b.tech textile technology - Technical symposium.

b.tech textile technology - Technical symposium.

b.tech textile technology - Technical symposium.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

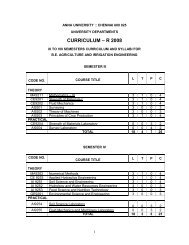

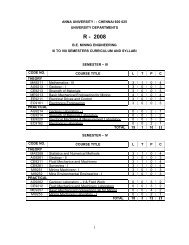

UNIT IV PERT / CPM 9<br />

CPM and PERT networks - finding critical path, probability and cost consideration in the project<br />

scheduling<br />

UNIT V GAME THEORY AND QUEING THEORY 9<br />

Game theory – two person zero sum games, saddle point, Dominance rule, graphical method.<br />

matrices method; Queuing theory – basic elements of queuing model, single and multi channel<br />

models- infinite number of customers and infinite calling source<br />

TOTAL : 45 PERIODS<br />

REFERENCES<br />

1. Heizer J. and Render B., “Production and Operations Management”, Prentice Hall, New<br />

Jersey, 1993, ISBN: 0-205-14048-3.<br />

2. Hamdy A. and Taha, “Operations Research an introduction”, Maxmillan Publishing<br />

Company, New York, Third Edition, 1982.<br />

3. Panneerselvam R., “Operations Research”, Prentice Hall of india, 4 th print, 2003.<br />

4. Hamdy A. and Taha, “An introduction to Operations Research”, Maxmillan Publishing<br />

Company, New York, V th edition, 1996.<br />

5. Narayan Bhat U., “Elements of Applied Stochastic processes”, John Wiley and Sons, New<br />

York, 1972.<br />

6. Fredrick S., Hiller and Gerald J Liberman., “Introduction to Operations Research”, Industrial<br />

Engineering Series, International edition, McGraw-Hill, New York, 1995.<br />

TT 9042 PRODUCTION AND OPERATIONS MANAGEMENT L T P C<br />

3 0 0 3<br />

UNIT I 9<br />

Factors of production; environmental and social concerns of operations; design of production<br />

system; forecasting in production and operation management – various qualitative and<br />

quantitative <strong>tech</strong>niques<br />

UNIT II 9<br />

Capacity planning – single stage system, multistage system; facility planning – objectives;<br />

different types of layouts, developing process layout, product layout; job design <strong>tech</strong>niques<br />

UNIT III 9<br />

Aggregate production planning – procedure, importance; scheduling in operation management –<br />

mass production system, batch and job shop<br />

UNIT IV 9<br />

Material management – material planning, purchase, stores, material handling and disposal;<br />

inventory models – basic inventory model, gradual replacement model, basic model with<br />

backlogging, bulk discount model, independent demand system for multiple products, models<br />

with uncertain demand, multiple period model; MRP-objectives, elements of MRP, MRP<br />

computation, implementation<br />

UNIT V 9<br />

Concepts - Total Productive Maintenance, Autonomous Maintenance, Just In Time, Total<br />

Quality Management, Automated Technology, Hard Technology, Soft Technology, Hybrid<br />

Technology, CIM, CAD, GT, CAM, CAPP, robotic FMS; application of MIS in production and<br />

operations management<br />

TOTAL : 45 PERIODS<br />

54