SET-XP - Simpson Strong-Tie

SET-XP - Simpson Strong-Tie

SET-XP - Simpson Strong-Tie

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>SET</strong>-<strong>XP</strong><br />

PURE EPOXY<br />

Seismically approved, pure epoxy adhesive.<br />

Set-<strong>XP</strong> is a high<br />

strength epoxy<br />

injection adhesive<br />

for fastening heavy<br />

structural fixings in<br />

cracked and noncracked<br />

concrete.<br />

It's high bond<br />

strength and nonshrinking<br />

formula<br />

are suitable for use<br />

in oversized or wet<br />

holes.<br />

ICC-ES approved<br />

for cracked<br />

concrete.<br />

ETA option 1<br />

approved.<br />

Extended<br />

working time.<br />

High bond<br />

strength.<br />

non-shrinking<br />

formula.<br />

Seismically<br />

approved.<br />

23

Adhesive Systems<br />

<strong>SET</strong>-<strong>XP</strong> TECHNICAL DATA<br />

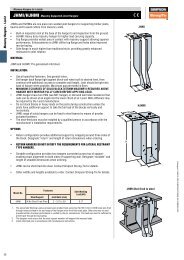

<strong>SET</strong>-<strong>XP</strong> is a pure epoxy resin suitable for heavy threaded rod fixing applications in both cracked and noncracked<br />

concrete (ETA Option 1). It's specially designed for highly technical and structural fixings. This<br />

solution is perfect for large diameters and applications in hot weather countries. <strong>SET</strong>-<strong>XP</strong> is tested in seismic<br />

conditions.<br />

Cartridges available (650 ml) perfectly adapted for big job sides.<br />

Reference Contents Weight Qty. Box Qty. Outer-box Unit Bar Code<br />

<strong>SET</strong>-<strong>XP</strong> 650 650 ml 1,1 kg 10 10 3523140538402<br />

Two mixers are supplied with each cartridge.<br />

BENEFITS:<br />

ICC-ES for cracked concrete<br />

Extended working time<br />

High-bond strength<br />

Non-shrinking<br />

Suitable for wet holes<br />

Easy storage in hot weather countries<br />

MATERIAL:<br />

Cracked or non-cracked concrete<br />

APPLICATIONS:<br />

Heavy structural fixings into cracked or non-cracked<br />

concrete<br />

Oversized holes<br />

CERTIFICATION:<br />

ICC-ES for cracked concrete<br />

ETA (Option 1)<br />

<strong>SET</strong>-<strong>XP</strong><br />

650 ml<br />

Teal<br />

colour<br />

ETAG 001-5 Option 1<br />

M12-M27<br />

Tested according to<br />

ACI 355.2.<br />

ICC-ES ESR-2508<br />

NSF/ANSI Std. 61<br />

LMAS<br />

Zinc-plated steel<br />

See page 24.<br />

CURING SCHEDULE:<br />

Let anchor fully cure without disturbing<br />

T °C Working time Curing time 6)<br />

10 60 min 72 h<br />

21 45 min 24 h<br />

32 25 min 24 h<br />

43 12 min 24 h<br />

METHOD OF CLEANING HOLES:<br />

Normal diameter<br />

Method of cleaning hole<br />

All diameter<br />

Clean hole by brushing and<br />

blowing alternately with<br />

oil-free compressed air at<br />

minimum 5.5 bar: 2x blow,<br />

4x brush, 2x blow.<br />

Mixer MN2<br />

Safety and environement<br />

We care about developing products that are user-safe and environmentally<br />

respectful when properly handled and disposed of. Once empty, dispose of this<br />

cartridge in a hazardous waste disposal skip.<br />

Xn Harmful Dangerous C Corrosive<br />

for the<br />

environment<br />

Observe these safety precautions:<br />

R51/53 Toxic to aquatic organisms, may cause long-term adverse effects in the aquatic environment (A).<br />

R43 May cause sensitisation by skin contact (A, B). R36/37/38 Irritating to eyes, respiratory system and<br />

skin (A). R34 Causes burns (B). R40 Limited evidence of a carcinogenic effect (A). R68 Possible risk of<br />

irreversible effects (A, B). S36/37/39 Wear suitable protective clothing, gloves and eye/face protection (A,<br />

B). S61 Avoid release to the environment. Refer to special instructions/safety data sheets (A). S26 In case of<br />

contact with eyes, rinse immediately with plenty of water and seek medical advice (A, B). S39 Wear eye/face<br />

protection (A). S45 In case of accident or if you feel unwell, seek medical advice immediately (show the label<br />

where possible) (B). S60 This material and its container must be disposed of as hazardous waste (A, B).<br />

S57 Use appropriate container to avoid environmental contamination (A).<br />

24

Adhesive Systems<br />

<strong>SET</strong>-<strong>XP</strong> TECHNICAL DATA<br />

Material: Carbon steel, Grade 5.8, zinc plated and blue passivated; A4-70 (≤M24) and A4-50 (>M24) stainless steel / <strong>SET</strong>-<strong>XP</strong> TM<br />

Installation parameters<br />

M12 M16 M20 M24 M27<br />

Drill hole diameter, d 0<br />

mm 14 18 24 28 30<br />

Drill hole depth, h 0<br />

mm 70 240 80 320 90 400 100 480 110 540<br />

Clearance hole in the fixture, d f<br />

mm 14 18 22 26 30<br />

Width across flats, sw mm 19 24 30 36 41<br />

Installation torque, T inst<br />

Nm 40 60 80 100 120<br />

Spacings, edge distances and member thicknesses<br />

M12 M16 M20 M24 M27<br />

Effective embedment depth, h ef<br />

mm 70 240 80 320 90 400 100 480 110 540<br />

Characteristic spacing 4) , s cr,N<br />

mm 210 720 240 960 270 1200 300 1440 330 1620<br />

Minimum spacing, s min<br />

mm 45 60 70 80 90<br />

Characteristic edge distance 4) , c cr,N<br />

mm 105 360 120 480 135 600 150 720 165 810<br />

Minimum edge distance, c min<br />

mm 80 100 115 135 155<br />

Minimum member thickness, h min<br />

mm 100 270 116 356 138 448 156 536 170 600<br />

Recommended values for resistance to tension and shear loads<br />

M12 M16 M20 M24 M27<br />

h ef 70 240 80 320 90 400 100 480 110 540<br />

Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4 Steel A4<br />

Permissible tension loads 1) , for Temperature range: I 5) in Cracked concrete 3) ≥ C20/25, N perm<br />

kN 5.4 5.4 18.4 18.4 6.1 6.1 24.6 24.6 5.7 5.7 25.6 25.6 7.6 7.6 36.9 36.9 9.5 9.5 46.7 46.7<br />

Permissible tension loads 1) , for Temperature range: I 5) in Non-cracked concrete 3) ≥ C20/25, N perm<br />

kN 10.0 10.0 20.0 22.5 12.3 12.3 37.6 42.0 14.6 14.6 58.5 65.6 17.1 17.1 84.2 94.3 19.8 19.8 109.0 57.4<br />

Permissible shear loads 1)2) for Temperature range: I 5) in Cracked concrete 3) ≥ C20/25, V perm<br />

kN 12.0 13.7 12.0 13.7 17.2 17.2 22.2 25.1 16.1 16.1 34.8 39.3 21.6 21.6 50.2 56.7 26.6 26.6 65.7 34.5<br />

Permissible shear loads 1)2) for Temperature range: I 5) in Non-cracked concrete 3) ≥ C20/25, V perm<br />

kN 12.0 13.7 12.0 13.7 22.2 25.1 22.2 25.1 34.8 39.3 34.8 39.3 48.0 48.0 50.2 56.7 55.4 34.5 65.7 34.5<br />

NOTES :<br />

1)<br />

The permissible loads have been calculated<br />

using the partial safety factors for<br />

resistances stated in the ETA-approvals<br />

and a partial safety factor for actions of<br />

F = 1.4. The permissible loads are valid<br />

for unreinforced concrete and reinforced<br />

concrete with a rebar spacing s ≥ 15<br />

cm and reinforced concrete with a rebar<br />

spacing s ≥ 10 cm if the rebar is 10 mm<br />

or smaller.<br />

2)<br />

The permissible shear loads are based<br />

on a single anchor without influencing<br />

concrete edges. For shear loads applied<br />

close to an edge (c ≤ 10 h ef<br />

and 60d)<br />

concrete edge failure must be checked<br />

per ETAG 001, Annex C, design method<br />

A.<br />

3)<br />

Concrete is considered non-cracked<br />

when the tensile stress within the<br />

concrete is L + R ≤ 0. In the absence<br />

of detailed verification R = 3 N/mm² can<br />

be assumed (L equals the tensile stress<br />

within the concrete as a result of external<br />

loads, forces on anchors included).<br />

4)<br />

If spacings or edge distances become<br />

smaller than the characteristic values<br />

(i.e. s ≤ s cr,N<br />

and/or c ≤ c cr,N<br />

) a calculation<br />

per TR 029, design method A must be<br />

performed. For details, see approval<br />

ETA-11/xxxx.<br />

5)<br />

Temperature range I: -40°C to +43°C<br />

(max long term temperature: +24°C; max<br />

short term temperature: 43°C).<br />

6)<br />

For installation in wet concrete the<br />

curing times shall be doubled (installation<br />

in water-filled drill holes is not<br />

allowed).<br />

Permissible bending moments 1) , M perm<br />

Nm 37.7 42.1 37.7 42.1 94.8 106.6 94.8 106.6 185.7 207.9 185.7 207.9 320.5 359.9 320.5 359.9 475.4 249.7 475.4 249.7<br />

C-ANCHORS-2013 © SIMPSON STRONG-TIE ®<br />

25