NITRIFICATION AND ACTIVATED SLUDGE FOAMING ...

NITRIFICATION AND ACTIVATED SLUDGE FOAMING ...

NITRIFICATION AND ACTIVATED SLUDGE FOAMING ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

METHODOLOGY<br />

An integrated, hands-on operations approach was used to evaluate the issues of foaming and nitrification<br />

performance at the WRF. The steps included:<br />

• Defining the situation at the facility with regard to foaming and nitrification issues<br />

• Understanding background information - assimilating process data and information resources<br />

• Assessing the information, and<br />

• Developing recommendations to address the issues<br />

Background data used for the evaluation were historical operations and process data from operator<br />

sampling, and archived and real-time data from SCADA via on-line analyzers. Key on-line monitoring<br />

includes ammonia, pH and dissolved oxygen (DO). As the evaluation program progressed, additional online<br />

analyzers for ammonia (primary effluent and aeration basins) and TSS (aeration basins and<br />

secondary effluent) were installed for process/performance monitoring and data trending. To fully<br />

understand the components of the foam to help establish the root causes, microscopic analyses of MLSS<br />

and foam were conducted.<br />

The initial review of historical data from periods of ammonia pass-through of the aeration basins was<br />

somewhat puzzling as no critical process factors seemed to be askew – DO, MLSS/MCRT, alkalinity, and<br />

temperature all appeared to be in good range for providing complete nitrification based on the flows and<br />

loading conditions to the WRF. Short circuiting through the aeration basins was not a factor. From this<br />

review, sample collection points were examined and additional MLSS sampling points along with<br />

additional auto samplers for TSS (MLSS) were implemented to help with understanding the MLSS<br />

concentration and profiles in the aeration basins and in aeration basin effluent. Grab samples from the<br />

aeration basin were collected and analyzed for ammonia nitrogen to develop a nitrification profile along<br />

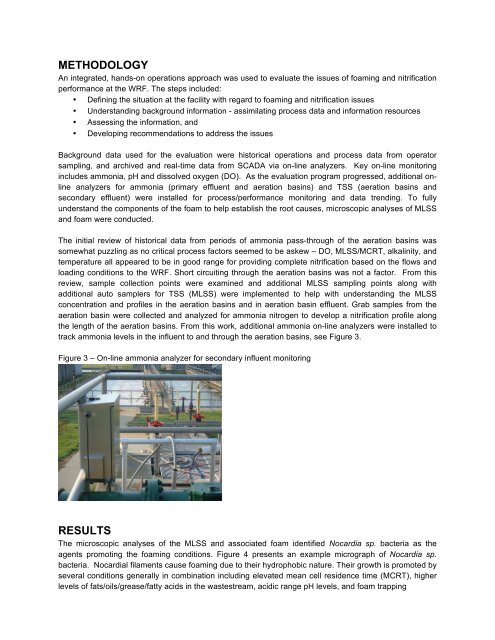

the length of the aeration basins. From this work, additional ammonia on-line analyzers were installed to<br />

track ammonia levels in the influent to and through the aeration basins, see Figure 3.<br />

Figure 3 – On-line ammonia analyzer for secondary influent monitoring<br />

RESULTS<br />

The microscopic analyses of the MLSS and associated foam identified Nocardia sp. bacteria as the<br />

agents promoting the foaming conditions. Figure 4 presents an example micrograph of Nocardia sp.<br />

bacteria. Nocardial filaments cause foaming due to their hydrophobic nature. Their growth is promoted by<br />

several conditions generally in combination including elevated mean cell residence time (MCRT), higher<br />

levels of fats/oils/grease/fatty acids in the wastestream, acidic range pH levels, and foam trapping