The 560m stretch was the first motorway job undertaken by<br />

contractor Paschmann. Normally, the company specializes in<br />

smaller jobs, frequently surfacing footpaths or cycle paths.<br />

“The SUPER 1300-2 is highly manœuvrable and can even<br />

enter narrow courtyards,” explains Managing Director and<br />

proprietor Martin Paschmann when asked why he once decided<br />

to purchase this paver. Now he has pulled off the motorway<br />

job with aplomb thanks to the SUPER 1300-2’s excellent<br />

performance. Paschmann was delighted with the additional<br />

areas of application which this powerful machine offered his<br />

company: “Without the paver, we would have had to turn<br />

down the job.”<br />

Driving on a closed lane<br />

The pave width was 3.9m. The AB 340 Extending Screed in<br />

TV version, which can be hydraulically extended to a width<br />

of 3.4m, was fitted with 40cm bolt-on extensions for the<br />

job. An 18cm thick base was first placed in two 9cm layers,<br />

followed by a 9cm binder course of asphaltic concrete.<br />

Finally, stone mastic asphalt was paved for the 4cm<br />

surface course. “As part of the job on the A8 motorway,<br />

we also built five crossovers over the central reservation,” says<br />

Paschmann. “They are required for the redirection of traffic<br />

to carry out paving work on other sections along the A8.<br />

To reach the construction sections, we drove the SUPER 1300-2<br />

down the closed left-hand lane. That would not have been<br />

possible with a wider paver.”<br />

Length of section: 560m<br />

Width of section: 3.9m<br />

Paving Details<br />

Pave width: 3.9m<br />

Layer thickness:<br />

Material<br />

base course 18cm (2 x 9cm)<br />

binder course 9cm<br />

surface course 4cm<br />

Base course: asphaltic concrete (AC 32 T S)<br />

Binder course: asphaltic concrete (AC 16 B S)<br />

Surface course: stone mastic asphalt (SMA 8)<br />

Equipment<br />

SUPER 1300-2 with AB 340 Extending Screed<br />

in TV Version<br />

HAMM HD 75 Tandem Roller<br />

02 //<br />

“Without the powerful<br />

SUPER 1300-2, we would<br />

have had to turn down<br />

the motorway job.”<br />

Martin Paschmann, Proprietor<br />

Martin Paschmann Asphaltbau GmbH<br />

01 // Thanks to its excellent performance,<br />

the SUPER 1300-2 also cut a fine figure on the<br />

motorway job site.<br />

02 // The Paschmann team is proud of their versatile<br />

SUPER 1300-2.<br />

03 // Operating a paver with ErgoPlus ® is always easy,<br />

whatever the job.<br />

01 //<br />

03 //<br />

28<br />

29

Site Report<br />

Pavement Rehabilitation and New Construction with SUPER 1300-2<br />

2 nd Job Site<br />

Rehabilitation of Access Road<br />

Requirement: Compact Design<br />

The Gruibingen motorway service station is located little more<br />

than 100km away on the A8. Its access road was in urgent need<br />

of rehabilitation. Here too, the SUPER 1300-2 from VÖGELE<br />

was the preferred choice of contractor Kurt Gansloser GmbH<br />

Bauunternehmung. “We chose the SUPER 1300-2 for two<br />

reasons,” explains proprietor and Managing Director Kurt<br />

Gansloser. “Firstly because of the required pave width and<br />

secondly because of the excellent transport logistics.”<br />

A single low-bed trailer all that was needed<br />

For rehabilitation of the 8m wide and 100m long access road,<br />

two 80cm bolt-on extensions were added to the AB 340 TV<br />

Extending Screed. This enabled the screed to pave stone mastic<br />

asphalt for the new surfacing in two strips, each of them 4m<br />

wide. “Of course, we could have used a larger paver and placed<br />

the surface course in a single pass,” says Gansloser, “but our<br />

solution was cheaper.” A larger paver would have given rise<br />

to additional transport costs, for “we would have needed<br />

two low-bed trailers for the paver and the roller,” explains<br />

Gansloser. “The compact SUPER 1300-2, on the other hand,<br />

was transported together with the roller on a single low-bed<br />

trailer.”<br />

Below the maximum transport width,<br />

even with bolt-on extensions fitted<br />

This is due to the compact size of the SUPER 1300-2. When<br />

developing the machine, VÖGELE’s engineers took care to<br />

ensure that none of its components or edges protruded beyond<br />

the machine’s outline. In this way, they reduced the transport<br />

width to just 1.85m. Even with two 25cm bolt-on extensions<br />

and side plates fitted, the paver does not exceed the maximum<br />

width of 2.55m for transport. At the same time, the paver<br />

can handle pave widths ranging from 0.75m to 5m, ensuring<br />

maximum variability.<br />

02 //<br />

Job Site Details<br />

Pavement rehabilitation on access road leading<br />

to the Gruibingen motorway service station,<br />

A8, Germany<br />

Length of section: 100m<br />

Width of section: 8m<br />

Paving Details<br />

Pave width: 4m<br />

Layer thickness: 4cm<br />

Material<br />

Surface course: stone mastic asphalt (SMA 11)<br />

01 // The new surface course was exactly 4cm thick.<br />

02 // Everything in view: the paver and screed operators<br />

controlled the paving process from their ErgoPlus ® consoles.<br />

“We chose the SUPER 1300-2<br />

for this job because of its logistic<br />

advantages.”<br />

SUPER 1300-2 at a Glance<br />

Maximum pave width 5m<br />

Laydown rate up to 350 tonnes/h<br />

Transport width only 1.85m<br />

Powerful DEUTZ engine rated at 74.9kW<br />

Combines with AB 340 Extending Screed<br />

in TV version (with tamper and vibrators)<br />

Electric screed heating<br />

Comes with ErgoPlus ® , the concept<br />

for easy paver handling<br />

Hardtop with wide sunshades<br />

01 //<br />

Equipment<br />

SUPER 1300-2 with AB 340 Extending Screed<br />

in TV Version<br />

HAMM HD 13 VT Tandem Roller<br />

Kurt Gansloser, Proprietor<br />

Kurt Gansloser GmbH Bauunternehmung<br />

30<br />

31

Site Report<br />

Pavement Rehabilitation and New Construction with SUPER 1300-2<br />

3 rd Job Site<br />

Building Asphalt Tracks<br />

Requirement: Versatility<br />

Gansloser also profited from that same versatility when<br />

undertaking the job for trout breeder Erwin Steinhart in<br />

Geislingen an der Steige: hitherto unpaved gravel tracks<br />

between the fish ponds had to be surfaced with asphalt so<br />

that they could be cleaned more easily and cleared of snow<br />

in winter. Once again, the SUPER 1300-2 was Gansloser’s<br />

preferred choice for this unusual job.<br />

paver to deliver the required performance.” As a result, placing<br />

of the 30cm crushed-stone base proceeded just as perfectly<br />

as that of the 10cm thick combined base and surface course<br />

with polymer modified binder. The pave width of the AB 340<br />

Extending Screed in TV version came to 3m.<br />

“It is simply indispensable”<br />

The paver’s short overall length makes manœuvring easy<br />

“The job site was relatively confined,” explains Kurt Gansloser.<br />

“The SUPER 1300-2’s short overall length of just 4.95m was<br />

hence a very great boon when manœuvring between the<br />

fish ponds. At the same time, we could always rely on the<br />

Kurt Gansloser’s opinion of VÖGELE's compact paver reflects<br />

the experience of many contractors: “The SUPER 1300-2 fills<br />

the gap between SUPER 800 and SUPER 1800-2. Versatile<br />

and quickly transported, this powerful paver is equally<br />

adept at paving base course, binder course or surface course.<br />

The SUPER 1300-2 is simply indispensable when it comes to<br />

meeting our customers’ requirements.”<br />

Job Site Details<br />

Building asphalt tracks on a fish farm<br />

in Geislingen an der Steige, Germany<br />

Length of section: 300m<br />

Width of section: 3m<br />

Paving Details<br />

Pave width: 3m<br />

Layer thickness: 10cm<br />

Material<br />

Asphaltic mix (AC 16 TD)<br />

for combined base and surface course<br />

02 //<br />

01 // Even on this confined job site, outstanding<br />

performance was assured by the ErgoPlus ® operating<br />

system.<br />

02 // The SUPER 1300-2 paved asphalt on the tracks<br />

between the fish ponds.<br />

“The compact SUPER 1300-2<br />

is simply indispensable<br />

when it comes to meeting<br />

our customers’ requirements.”<br />

Equipment<br />

SUPER 1300-2 with AB 340 Extending Screed<br />

in TV Version<br />

HAMM HD 13 VT Tandem Roller<br />

01 //<br />

Kurt Gansloser, Proprietor<br />

Kurt Gansloser GmbH Bauunternehmung<br />

32<br />

33

Site Report<br />

SUPER 3000-2 Builds Expressway<br />

Enormous performance impresses more and more contractors in the Middle Kingdom.<br />

Gigantic SUPER 3000-2<br />

Captivates China<br />

Since it was premièred at Bauma 2010, the international trade fair for<br />

construction machinery in Munich, VÖGELE’s new heavy-duty SUPER 3000-2<br />

has won many friends in China. Following its arrival in the Middle Kingdom,<br />

the SUPER 3000-2 has been used for various paving jobs in several provinces<br />

in order to draw attention to its outstanding performance. Its first job was<br />

to build the expressway from Datong to Tianzhen in Shanxi province.<br />

34<br />

35

Site Report<br />

SUPER 3000-2 Builds Expressway<br />

China<br />

Mongolia<br />

Beijing<br />

Datong<br />

The large SUPER 3000-2 from VÖGELE is a real workhorse.<br />

With its SB 300 Fixed-Width Screed, it can achieve a laydown<br />

rate of 1,600 tonnes per hour, a pave width of 16m and a layer<br />

thickness of 50cm. A powerful DEUTZ engine, rated at 300kW,<br />

is installed. Thanks to the proven ultramodern technology<br />

of the “dash 2” paver generation and the ErgoPlus ® operating<br />

concept, the SUPER 3000-2 truly reflects the very latest state<br />

of the art.<br />

Hohhot<br />

Inner Mongolia<br />

Ulanqab<br />

Datong<br />

Tianzhen<br />

Zhangjiakou<br />

Beijing<br />

Japan<br />

China<br />

Indian Ocean<br />

Job Site Details<br />

Construction of new expressway from Tianzhen<br />

to Datong in Shanxi province, China<br />

Length of section: 97km<br />

Width of section: 21m<br />

Paving Details<br />

Pave width: 11.5 – 12.5m<br />

Layer thickness: 1 st base course 20cm<br />

2 nd base course 34cm<br />

(2 x 17cm)<br />

Material<br />

1 st base course: cement-treated base<br />

of sand and gravel<br />

2 nd base course: cement-treated<br />

crushed-stone base<br />

New expressway for Shanxi<br />

VÖGELE’s flagship paver was able to demonstrate its<br />

exceptionally high performance in China during the<br />

construction of the expressway from Datong to Tianzhen.<br />

This almost 100km long stretch is a major traffic artery in<br />

China’s Shanxi province, simultaneously providing a fast<br />

link with Beijing and Tianjin. The entire project is scheduled<br />

to take three years and will be completed in two phases.<br />

The first stretch from Datong to the Tianzhen interchange was<br />

opened to traffic in late October 2011, while the stretch from<br />

Tianzhen to the connecting road with the Peking-Xinjiang<br />

expressway in Hebei province is due to be completed by the<br />

end of November 2012.<br />

Paving without joints<br />

The expressway from Datong to Tianzhen is a four-lane road<br />

comprising two lanes with a combined width of 10.5m in each<br />

direction, reports Liu Qingshan, Demo Manager at WIRTGEN<br />

China. The pavement comprised a cement-treated base of sand<br />

and gravel, a cement-treated crushed-stone base and three<br />

asphalt layers. The SUPER 3000-2 was needed to place the<br />

cement-treated crushed-stone base in two 17cm layers, with<br />

pave widths of 12.5m and 11.5m.<br />

Shuozhou<br />

Shanxi Province<br />

01 // The new expressway from Datong to Tianzhen<br />

later links up with Beijing and Tianjin, too.<br />

02 // Paver operator Jianlong Lu (at rear) was thrilled<br />

with the SUPER 3000-2. VÖGELE Product Support Manager<br />

Joseph Chen and the members of the WIRTGEN<br />

demo show, Hongshan Wang, Nut Liu and Hailong Liu<br />

(front, from left to right) confirmed the first-class<br />

pavement result.<br />

Baoding<br />

Hebei Province<br />

Dezhou<br />

Cangzhou<br />

Tianjin<br />

Tangshan<br />

Binzhou<br />

01 //<br />

Equipment<br />

SUPER 3000-2 with SB 300 Fixed-Width Screed<br />

in TP1 Version<br />

02 //<br />

36<br />

37

Site Report<br />

SUPER 3000-2 Builds Expressway<br />

01 // Mechanical segregation is prevented by the<br />

specially designed auger.<br />

02 // The material hopper of the SUPER 3000-2<br />

can accommodate up to 17.5 tonnes.<br />

“We are overjoyed<br />

with the results achieved<br />

by the SUPER 3000-2.”<br />

Jiang Chao, Project Manager,<br />

5th Construction Company Ltd.<br />

01 //<br />

02 //<br />

Maximum performance guaranteed<br />

According to Jiang Chao, Project Manager for the contractor<br />

“5th Construction Company Ltd.” of the “China Railway<br />

Construction 15th Corporation”, the 34cm thick cement-bound<br />

crushed-stone base was even paved in a single layer on some<br />

stretches. The only reason behind the decision to pave in<br />

separate layers on other sections was the wish to assure the<br />

required degree of compaction by the rollers. The paver could<br />

easily pave all 34 centimetres. Indeed, whether it was paving<br />

thicknesses of 17 or 34cm, the SUPER 3000-2 always achieved<br />

impressive results.<br />

Roadbase construction<br />

The SUPER 3000-2’s high traction and laydown rate make it<br />

ideal for roadbase applications. For placing non-bituminous<br />

materials of a particularly abrasive nature, a heavy-duty kit<br />

is available as an option, guaranteeing the long service life<br />

of all wearing parts. And the SB 300 Fixed-width Screed, too,<br />

is perfectly equipped to take on big challenges. On this project,<br />

the screed came in the TP1 version with tamper and one<br />

pressure bar for a high compacting effort. This reduced the<br />

time needed for compaction and resulted in a uniform density.<br />

Perfect evenness, on the other hand, was guaranteed by<br />

NIVELTRONIC Plus ® . The system used data picked up by two<br />

mechanical grade sensors from a tensioned wire for grade<br />

and slope control.<br />

Uninterrupted flow of material<br />

The overall technical concept of the SUPER 3000-2 is designed<br />

to ensure top performance, even under extreme conditions.<br />

The 1.62m wide and 40cm high conveyor tunnel provides for<br />

an uninterrupted flow of material to the paver. Segregation is<br />

prevented effectively by the optimal angle at which material<br />

is dumped from the conveyors onto the auger. In addition,<br />

the large 480mm diameter of the auger blades ensures that<br />

exactly the required amount of material is always available<br />

in front of the screed and the paving process can continue<br />

without interruption.<br />

Conveyors with separate drives<br />

The material hopper holding 17.5 tonnes and featuring<br />

individually operated hopper sides as well as an optional<br />

hydraulic hopper front, is another key factor, preventing<br />

spills of mix when feed vehicles change. For the conveyors,<br />

particularly powerful separate hydraulic drives are provided<br />

which, together with the high-performance auger system,<br />

ensure a continual flow of material, even when operating<br />

at varying speeds.<br />

Promising future for large pavers<br />

“After completing the cement-treated crushed-stone base<br />

with the SUPER 3000-2, we are still thoroughly impressed<br />

with the results. It is simply fantastic and we are certain that<br />

paving the much thinner asphalt layers will yield even more<br />

impressive results. We are also enthusiastic about the ErgoPlus ®<br />

operating concept. It makes the machine as simple and easy to<br />

operate as the smaller pavers from VÖGELE,” says Jiang Chao<br />

admiringly after working with the giant for a few days.<br />

His conclusion: “Expressway construction projects abound in<br />

this country. The Chinese market therefore promises a rosy<br />

future for pavers handling large pave widths.”<br />

38<br />

39

VÖGELE News<br />

Technology Days 2011 of the WIRTGEN Group<br />

You can find a video<br />

on the Technology Days on the Web at:<br />

www.voegele.info<br />

> News & Media > Mediathek<br />

01 //<br />

01 // WIRTGEN, VÖGELE, HAMM and KLEEMANN<br />

presented their latest developments.<br />

02 // Jürgen Wirtgen (left) and Stefan Wirtgen (middle),<br />

the WIRTGEN Group’s managing partners, answered<br />

visitors’ questions.<br />

03 // Visitors flocked to the “WIRTGEN Group Avenue”<br />

for a close-up view of the machines.<br />

Visitors throng to the Technology Days 2011 in the VÖGELE plant in Ludwigshafen.<br />

Innovative Technology<br />

Thrills Thousands<br />

something new here, but the “i” machines clearly drew the<br />

biggest crowds: new developments by the WIRTGEN Group<br />

with particularly eco-friendly engines.<br />

Visitors see quality in the making<br />

The tour of the VÖGELE factory was just as fascinating for<br />

the visitors. At 20 different stations they were able to see how<br />

quality is produced in the world’s most modern factory for<br />

road pavers.<br />

02 //<br />

Around 3,500 visitors from more than 80 countries came<br />

to the VÖGELE plant in Ludwigshafen, Germany, for the<br />

WIRTGEN Group’s Technology Days in September 2011.<br />

They toured the most modern paver factory in the world and<br />

were able to see first-hand just how the ultramodern pavers<br />

and screeds are produced. In spectacular demonstrations, the<br />

four brands WIRTGEN, VÖGELE, HAMM and KLEEMANN<br />

presented their latest innovative high-end products for road<br />

construction, as well as for mining and recycling pavement<br />

materials.<br />

The holding company’s four brands presented their latest<br />

products in the machine exhibition “WIRTGEN Group<br />

Avenue”. VÖGELE, for example, presented the PowerFeeder<br />

MT 3000-2 Offset, while the WIRTGEN exhibits included the<br />

high-tech W 220 cold milling machine and the new autopilot<br />

for slipform pavers. The new H 20i and H 18i compactors from<br />

HAMM attracted great interest, as did the KLEEMANN crushers<br />

with EVO technology. All visitors were able to discover<br />

Numerous papers and three live demonstrations provided<br />

detailed information on machine technology, processes and<br />

prospects for road construction, as well as for mining and<br />

recycling pavement material. Experts from all four brands<br />

worked hand in hand – just as they do in development,<br />

service and applications consulting. Their enthusiasm infected<br />

the crowd.<br />

03 //<br />

40<br />

41

VÖGELE News<br />

RoadNews Online<br />

The entire RoadNews content can now be accessed<br />

in a unique knowledge database.<br />

The Digital Library<br />

for Road Contractors<br />

RoadNews<br />

online<br />

For almost eight years now, the RoadNews magazine has published gripping<br />

job site reports, technical background reports and valuable practical tips on<br />

everything associated with road construction. All this content can now be<br />

accessed on a website with a simple search function: the new online database<br />

of the RoadNews magazine – unique in the construction industry – ensures<br />

that you can instantly find whatever you need to know on a given topic.<br />

01<br />

01<br />

02<br />

03<br />

The entire content from almost eight years<br />

of RoadNews has been classified according<br />

to certain subject headings. Defined search<br />

criteria simplify your research: choose from<br />

46 products, 34 technology topics, 17 issues<br />

of “Tips & Tricks”, 18 job site types, 19 paving<br />

materials and lots more with a single click.<br />

All results are presented in a summary<br />

with brief information on the respective<br />

contents. No other database provides such a<br />

comprehensive range – it already contains<br />

17 articles on the subject of “High Compaction<br />

Technology”, for example.<br />

The full-text search permits unrestricted<br />

research using any search term. One click<br />

is all it takes for the database to access all<br />

articles containing the search term – from<br />

the first to the latest issue of RoadNews.<br />

02<br />

04<br />

Each article is displayed with the full text<br />

and all the photos, job site details and other<br />

information.<br />

03<br />

05<br />

However, RoadNews Online can also offer a<br />

great deal more: videos, animated sequences,<br />

photos, documents, additional articles on the<br />

selected topic and web links can be selected<br />

via the button “Associated Media”.<br />

05<br />

06<br />

And last but not least: with just one click,<br />

you can “share” the article on Facebook or<br />

Twitter, send it to someone by e-mail or set<br />

a bookmark in order to find it quickly when<br />

needed later on.<br />

04<br />

We hope you enjoy using the new<br />

RoadNews Online!<br />

Scan this QR code with your smartphone to go straight<br />

to our homepage www.voegele.info.<br />

There you will find a direct link to RoadNews Online.<br />

06<br />

42<br />

43

Dawn breaking on a road<br />

near Fort Davis in Texas, USA.<br />

Scan this QR code with your smartphone to go straight<br />

to our homepage www.voegele.info.<br />

There you will find a direct link to RoadNews Online.<br />

RoadNews<br />

online<br />

Your feedback on RoadNews would be much appreciated. Suggestions are welcome. Please write to us at roadnews@voegele.info<br />

EN 2257972