Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Penpak raises <strong>the</strong><br />

manufacturing bar<br />

Peninsula Packaging is entrenching its position as one of<br />

<strong>the</strong> premier manufacturers of blown and printed film in <strong>the</strong><br />

Western Cape with <strong>the</strong> recent commissioning of state-of-<strong>the</strong>-art<br />

equipment valued in excess of R30 million.<br />

Peninsula Packaging (Penpak)<br />

is in <strong>the</strong> process of reorganising<br />

its production capabilities to<br />

ensure that each operation is a centre<br />

of excellence, offering <strong>the</strong> very best in<br />

quality in both production and print.<br />

That was <strong>the</strong> message from regional<br />

chief executive Keith Watkins at an<br />

open day attended by 70 customers.<br />

‘The new equipment is industry-leading<br />

kit and will provide opportunities and<br />

capabilities that we simply did not have<br />

access to in <strong>the</strong> past,’ Keith said.<br />

The new Reifenhäuser-Keifel extruder<br />

– one of four in <strong>the</strong> Group – is capable<br />

of producing 500kg per hour of multilayered<br />

film and, coupled with its<br />

radioactive isotope gauge monitoring<br />

system, can ensure that manufacturing<br />

specifications are maintained within 2%<br />

of tolerances.<br />

Ano<strong>the</strong>r addition to Penpak’s<br />

production line is <strong>the</strong> W&H Miraflex<br />

eight-colour printer. With a high runspeed<br />

and advanced registration<br />

technology, <strong>the</strong> new printer is capable<br />

of producing <strong>the</strong> highest-quality printed<br />

film, with product changeovers taking<br />

less than 20 minutes.<br />

‘This equipment is part of our national<br />

programme to streng<strong>the</strong>n and position<br />

our operations as <strong>the</strong> industry leaders<br />

in <strong>the</strong>ir chosen segments,’ Keith said.<br />

‘The new multi-layer extruder will<br />

produce several product lines, including<br />

specialised film <strong>for</strong> <strong>the</strong> milk-sachet<br />

market. This industry is capital intensive<br />

and demands regular investment to stay<br />

abreast of technological advances.<br />

Astrapak is committed to remaining a<br />

leader, a strategy underscored by <strong>the</strong><br />

Group’s investment of around R180<br />

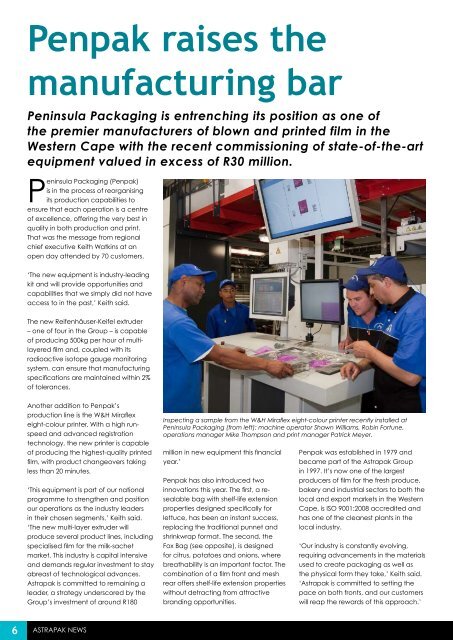

Inspecting a sample from <strong>the</strong> W&H Miraflex eight-colour printer recently installed at<br />

Peninsula Packaging (from left): machine operator Shawn Williams, Robin Fortune,<br />

operations manager Mike Thompson and print manager Patrick Meyer.<br />

million in new equipment this financial<br />

year.’<br />

Penpak has also introduced two<br />

innovations this year. The first, a resealable<br />

bag with shelf-life extension<br />

properties designed specifically <strong>for</strong><br />

lettuce, has been an instant success,<br />

replacing <strong>the</strong> traditional punnet and<br />

shrinkwrap <strong>for</strong>mat. The second, <strong>the</strong><br />

Fox Bag (see opposite), is designed<br />

<strong>for</strong> citrus, potatoes and onions, where<br />

breathability is an important factor. The<br />

combination of a film front and mesh<br />

rear offers shelf-life extension properties<br />

without detracting from attractive<br />

branding opportunities.<br />

Penpak was established in 1979 and<br />

became part of <strong>the</strong> Astrapak Group<br />

in 1997. It’s now one of <strong>the</strong> largest<br />

producers of film <strong>for</strong> <strong>the</strong> fresh produce,<br />

bakery and industrial sectors to both <strong>the</strong><br />

local and export markets in <strong>the</strong> Western<br />

Cape, is ISO 9001:2008 accredited and<br />

has one of <strong>the</strong> cleanest plants in <strong>the</strong><br />

local industry.<br />

‘Our industry is constantly evolving,<br />

requiring advancements in <strong>the</strong> materials<br />

used to create packaging as well as<br />

<strong>the</strong> physical <strong>for</strong>m <strong>the</strong>y take,’ Keith said.<br />

‘Astrapak is committed to setting <strong>the</strong><br />

pace on both fronts, and our customers<br />

will reap <strong>the</strong> rewards of this approach.’<br />

6<br />

ASTRAPAK NEWS