FANUC - UNIDO-ICAMT

FANUC - UNIDO-ICAMT

FANUC - UNIDO-ICAMT

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

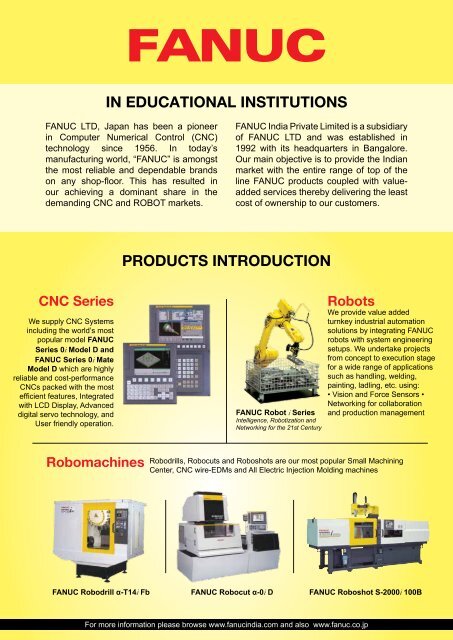

<strong>FANUC</strong><br />

IN EDUCATIONAL INSTITUTIONS<br />

<strong>FANUC</strong> LTD, Japan has been a pioneer<br />

in Computer Numerical Control (CNC)<br />

technology since 1956. In today’s<br />

manufacturing world, “<strong>FANUC</strong>” is amongst<br />

the most reliable and dependable brands<br />

on any shop-floor. This has resulted in<br />

our achieving a dominant share in the<br />

demanding CNC and ROBOT markets.<br />

<strong>FANUC</strong> India Private Limited is a subsidiary<br />

of <strong>FANUC</strong> LTD and was established in<br />

1992 with its headquarters in Bangalore.<br />

Our main objective is to provide the Indian<br />

market with the entire range of top of the<br />

line <strong>FANUC</strong> products coupled with valueadded<br />

services thereby delivering the least<br />

cost of ownership to our customers.<br />

PRODUCTS INTRODUCTION<br />

CNC Series<br />

We supply CNC Systems<br />

including the world’s most<br />

popular model <strong>FANUC</strong><br />

Series 0i Model D and<br />

<strong>FANUC</strong> Series 0i Mate<br />

Model D which are highly<br />

reliable and cost-performance<br />

CNCs packed with the most<br />

efficient features, Integrated<br />

with LCD Display, Advanced<br />

digital servo technology, and<br />

User friendly operation.<br />

<strong>FANUC</strong> Robot i Series<br />

Intelligence, Robotization and<br />

Networking for the 21st Century<br />

Robots<br />

We provide value added<br />

turnkey industrial automation<br />

solutions by integrating <strong>FANUC</strong><br />

robots with system engineering<br />

setups. We undertake projects<br />

from concept to execution stage<br />

for a wide range of applications<br />

such as handling, welding,<br />

painting, ladling, etc. using:<br />

• Vision and Force Sensors •<br />

Networking for collaboration<br />

and production management<br />

Robomachines<br />

Robodrills, Robocuts and Roboshots are our most popular Small Machining<br />

Center, CNC wire-EDMs and All Electric Injection Molding machines<br />

<strong>FANUC</strong> Robodrill α-T14i Fb<br />

<strong>FANUC</strong> Robocut α-0i D<br />

<strong>FANUC</strong> Roboshot S-2000i 100B<br />

For more information please browse www.fanucindia.com and also www.fanuc.co.jp

EDUCATIONAL INSTITUTION<br />

CNC Turning Simulator<br />

Understanding the basic mechanicals in the two axes lathe simulator; Development<br />

of part program and simulation for turning applications, navigation of screens in a<br />

turning controller<br />

• Learning of CNC hardware interfacing concepts for the two axis package of a<br />

lathe<br />

• Development of PLC logic for CNC turning centre and simulation of the same.<br />

• Parameterization of the CNC system for turning<br />

• Learning and simulation of Servo tuning concepts for lathe<br />

• Learning of the PLC Input/Output connections<br />

• Development and Simulation of spindle position control and Cs contouring<br />

• Learning the trouble shooting concepts using the various tools like alarm guide,<br />

Diagnostics, Trace function etc., for the lathe functions<br />

CNC Vertical machining centre Simulator<br />

• Understanding the basic mechanicals in the 3 axes machining centre simulator<br />

• Development of Part program and simulation for milling applications<br />

• Navigation of screens in a milling controller<br />

• Learning of CNC hardware interfacing concepts for the three axis package of a<br />

VMC<br />

• Development of PLC logic for CNC machining centre and simulation of the same.<br />

• Parameterization of the CNC system for Milling operations<br />

• Learning and simulation of Servo tuning concepts for a machining centre<br />

• Learning of the PLC Input/Output connections<br />

• Development of PLC logic for high end concepts like ATC and APC concepts<br />

• Learning the trouble shooting concepts using the various tools like alarm guide,<br />

Diagnostics, Trace function etc., for the VMC functions<br />

NC Guide: CNC on your desktop<br />

• Perfect tool for learning of different modes of operations of a CNC<br />

machine<br />

• A single tool can be configured to be used as a lathe / machining centre<br />

• Navigation of the CNC screens<br />

• Part program development and simulation using tool path graphics<br />

• CAD facility to draft a profile and 3D animation<br />

• Cycle time evaluation using the 3D simulation software - Manual guide i<br />

NC Guide PRO:<br />

All in one - CNC tool for operation and<br />

maintenance<br />

•<br />

• It contain all the features of NC guide<br />

• PLC logic development and simulation<br />

• Customized Screen development and simulation<br />

• Trouble shooting using diagnostics features<br />

• Machine Input/Output signals simulation<br />

• Complete CNC simulator with ALL-IN-ONE

SPECIFIC PRODUCT OFFERINGS<br />

Roboguide<br />

Robot applications<br />

We developed lot of application packages and software tools that<br />

make the most of the flexibility of articulated robots for gantry<br />

loaders and scalar robots. <strong>FANUC</strong> will provide the robot system<br />

best suited for customer needs.<br />

The various Robot applications are as follows<br />

• Material handling and picking<br />

• Material handling and palletizing<br />

• Spot welding<br />

• Arc welding<br />

• Assembling<br />

• Bin-picking<br />

• Quick and easy investigation of robot system integration<br />

• Ease of use with specific set up environments for peripheral<br />

environment and conditions without specific skills.<br />

• Animated teaching support results quick job completion for teaching<br />

• Accurate cycle time simulation<br />

• Off-line verification on site saves system start up and recovery time<br />

• Robot simulator for practical use<br />

• Highly accurate cycle time simulation<br />

• Robot program simulation<br />

• Animated verification of motion<br />

• Simulation with actual PLC and Input/Output device<br />

Robodrill with LR Mate 200iC<br />

• Nano CNC System with ultra precision pulse coder and interpolation in nanometer<br />

• High acceleration positioning<br />

• Rigid structure of machine mechanism<br />

• High speed indexing table<br />

• Pallet change and work piece exchange are done by a robot.<br />

• Quick pallet change operation.<br />

• The machine can run continuously at minimum idle time in changing the pallets even<br />

in case of busy handling required for the parts on the multiple-parts setting jig.<br />

• Robot can exchange work pieces that are randomly piled by using 3-D vision sensor.<br />

LR mate 200iC<br />

• The latest generation of the proven design<br />

• 5 or 6 degrees of freedom<br />

• Table top size, slim wrist, and small footprint permit operation in tight work spaces<br />

• Enclosed mechanical design eliminates cables and hose snagging<br />

• Highest joint speeds maximize throughput.<br />

• Upright, angle, wall or invert mounting increases installation flexibility<br />

• Higher rigidity and the most advanced servo technology enable smooth motion without<br />

vibration in high speed operation<br />

• Integrated PMC provides<br />

• ladder-logic control for<br />

• peripheral devices

USER FEEDBACK<br />

We are using Fanuc products like CNC<br />

systems and robots for production as well<br />

as to train operators, technicians and<br />

graduate engineers for several decades. We<br />

chose Fanuc not only for their technological<br />

superiority combined with built-in<br />

robustness and flexibility but also because<br />

they are the easiest to learn and operate.<br />

We have made learning Fanuc products<br />

an integral part of the curriculum and to us,<br />

Fanuc is the synonym for mechatronics.<br />

C.R. Swaminathan<br />

Chief Executive,<br />

PSG Group of Institutions,<br />

Coimbatore 641 004,<br />

Chairman CII-Southern Region<br />

NTTF is glad with the performance of<br />

<strong>FANUC</strong> products we use in Training and in<br />

Production activities. In our Mechatronics<br />

Program which is extensively accepted<br />

by industries we use <strong>FANUC</strong> products<br />

like CNC Controllers and Robots. We are<br />

extremely happy with the technical support<br />

extended by <strong>FANUC</strong> in the past. We wish<br />

<strong>FANUC</strong> to come out with more products<br />

which will be used as bench-mark by the<br />

users as in the past.<br />

N. Reguraj<br />

Managing Director, NTTF<br />

Nettur Technical Training Foundation,<br />

Bangalore<br />

<strong>FANUC</strong> India Private Limited<br />

41A, Electronics City, Hosur Road, Bangalore, India - 560 100<br />

Tel: +91-80-2852 0057, Fax: +91-80-2852 8491<br />

Email: filhq@ fanucindia.com; website: www.fanucindia.com<br />

Bangalore Head Office<br />

FA Sales Tel: 080-2852-0041 Fax:080-2852-8491<br />

Robot Sales Tel: 080-2852-1145 Fax:080-2852-8529<br />

Robomachine Sales Tel: 080-2852-2171 Fax:080-2852-8491<br />

Service Tel: 080-2852-0040 Fax:080-2852-8528<br />

Pune Branch Office<br />

FA Sales Tel: 020-27373181 Fax: 020-27373182<br />

Robot Sales Tel: 020-27373188 Fax: 020-27373182<br />

Service Tel: 020-27373183 Fax: 020-27373182<br />

New Delhi Branch Office<br />

FA Sales Tel:011-416-32781 Fax:011-416-78178<br />

Robot Sales Tel:011-416-32783 Fax:011-416-78178<br />

Robomachine Sales Tel:011-416-32782 Fax:011-416-78178