NITRIFICATION AND ACTIVATED SLUDGE FOAMING ...

NITRIFICATION AND ACTIVATED SLUDGE FOAMING ...

NITRIFICATION AND ACTIVATED SLUDGE FOAMING ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

unique and must develop its own set of conditions and control measures for addressing relative process<br />

issues. The work effort described and the resulting information presented in this paper is part of a<br />

program to promote continuous improvement at the WRF - a key initiative throughout CMU.<br />

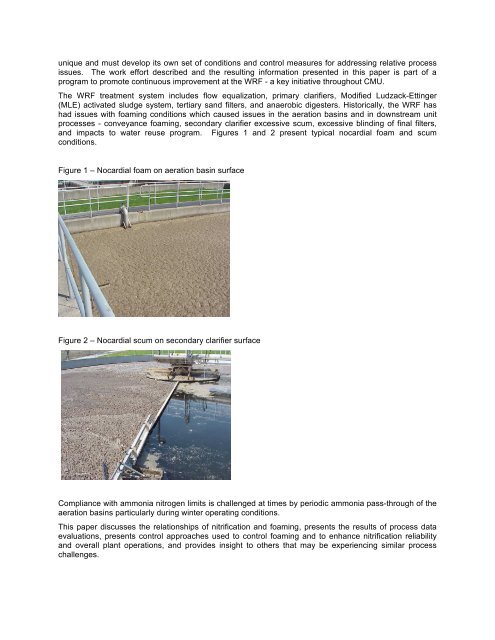

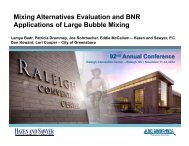

The WRF treatment system includes flow equalization, primary clarifiers, Modified Ludzack-Ettinger<br />

(MLE) activated sludge system, tertiary sand filters, and anaerobic digesters. Historically, the WRF has<br />

had issues with foaming conditions which caused issues in the aeration basins and in downstream unit<br />

processes - conveyance foaming, secondary clarifier excessive scum, excessive blinding of final filters,<br />

and impacts to water reuse program. Figures 1 and 2 present typical nocardial foam and scum<br />

conditions.<br />

Figure 1 – Nocardial foam on aeration basin surface<br />

Figure 2 – Nocardial scum on secondary clarifier surface<br />

Compliance with ammonia nitrogen limits is challenged at times by periodic ammonia pass-through of the<br />

aeration basins particularly during winter operating conditions.<br />

This paper discusses the relationships of nitrification and foaming, presents the results of process data<br />

evaluations, presents control approaches used to control foaming and to enhance nitrification reliability<br />

and overall plant operations, and provides insight to others that may be experiencing similar process<br />

challenges.