SECTION 1028 -- SUPERPAVE ASPHALTIC CONCRETE

SECTION 1028 -- SUPERPAVE ASPHALTIC CONCRETE

SECTION 1028 -- SUPERPAVE ASPHALTIC CONCRETE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

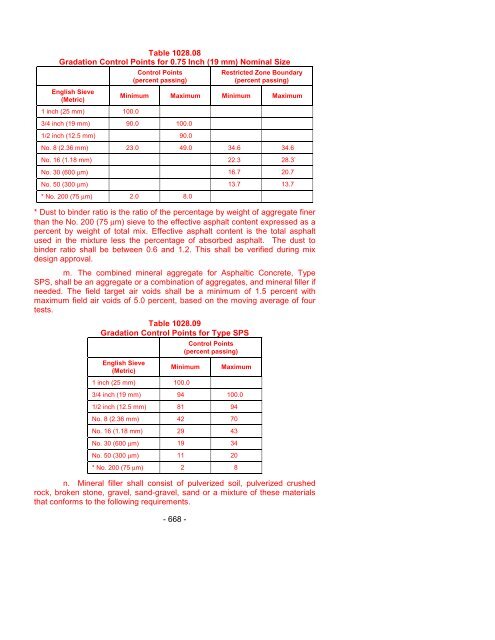

Table <strong>1028</strong>.08<br />

Gradation Control Points for 0.75 Inch (19 mm) Nominal Size<br />

English Sieve<br />

(Metric)<br />

1 inch (25 mm) 100.0<br />

Control Points<br />

(percent passing)<br />

3/4 inch (19 mm) 90.0 100.0<br />

1/2 inch (12.5 mm) 90.0<br />

- 668 -<br />

Restricted Zone Boundary<br />

(percent passing)<br />

Minimum Maximum Minimum Maximum<br />

No. 8 (2.36 mm) 23.0 49.0 34.6 34.6<br />

No. 16 (1.18 mm) 22.3 28.3`<br />

No. 30 (600 µm) 16.7 20.7<br />

No. 50 (300 µm) 13.7 13.7<br />

* No. 200 (75 µm) 2.0 8.0<br />

* Dust to binder ratio is the ratio of the percentage by weight of aggregate finer<br />

than the No. 200 (75 µm) sieve to the effective asphalt content expressed as a<br />

percent by weight of total mix. Effective asphalt content is the total asphalt<br />

used in the mixture less the percentage of absorbed asphalt. The dust to<br />

binder ratio shall be between 0.6 and 1.2. This shall be verified during mix<br />

design approval.<br />

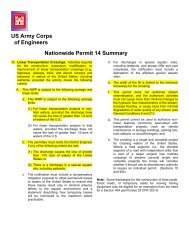

m. The combined mineral aggregate for Asphaltic Concrete, Type<br />

SPS, shall be an aggregate or a combination of aggregates, and mineral filler if<br />

needed. The field target air voids shall be a minimum of 1.5 percent with<br />

maximum field air voids of 5.0 percent, based on the moving average of four<br />

tests.<br />

Table <strong>1028</strong>.09<br />

Gradation Control Points for Type SPS<br />

English Sieve<br />

(Metric)<br />

Control Points<br />

(percent passing)<br />

Minimum<br />

1 inch (25 mm) 100.0<br />

Maximum<br />

3/4 inch (19 mm) 94 100.0<br />

1/2 inch (12.5 mm) 81 94<br />

No. 8 (2.36 mm) 42 70<br />

No. 16 (1.18 mm) 29 43<br />

No. 30 (600 µm) 19 34<br />

No. 50 (300 µm) 11 20<br />

* No. 200 (75 µm) 2 8<br />

n. Mineral filler shall consist of pulverized soil, pulverized crushed<br />

rock, broken stone, gravel, sand-gravel, sand or a mixture of these materials<br />

that conforms to the following requirements.