Metallic Expansion Joints - Thorburn Flex Inc

Metallic Expansion Joints - Thorburn Flex Inc

Metallic Expansion Joints - Thorburn Flex Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

THORBURN<br />

FLEXIBLE PIPING SPECIALIST<br />

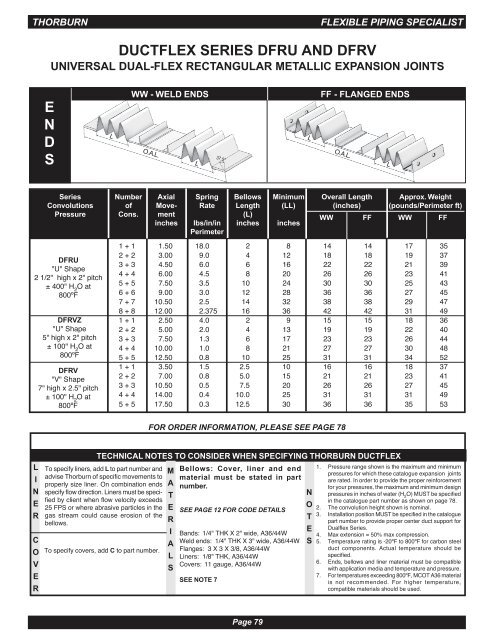

DUCTFLEX SERIES DFRU AND DFRV<br />

UNIVERSAL DUAL-FLEX RECTANGULAR METALLIC EXPANSION JOINTS<br />

E<br />

N<br />

D<br />

S<br />

WW - WELD ENDS<br />

L O.A.L.<br />

L<br />

37.5°<br />

L<br />

FF - FLANGED ENDS<br />

O.A.L.<br />

L<br />

Series Number Axial Spring Bellows Minimum Overall Length Approx. Weight<br />

Convolutions of Move- Rate Length (LL) (inches) (pounds/Perimeter ft)<br />

Pressure Cons. ment (L)<br />

inches lbs/in/in inches inches<br />

Perimeter<br />

WW FF WW FF<br />

DFRU<br />

"U" Shape<br />

2 1/2" high x 2" pitch<br />

± 400" H 2<br />

O at<br />

800ºF<br />

DFRVZ<br />

"U" Shape<br />

5" high x 2" pitch<br />

± 100" H 2<br />

O at<br />

800ºF<br />

DFRV<br />

"V" Shape<br />

7" high x 2.5" pitch<br />

± 100" H 2<br />

O at<br />

800ºF<br />

1 + 1 1.50 18.0 2 8 14 14 17 35<br />

2 + 2 3.00 9.0 4 12 18 18 19 37<br />

3 + 3 4.50 6.0 6 16 22 22 21 39<br />

4 + 4 6.00 4.5 8 20 26 26 23 41<br />

5 + 5 7.50 3.5 10 24 30 30 25 43<br />

6 + 6 9.00 3.0 12 28 36 36 27 45<br />

7 + 7 10.50 2.5 14 32 38 38 29 47<br />

8 + 8 12.00 2.375 16 36 42 42 31 49<br />

1 + 1 2.50 4.0 2 9 15 15 18 36<br />

2 + 2 5.00 2.0 4 13 19 19 22 40<br />

3 + 3 7.50 1.3 6 17 23 23 26 44<br />

4 + 4 10.00 1.0 8 21 27 27 30 48<br />

5 + 5 12.50 0.8 10 25 31 31 34 52<br />

1 + 1 3.50 1.5 2.5 10 16 16 18 37<br />

2 + 2 7.00 0.8 5.0 15 21 21 23 41<br />

3 + 3 10.50 0.5 7.5 20 26 26 27 45<br />

4 + 4 14.00 0.4 10.0 25 31 31 31 49<br />

5 + 5 17.50 0.3 12.5 30 36 36 35 53<br />

FOR ORDER INFORMATION, PLEASE SEE PAGE 78<br />

L<br />

I<br />

N<br />

E<br />

R<br />

C<br />

O<br />

V<br />

E<br />

R<br />

TECHNICAL NOTES TO CONSIDER WHEN SPECIFYING THORBURN DUCTFLEX<br />

To specify liners, add L to part number and<br />

advise <strong>Thorburn</strong> of specific movements to<br />

properly size liner. On combination ends<br />

specify flow direction. Liners must be specified<br />

by client when flow velocity exceeds<br />

25 FPS or where abrasive particles in the<br />

gas stream could cause erosion of the<br />

bellows.<br />

To specify covers, add C to part number.<br />

M<br />

A<br />

T<br />

E<br />

R<br />

I<br />

A<br />

L<br />

S<br />

Bellows: Cover, liner and end<br />

material must be stated in part<br />

number.<br />

SEE PAGE 12 FOR CODE DETAILS<br />

Bands: 1/4" THK X 2" wide, A36/44W<br />

Weld ends: 1/4" THK X 3" wide, A36/44W<br />

Flanges: 3 X 3 X 3/8, A36/44W<br />

Liners: 1/8" THK, A36/44W<br />

Covers: 11 gauge, A36/44W<br />

SEE NOTE 7<br />

N<br />

O<br />

T<br />

E<br />

S<br />

1. Pressure range shown is the maximum and minimum<br />

pressures for which these catalogue expansion joints<br />

are rated. In order to provide the proper reinforcement<br />

for your pressures, the maximum and minimum design<br />

pressures in inches of water (H 2<br />

O) MUST be specified<br />

in the catalogue part number as shown on page 78.<br />

2. The convolution height shown is nominal.<br />

3. Installation position MUST be specified in the catalogue<br />

part number to provide proper center duct support for<br />

Dualflex Series.<br />

4. Max extension = 50% max compression.<br />

5. Temperature rating is -20ºF to 800ºF for carbon steel<br />

duct components. Actual temperature should be<br />

specified.<br />

6. Ends, bellows and liner material must be compatible<br />

with application media and temperature and pressure.<br />

7. For temperatures exceeding 800ºF, MCOT A36 material<br />

is not recommended. For higher temperature,<br />

compatible materials should be used.<br />

Page 79