Ultraflux Clamp-on probe SE_1586E2 - hsa-asia.com

Ultraflux Clamp-on probe SE_1586E2 - hsa-asia.com

Ultraflux Clamp-on probe SE_1586E2 - hsa-asia.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Ultras<strong>on</strong>ic flow measurements<br />

Ref.<strong>1586E2</strong><br />

<str<strong>on</strong>g>Clamp</str<strong>on</strong>g>-<strong>on</strong> <strong>probe</strong>s<br />

For flow measurements<br />

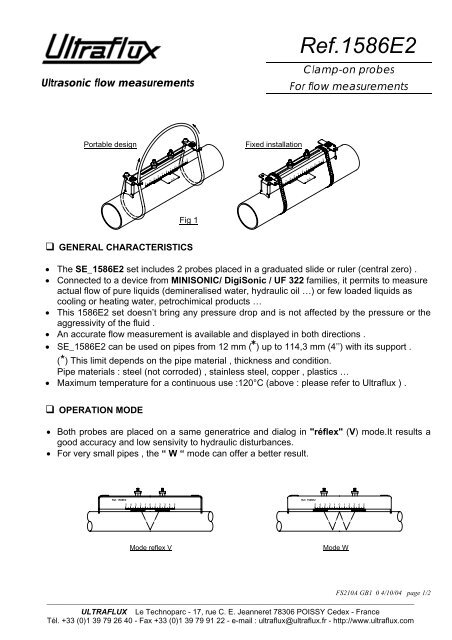

Portable design<br />

Fixed installati<strong>on</strong><br />

5<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

4<br />

3<br />

2<br />

1<br />

D.S<br />

0<br />

1<br />

2<br />

3<br />

4<br />

5<br />

4<br />

3<br />

2<br />

1<br />

D.S<br />

Fig 1<br />

GENERAL CHARACTERISTICS<br />

• The <strong>SE</strong>_<strong>1586E2</strong> set includes 2 <strong>probe</strong>s placed in a graduated slide or ruler (central zero) .<br />

• C<strong>on</strong>nected to a device from MINISONIC/ DigiS<strong>on</strong>ic / UF 322 families, it permits to measure<br />

actual flow of pure liquids (demineralised water, hydraulic oil …) or few loaded liquids as<br />

cooling or heating water, petrochimical products …<br />

• This <strong>1586E2</strong> set doesn’t bring any pressure drop and is not affected by the pressure or the<br />

aggressivity of the fluid .<br />

• An accurate flow measurement is available and displayed in both directi<strong>on</strong>s .<br />

• <strong>SE</strong>_<strong>1586E2</strong> can be used <strong>on</strong> pipes from 12 mm (*) up to 114,3 mm (4’’) with its support .<br />

(*) This limit depends <strong>on</strong> the pipe material , thickness and c<strong>on</strong>diti<strong>on</strong>.<br />

Pipe materials : steel (not corroded) , stainless steel, copper , plastics …<br />

• Maximum temperature for a c<strong>on</strong>tinuous use :120°C (above : please refer to <str<strong>on</strong>g>Ultraflux</str<strong>on</strong>g> ) .<br />

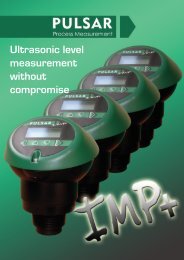

OPERATION MODE<br />

• Both <strong>probe</strong>s are placed <strong>on</strong> a same generatrice and dialog in "réflex" (V) mode.It results a<br />

good accuracy and low sensivity to hydraulic disturbances.<br />

• For very small pipes , the “ W “ mode can offer a better result.<br />

Ref. <strong>1586E2</strong><br />

Ref. <strong>1586E2</strong><br />

5 4 3 2 1 0 1 2 3 4 5<br />

5<br />

4 3 2<br />

1 0<br />

1<br />

2 3 4<br />

5<br />

Mode reflex V<br />

Mode W<br />

FS210A GB1 0 4/10/04 page 1/2<br />

________________________________________________________________________________________________<br />

ULTRAFLUX Le Technoparc - 17, rue C. E. Jeanneret 78306 POISSY Cedex - France<br />

Tél. +33 (0)1 39 79 26 40 - Fax +33 (0)1 39 79 91 22 - e-mail : ultraflux@ultraflux.fr - http://www.ultraflux.<strong>com</strong>

PROBE LOCATION<br />

• When possible, locate <strong>probe</strong>s upstream from a hydraulic disturbance..<br />

• When possible, respect following minimum straight length :<br />

10 Ø upstream<br />

3 Ø downstream, Ø means diameter of the pipe .<br />

• In the case of an horiz<strong>on</strong>tal pipe, avoid installing the <strong>probe</strong>s<br />

<strong>on</strong> the top or the bottom part of the pipe because the<br />

risk of bubbles or deposits<br />

On a vertical pipe, there is no restricti<strong>on</strong> for <strong>probe</strong> locati<strong>on</strong>.<br />

• Requested accuracy <strong>on</strong> distance inter-<strong>probe</strong>s : +/- 0,5 mm<br />

• The c<strong>on</strong>verter calculates and displays this distance D.S to be adjusted between <strong>probe</strong>s<br />

around the central zero (see fig 1).<br />

PROBES INSTALLATION<br />

• Clean upthe pipe (rust, roughness). In most cases, the paint doesn’t matter .<br />

• Apply plenty of coupling agent <strong>on</strong> <strong>probe</strong>s face and <strong>on</strong> the pipe wall at the locati<strong>on</strong> .<br />

- Standard coupling gel for temperatures lower than 60°C (during a few hours).<br />

- High temperature special grease for temperatures up to 120°C or l<strong>on</strong>g term use .<br />

- Coupling elastomer, coated <strong>on</strong> both faces with special grease, for very l<strong>on</strong>g term use. It<br />

must be hardly tight.<br />

• The fixing is d<strong>on</strong>e by stretching the elastic around the pipe, or with stainless steel straps for<br />

fixed installati<strong>on</strong> (see fig 1).<br />

CONNECTIONS<br />

• The <strong>probe</strong> holder is equipped of two push-pull c<strong>on</strong>nectors for twinax shielded cables.<br />

• Use the cables re<strong>com</strong>mended by ULTRAFLUX.<br />

• C<strong>on</strong>nect upstream and downstream transducers to c<strong>on</strong>verter using corresp<strong>on</strong>ding inputs .<br />

COMMISSIONING<br />

• A good installati<strong>on</strong> in good site c<strong>on</strong>diti<strong>on</strong> must give a good echo signal and a reliable<br />

measurement result.<br />

• If the acoustic transmissi<strong>on</strong> result through the pipe is too poor (no echo or too high<br />

amplificati<strong>on</strong> gain), proceed as follows :<br />

- Check the distance D.S .between <strong>probe</strong>s .<br />

- Check the coupling agent between the <strong>probe</strong>s and the pipe .<br />

- If fault persists, try at another locati<strong>on</strong> (pipe internally corroded ?).<br />

- If no result, try with lower frequency transducers .<br />

- If liquid is flowing bubbles, try to improve these c<strong>on</strong>diti<strong>on</strong>s.<br />

FS210A GB1 04/10/04 page 2/2<br />

________________________________________________________________________________________________<br />

ULTRAFLUX Le Technoparc - 17, rue C. E. Jeanneret 78306 POISSY Cedex - France<br />

Tél. +33 (0)1 39 79 26 40 - Fax +33 (0)1 39 79 91 22 - e-mail : ultraflux@ultraflux.fr - http://www.ultraflux.<strong>com</strong>