machine building & automation - Industrial Technology Magazine

machine building & automation - Industrial Technology Magazine

machine building & automation - Industrial Technology Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

POWER TRANSMISSION<br />

Gears & Gearboxes<br />

Magnetic gear at the heart<br />

of innovative CVT design<br />

Applications as diverse as hybrid vehicles and wind turbines,<br />

as well as industrial gear applications, could all benefit from<br />

the latest developments in magnetic gear technology<br />

Magnomatics has been working hard on its<br />

magnetic gear since we last reported on it in<br />

<strong>Industrial</strong> <strong>Technology</strong> and there have been a<br />

number of new innovations that extend the<br />

applications potential of this innovative technology. The<br />

range has been extended to include fixed-ratio magnetic<br />

gears, magnetically-geared motor generators (PDD) and<br />

most recently a magnetic continuously variable<br />

transmission (MAGSPLIT).<br />

In operation, as with any gear technology, one shaft<br />

rotates at a different speed to the other. However, instead<br />

of using meshing teeth to connect the shafts and transmit<br />

mechanical power, this gear uses the magnetic field of<br />

powerful rare earth magnets. It has no contacting parts,<br />

and so does not require lubrication. This means that the<br />

gear offers inherently high reliability, with little<br />

or no requirement for maintenance. The<br />

gear is also more efficient because there<br />

is no friction.<br />

A magnetic gear is directly<br />

analogous to a planetary, or<br />

epicyclic, gear and consists of three<br />

rings. The outer and inner rings have<br />

powerful magnets, arranged in an<br />

alternating north-south pattern,<br />

whilst the middle ring consists of steel<br />

segments which alter the magnetic<br />

field between the inner and outer<br />

magnet rings.<br />

The inner ring consists of a low number<br />

of magnets and is connected to the high speed<br />

shaft. The middle ring consists of a number of steel<br />

segments held within a mechanical structure and is<br />

typically connected to the low speed shaft. The outer ring,<br />

consisting of a high number of magnets, is usually held<br />

stationary in conventional gear applications. There is no<br />

physical contact between any of the rings as the motion<br />

ICE<br />

MAGSPLIT mCVT<br />

Motor/Generator<br />

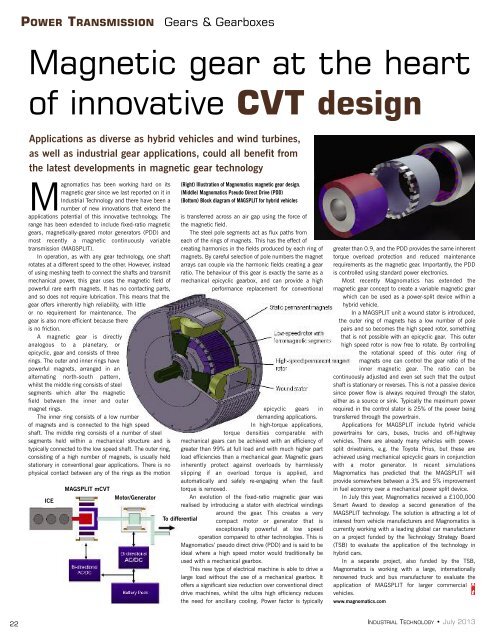

(Right) Illustration of Magnomatics magnetic gear design.<br />

(Middle) Magnomatics Pseudo Direct Drive (PDD)<br />

(Bottom) Block diagram of MAGSPLIT for hybrid vehicles<br />

is transferred across an air gap using the force of<br />

the magnetic field.<br />

The steel pole segments act as flux paths from<br />

each of the rings of magnets. This has the effect of<br />

creating harmonics in the fields produced by each ring of<br />

magnets. By careful selection of pole numbers the magnet<br />

arrays can couple via the harmonic fields creating a gear<br />

ratio. The behaviour of this gear is exactly the same as a<br />

mechanical epicyclic gearbox, and can provide a high<br />

performance replacement for conventional<br />

epicyclic gears in<br />

demanding applications.<br />

In high-torque applications,<br />

torque densities comparable with<br />

mechanical gears can be achieved with an efficiency of<br />

greater than 99% at full load and with much higher part<br />

load efficiencies than a mechanical gear. Magnetic gears<br />

inherently protect against overloads by harmlessly<br />

slipping if an overload torque is applied, and<br />

automatically and safely re-engaging when the fault<br />

torque is removed.<br />

An evolution of the fixed-ratio magnetic gear was<br />

realised by introducing a stator with electrical windings<br />

around the gear. This creates a very<br />

compact motor or generator that is<br />

exceptionally powerful at low speed<br />

operation compared to other technologies. This is<br />

Magnomatics’ pseudo direct drive (PDD) and is said to be<br />

ideal where a high speed motor would traditionally be<br />

used with a mechanical gearbox.<br />

This new type of electrical <strong>machine</strong> is able to drive a<br />

large load without the use of a mechanical gearbox. It<br />

offers a significant size reduction over conventional direct<br />

drive <strong>machine</strong>s, whilst the ultra high efficiency reduces<br />

the need for ancillary cooling. Power factor is typically<br />

To differential<br />

greater than 0.9, and the PDD provides the same inherent<br />

torque overload protection and reduced maintenance<br />

requirements as the magnetic gear. Importantly, the PDD<br />

is controlled using standard power electronics.<br />

Most recently Magnomatics has extended the<br />

magnetic gear concept to create a variable magnetic gear<br />

which can be used as a power-split device within a<br />

hybrid vehicle.<br />

In a MAGSPLIT unit a wound stator is introduced,<br />

the outer ring of magnets has a low number of pole<br />

pairs and so becomes the high speed rotor, something<br />

that is not possible with an epicyclic gear. This outer<br />

high speed rotor is now free to rotate. By controlling<br />

the rotational speed of this outer ring of<br />

magnets one can control the gear ratio of the<br />

inner magnetic gear. The ratio can be<br />

continuously adjusted and even set such that the output<br />

shaft is stationary or reverses. This is not a passive device<br />

since power flow is always required through the stator,<br />

either as a source or sink. Typically the maximum power<br />

required in the control stator is 25% of the power being<br />

transferred through the powertrain.<br />

Applications for MAGSPLIT include hybrid vehicle<br />

powertrains for cars, buses, trucks and off-highway<br />

vehicles. There are already many vehicles with powersplit<br />

drivetrains, e.g. the Toyota Prius, but these are<br />

achieved using mechanical epicyclic gears in conjunction<br />

with a motor generator. In recent simulations<br />

Magnomatics has predicted that the MAGSPLIT will<br />

provide somewhere between a 3% and 5% improvement<br />

in fuel economy over a mechanical power split device.<br />

In July this year, Magnomatics received a £100,000<br />

Smart Award to develop a second generation of the<br />

MAGSPLIT technology. The solution is attracting a lot of<br />

interest from vehicle manufacturers and Magnomatics is<br />

currently working with a leading global car manufacturer<br />

on a project funded by the <strong>Technology</strong> Strategy Board<br />

(TSB) to evaluate the application of the technology in<br />

hybrid cars.<br />

In a separate project, also funded by the TSB,<br />

Magnomatics is working with a large, internationally<br />

renowned truck and bus manufacturer to evaluate the<br />

application of MAGSPLIT for larger commercial<br />

vehicles.<br />

www.magnomatics .com<br />

22<br />

INDUSTRIAL TECHNOLOGY • July 2013