A4 Grilles - Linear Bar.qxd - Scottaire

A4 Grilles - Linear Bar.qxd - Scottaire

A4 Grilles - Linear Bar.qxd - Scottaire

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

LINEAR BAR<br />

GRILLES<br />

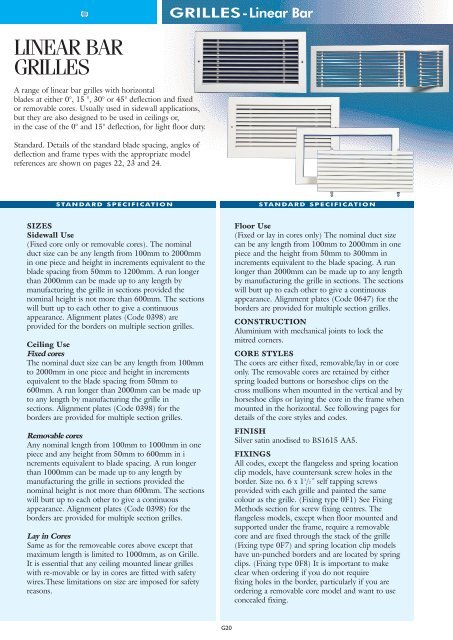

A range of linear bar grilles with horizontal<br />

blades at either 0°, 15 °, 30° or 45° deflection and fixed<br />

or removable cores. Usually used in sidewall applications,<br />

but they are also designed to be used in ceilings or,<br />

in the case of the 0° and 15° deflection, for light floor duty.<br />

Standard. Details of the standard blade spacing, angles of<br />

deflection and frame types with the appropriate model<br />

references are shown on pages 22, 23 and 24.<br />

STANDARD SPECIFICATION<br />

STANDARD SPECIFICATION<br />

SIZES<br />

Sidewall Use<br />

(Fixed core only or removable cores). The nominal<br />

duct size can be any length from 100mm to 2000mm<br />

in one piece and height in increments equivalent to the<br />

blade spacing from 50mm to 1200mm. A run longer<br />

than 2000mm can be made up to any length by<br />

manufacturing the grille in sections provided the<br />

nominal height is not more than 600mm. The sections<br />

will butt up to each other to give a continuous<br />

appearance. Alignment plates (Code 0398) are<br />

provided for the borders on multiple section grilles.<br />

Ceiling Use<br />

Fixed cores<br />

The nominal duct size can be any length from 100mm<br />

to 2000mm in one piece and height in increments<br />

equivalent to the blade spacing from 50mm to<br />

600mm. A run longer than 2000mm can be made up<br />

to any length by manufacturing the grille in<br />

sections. Alignment plates (Code 0398) for the<br />

borders are provided for multiple section grilles.<br />

Removable cores<br />

Any nominal length from 100mm to 1000mm in one<br />

piece and any height from 50mm to 600mm in i<br />

ncrements equivalent to blade spacing. A run longer<br />

than 1000mm can be made up to any length by<br />

manufacturing the grille in sections provided the<br />

nominal height is not more than 600mm. The sections<br />

will butt up to each other to give a continuous<br />

appearance. Alignment plates (Code 0398) for the<br />

borders are provided for multiple section grilles.<br />

Lay in Cores<br />

Same as for the removeable cores above except that<br />

maximum length is limited to 1000mm, as on Grille.<br />

It is essential that any ceiling mounted linear grilles<br />

with re-movable or lay in cores are fitted with safety<br />

wires.These limitations on size are imposed for safety<br />

reasons.<br />

Floor Use<br />

(Fixed or lay in cores only) The nominal duct size<br />

can be any length from 100mm to 2000mm in one<br />

piece and the height from 50mm to 300mm in<br />

increments equivalent to the blade spacing. A run<br />

longer than 2000mm can be made up to any length<br />

by manufacturing the grille in sections. The sections<br />

will butt up to each other to give a continuous<br />

appearance. Alignment plates (Code 0647) for the<br />

borders are provided for multiple section grilles.<br />

CONSTRUCTION<br />

Aluminium with mechanical joints to lock the<br />

mitred corners.<br />

CORE STYLES<br />

The cores are either fixed, removable/lay in or core<br />

only. The removable cores are retained by either<br />

spring loaded buttons or horseshoe clips on the<br />

cross mullions when mounted in the vertical and by<br />

horseshoe clips or laying the core in the frame when<br />

mounted in the horizontal. See following pages for<br />

details of the core styles and codes.<br />

FINISH<br />

Silver satin anodised to BS1615 AA5.<br />

FIXINGS<br />

All codes, except the flangeless and spring location<br />

clip models, have countersunk screw holes in the<br />

border. Size no. 6 x 1 1 /2˝ self tapping screws<br />

provided with each grille and painted the same<br />

colour as the grille. (Fixing type 0F1) See Fixing<br />

Methods section for screw fixing centres. The<br />

flangeless models, except when floor mounted and<br />

supported under the frame, require a removable<br />

core and are fixed through the stack of the grille<br />

(Fixing type 0F7) and spring location clip models<br />

have un-punched borders and are located by spring<br />

clips. (Fixing type 0F8) It is important to make<br />

clear when ordering if you do not require<br />

fixing holes in the border, particularly if you are<br />

ordering a removable core model and want to use<br />

concealed fixing.<br />

G20

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

OPTIONAL ALTERNATIVES/ADDITIONS<br />

PAN ADAPTORS, PLENUM & HEADER BOXES<br />

PACKAGING<br />

Each grille is individually shrink wrapped in<br />

polythene with additional cardboard support to the<br />

faces. Alignment plates are attached to one section<br />

in a linen draw-string bag.<br />

TECHNICAL INFORMATION<br />

See page 28<br />

SIZES<br />

Non standard sizes. We are not able to manufacture<br />

sizes other than those shown under the standard<br />

specification.<br />

DAMPERS<br />

Opposed blade damper. A clip on opposed blade<br />

damper (Code 0106) can be fitted, provided the<br />

nominal height does not exceed 450mm. The<br />

exceptions are all the fixed core linear grilles that<br />

have a blade pitch of 6.25mm and the 45° deflection<br />

with a blade pitch of 12.5mm because it is not<br />

possible to access the damper operator on these<br />

particular models, unless the core is removable.<br />

Dampers cannot be fitted to ceiling mounted lay in<br />

models either.<br />

FINISHES<br />

Any BS, RAL or NCS colour. Code 0145. Please<br />

specify the colour reference. We suggest powder<br />

coating on top of anodising for swimming pool<br />

applications. It may also be possible to anodise to<br />

alternative finishes for substantial quantities.<br />

Details on request.<br />

FIXINGS<br />

Concealed fixings / sub-frames are available. (Fixing<br />

type OF3) See Fixing Methods section. Please make<br />

sure that if you are fixing the grille by concealed<br />

methods, you order the grille with un-punched<br />

borders. The 0 in the product code becomes 9.<br />

MITRED CORNERS<br />

Angled mitred corners. Any angled corner section can<br />

be manufactured from 40° to 179°. See page G27 for<br />

Codes and details.<br />

2 WAY DISCHARGE<br />

Two way blow. Most of the 15°, 30° and 45°<br />

models can be made as two way opposite blow with<br />

the blades parallel to the long dimension. The first<br />

figure in the code would be 9 not 0. Please contact<br />

Head Office for details.<br />

SAFETY WIRES<br />

Safety wires (Code 0379) can be provided to attach<br />

the core to the border, where the core is removable,<br />

in order to minimise the possibility of accidents.<br />

They are fitted as standard on ceiling mounted<br />

removable core models.<br />

(Un-insulated)<br />

Top entry pan adaptor without flange (120mm high)*. Code 0323.<br />

Top entry pan adaptor without flange (17mm high). Code 0338.<br />

This height of pan adaptor should only be used where the spigot<br />

diameter plus 50mm is equal to or greater than the largest nominal<br />

dimension of the pan and the grille does not have a damper fitted<br />

to it.<br />

Top entry pan adaptor with flange*. Code 0328.<br />

Side entry plenum flange for use on single grilles up to and<br />

including 2 metres in length*. Code 0335.<br />

Side entry plenum with flange for use on single grilles up to and<br />

including 2 metres in length*. Code 0324.<br />

Side entry header box without flange for use on continuous runs<br />

over 2 metres long without opposed blade dampers. Code 0350.<br />

Side entry header box without flange for use on continuous runs<br />

over 2 metres long with opposed blade dampers. Code 0362.<br />

Side entry header box with flange for use on continuous runs over<br />

2 metres long without opposed blade dampers.Code 0363.<br />

Top entry header box with flange and flush fitting end caps<br />

for use on continuous runs over 2 metres long without dampers.<br />

Code 0374.<br />

Top entry header box with flange and flush fitting end caps for use<br />

on continuous runs over 2 metres long with dampers. Code 0364.<br />

Items with an * can be used on grilles with or without an opposed<br />

blade damper.<br />

Please see Sheet MetalWork section for details and codes for top<br />

entry plenum and header boxes, additional spigots and insulation<br />

for plenums and header boxes that are available.<br />

Pan adaptors, plenum boxes and header boxes can be fitted with<br />

quadrant dampers for either manual (Code 0483) or cord operated<br />

(Code 0484) control.<br />

We can also design boxes with non standard heights where there is<br />

limited space above the ceiling or in the cavity.<br />

ORDERING DETAILS<br />

• The code for the basic product should have at least<br />

13 digits. See page 1.<br />

• Please always give the length first then the height.<br />

• Add Codes for additions / alternatives as suffixes.<br />

• Please make sure you order un-punched borders if you<br />

order concealed fixings.<br />

EXAMPLE:<br />

A linear grille to fit an opening 2300mm long x<br />

200mm high having 15° deflection blades, a removable<br />

core retained by horse-shoe clips, opposed blade<br />

damper, pan adaptor without flange, to be concealed fix<br />

through the stack of the grille and painted<br />

RAL 9010 satin would be coded:-<br />

0237/02300/0200+0106+0323+0145-RAL 9010<br />

satin, + OF2.<br />

(un-punched borders).<br />

Applications. Supply * Extract * Sidewall * Ceiling *<br />

Floor * Transfer *<br />

G21

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

3.3mm Blades with 0° Deflection<br />

18.75<br />

18.75mm Centres.<br />

FLANGED.<br />

Code 0221 Fixed Core.<br />

Code 0384 Fixed Core. Spring Location Clips.<br />

Code 0402 Core Only.<br />

Code 0228 Removable Core Spring. Spring button.<br />

Code 0235 Removable Core Spring. Spring Clip.<br />

Code 0242 Removable Core, Lay-in.<br />

30mm clearance required above core.<br />

Code 0512 Floor Frame Fixed Core.*<br />

Code 0516 Floor Frame with lay-in Core.*<br />

RECESSED.<br />

Code 0452 Fixed Core.* + Sidewall or Ceiling<br />

Code 0453 Lay-in Core.* Floor<br />

Code 0624 Removable core. Spring Button.<br />

Code 0674 Fixed Core Floor.* +<br />

* Need to be supported under frame when used in the floor.<br />

+ Fixing only through the back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 70% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3 3<br />

3 3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3 3<br />

3 3<br />

3 3 3 3<br />

3 3 3<br />

3 3 3 3 3<br />

3 3<br />

6.25<br />

6.25mm Centres.<br />

FLANGED.<br />

Code 0222 Fixed Core.<br />

Code 0382 Fixed Core. Spring Location Clips.<br />

Code 0400 Core Only.<br />

Code 0229 Removable Core Spring. Spring button.<br />

Code 0236 Removable Core Spring. Spring Clip.<br />

Code 0243 Removable Core, Lay-in Removable Core.<br />

30mm clearance required above core.<br />

Code 0510 Floor Frame Fixed Core.*<br />

Code 0514 Floor Frame with lay-in Core.*<br />

RECESSED.<br />

Code 0450 Fixed Core.*+ Sidewall & Ceiling<br />

Code 0451 Lay-in Core. Floor<br />

Code 0623 Removable core. Spring Button.<br />

Code 0675 Fixed Core Floor.* +<br />

* Need to be supported under frame.<br />

+ Fixing only through the back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 42% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3<br />

3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3<br />

3 3<br />

3 3 3<br />

3 3 3<br />

3 3 3 3<br />

3<br />

12.5<br />

12.5mm Centres.<br />

FLANGED.<br />

Code 0217 Fixed Core.<br />

Code 0383 Fixed Core. Spring Location Clips.<br />

Code 0401 Core Only.<br />

Code 0225 Removable Core Spring. Spring button.<br />

Code 0232 Removable Core Spring. Spring Clip.<br />

Code 0238 Removable Core, Lay-in Removable Core.<br />

30mm clearance required above core.<br />

Code 0511 Floor Frame Fixed Core.*<br />

Code 0515 Floor Frame with lay-in Core.*<br />

RECESSED.<br />

Code 0462 Fixed Core.*+ Sidewall & Ceiling<br />

Code 0463 Lay-in Core. Floor<br />

Code 0622 Removable core. Spring Button.<br />

Code 0676 Fixed Core Floor.* +<br />

* Need to be supported under frame.<br />

+ Fixing only through the back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 61% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3 3<br />

3 3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3 3<br />

3 3<br />

3 3 3 3<br />

3 3 3<br />

3 3 3 3<br />

3 3<br />

G22

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

3.3mm Blades with 15° Deflection<br />

15°<br />

12.5<br />

12.5mm Centres.<br />

FLANGED.<br />

Code 0230 Fixed Core.<br />

Code 0391 Fixed Core. Spring Location Clips.<br />

Code 0405 Core Only.<br />

Code 0231 Removable Core. Spring Button.<br />

Code 0237 Removable Core. Spring Clip.<br />

Code 0244 Removable Core. Lay-in.<br />

30mm clearance required above core.<br />

Code 0513 Floor Frame Fixed Core.*<br />

Code 0517 Floor Frame Lay-in Core.*<br />

RECESSED<br />

Code 0458 Fixed Core.*+<br />

Code 0459 Lay-in Core<br />

Code 0625 Removable Core. Spring Button<br />

Code 0678 Fixed Core Floor.* +<br />

* Need to be supported under frame.<br />

+ Fixing only through the back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 62% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3 3<br />

3 3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3 3<br />

3 3<br />

3 3 3 3<br />

3 3<br />

3 3 3 3<br />

3 3<br />

3.3mm Blades with 30° Deflection<br />

30°<br />

12.5<br />

12.5mm Centres.<br />

FLANGED.<br />

Code 0251 Fixed Core.<br />

Code 0392 Fixed Core. Spring Location Clips<br />

Code 0406 Core Only.<br />

Code 0253 Removable Core. Spring Button.<br />

Code 0252 Removable Core. Spring Clip.<br />

Code 0254 Removable Core Lay-in.<br />

30mm clearance required above core.<br />

RECESSED<br />

Code 0671 Fixed Core.*+<br />

Code 0626 Removable Core. Spring Button<br />

+ Fixing only through the back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 60% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3 3<br />

3 3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3<br />

3 3 3 3<br />

3 3 3 3 3<br />

3.3mm Blades with 45° Deflection<br />

45°<br />

12.5<br />

12.5mm Centres.<br />

FLANGED.<br />

Code 0218 Fixed Core.<br />

Code 0385 Fixed Core. Spring Location Clips.<br />

Code 0403 Core Only.<br />

Code 0226 Removable Core. Spring Button.<br />

Code 0233 Removable Cor.e Spring Clip.<br />

Code 0239 Removable Core. Lay-in.<br />

30mm Clearance Required Above Core.<br />

RECESSED<br />

Code 0627 Removable Cor.e Spring Button.<br />

Code 0670 Fixed Core.*+<br />

* Need to be supported under frame.<br />

+ Fixing only through the back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 59% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3<br />

3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3 3 3<br />

3<br />

G23

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

3.3mm Blades with 45° Deflection<br />

45°<br />

18.75<br />

18.75mm Centres.<br />

Flanged.<br />

Code 0219 Fixed Core.<br />

Code 0390 Fixed Core. Spring Location Clips.<br />

Code 0404 Core Only.<br />

Code 0227 Re-movable Core. Spring Button.<br />

Code 0234 Re-movable Core. Spring Clip.<br />

Code 0240 Re-movable Core. Lay-in.<br />

30mm Clearance Required Above Core.<br />

RECESSED<br />

Code 0672 Fixed Core.*+<br />

Code 0673 Re-movable Core. Spring Button.<br />

* Need to be supported under frame.<br />

+ Fixing only through back of the stack or with duct straps.<br />

FREE AREA APPROXIMATELY 67% OF DUCT CONNECTION<br />

Sidewall<br />

Suggested Uses<br />

Ceiling<br />

Light<br />

Floor<br />

Convector<br />

Casings<br />

Can OBD<br />

be Fitted<br />

Safety Wires<br />

required if<br />

fitted in<br />

ceiling<br />

3 3 3 3<br />

3 3<br />

3<br />

3 3 3 3 3<br />

3 3 3 3 3<br />

3 3 3<br />

3 3 3 3<br />

3 3<br />

3 3 3 3 3<br />

Model shown is Code 0511 + 0106<br />

0° <strong>Linear</strong> Grille in a Flanged Floor Frame, fitted with Damper<br />

If Lay-in Core is Required, Code becomes 0515 +0106<br />

23.5<br />

Overall = D + 35mm<br />

4<br />

20.5<br />

36<br />

78<br />

15 Max Clearance<br />

Over Stack = D - 2mm<br />

Opening Size = D<br />

For grille lengths less than and including 2m.<br />

The frame would be made in one section as below.<br />

2000mm Max.<br />

300mm Max Centres<br />

For grille runs greater than 2m but less than 4m,<br />

grille would be made in 2 equal sections as below<br />

Equal<br />

Equal<br />

For grille runs greater than 4m the length is divided<br />

The nearest number of equal sections below 2m long.<br />

Equal Equal Equal<br />

No end border fitted when<br />

part of a continuous run<br />

Mullions fitted inside<br />

2m Max Length in 1 Section<br />

G24

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

25<br />

2.5<br />

D + 35mm<br />

12.5<br />

11.5<br />

6<br />

1.5<br />

12.5<br />

23.7<br />

3.5<br />

22.5<br />

67<br />

D + 35mm<br />

D<br />

23.5<br />

68<br />

D = Nominal Duct size<br />

Model shown is Code 0217 + 0106<br />

<strong>Linear</strong> <strong>Bar</strong> Grille with fixed core, blades with<br />

0° deflection on 12.5mm centres and fitted<br />

with Opposed Blade Damper<br />

D = Nominal Duct size<br />

Model shown is Code 0225 + 0106<br />

<strong>Linear</strong> <strong>Bar</strong> Grille with 0° deflection blades on<br />

12.5mm centres. Removable core retained by<br />

Button Fasteners and fitted with Opposed Blade Damper<br />

23.5<br />

68<br />

D<br />

D - 2mm<br />

30mm Min. Clearance<br />

For Core Removal<br />

22.5<br />

23.7<br />

12.5<br />

D + 43mm<br />

27.7<br />

12.5<br />

D + 35mm<br />

D<br />

D = Nominal Duct size<br />

Model shown is Code 0238<br />

<strong>Linear</strong> <strong>Bar</strong> Grille with 0° deflection blades<br />

On 12.5mm centres with Lay-in removable core<br />

D<br />

D + 0.5mm<br />

Pitch<br />

2.7<br />

X<br />

19.5<br />

D = Nominal Duct size<br />

Model shown is Code 0232 + 0106<br />

<strong>Linear</strong> <strong>Bar</strong> Grille with 0° deflection blades on<br />

12.5mm centres. Removable core retained by<br />

Horseshoe Spring Clips. Fitted with Opposed<br />

Blade Damper<br />

Code 0401 core only <strong>Linear</strong> <strong>Bar</strong> Grille 0° deflection blades on<br />

12.5mm Centres<br />

Standard sizes for the D dimension should be in 12.5mm increments<br />

Some intermediate aizes can be made by adjusting dimension X<br />

Contact Head Office for details<br />

D + 35mm<br />

100 Min.<br />

4.5<br />

23.5<br />

D + 10mm<br />

D = Nominal Duct size<br />

<strong>Linear</strong> Grille with access door<br />

Suffix Code 0248 on <strong>Linear</strong> Model<br />

G25

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

D = Nominal Duct size<br />

Model shown is Code 0462 +01060<br />

<strong>Linear</strong> <strong>Bar</strong> Grille 0° deflection blades on 12.5mm centres with fixed<br />

core<br />

In a Recessed Flangeless Frame with Opposed Blade Damper.<br />

NOTE - the core can be Lay-in if the floor code becomes 0463<br />

5<br />

D<br />

D - 2mm<br />

12.5<br />

24.5<br />

40<br />

82<br />

15<br />

15<br />

For grille lengths less than and including 2m.<br />

The frame would be made in one section as below.<br />

2000mm Max.<br />

For grille runs greater than 2m but less than 4m,<br />

<strong>Grilles</strong> would be made In 2 equal sections as below<br />

Equal<br />

Equal<br />

For grille runs greater than 4m the length is divided into<br />

The nearest number of equal sections below 2m long.<br />

Equal Equal Equal<br />

Mullions fitted inside<br />

No end<br />

border<br />

fitted<br />

when<br />

part of a<br />

continuous<br />

run<br />

300mm Max Centres<br />

2m Max Length in 1 Section<br />

40<br />

81.5<br />

1 5<br />

5<br />

2.5<br />

D + 35mm<br />

12.5<br />

25<br />

22.5<br />

67<br />

12.5<br />

D - 2mm<br />

D<br />

D<br />

D = Nominal Duct size<br />

Model shown is Code 0383 + 0106<br />

<strong>Linear</strong> <strong>Bar</strong> Grille With 0° deflection blade on 12.5mm<br />

centres with fixed core, located in a horizontal surface by<br />

Spring Location Clips. Fitted with an Opposed Blade<br />

Damper. (Unpunched borders as standard)<br />

Not to be used in ceiling or vertical surfaces<br />

D = Nominal Duct size<br />

Model shown is Code 0622 +0106<br />

Recessed Frame <strong>Linear</strong> <strong>Bar</strong> Grille 0° deflection blades on<br />

12.5mm centres<br />

Removable core retained by Button Fasteners and fitted<br />

with Opposed Blade Damper<br />

Caution: Fixing this type of frame with a fixed core is not<br />

possible.<br />

G26

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

<strong>Linear</strong> Grille Mitred Corner<br />

Code 0464 0° deflection blades on 6.25mm centres<br />

Code 0465 0° deflection blades on 12.50mm centres<br />

Code 0466 0° deflection blades on 18.75mm centres<br />

Code 0467 45° deflection blades on 12.50mm centres<br />

Code 0468 45° deflection blades on 18.75mm centres<br />

Code 0469 15° deflection blades on 12.50mm centres<br />

Code 0470 30° deflection blades on 12.50mm centres<br />

90°<br />

300 Inside<br />

Opening = Nominal Grille Height + 317.5mm<br />

300 Inside<br />

Opening = Nominal Grille Height + 317.5mm<br />

Use Formula<br />

Nom Opening<br />

Use Formula<br />

300 Inside<br />

300 Inside<br />

Nom Opening<br />

To Calculate The Outside Length For Any Angle Other Than 90°, Use The Formula Below<br />

First Calculate The Angle Of The Cut = (180 - ) divided by 2<br />

Then The Outside Opening Length = [ (Nominal Opening + 17.5mm) x Tan of The Angle Of Cut ] + 300mm<br />

e.g. Assume Nominal Dimension = 300mm and = 135° then angle of cut = (180 - 135) / 2 = 22.5°<br />

Outside Opening Length = [ (300 + 17.5mm) x Tan 22.5° ] + 300 = 431.5mm<br />

G27

GRILLES-<strong>Linear</strong> <strong>Bar</strong><br />

PERFORMANCE DATA FOR<br />

LINEAR GRILLES<br />

• This nomogram is based on Code 217 <strong>Linear</strong><br />

<strong>Grilles</strong> and corrections should be applied for other<br />

codes. In the case of <strong>Linear</strong> grilles, the fixed parameters<br />

for selection are usually volume, throw and/or<br />

width of grille. To select for the volume and throw, the<br />

volume should be related to a metre run. For example,<br />

if the length is to be 500mm and the volume 0.15m 3 /s,<br />

then volume per metre would be 1 ÷ 0.5 x 0.15 =<br />

0.3m 3 /s/. If the required throw is 7 metres, place a<br />

ruler on the volume line at 0.3 and cross the throw<br />

line at 7 metres. The rule crosses the width line at<br />

275mm. If there is a limitation on the width of the<br />

grille, say 200mm wide in the above case, and the<br />

throw was critical, then the length would have to be<br />

increased. Design throws should always be corrected<br />

using tables 1, 2, 3 and 4 as appropriate, before<br />

entering the nomogram. Pressure drop and NR<br />

should be corrected after using the nomogram.<br />

PERFORMANCE DATA<br />

TABLE 1<br />

Corrections for<br />

other <strong>Grilles</strong><br />

Data given is for isothermal conditions and for free space application.<br />

No opposed blade damper. For dampers add 40% to the pressure drop and 5NR.<br />

Grille<br />

Type<br />

116<br />

117<br />

118<br />

119<br />

Pressure<br />

Correction Factors<br />

x 1.1<br />

x 1.0<br />

x 1.2<br />

x 1.4<br />

Sound<br />

Factors<br />

÷3<br />

x 1<br />

÷ 4<br />

÷ 10<br />

Throw<br />

Factors<br />

x 1<br />

x 1<br />

÷ 0.95<br />

÷ 0.95<br />

Volume (Q)<br />

m 3 /s/ metre run<br />

2.0<br />

Nominal Grille<br />

Width mm x 1000mm long<br />

222<br />

229<br />

236<br />

243<br />

217<br />

225<br />

232<br />

238<br />

221<br />

228<br />

235<br />

242<br />

230<br />

231<br />

237<br />

244<br />

251<br />

253<br />

252<br />

254<br />

218<br />

226<br />

233<br />

239<br />

219<br />

227<br />

234<br />

240<br />

x 1.2<br />

x 1.2<br />

x 1.2<br />

x 1.2<br />

x 1.0<br />

x 1.0<br />

x 1.0<br />

x 1.0<br />

x 0.8<br />

x 0.8<br />

x 0.8<br />

x 0.8<br />

x 1.1<br />

x 1.1<br />

x 1.1<br />

x 1.1<br />

x 1.2<br />

x 1.2<br />

x 1.2<br />

x 1.2<br />

x 1.3<br />

x 1.3<br />

x 1.3<br />

x 1.3<br />

x 1.2<br />

x 1.2<br />

x 1.2<br />

x 1.2<br />

÷ 4<br />

÷4<br />

÷4<br />

÷ 4<br />

x 1<br />

x 1<br />

x 1<br />

x 1<br />

÷4<br />

÷ 4<br />

÷4<br />

÷4<br />

÷3<br />

÷3<br />

÷ 3<br />

÷3<br />

÷10<br />

÷10<br />

÷10<br />

÷ 10<br />

÷15<br />

÷15<br />

÷15<br />

÷15<br />

÷10<br />

÷10<br />

÷10<br />

÷ 10<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

x 1<br />

x 1<br />

x 1<br />

x 1<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.95<br />

÷ 0.82<br />

÷ 0.82<br />

÷ 0.82<br />

÷ 0.82<br />

÷ 0.70<br />

÷ 0.70<br />

÷ 0.70<br />

÷ 0.70<br />

÷ 0.70<br />

÷ 0.70<br />

÷ 0.70<br />

÷ 0.70<br />

1.5<br />

1.0<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.15<br />

20<br />

10<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

Pressure drop<br />

(∆Pt ) Pa<br />

60<br />

50<br />

40<br />

30<br />

20<br />

NRLW<br />

50<br />

40<br />

30<br />

20<br />

10<br />

6.0<br />

5.0<br />

4.0<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

Duct<br />

velocity<br />

m/s<br />

100<br />

150<br />

200<br />

250<br />

300<br />

350<br />

400<br />

450<br />

500<br />

550<br />

600<br />

TABLE 2<br />

Corrections to throw<br />

due to ceiling.<br />

Grille more than<br />

600mm from ceiling<br />

Grille more than<br />

600mm from ceiling<br />

0<br />

0<br />

TABLE 3<br />

Throw corrections<br />

for length<br />

Grille Length (m) Factor<br />

0.66 - 1.00 -<br />

1.66 - 2.00 +1.1<br />

› 2.01 +1.2<br />

0.1<br />

0.09<br />

0.08<br />

0.07<br />

0.06<br />

0.05<br />

1<br />

Throw in metres.<br />

Terminal Velocity<br />

(Vt) 0.25m/s<br />

0.04<br />

TABLE 4<br />

Throw corrections<br />

for other (V t )<br />

TABLE 5<br />

Sound corrections<br />

for length<br />

0.03<br />

Terminal Velocity Factor<br />

0.25 m/s + 1.0<br />

0.375 m/s +0.67<br />

0.5 m/s +0.5<br />

Grille Length (m) Factor<br />

0.33 - 1.00 -<br />

1.01 - 1.66 +1 NR<br />

1.67 - 2.00 +2 NR<br />

2.30 - 3.00 +3 NR<br />

0.02<br />

G28