If Preferred -- Download The Entire Booklet - Spears Manufacturing ...

If Preferred -- Download The Entire Booklet - Spears Manufacturing ...

If Preferred -- Download The Entire Booklet - Spears Manufacturing ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Installation<br />

Deflection<br />

Gasketed joints permit an angular deflection of 2° at the joint.<br />

Adequate deflection can usually be achieved for gentle curves by<br />

using the inherent flexibility of the pipe itself, without using joint<br />

deflection.<br />

Thrust Blocking Gasket Joints<br />

All gasket-joint piping requires adequate thrust restraints to prevent<br />

movement from forces generated by changes in direction, valve<br />

operation, dead ends, reduction in pipe size, and other areas where<br />

thrusts can be developed. <strong>The</strong> size and type of thrust restraint<br />

depends on the pipe size, type of fitting, soil properties, and waterhammer<br />

possibilities. Keeping flow velocities at or below 5 ft/sec<br />

will help minimize surge pressures. Fittings and valves used to<br />

make vertical changes in direction should be anchored to the thrust<br />

restraint to prevent outward and upward thrusts at the fitting junctures.<br />

In pressure lines, valves 3" in diameter and larger should be<br />

anchored to the thrust restraint to prevent movement when operated.<br />

Consideration should also be given for the proper support, anchoring,<br />

and thrust restraint for lines installed on slopes.<br />

<strong>The</strong> size of thrust block required (in square feet) can be determined<br />

by dividing the total thrust developed (in psi) by the capacity of the<br />

soil (in pounds/square foot).<br />

<strong>The</strong> most common method of thrust blocking involves the pouring<br />

of concrete (to the size of block required) between the pipe fitting<br />

and the bearing wall of the trench. Mechanical thrust restraint with<br />

PVC pipe.<br />

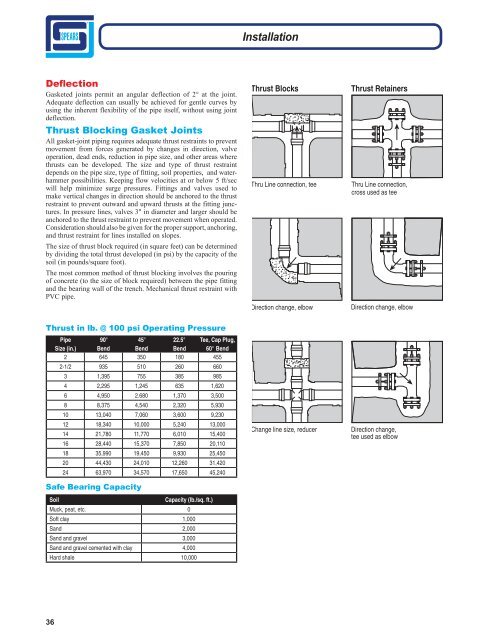

Thrust Blocks<br />

Thru Line connection, tee<br />

Direction change, elbow<br />

Thrust Retainers<br />

Thru Line connection,<br />

cross used as tee<br />

Direction change, elbow<br />

Thrust in lb. @ 100 psi Operating Pressure<br />

Pipe<br />

Size (in.)<br />

90°<br />

Bend<br />

45°<br />

Bend<br />

22.5°<br />

Bend<br />

Tee, Cap Plug,<br />

60° Bend<br />

2 645 350 180 455<br />

2-1/2 935 510 260 660<br />

3 1,395 755 385 985<br />

4 2,295 1,245 635 1,620<br />

6 4,950 2.680 1,370 3,500<br />

8 8,375 4,540 2,320 5,930<br />

10 13,040 7,060 3,600 9,230<br />

12 18,340 10,000 5,240 13,000<br />

14 21,780 11,770 6,010 15,400<br />

16 28,440 15,370 7,850 20,110<br />

18 35,990 19,450 9,930 25,450<br />

20 44,430 24,010 12,260 31,420<br />

24 63,970 34,570 17,650 45,240<br />

Safe Bearing Capacity<br />

Soil<br />

Capacity (lb./sq. ft.)<br />

Muck, peat, etc. 0<br />

Soft clay 1,000<br />

Sand 2,000<br />

Sand and gravel 3,000<br />

Sand and gravel cemented with clay 4,000<br />

Hard shale 10,000<br />

Change line size, reducer<br />

Direction change,<br />

tee used as elbow<br />

36