Acoustic Vibration Isolation Bearings - Trelleborg.com.au

Acoustic Vibration Isolation Bearings - Trelleborg.com.au

Acoustic Vibration Isolation Bearings - Trelleborg.com.au

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

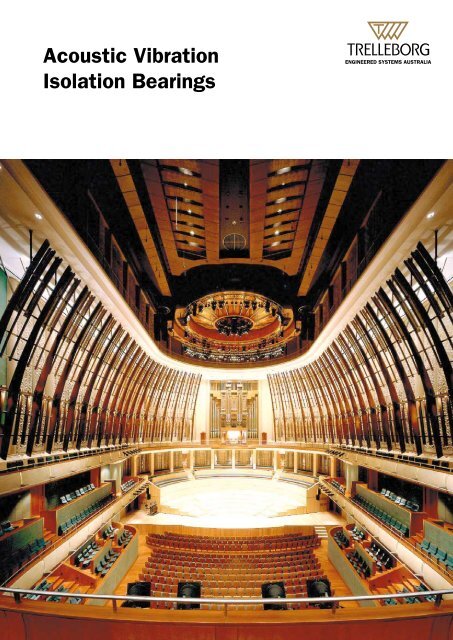

<strong>Acoustic</strong> <strong>Vibration</strong><br />

<strong>Isolation</strong> <strong>Bearings</strong>

<strong>Trelleborg</strong> <strong>Acoustic</strong> <strong>Vibration</strong><br />

<strong>Isolation</strong> <strong>Bearings</strong><br />

<strong>Trelleborg</strong> is a global supplier of acoustic bearings for building isolation.<br />

Concert halls, lyric theatres, movie production studios and other noise and<br />

vibration-sensitive buildings often require isolation from the surrounding structure.<br />

<strong>Acoustic</strong> bearings are a reliable and durable solution for supporting loads,<br />

ac<strong>com</strong>modating movements and attenuating the effects of noise and vibration<br />

transmitted into the structure<br />

Urban land availability for building new<br />

structures is be<strong>com</strong>ing more restrictive.<br />

There appears to be an increasing trend<br />

to construct new performance spaces<br />

such as Cultural Centres above, or in<br />

close proximity to, existing railway lines,<br />

underground systems, major roads and<br />

other “noisy” infrastructure.<br />

Performance halls located on vibrationcontaminated<br />

land need to be<br />

stringently designed to minimise the<br />

potential for any sound transmission<br />

through the foundations.<br />

Recent Projects<br />

Singapore Theatres on the Bay,<br />

Concert Hall and Lyric<br />

Theatre<br />

Hong Kong Hong Kong Movie City<br />

Budapest National Philharmonic Hall,<br />

Cultural Complex<br />

Adelaide Adelaide Convention Centre<br />

Brunei Sultan of Brunei’s Palace,<br />

Helicopter Pad<br />

Sydney Angel Place<br />

Brisbane Queensland Conservatorium<br />

of Music<br />

Perth Lakeside Joondalup<br />

Theatres<br />

Brisbane Queensland Performing<br />

Arts Complex

Bearing Design<br />

<strong>Acoustic</strong> isolation involves supporting<br />

the structure on a <strong>com</strong>prehensive<br />

system of bearings, specially designed<br />

to perform under the specified operating<br />

criteria. Selecting the appropriate<br />

bearing design is dependent on a large<br />

number of variables including:<br />

• Characteristics of the disturbance<br />

frequencies<br />

• Degree of vibration attenuation<br />

required of the bearings<br />

(ie. required natural frequency of<br />

the bearing pads)<br />

• Vertical and lateral loads<br />

• Wind and earthquake loads<br />

<strong>Trelleborg</strong> custom design all bearings<br />

to meet the specified static deflection<br />

and natural frequency requirements.<br />

<strong>Bearings</strong> are generally designed as a<br />

<strong>com</strong>posite of rubber and steel.<br />

The quantity and geometry of the steel<br />

plates principally determine the load<br />

bearing and stiffness characteristics.<br />

<strong>Bearings</strong> are designed with sufficient<br />

thickness to ensure they are not<br />

overstressed when operating over the<br />

full load range.<br />

Under dynamic load conditions the<br />

effectiveness of the bearings is<br />

dependent on their dynamic-to-static<br />

stiffness ratio.<br />

In general, we manufacture most of<br />

our bearings using natural rubber to<br />

maintain low dynamic-to-static stiffness<br />

ratios (eg. 1.2 - 1.3).<br />

<strong>Bearings</strong> can be supplied pre<strong>com</strong>pressed<br />

to assist with construction.<br />

This avoids problems associated with<br />

the bearings gradually deflecting as<br />

additional structure increases the<br />

support weight. <strong>Bearings</strong> can also<br />

be designed as continuous strips to<br />

support walls.<br />

We use tried and proven modelling<br />

procedures such as mathematical<br />

modelling and Finite Element Analysis<br />

(FEA) to predict the load and deflection<br />

characteristics.<br />

All designs are verified by testing<br />

prototype bearings prior to <strong>com</strong>mencing<br />

production. Full destruction tests can<br />

be <strong>com</strong>pleted on prototype bearings if<br />

required.<br />

<strong>Trelleborg</strong> has an experienced<br />

engineering team available to discuss<br />

your project in the design phase, to<br />

enable accurate sizing of columns<br />

and provide options for reducing<br />

construction costs.

Uplift Loads<br />

<strong>Trelleborg</strong> Laminated rubber<br />

bearings are suitable for carrying<br />

load by <strong>com</strong>pression and under no<br />

circumstances should they be subjected<br />

to tension. If tensile forces could arise<br />

due to uplift in the bearing (eg. seismic<br />

or wind loads), we can design a multibearing<br />

arrangement to restrain the<br />

bearing under uplift loads.<br />

Fire Protection<br />

We can design bearings with an inherent<br />

system of fire protection (eg. 2 hour<br />

fire rating). Alternatively we can design<br />

and supply a fire protection system<br />

to be installed around the column or<br />

structure supporting the bearing. All<br />

fire protection systems for acoustic<br />

isolation bearings should be designed<br />

so the potential for bridging between<br />

the substructure and superstructure is<br />

minimised.<br />

TOP BEAM<br />

SUPPORT COLUMN<br />

Bearing assembly designed to withstand<br />

uplift loads

Failsafe Design<br />

If required, we can design bearings with<br />

either an internal or external failsafe<br />

system.<br />

Failsafe devices are provided to support<br />

the structure in the highly unlikely event<br />

of catastrophic failure (eg. fire).<br />

Failsafe devices typically consist of<br />

cylindrical steel <strong>com</strong>ponents designed<br />

to support the column load.<br />

In acoustic isolation applications, the<br />

clearance between the failsafe device<br />

and upper beam under full load is<br />

critical.<br />

This gap must not be bridged under<br />

normal operation however must also<br />

minimise the potential movement in the<br />

structure if any bearings fail.<br />

Our focus is to supply high<br />

quality products that provide<br />

superior acoustic performance.<br />

In general, all bearings are fully tested<br />

and verified using our extensive inhouse<br />

testing facilities.<br />

Our manufacturing site in Brisbane,<br />

Australia is certified to the Quality<br />

Standard ISO 9001.<br />

We are focussed on working closely<br />

with our clients to develop innovative<br />

designs, cost-effective solutions and<br />

ensure on-time deliveries.

<strong>Trelleborg</strong> Hi-Shear <strong>Bearings</strong><br />

<strong>Trelleborg</strong> has developed innovative<br />

manufacturing techniques to<br />

significantly increase the shear stiffness<br />

of bearings supporting vertical loads.<br />

50kN<br />

1000kN<br />

SUPPORT COLUMN<br />

railway vibrations<br />

5<br />

mm<br />

BEAM<br />

Typical Hi-shear laminated bearing<br />

Laminated bearings typically have very<br />

low ratios of shear stiffness to vertical<br />

stiffness (ie. < 1%). Our Hi-Shear<br />

<strong>Bearings</strong> provide shear stiffnesses, in<br />

all lateral directions, in excess of 4% of<br />

the vertical stiffness.<br />

To provide lateral restraint against<br />

wind and earthquake loads, acoustic<br />

isolation systems conventionally employ<br />

a large number of lateral bearing<br />

assemblies that are often supplied pre<strong>com</strong>pressed.<br />

Our bearings with the integrated design<br />

of high vertical and shear stiffness<br />

significantly reduce or eliminate the<br />

requirement for supply and installation<br />

of pre-<strong>com</strong>pressed lateral bearing<br />

assemblies and the additional structure<br />

required to support these lateral<br />

bearings.<br />

Our integrated bearings provide a<br />

simple, cost effective, more reliable<br />

and acoustically superior system of<br />

isolation.<br />

Recent projects include the Theatres on<br />

the Bay in Singapore, Hong Kong Movie<br />

City and the Adelaide Convention Centre<br />

in Australia.<br />

Lo-Frequency <strong>Bearings</strong><br />

<strong>Trelleborg</strong> has developed an innovative<br />

elastomeric bearing for acoustic<br />

isolation of low frequency vibrations (eg.<br />

< 8 Hz). The conventional method often<br />

used to isolate low frequency vibrations<br />

is to install an arrangement of steel<br />

springs.<br />

PRECOMPRESSION BOLT<br />

(release after installation)<br />

BEAM<br />

SUPPORT COLUMN<br />

railway vibrations<br />

Compressed low frequency acoustic<br />

vibration isolation bearing<br />

Elastomeric bearings provide superior<br />

acoustic isolation over the long term<br />

<strong>com</strong>pared with other alternatives such<br />

as steel springs.<br />

• Elastomeric bearings contain<br />

inherent material damping that<br />

limits vibration amplification at the<br />

system’s natural frequency. Steel<br />

springs inherently lose vibration<br />

isolation at their internal resonance<br />

and often require supplementary<br />

damping systems.<br />

• More corrosion resistant <strong>com</strong>pared<br />

with steel springs<br />

• Less mechanical <strong>com</strong>plexity<br />

<strong>com</strong>pared with steel springs<br />

• History of good long-term durability<br />

indicates an effective life in<br />

excess of 50 years. Resistance to<br />

degradation is superior to steel and<br />

concrete.<br />

Lo-frequency bearings can be supplied<br />

either <strong>com</strong>pressed or un<strong>com</strong>pressed.<br />

They are specially designed with<br />

increased stability and increased lateral<br />

restraint.

<strong>Trelleborg</strong> Floating Slab Track <strong>Bearings</strong><br />

The majority of the building isolation<br />

projects we have been involved with are<br />

the result of noise and vibration from<br />

rail systems. We also have expertise in<br />

preventing or alleviating the effects of<br />

sound transmission from the source.<br />

<strong>Trelleborg</strong> is a leading supplier of<br />

rail track isolation systems including<br />

floating slab track bearings.<br />

If a high degree of vibration attenuation<br />

is required to acoustically isolate<br />

a performance space then our<br />

re<strong>com</strong>mendation is a <strong>com</strong>bined<br />

system of acoustic bearings to isolate<br />

vibrations into the building structure<br />

and floating slab track bearings to<br />

isolate noise and vibration out of the<br />

rail structure. This “double isolation”<br />

system has been specified on a number<br />

of our projects.

Other <strong>Trelleborg</strong> Products<br />

Elastomeric Bearing<br />

Pads & Strips<br />

Elastomeric Bridge <strong>Bearings</strong><br />

Pot <strong>Bearings</strong><br />

Fixed (TF), Guided (TGe), Free (TGa)<br />

Rail Track <strong>Isolation</strong> Systems<br />

Structural Sliding<br />

and Fixed <strong>Bearings</strong><br />

Impact Products<br />

Fenders, Bumpers, Guards and Stoppers<br />

Brisbane<br />

Phone +61 (7) 3866 7444<br />

Facsimile + 61 (7) 3263 4912<br />

Email: tqr.info@trelleborg.<strong>com</strong><br />

www.trelleborg.<strong>com</strong>.<strong>au</strong><br />

Perth<br />

Phone +61 (8) 9256 6000<br />

Facsimile + 61 (8) 9353 5990<br />

Email: admin.perth@trelleborg.<strong>com</strong>.<strong>au</strong><br />

www.trelleborg.<strong>com</strong>.<strong>au</strong><br />

CREATIVE 9089 7/08