Haas lifting instruction_lathe and mill

Haas lifting instruction_lathe and mill

Haas lifting instruction_lathe and mill

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

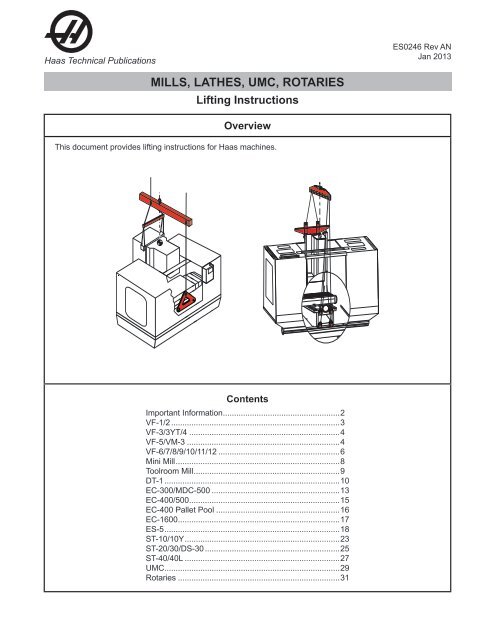

<strong>Haas</strong> Technical Publications<br />

ES0246 Rev AN<br />

Jan 2013<br />

MILLS, <strong>lathe</strong>s, UMC, rotaries<br />

Lifting Instructions<br />

Overview<br />

This document provides <strong>lifting</strong> <strong>instruction</strong>s for <strong>Haas</strong> machines.<br />

Contents<br />

Important Information.....................................................2<br />

VF-1/2............................................................................3<br />

VF-3/3YT/4....................................................................4<br />

VF-5/VM-3.....................................................................4<br />

VF-6/7/8/9/10/11/12.......................................................6<br />

Mini Mill..........................................................................8<br />

Toolroom Mill..................................................................9<br />

DT-1...............................................................................10<br />

EC-300/MDC-500..........................................................13<br />

EC-400/500....................................................................15<br />

EC-400 Pallet Pool........................................................16<br />

EC-1600.........................................................................17<br />

ES-5...............................................................................18<br />

ST-10/10Y......................................................................23<br />

ST-20/30/DS-30.............................................................25<br />

ST-40/40L......................................................................27<br />

UMC...............................................................................29<br />

Rotaries.........................................................................31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Important Information<br />

Please read these <strong>instruction</strong>s in their entirety before attempting to lift the <strong>mill</strong>.<br />

WARNING<br />

It is imperative that preparation <strong>and</strong> <strong>lifting</strong> of the machine be<br />

performed by PROFESSIONAL RIGGERS. These <strong>instruction</strong>s are to be<br />

used as a reference guide only.<br />

Specialized equipment is necessary to ensure that the machine is secure <strong>and</strong> level while being raised.<br />

IMPORTANT: VF-Series - The top column attachment points are the main <strong>lifting</strong> points <strong>and</strong> should remain<br />

vertically oriented to the floor throughout the entire lift.<br />

The front chains attached to the base are to help stabilize the machine <strong>and</strong> should not carry the main<br />

load.<br />

When <strong>lifting</strong> the machine, slowly lift until all chains are taut, then lift the machine ensuring it remains<br />

balanced.<br />

Lifting brackets <strong>and</strong> hardware must be removed before machine operation, unless otherwise noted.<br />

Lifting kits are available for most machines. Kits include <strong>lifting</strong> brackets <strong>and</strong> mounting hardware. It is<br />

the customer's responsibility to supply all chains <strong>and</strong> spreader bars required to properly lift the machine.<br />

Contact a local <strong>Haas</strong> Factory Outlet (HFO) for more information.<br />

Store <strong>lifting</strong> brackets <strong>and</strong> hardware in a safe place. They must be used if the machine is to be moved. Only<br />

<strong>Haas</strong> supplied replacement hardware is authorized for use. If <strong>lifting</strong> hardware is lost or damaged, contact<br />

your HFO.<br />

Refer to the <strong>lifting</strong> placard located on the rear of the machine for model specific <strong>lifting</strong> information.<br />

For <strong>lifting</strong> of machines built before Oct 2012, refer to ES0246 Rev AL available from <strong>Haas</strong> Automation.<br />

ES0246 Rev AN Jan 2013 Page 2 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Vertical Machining Centers<br />

VF-1 Series, VF-2 Series, VM-2 Lift Placard<br />

Refer to the <strong>lifting</strong> placard for small VMCs. Attach the <strong>lifting</strong> bracket <strong>and</strong> chains as shown. Ensure that the<br />

chains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars.<br />

90°<br />

13"<br />

(330 mm)<br />

14"<br />

(356 mm)<br />

VF-1<br />

VF-2<br />

45"<br />

(1143 mm)<br />

VF-2YT<br />

VM-2<br />

51"<br />

(1295 mm)<br />

90°<br />

24"<br />

(607 mm)<br />

6' 10" (2083 mm)<br />

19" (483 mm)<br />

29-0881A Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

ES0246 Rev AN Jan 2013 Page 3 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

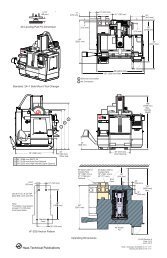

Medium VMC Lift Placard<br />

Refer to the <strong>lifting</strong> placard for medium VMCs. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the<br />

chains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars.<br />

13" (330 mm)<br />

16" (406 mm)<br />

Medium VMC<br />

51" (1295 mm)<br />

29" (737 mm)<br />

VF-3<br />

VF-4<br />

9' 6"<br />

(2896 mm)<br />

29" (737 mm)<br />

90°<br />

90°<br />

18" (457 mm)<br />

65" (1651 mm)<br />

16" (406 mm)<br />

9' 6"<br />

(2896 mm)<br />

29" (737 mm)<br />

VF-3YT<br />

VF-5<br />

VM-3<br />

29-0882A Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

ES0246 Rev AN Jan 2013 Page 4 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

VF-3/4 Lifting Hardware Details<br />

1. Install two <strong>lifting</strong> brackets with 1/2"-13 SHCS<br />

<strong>and</strong> 1/2" hard washers. Use one washer above<br />

the bracket <strong>and</strong> two below. H<strong>and</strong> tighten only.<br />

VF-3YT/5, VM-3 Lifting Hardware Details<br />

1. Install two 5/8"-11 eyebolts into the base<br />

casting near the Y-axis way cover. H<strong>and</strong><br />

tighten the eyebolt with the eye facing the front<br />

of the machine.<br />

ES0246 Rev AN Jan 2013 Page 5 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Large VMC Lift Placard<br />

Refer to the <strong>lifting</strong> placard for large VMCs. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the<br />

chains do not contact the sheet metal enclosure or electrical cables. Note the use of spreader bars <strong>and</strong><br />

spacers.<br />

VF-6/7/10/12: 83" (2108 mm)<br />

VF-8/9/11: 106" (2692 mm)<br />

VF-6/7/10/12, VM-6: 39" (991 mm)<br />

VF-8/9/11, VR-8/11: 46" (1168 mm)<br />

106"<br />

(2692 mm)<br />

117"<br />

(2972 mm)<br />

VF-8/9/11: 46" (1168 mm)<br />

VF-6/7/10/12: 47" (1194 mm)<br />

40"<br />

(1020 mm)<br />

90°<br />

90°<br />

29-0883A Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

ES0246 Rev AN Jan 2013 Page 6 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

VF-6 to 12, VM-6, VR-8/11 Lifting Hardware Details<br />

1. The <strong>lifting</strong> bracket can be found beneath<br />

the step enclosure. Remove the two steps<br />

located on the sides of the Y-axis way cover.<br />

1. Remove<br />

screws<br />

2. Slide step<br />

out<br />

2. The bracket will remain in place after <strong>lifting</strong><br />

operation is complete. Replace the steps<br />

over the <strong>lifting</strong> brackets.<br />

Remove the step from the inside-front enclosure<br />

The <strong>lifting</strong> brac<br />

Lifting<br />

Bracket<br />

ES0246 Rev AN Jan 2013 Page 7 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Mini Mill Lift Placard<br />

<strong>Haas</strong> Automation does not provide a <strong>lifting</strong> kit for the Mini Mill. It is the machine rigger’s responsibility to<br />

provide the means to lift <strong>and</strong> position the Mini Mill. The customer must supply all hardware required for<br />

<strong>lifting</strong>.<br />

Attach chains to the <strong>lifting</strong> points as shown. Ensure that the chains do not contact the sheet metal enclosure<br />

or electrical cables. Note the use of spreader bars.<br />

ES0246 Rev AN Jan 2013 Page 8 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

TM-1/1P to TM-3/3P Lift Placard<br />

<strong>Haas</strong> Automation does not provide a <strong>lifting</strong> kit for the Toolroom Mill. It is the machine rigger’s responsibility<br />

to provide the means to lift <strong>and</strong> position the Toolroom Mill. The customer must supply all hardware required<br />

for <strong>lifting</strong>. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the chains do not contact the sheet metal<br />

enclosure or electrical cables.<br />

TM-1/1P <strong>and</strong> TM-2/2P: The front <strong>lifting</strong> points are 1/2"-13 tapped holes.<br />

TM-3/3P: Remove the pendant arm shipping bracket before installing hardware. Move the pendant arm to<br />

the operating position <strong>and</strong> secure in place to avoid damage from <strong>lifting</strong> chains. The front <strong>lifting</strong> points are<br />

1/2" (13 mm) through holes which will accept 1/2" (13 mm) eyebolts, washers, <strong>and</strong> nuts.<br />

*<br />

45" (1140 mm) TM-1/1P/2/2P<br />

57" (1450 mm) TM-3/3P<br />

TM-1/1P<br />

TM-2/2P<br />

TM-3/3P<br />

4500 lb<br />

(2050 kg)<br />

5000 lb<br />

(2300 kg)<br />

6500 lb<br />

(2950 kg)<br />

41"<br />

(1041 mm)<br />

TM-3/3P<br />

97"<br />

(2460 mm)<br />

TM-1/1P<br />

TM-2/2P<br />

110"<br />

(2790 mm)<br />

TM-1/1P: 18" (432 mm)<br />

TM-2/2P: 20" (483 mm)<br />

TM-3/3P: 30" (762 mm)<br />

TM-3/3P<br />

ø1/2" (13mm) Through Hole<br />

TM-1/1P/2/2P<br />

ø1/2"-13 Threaded Hole<br />

29-0888A Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

ES0246 Rev AN Jan 2013 Page 9 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

DT-1 Lift Placard<br />

Refer to the <strong>lifting</strong> placard for the DT-1. Attach <strong>lifting</strong> chains <strong>and</strong> hooks to the <strong>lifting</strong> points as shown. Ensure<br />

that the chains do not contact the sheet metal enclosure or electrical cables.<br />

2 x 156"<br />

(3962 mm)<br />

2 x 100"<br />

(2540 mm)<br />

34"<br />

(864 mm)<br />

12"<br />

(305 mm)<br />

ES0246 Rev AN Jan 2013 Page 10 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

DT-1 Lifting Hardware Details<br />

1. Loosen, but do not remove the top row of<br />

screws for the Y-axis way cover.<br />

Loosen<br />

2. Remove the two lower screws.<br />

Remove<br />

3. Remove the two bolts on the front sides of the<br />

Y-axis way cover.<br />

Remove<br />

ES0246 Rev AN Jan 2013 Page 11 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

4. Lift up the Y-axis way cover over the linear<br />

guides <strong>and</strong> push the cover toward the table.<br />

5. Install the eyebolts <strong>and</strong> necessary shackles.<br />

6. Remove the screws to open the roof access<br />

panel for <strong>lifting</strong> strap access.<br />

ES0246 Rev AN Jan 2013 Page 12 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Horizontal Machining Centers<br />

EC-300/MDC-500 Lift Placard<br />

Refer to the <strong>lifting</strong> placard for EC-300/MDC-500. Attach chains to the <strong>lifting</strong> points as shown. Ensure that<br />

the chains do not contact the sheet metal enclosure or electrical cables.<br />

ES0246 Rev AN Jan 2013 Page 13 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-300/MDC-500 Lifting Hardware Details<br />

1. Before <strong>lifting</strong> the machine, remove the hole<br />

plugs <strong>and</strong> install four 1"-8 TPI forged steel<br />

shoulder eyebolts, 1" steel washers <strong>and</strong><br />

spacers.<br />

EC-300 Only<br />

Top Panels<br />

EC-300 only - Remove the two top panels.<br />

C<br />

42” (107 cm)<br />

16” (41 cm)<br />

2. Once the machine is in position, remove the<br />

eyebolts from the <strong>lifting</strong> holes <strong>and</strong> replace with<br />

bolts <strong>and</strong> washers<br />

3. After installation, re-install the chip screen with<br />

bolts <strong>and</strong> washers.<br />

This dimension is<br />

critical to prevent the<br />

lift chain from<br />

contacting the<br />

spindle head cover.<br />

*<br />

*<br />

25”<br />

(64 cm)<br />

MDC<br />

Chip Screen<br />

DUAL PA LET<br />

INLINE<br />

SPINDLE<br />

*<br />

*<br />

4X Lifting Eyebolt<br />

Spacer<br />

4X Forged Steel Shoulder Eyebolt<br />

1”- 8 TPI <strong>and</strong> 1” Steel Washer<br />

Min 9000 lb Working Load<br />

Limit (WLL) at Vertical Pull (08)<br />

ES0246 Rev AN Jan 2013 Page 14 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-400/500 Lift Placard<br />

Refer to the <strong>lifting</strong> placard for EC-400/500. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the<br />

chains do not contact the sheet metal enclosure or electrical cables.<br />

ES0246 Rev AN Jan 2013 Page 15 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-400/500 Lifting Hardware Details<br />

1. Remove the top front panels of the machine.<br />

2. Before <strong>lifting</strong> the machine, remove the hole<br />

plugs <strong>and</strong> install four 1"-8 TPI forged steel<br />

shoulder eyebolts, 1" steel washers, <strong>and</strong><br />

spacers.<br />

Top Front Panels<br />

3. Once the machine is in position, remove the<br />

eyebolts from the <strong>lifting</strong> holes <strong>and</strong> replace with<br />

bolts <strong>and</strong> washers.<br />

EC<br />

400<br />

EC<br />

400<br />

ES0246 Rev AN Jan 2013 Page 16 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-400 Pallet Pool Lift Placard<br />

Refer to the <strong>lifting</strong> placard for the EC-400 pallet pool. Attach chains to the <strong>lifting</strong> points as shown. Ensure<br />

that the chains do not contact the sheet metal enclosure or electrical cables.<br />

ES0246 Rev AN Jan 2013 Page 17 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-400 Pallet Pool Lifting Hardware Details<br />

1. Before <strong>lifting</strong> the machine, install four (4) 5/8"<br />

x 1-1/16" eyebolts <strong>and</strong> four 5/8" flat washers.<br />

Note: The two left eyebolts are installed into<br />

blocks bolted to the base plate.<br />

2. Once the machine is in position, remove the<br />

eyebolts from the <strong>lifting</strong> holes <strong>and</strong> replace with<br />

bolts <strong>and</strong> washers.<br />

ES0246 Rev AN Jan 2013 Page 18 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-1600 Lift Placard<br />

Refer to the <strong>lifting</strong> placard for EC-1600. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the chains<br />

do not contact the sheet metal enclosure or electrical cables.<br />

ES0246 Rev AN Jan 2013 Page 19 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

EC-1600 Lifting Hardware Details<br />

1. Wheels can be used to help position the <strong>lifting</strong><br />

beams beneath the EC-1600. The <strong>lifting</strong> kit<br />

(LK1600) is available from <strong>Haas</strong> Automation.<br />

2. Position the <strong>lifting</strong> beams under the machine so<br />

that the EC-1600 is located in the <strong>lifting</strong> beam<br />

recesses.<br />

EC-1600<br />

ES0246 Rev AN Jan 2013 Page 20 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ES-5 Lift Placard<br />

Refer to the <strong>lifting</strong> placard for the ES-5. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the chains<br />

do not contact the sheet metal enclosure or electrical cables.<br />

23" (590 mm)<br />

39"<br />

(980 mm)<br />

ES-5<br />

16000 lb<br />

(7300 kg)<br />

18"<br />

(457 mm)<br />

12"<br />

(304 mm)<br />

101"<br />

(2565 mm)<br />

119"<br />

(3022 mm)<br />

84"<br />

(213 mm)<br />

4X Lifting<br />

Eyebolt Spacer<br />

29-0875 Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

ES0246 Rev AN Jan 2013 Page 21 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ES-5 Lifting Hardware Details<br />

1. Before <strong>lifting</strong> the machine, remove the hole<br />

plugs <strong>and</strong> install four 1"-8 TPI forged steel<br />

shoulder eyebolts, 1" steel washers, <strong>and</strong><br />

spacers.<br />

2. Once the machine is in position, remove the<br />

eyebolts from the <strong>lifting</strong> holes <strong>and</strong> replace with<br />

bolts <strong>and</strong> washers.<br />

ES0246 Rev AN Jan 2013 Page 22 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Turning Centers<br />

ST-10/10Y<br />

Refer to the <strong>lifting</strong> placard for the ST-10/10Y. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the<br />

chains do not contact the sheet metal enclosure or electrical cables.<br />

<br />

<br />

<br />

ES0246 Rev AN Jan 2013 Page 23 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ST-10/10Y<br />

1. To install the lift kit, remove the top air duct<br />

panel <strong>and</strong> top right rear panel.<br />

ES0246 Rev AN Jan 2013 Page 24 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ST-20 Series, ST-30 Series, DS-30 Series<br />

Refer to the <strong>lifting</strong> placard for the ST-20/30 <strong>and</strong> DS-30 series. Attach chains to the <strong>lifting</strong> points as shown.<br />

Ensure that the chains do not contact the sheet metal enclosure or electrical cables.<br />

ES0246 Rev AN Jan 2013 Page 25 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ST-20/30/DS-30<br />

1. To install the lift kit, remove the left side <strong>and</strong> two<br />

back panels.<br />

ES0246 Rev AN Jan 2013 Page 26 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ST-40/40L Lift Placard<br />

Refer to the <strong>lifting</strong> placard for the ST-40/40L. Attach chains to the <strong>lifting</strong> points as shown. The <strong>lifting</strong> points<br />

are cast into the machine, not in a lift kit. Ensure that the chains do not contact the sheet metal enclosure or<br />

electrical cables.<br />

ST-40 25500 lb<br />

(11600 kg)<br />

ST-40L 29500 lb<br />

(13400 kg)<br />

ST-40/40L<br />

138"<br />

(3505 mm)<br />

57"<br />

(1448 mm)<br />

3<br />

1<br />

4<br />

2<br />

1<br />

3<br />

2<br />

29-0878 Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

65" (1651 mm)<br />

61" (1549 mm )<br />

4<br />

ES0246 Rev AN Jan 2013 Page 27 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

ST-40/40L<br />

1. To access the <strong>lifting</strong> points, remove the top<br />

access panels.<br />

ES0246 Rev AN Jan 2013 Page 28 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

UMC-750 Placard<br />

Refer to the <strong>lifting</strong> placard for the UMC-750. Attach chains to the <strong>lifting</strong> points as shown. Ensure that the<br />

chains do not contact the sheet metal enclosure or electrical cables.<br />

UMC-750<br />

72"<br />

(1830 mm) Min. 144" ea.<br />

(3700 mm)<br />

Min. 192"<br />

(4900 mm)<br />

Each bracket<br />

4x 3/4" SHCS<br />

320 ft-lb (435 Nm)<br />

UMC-750<br />

18000 lb<br />

(8200 kg)<br />

29-0929 Rev A<br />

© 2012 <strong>Haas</strong> Automation, Inc.<br />

Remove this bracket before<br />

operating the machine.<br />

ES0246 Rev AN Jan 2013 Page 29 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

UMC-750 Lifting Hardware Details<br />

1. Remove the front <strong>lifting</strong> bracket before<br />

operating the machine.<br />

ES0246 Rev AN Jan 2013 Page 30 of 31

<strong>Haas</strong> Technical Publications<br />

Lifting Instructions<br />

Rotaries<br />

Lift the rotary table with the lift rings as shown to prevent damage to the gear set. Attach air supply to unit<br />

prior to <strong>lifting</strong>.<br />

TR-160<br />

HAAS AUTOMATION INC.<br />

TR-210<br />

HAAS AUTOMATION INC.<br />

HAAS AUTOMATION INC.<br />

TR-310<br />

ES0246 Rev AN Jan 2013 Page 31 of 31