- Page 1 and 2:

2013 WÄRTSILÄ SOLUTIONS FOR MARIN

- Page 3 and 4: Oil Separation 114 Power Electric S

- Page 5 and 6: Fuel flexibility Natural gas is the

- Page 7 and 8: YOUR SHORTER ROUTE TO BIGGER PROFIT

- Page 9 and 10: SHIP DESIGN Wärtsilä is passionat

- Page 11 and 12: SHIP DESIGN Offshore Vessels VS 485

- Page 13 and 14: SHIP DESIGN Special Vessels VS 6208

- Page 15 and 16: The multifunction displays (widescr

- Page 17 and 18: Wärtsilä Power Management System

- Page 19 and 20: Wärtsilä Propulsion Control Syste

- Page 21 and 22: The Wärtsilä AQUARIUS ® BWMS ran

- Page 23 and 24: Wärtsilä AQUARIUS ® UV system Ca

- Page 25 and 26: Wärtsilä AQUARIUS ® EC system Ca

- Page 27 and 28: Wärtsilä Hamworthy CNG Compressor

- Page 29 and 30: Wärtsilä Hamworthy Seismic Compre

- Page 31 and 32: LOW-SPEED ENGINES • z Operate on

- Page 33 and 34: Wärtsilä RT-flex50DF LOW-SPEED EN

- Page 35 and 36: Wärtsilä X40 LOW-SPEED ENGINES IM

- Page 37 and 38: Wärtsilä X72 LOW-SPEED ENGINES IM

- Page 39 and 40: Wärtsilä X92 LOW-SPEED ENGINES IM

- Page 41 and 42: Wärtsilä RT-flex50, version D LOW

- Page 43 and 44: Wärtsilä RT-flex58T, version D, E

- Page 45 and 46: LOW-SPEED ENGINES Wärtsilä RT-fle

- Page 47 and 48: Wärtsilä RT-flex68 / RTA68, versi

- Page 49 and 50: Wärtsilä RT-flex82C / RTA82C LOW-

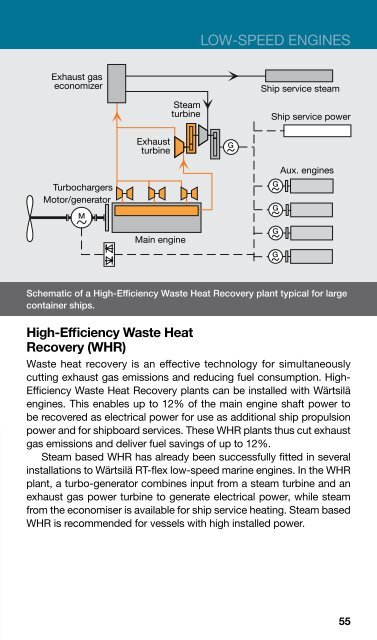

- Page 51 and 52: LOW-SPEED ENGINES Wärtsilä RT-fle

- Page 53: R1, or R1+ instead if applicable, i

- Page 57 and 58: MEDIUM-SPEED ENGINES Dual-Fuel Engi

- Page 59 and 60: Wärtsilä 26 MEDIUM-SPEED ENGINES

- Page 61 and 62: Wärtsilä 38 IMO Tier II Cylinder

- Page 63 and 64: Wärtsilä 20DF IMO Tier II Cylinde

- Page 65 and 66: Wärtsilä 50DF IMO Tier II Cylinde

- Page 67 and 68: MEDIUM-SPEED ENGINES Dimensions and

- Page 69 and 70: GENERATING SETS Pre-Engineered Medi

- Page 71 and 72: Wärtsilä Genset 20 IMO Tier II Cy

- Page 73 and 74: Wärtsilä Genset 32 IMO Tier II Cy

- Page 75 and 76: Wärtsilä Genset 20DF Cylinder bor

- Page 77 and 78: GENERATING SETS Definitions and Not

- Page 79 and 80: ENGINE AUXILIARY SYSTEMS Customised

- Page 81 and 82: Wärtsilä Open Loop Scrubber Syste

- Page 83 and 84: Wärtsilä closed loop scrubber sys

- Page 85 and 86: Wärtsilä NO X Reducer (NOR) Engin

- Page 87 and 88: Wärtsilä Hamworthy Flare Gas Igni

- Page 89 and 90: GAS RECOVERY The first VOC condensa

- Page 91 and 92: GAS RECOVERY Environmental excellen

- Page 93 and 94: LNG HANDLING Customised solution Th

- Page 95 and 96: LNG HANDLING We have delivered and

- Page 97 and 98: LNG HANDLING Propulsion LNG fuel sy

- Page 99 and 100: LPG SYSTEMS Wärtsilä Hamworthy LP

- Page 101 and 102: Land gauging DCS operator workstati

- Page 103 and 104: Wärtsilä gear type SCV128. Power

- Page 105 and 106:

Wärtsilä horizontal offset gears

- Page 107 and 108:

Wärtsilä TCH range gears - dimens

- Page 109 and 110:

customers in their efforts to optim

- Page 111 and 112:

Wärtsilä Moss Mult-Inert System T

- Page 113 and 114:

Wärtsilä Moss Nitrogen Generators

- Page 115 and 116:

115

- Page 117 and 118:

Wärtsilä Direct Electric Heating

- Page 119 and 120:

Wärtsilä Low Voltage Power Drive

- Page 121 and 122:

Wärtsilä MSS36 Switchboard - LV T

- Page 123 and 124:

CP PROPELLERS Wärtsilä CP propell

- Page 125 and 126:

CP PROPELLERS Dimensions of Wärtsi

- Page 127 and 128:

CP PROPELLERS Dimensions of Wärtsi

- Page 129 and 130:

FP PROPELLERS good repairability. W

- Page 131 and 132:

FP PROPELLERS For fixed pitch propu

- Page 133 and 134:

STEERABLE THRUSTERS Wärtsilä retr

- Page 135 and 136:

Wärtsilä compact thruster dimensi

- Page 137 and 138:

Wärtsilä modular thrusters for ov

- Page 139 and 140:

STEERABLE THRUSTERS CT FT 139

- Page 141 and 142:

WATERJETS Waterjet Types Wärtsilä

- Page 143 and 144:

WATERJETS Waterjet size selection T

- Page 145 and 146:

Wärtsilä Axial Jet Series, 6-Blad

- Page 147 and 148:

studies show that for the same cour

- Page 149 and 150:

In addition to deepwell cargo pumps

- Page 151 and 152:

The actual Booster Pumps are in-lin

- Page 153 and 154:

Wärtsilä Svanehøj deepwell balla

- Page 155 and 156:

The Wärtsilä Hamworthy range of d

- Page 157 and 158:

GENERAL SERVICE CENTRIFUGAL PUMPS W

- Page 159 and 160:

JOHN MILLS VALVES Established in 18

- Page 161 and 162:

Wärtsilä Sealing Solutions Wärts

- Page 163 and 164:

ABRASION RESISTANT & ANTI-POLLUTION

- Page 165 and 166:

Wärtsilä Bearing Solutions Wärts

- Page 167 and 168:

Wärtsilä Stern Tube Solutions Our

- Page 169 and 170:

All of our products can be describe

- Page 171 and 172:

Wärtsilä Serck Como Fresh Water G

- Page 173 and 174:

Wärtsilä Bilge Water Guard The W

- Page 175 and 176:

ADVANCED WASTE WATER PROCESSING Wä

- Page 177 and 178:

VACUUM SYSTEM TECHNOLOGY Wärtsilä

- Page 179 and 180:

LIFECYCLE SOLUTIONS 179

- Page 181 and 182:

LIFECYCLE SOLUTIONS SYSTEM INTEGRAT

- Page 183 and 184:

LIFECYCLE SOLUTIONS teams work clos

- Page 185 and 186:

LIFECYCLE SOLUTIONS Wärtsilä Serv

- Page 187 and 188:

Shanghai, Ship Power Satellite Offi

- Page 189 and 190:

Iceland Vélar og Skip ehf. Ship Po

- Page 191 and 192:

Wärtsilä Ship Design Poland Sp.z

- Page 193 and 194:

North America Headquarters 16330 Ai

- Page 195 and 196:

NOTES . . . . . . . . . . . . . . .

- Page 197 and 198:

Photo: Harald Valderhaug Viking Pri

- Page 199 and 200:

Bit Viking In 2011, the first ever

- Page 201 and 202:

MV Twister The Wärtsilä AQUARIUS

- Page 203 and 204:

SuperSpeed 2 Wärtsilä will supply

- Page 205 and 206:

MV Shansi Wärtsilä will supply pr

- Page 207 and 208:

P-63 FPSO Wärtsilä’s P-63 FPSO

- Page 209 and 210:

Heidrun FSU Wärtsilä will supply

- Page 211 and 212:

Dragon 27 500 Wärtsilä will suppl