Metallic Expansion Joints - Thorburn Flex Inc

Metallic Expansion Joints - Thorburn Flex Inc

Metallic Expansion Joints - Thorburn Flex Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

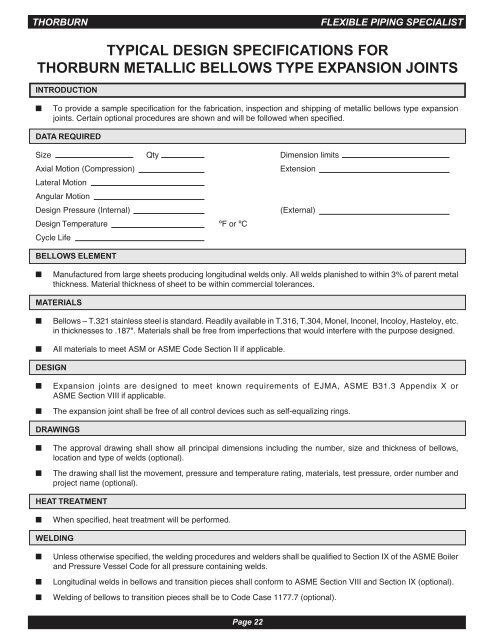

THORBURN<br />

FLEXIBLE PIPING SPECIALIST<br />

TYPICAL DESIGN SPECIFICATIONS FOR<br />

THORBURN METALLIC BELLOWS TYPE EXPANSION JOINTS<br />

INTRODUCTION<br />

■<br />

To provide a sample specification for the fabrication, inspection and shipping of metallic bellows type expansion<br />

joints. Certain optional procedures are shown and will be followed when specified.<br />

DATA REQUIRED<br />

Size Qty Dimension limits<br />

Axial Motion (Compression)<br />

Extension<br />

Lateral Motion<br />

Angular Motion<br />

Design Pressure (Internal)<br />

(External)<br />

Design Temperature ºF or ºC<br />

Cycle Life<br />

BELLOWS ELEMENT<br />

■<br />

Manufactured from large sheets producing longitudinal welds only. All welds planished to within 3% of parent metal<br />

thickness. Material thickness of sheet to be within commercial tolerances.<br />

MATERIALS<br />

■<br />

■<br />

Bellows – T.321 stainless steel is standard. Readily available in T.316, T.304, Monel, <strong>Inc</strong>onel, <strong>Inc</strong>oloy, Hasteloy, etc.<br />

in thicknesses to .187". Materials shall be free from imperfections that would interfere with the purpose designed.<br />

All materials to meet ASM or ASME Code Section II if applicable.<br />

DESIGN<br />

■<br />

■<br />

<strong>Expansion</strong> joints are designed to meet known requirements of EJMA, ASME B31.3 Appendix X or<br />

ASME Section VIII if applicable.<br />

The expansion joint shall be free of all control devices such as self-equalizing rings.<br />

DRAWINGS<br />

■<br />

■<br />

The approval drawing shall show all principal dimensions including the number, size and thickness of bellows,<br />

location and type of welds (optional).<br />

The drawing shall list the movement, pressure and temperature rating, materials, test pressure, order number and<br />

project name (optional).<br />

HEAT TREATMENT<br />

■<br />

When specified, heat treatment will be performed.<br />

WELDING<br />

■<br />

■<br />

■<br />

Unless otherwise specified, the welding procedures and welders shall be qualified to Section IX of the ASME Boiler<br />

and Pressure Vessel Code for all pressure containing welds.<br />

Longitudinal welds in bellows and transition pieces shall conform to ASME Section VIII and Section IX (optional).<br />

Welding of bellows to transition pieces shall be to Code Case 1177.7 (optional).<br />

Page 22