Download Press Release - TDK Electronics Europe GmbH

Download Press Release - TDK Electronics Europe GmbH

Download Press Release - TDK Electronics Europe GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Press</strong> release<br />

For Immediate <strong>Release</strong><br />

16 October 2006<br />

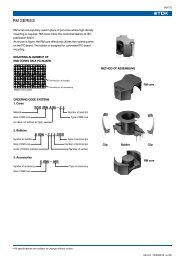

<strong>TDK</strong> launches Noise Reduction Coil for Power Supplies with<br />

improved inductance<br />

-New Noise Reduction Coil is 38% smaller than existing coils with the same<br />

characteristics and shows a 60% improvement in characteristics compared to<br />

coils of the same size-<br />

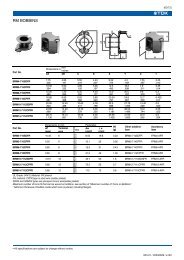

<strong>TDK</strong> Corporation has developed and launched a high-performance commonmode<br />

choke coil for use in power supply noise reduction. <strong>TDK</strong> has achieved this<br />

by developing a new ferrite material with high magnetic permeability 1 and<br />

improved high-frequency characteristics. The high-frequency characteristics<br />

provide improved noise reduction, while the high magnetic permeability has<br />

allowed <strong>TDK</strong> to reduce the component’s size by 38%. <strong>TDK</strong> has also optimised<br />

the shape of the choke coil, as well as significantly improving the inductance<br />

characteristics. In addition, the rated current is approximately 26% higher. The<br />

new coils of the HF and TF Series are ideal for devices that require high rated<br />

current such as air conditioners, lighting devices, PC, and liquid crystal<br />

televisions as well as information industry equipment<br />

Common mode choke coils are key components in power supply noise reduction<br />

and therefore a major factor in determining the size of power supplies. As<br />

electronic devices become smaller and incorporate advanced functions there is<br />

increased demand for power supplies to shrink and exhibit higher performance.<br />

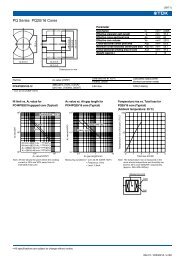

Coils can be miniaturized by using materials of high magnetic permeability.<br />

However, miniaturization while maintaining enhanced performance has been<br />

difficult in the past due to the fact that permeability of materials drop off at<br />

1<br />

Magnetic permeability: An indication of the ability of magnetic flux to pas through a material. The higher the permeability<br />

(i.e., the easier it is for magnetic flux to pass through) of ferrite materials used in choke coils and other components, the<br />

higher the inductance wand the greater the noise reduction effects.

frequencies below 100kHz and the high-permeability characteristics cannot be<br />

maintained at frequencies higher than 150kHz where noise control starts.<br />

<strong>TDK</strong>s new ferrite material with high magnetic permeability and improved highfrequency<br />

characteristics significantly solves these problems. Combined with the<br />

reduction in volume and weight, substantially improved inductance characteristics<br />

and rated current <strong>TDK</strong>’s new common-mode choke coil provides the benefits of<br />

better noise reduction within a smaller design.<br />

The new coils are RoHS compliant and comply with domestic overseas safety<br />

standards for electronic products 2 .<br />

Ends/<br />

About <strong>TDK</strong> <strong>Electronics</strong> <strong>Europe</strong> <strong>GmbH</strong><br />

<strong>TDK</strong> is a recognised world leader in the design and manufacture of electronic<br />

components. This position has been achieved through dedication to the development of<br />

new materials, new products, advanced manufacturing processes, improvements in<br />

product quality and exceptional customer service. Founded in Japan in 1935, <strong>TDK</strong> was<br />

created with the aim of becoming the world’s first manufacturer of the magnetic material<br />

ferrite. <strong>TDK</strong>’s <strong>Europe</strong>an operations, head quartered in Duesseldorf, Germany, includes 7<br />

regional sales offices, 2 R&D laboratories and 2 manufacturing centres. From these<br />

bases and with the support of a wide distribution network, <strong>TDK</strong> provides more than just<br />

access to components and technology.<br />

For further information please contact<br />

Frank Trampenau<br />

<strong>TDK</strong> <strong>Electronics</strong> <strong>Europe</strong> <strong>GmbH</strong><br />

Corporate Planning/Marketing<br />

Wanheimer Strasse 57<br />

D-40472 Duesseldorf<br />

Tel: +49 (0) 211 9077 127<br />

Fax: +49 (0) 211 9077 298<br />

Email: trampnau@tdk.de<br />

Internet: www.tdk-components.de<br />

Sarah Sambles<br />

TKO Marketing Consultants Ltd<br />

4 Lucastes Mews, Paddockhall Road<br />

Haywards Heath<br />

West Sussex<br />

RH16 1HE<br />

Tel: +44 (0) 1444 473 555<br />

Fax:+44 (0) 1444 473 666<br />

Email: sarah@tko.co.uk<br />

2<br />

Compliance with safety standards does not mean that the products have been approved or certified.