VSL Technical Report.. - Free

VSL Technical Report.. - Free

VSL Technical Report.. - Free

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3. Tanks for the storage of solids (silos)<br />

3.1. Cement and clinker silos<br />

3.1.1. Introduction<br />

Silos for the storage of cement and clinker as a<br />

rule are of cylindrical form, since this is the most<br />

suitable for the frequently changing loads.<br />

Beneath the actual storage space, the silos<br />

normally have a trough for discharging the<br />

contents and an access for loading transporting<br />

equipment, as the silos are filled from the top but<br />

emptied from the bottom.<br />

Silos are usually comparatively large structures,<br />

particularly in the vertical direction. Their walls are<br />

therefore normally constructed with slipforming<br />

and post-tensioned.<br />

3.1.2. Clinker silos, Pedro Leopoldo, Brazil<br />

Owner CIMINAS (Cimento Nacional de Minas<br />

S.A.),<br />

Sao Paulo<br />

Engineer H. Trachsel & H. J. Schibli<br />

AG, Olten, Switzerland<br />

Contractor Joint venture M. Roscoe/<br />

Moura, Schwark Ltda., Belo<br />

Horizonte<br />

Post-tensioning<br />

Sistemas <strong>VSL</strong> Engenharia<br />

S.A., Rio de Janeiro<br />

Years of construction<br />

1973-1974<br />

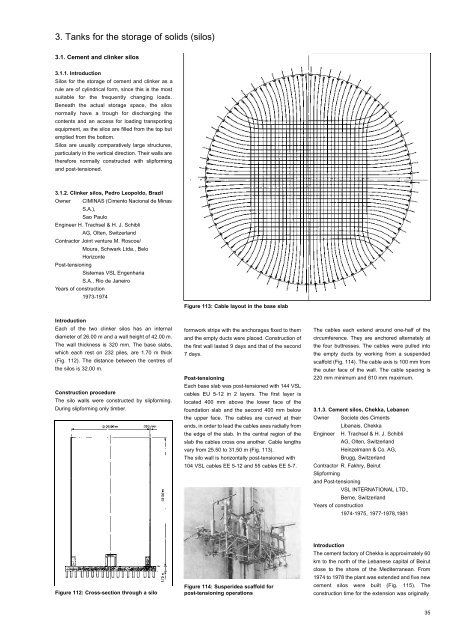

Figure 113: Cable layout in the base slab<br />

Introduction<br />

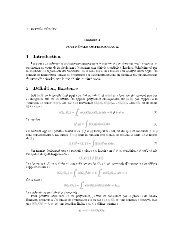

Each of the two clinker silos has an internal<br />

diameter of 26.00 m and a wall height of 42.00 m.<br />

The wall thickness is 320 mm. The base slabs,<br />

which each rest on 232 piles, are 1.70 m thick<br />

(Fig. 112). The distance between the centres of<br />

the silos is 32.00 m.<br />

Construction procedure<br />

The silo walls were constructed by slipforming.<br />

During slipforming only timber.<br />

formwork strips with the anchorages fixed to them<br />

and the empty ducts were placed. Construction of<br />

the first wall lasted 9 days and that of the second<br />

7 days.<br />

Post-tensioning<br />

Each base slab was post-tensioned with 144 <strong>VSL</strong><br />

cables EU 5-12 in 2 layers. The first layer is<br />

located 400 mm above the lower face of the<br />

foundation slab and the second 400 mm below<br />

the upper face. The cables are curved at their<br />

ends, in order to lead the cables axes radially from<br />

the edge of the slab. In the central region of the<br />

slab the cables cross one another. Cable lengths<br />

vary from 25.50 to 31.50 m (Fig. 113).<br />

The silo wall is horizontally post-tensioned with<br />

104 <strong>VSL</strong> cables EE 5-12 and 55 cables EE 5-7.<br />

The cables each extend around one-half of the<br />

circumference. They are anchored alternately at<br />

the four buttresses. The cables were pulled into<br />

the empty ducts by working from a suspended<br />

scaffold (Fig. 114). The cable axis is 100 mm from<br />

the outer face of the wall. The cable spacing is<br />

220 mm minimum and 810 mm maximum.<br />

3.1.3. Cement silos, Chekka, Lebanon<br />

Owner Societe des Ciments<br />

Libanais, Chekka<br />

Engineer H. Trachsel & H. J. Schibli<br />

AG, Olten, Switzerland<br />

Heinzelmann & Co. AG,<br />

Brugg, Switzerland<br />

Contractor R. Fakhry, Beirut<br />

Slipforming<br />

and Post-tensioning<br />

<strong>VSL</strong> INTERNATIONAL LTD.,<br />

Berne, Switzerland<br />

Years of construction<br />

1974-1975, 1977-1978,1981<br />

Figure 112: Cross-section through a silo<br />

Figure 114: Susperidea scaffold for<br />

post-tensioning operations<br />

Introduction<br />

The cement factory of Chekka is approximately 60<br />

km to the north of the Lebanese capital of Beirut<br />

close to the shore of the Mediterranean. From<br />

1974 to 1978 the plant was extended and five new<br />

cement silos were built (Fig. 115). The<br />

construction time for the extension was originally<br />

35