Wärtsilä Solutions for Marine and Oil&Gas; Markets 2013

Wärtsilä Solutions for Marine and Oil&Gas; Markets 2013

Wärtsilä Solutions for Marine and Oil&Gas; Markets 2013

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GAS RECOVERY<br />

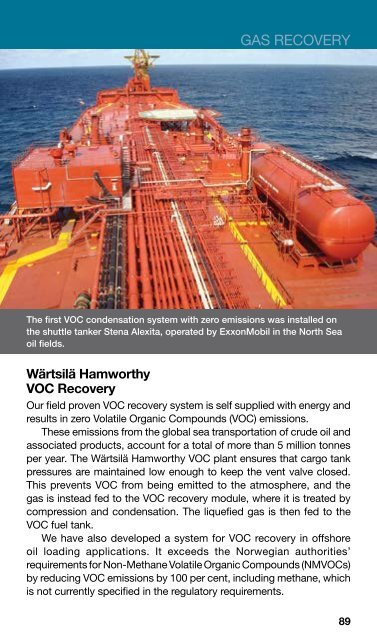

The first VOC condensation system with zero emissions was installed on<br />

the shuttle tanker Stena Alexita, operated by ExxonMobil in the North Sea<br />

oil fields.<br />

Wärtsilä Hamworthy<br />

VOC Recovery<br />

Our field proven VOC recovery system is self supplied with energy <strong>and</strong><br />

results in zero Volatile Organic Compounds (VOC) emissions.<br />

These emissions from the global sea transportation of crude oil <strong>and</strong><br />

associated products, account <strong>for</strong> a total of more than 5 million tonnes<br />

per year. The Wärtsilä Hamworthy VOC plant ensures that cargo tank<br />

pressures are maintained low enough to keep the vent valve closed.<br />

This prevents VOC from being emitted to the atmosphere, <strong>and</strong> the<br />

gas is instead fed to the VOC recovery module, where it is treated by<br />

compression <strong>and</strong> condensation. The liquefied gas is then fed to the<br />

VOC fuel tank.<br />

We have also developed a system <strong>for</strong> VOC recovery in offshore<br />

oil loading applications. It exceeds the Norwegian authorities’<br />

requirements <strong>for</strong> Non-Methane Volatile Organic Compounds (NMVOCs)<br />

by reducing VOC emissions by 100 per cent, including methane, which<br />

is not currently specified in the regulatory requirements.<br />

89