LEADING EDGE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE<br />

<strong>LEADING</strong> <strong>EDGE</strong><br />

A PUBLICATION OF WAYNE BROTHERS INC. | CIVIL / INFRASTRUCTURE & CONCRETE<br />

SPRING 2015<br />

INSIDE<br />

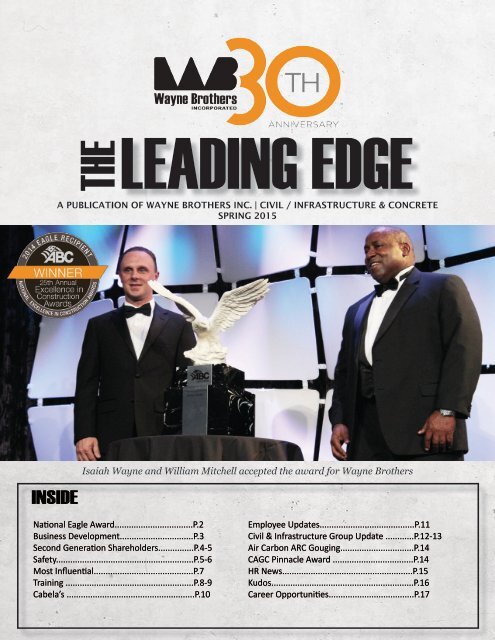

Isaiah Wayne and William Mitchell accepted the award for Wayne Brothers<br />

National Eagle Award.................................P.2<br />

Business Development...............................P.3<br />

Second Generation Shareholders...............P.4-5<br />

Safety..........................................................P.5-6<br />

Most Influential..........................................P.7<br />

Training ......................................................P.8-9<br />

Cabela’s ......................................................P.10<br />

Employee Updates........................................P.11<br />

Civil & Infrastructure Group Update ............P.12-13<br />

Air Carbon ARC Gouging...............................P.14<br />

CAGC Pinnacle Award ..................................P.14<br />

HR News.......................................................P.15<br />

Kudos............................................................P.16<br />

Career Opportunities....................................P.17

Milton Chicas, Isaiah Wayne, Candy Wayne, and Sonya Mitchell<br />

National Excellence in Construction Eagle Award<br />

BY: Jeff Leieritz, ABC Writer<br />

Associated Builders and Contractors (ABC) announced that Wayne Brothers Inc.’s work on the BB&T<br />

Ballpark project in Charlotte, N.C., has earned the company an Eagle Award in the Other Specialty Construction:<br />

Commercial - More than $10 million category of ABC’s Excellence in Construction Awards.<br />

Representatives from the company received the award March 5 during the 25th annual Excellence in<br />

Construction Awards celebration in Ft. Lauderdale, Fla.<br />

“Wayne Brothers and their team truly embraced the values of ABC and merit shop construction—innovation,<br />

quality and safety—during their work on the BB&T Ballpark and that’s why I’m honored to<br />

award them with an Excellence in Construction Eagle Award in the Other Specialty Construction: Commercial<br />

- More than $10 million category,” said 2015 ABC National Chairman Pamela Volm, president<br />

of Annapolis Contracting, Inc., Annapolis, Md. “This project is an outstanding example of how teamwork<br />

and quality craftsmanship and perseverance can result in a project that we are called to claim as<br />

merit shop.”<br />

Wayne Brothers completed the turnkey site work and concrete packages for a LEED-certified minor<br />

league ballpark located in the heart of Charlotte—relying on BIM to resolve issues offsite, coordinate<br />

rebar detailing and build custom formwork for the bleachers.<br />

The Excellence in Construction awards program is the industry’s leading competition, developed to<br />

honor innovative and high-quality merit shop construction projects. The award honors all construction<br />

team members, including the contractor, owner, architect and engineer. The winning projects, selected<br />

from entries submitted from across the nation, were judged on complexity, attractiveness, unique challenges<br />

overcome, completion time, workmanship, innovation, safety and cost.<br />

A panel of industry experts served as the competition’s judges. This year’s panel included representatives<br />

from the Design-Build Institute of America, Engineering News-Record, the American Institute of<br />

Architects, and the National Association of Women in Construction, and representatives from higher<br />

education, among others. Isaiah Wayne and William Mitchell accepted the award on behalf of Wayne<br />

Brothers at the 25th Annual Excellence in Construction Awards program on March 5, 2015 in Fort<br />

Lauderdale, Florida. Also in attendance was WBI’s Milton Chicas who also attended the ABC’s Workforce<br />

Conference, Candy Wayne, and Sonya Mitchell.<br />

Page 2

Business Development<br />

By: Shannon Sapp, Business Development Manager<br />

Business Development at Wayne Brothers has always been about two things, relationships and growth.<br />

A belief of establishing a trusting relationship with a client brings continued growth for the company.<br />

In the beginning, it was Bobby and Keith running the roads during the day and estimating projects at<br />

night. Always focused on commercial construction, they relied on past customers from their general<br />

construction days in the beginning, but soon developed clients that are still with us today. Early work<br />

included site concrete, churches, and the Fieldcrest Cannon Mills. But after a decade of splitting the<br />

BD/estimating role, growth became hindered and the first full time estimator was hired in the mid 90’s.<br />

Success followed us through the millennia and soon BD needed a full time person. Tim Waddell was<br />

hired in late 2002 and lead Wayne Brothers in new directions. A friend of the company already, Tim<br />

knew the importance of relationships but was tasked with providing new growth. One of Tim’s first<br />

opportunities stretched the company’s boundaries and led the largest project to date with Sterilyte<br />

in 2004. Determined to expand the awareness of Wayne Brothers, in 2004 a new marketing plan<br />

was established. It included the launching a new website and new branding ideas (wrapped vehicles,<br />

trade shows, and signage). Tim strengthened relationships with both new and existing clients; leading<br />

Wayne Brothers to doubling revenues and experiencing some of its greatest growth to date.<br />

I came on brink of the downturn in late 2009. Wayne Brothers was looking for a new revenue stream<br />

with special projects direct with the end-user. A turn of events changed when 8 months in, Tim decided<br />

to pursue new career. My focus changed to the subcontract construction that was our mainstay.<br />

I to, as Tim had done years early, launched a new website and new branding strategy in 2011 in hopes<br />

to prod new growth. In the middle 2012, as our revenue had returned to the pre-recession level, it was<br />

determined help was needed to continue the growth curve. Mark Muller, another friend of Wayne<br />

Brothers, joined us in late of that year. Our growth has broken records ever since.<br />

Now as we approach our 30th anniversary, WBI is position for even greater growth. BD has developed<br />

an aggressive strategic plan that will build on relationships and new areas of growth. From Mark and<br />

I who do it fulltime, we want to thank everyone at Wayne Brothers for your part in helping ensure we<br />

have the most satisfied clients and the best opportunities. It is the great team in the field that makes it<br />

so enjoyable.<br />

Charleston Subcontractors Event<br />

Recently, Wayne Brothers Inc. had the privilege of presenting<br />

a program to the Charleston Subcontractors Association<br />

on workforce development. It gave us the opportunity<br />

to convey an important message to which there is no silver<br />

bullet; the skills gap and labor shortage in our industry.<br />

The point was emphasized that we as industry must do a<br />

better job of communicating and conveying career opportunities<br />

in the construction industry. Wayne Brothers is<br />

doing our part in delivering training program to meet the<br />

needs of our trades. But it will take a greater effort together<br />

to change the image of industry and contribute even<br />

greater growth to this nation.<br />

Page 3<br />

Milton Chicas speaking for<br />

the Charleston Subcontractors<br />

Association

Second Generation Shareholders<br />

By: Keith Wayne, President/CEO<br />

As the company approaches its 30th anniversary, the company’s current shareholders Bobby Phillips,<br />

John Ashworth, Chad Hensley and Keith Wayne are excited to welcome Isaiah Wayne and Daniel<br />

Wayne as new shareholders of Wayne Brothers, Inc.<br />

As with any privately held company which proves itself capable of growing into a substantial business<br />

operation, Wayne Brothers founding principles are faced with the challenge of approaching an age<br />

when they must consider when and how they wish to leave their life’s work to a younger generation. In<br />

our case we have been underway with the ownership transition planning for years through the careful<br />

selection of key executives being offered the opportunity to become equity owners through their purchase<br />

of stock in the business.<br />

The time has arrived for the second generation of family members, who like the other shareholders<br />

have been trained to understand the full range of construction skills required in order to be successful,<br />

to come on board as equity owners of the business over the next several years. Ultimately it is planned<br />

that Keith’s two sons would own the majority interests of the company at or before his full retirement.<br />

With this transaction, Isaiah and Daniel are beginning this journey to a majority interest in the company<br />

by a planned purchasing of Keith’s Shares over the coming years.<br />

Keith expects to remain as President for some time yet and has not completed his role as the leader of<br />

WBI just yet. He is particularly gratified in seeing his two sons take this important step in their business<br />

career and is excited to be working with the Executive Team in crafting our next five year strategic plan<br />

over the course of the next few months.<br />

Isaiah currently serves on the Executive Committee and has also been a member of the Board of Directors<br />

for the company since 2007. Isaiah will continue to serve as one of three Project Executives and<br />

will focus his corporate management skills on the Workforce Development area of the business.<br />

Page 4

Isaiah has worked with the company since his early teenage years and later worked for about one year<br />

with another grading contractor, Earnhardt Grading as an equipment operator to gain experience in<br />

a field outside our company owned business. He graduated from CPCC with an Associate Degree in<br />

Construction Management while working in the field for WBI as foreman.<br />

After obtaining this degree he continued to perform increasingly more demanding and important roles<br />

within the company. Later becoming Project Manager then Senior Project Manager where he completed<br />

numerous high profile, high demand projects successfully. He simultaneously helped us build the<br />

other team members who worked with him in advancing their careers with the company.<br />

Daniel currently serves on our Management Team as our Director of Technology. He will continue to<br />

serve the company in this role and potentially train for other leadership roles of the future. Daniel began<br />

his career with Wayne Brothers at an even younger age than his brother. He worked with our mechanics<br />

in the original shop facility well before he was legal working age. After graduating from Northwest<br />

High School he was laser focused on becoming what he considered the company’s most important<br />

position of project superintendent. He worked through the field trades and became foremen and then<br />

decided to pursue his Associate Degree from RCCC in Construction Management using our accredited<br />

training program to achieve much of the required class credits. Daniel then changed his focus toward<br />

becoming a Project Manager through our PMIT program and then quickly climbed the scale of project<br />

management assignments. He ended up becoming a Senior Project Manager for us at the age of 27 after<br />

managing what was at the time our largest contract. Over the past three years he has been tasked<br />

with leading our technology planning and implementation and has done a stellar job in keeping us well<br />

ahead in this area of expertise. Additionally this past year he delivered our new Headquarters facility<br />

through his active management and design refinements of the facility.<br />

We encourage the entire WBI family to reach out to congratulate Isaiah and Daniel and to welcome<br />

them as the latest additions to the shareholder group. There is no doubt that the company is poised for<br />

a more secure and prosperous future with the addition of their significant investment added to their<br />

already valued service as team members.<br />

SAFETY IMPROVEMENT SUGGESTION DRAWING WINNERS!<br />

Employees are entered into a monthly drawing for submitting a valid safety improvement<br />

suggestion. Congratulations to the following winners:<br />

November 2014<br />

Alfred Linen, Barry Ingram, Chad Johnson, Charles Schultz, Christopher Sealy, Christopher Smith,<br />

Jesse Green, Joel Rivas, Larry Wells, Lazaro Martinez, Margarito Salazar, Moises Hernandez, Victor<br />

Portee & William Taulbee<br />

December 2014<br />

Benjamin Ballard, Bennie Grant, David Walker Jr., Eric Sheppard, Gary Chepke, Hans Radford, Heriberto<br />

Santiago, James Meade, James Shearer, Javier Colon, Jesse Green, Joaquin Reveles, Jonathan<br />

Burgarin, Marvin Spell, Ramiro Montalvo & Tony Davis<br />

January 2015<br />

Andrae Brewer, Cruz Cruz, Edgar Jaquez, Fon Newsom, Frederic Daniels, John Henderson, Noe Lazo,<br />

Peter Normandin, Richard Phillips, Tindes Hampton & Vickie Shantie<br />

February 2015<br />

David Lloyd, David Martinez, Eddie Shepard, Frankie Pressley, Jesse Dorsey, Jesse Green, Lawrence<br />

Goodine, Mike Smithwick, Moises Espinosa, Nakia Alston, Nazario Moreno, Nelson Lowers, Ramiro<br />

Montalvo, Rudis Lazo, Terry Toussaint, Theron Jenkins & Victor Borrero<br />

Page 5

History of Safety<br />

In 2007, Wayne Brothers, Inc. began its journey to build a safer company. Prior to 2007 it was WBI’s intention<br />

to provide a safe work environment for its employees and subcontractors but Safety was not the #1 priority. Over<br />

the last eight years WBI has implemented several new safety initiatives, policies and procedures to help insure<br />

that safety is the #1 priority on all of its projects. Some of those include criminal background checks for all new<br />

hires, post-offer pre-employment fit-for-duty exams for all craft level employees, a two day new hire orientation<br />

that includes OSHA 10 Hour training, daily pre-task planning, daily stretching routine and a 100% cut level 3<br />

(or higher) glove policy. WBI recently reached the goal of having 100% of its employees with OSHA 10 and/or<br />

30 Hour training. WBI strives daily to provide a safe work environment for its employees and subcontractors.<br />

As part of the safety journey that begun in 2007 safety has become a #1 priority at Wayne Brothers. Now WBI’s<br />

company culture truly reflects safety not just quality and production.<br />

1 YEAR WITH NO LOST TIME!<br />

Wayne Brothers Inc.’s efforts in safety have truly paid off. Since March 31, 2014 WBI has worked 812,164 hours<br />

and 1 Year without a Lost Time accident! I would like to congratulate all of you for a job well done! It has taken<br />

every one of you to achieve this success. I encourage all of you to continue watching out for and correcting any unsafe<br />

act(s), unsafe behavior(s), and/or unsafe condition(s) in order to maintain a safe work area. Please continue<br />

to encourage your employees to participate in hazard recognition techniques, such as the Safety Improvement<br />

submissions, to help identify and eliminate potential hazards on our projects.<br />

“Thanks to everyone for your support in our effort to “Safely Exceed Expectations”.<br />

100% OSHA 10/OSHA 30 Trained<br />

We are proud to announce that we have reached our goal of having 100% of our employees hold OSHA<br />

10 and/or 30 HR cards! We began working on this goal 18 months ago. Thanks for everyone’s participation<br />

in accomplishing this goal.<br />

C-MESH Certified<br />

We are pleased to announce Billy Honeycutt and Jason Sisk<br />

have successfully completed the prestigious C-MESH certification.<br />

They are now among a special group of professionals<br />

who have earned the Construction Manager of Environmental<br />

Safety and Health certificate from the Safety and Health<br />

Council of North Carolina, NC State University, and the NC<br />

Department of Labor. The MESH program is designed to increase<br />

the professionalism of environmental, safety and health<br />

managers of commercial, residential and governmental construction<br />

sites in NC through a rigorous series of continuing<br />

education programs. This program prepares managers for<br />

keeping their worksites safe and healthy, and that preparation<br />

improves employee protection and company productivity.<br />

Congratulations on your achievement!<br />

Page 6

Most Influential<br />

Wayne Brothers’ Keith Wayne was featured in the January<br />

issue of Concrete Construction Magazine for being Most Influential<br />

in the Concrete Industry. The following is an exert<br />

from William D. Palmer Jr.’s article.<br />

Taking risks is what contractors do—it’s how they make a living.<br />

Taking extra risk by adopting new technology and ideas,<br />

though, is something many contractors shy away from. Keith<br />

Wayne, president of Wayne Brothers in Kannapolis, N.C.<br />

doesn’t adopt new technology blindly, but he has been willing<br />

to move forward a little earlier than most contractors<br />

and that has been one secret to his company’s success. “I’m<br />

a pretty harsh critic and skeptic about new technology,” he<br />

says, “it must work well and consistently and be practical to<br />

use in a broad range of applications.”<br />

Today, Wayne Brothers is heavily into technology and new approaches, including building information<br />

modeling (BIM), self-consolidating concrete, laser-guided equipment, modular European formwork,<br />

and Ductilcrete floor slabs. “Ductilcrete is becoming more and more useful and accepted as the slabon-grade<br />

of choice because of its ability to maintain its flatness over time, which a conventional slab<br />

doesn’t, and to eliminate 70 to 75% of the joints, which minimizes the maintenance program since it’s<br />

the joints that create the problems. I’m pretty pumped up about Ductilcrete.”<br />

On the strength of that new business and a diversified approach, including site work and vertical forming,<br />

Wayne Brothers broke into Engineering NewsRecord’s top 20 concrete firms in 2014. “We’re proud<br />

of that but humble,” says Wayne. “We’ve had great blessings; good clients who continue to call to ask us<br />

to work for them. The old adage works for us: the best way to sell your next job is your last job.” Wayne<br />

Brothers works throughout the Southeast U.S. from offices in North Carolina and South Carolina.<br />

One money-maker has been BIM. “We are using BIM extensively — on every job with only a few exceptions<br />

for very small projects” says Wayne. “We start with the modeling on some projects during the<br />

preconstruction phase and use it for estimating. The modeling is useful during negotiations, too, well<br />

before we get to the field. In the construction phase, BIM helps us to manage conflicts and to modularize<br />

construction activity which allows us to do some work in the shop so that less space is needed on the<br />

jobsite.”<br />

ALL IN THE FAMILY<br />

Wayne Brothers is now moving into the next generation. “My two sons both work in the business,”<br />

Wayne says. “Isaiah manages our strategic workforce issues including training. Daniel is the Director<br />

of Technology. He was the project manager for our new operations center which we built ourselves.”<br />

Wayne isn’t relying solely on family, though, there are three other partners who are all shareholders<br />

and company leaders, which he believes will smooth out the company’s succession when he decides to<br />

retire.<br />

You can the entire article here: http://www.concreteconstruction.net/commercial-projects/successby-embracing-change-keith-wayne_o.aspx?dfpzone=general<br />

Page 7

Performance Excellence Training Program<br />

By: Milton Chicas, Training Manager<br />

We have all heard about the construction worker shortage, and even more concerning the possibility<br />

that our industry is not adjusting rapidly to the exponential growth and the need for craft workers.<br />

Despite all the challenges that you might have heard related to a formalized training program for construction<br />

companies, the reality is that such ambitions can become a daunting task if one is not aware<br />

of the magnitude of this pursuit. It might be easy to succumb to all the possible challenges you could<br />

possibly face in participating in such a program and become discouraged.<br />

An effective formalized training program can be achieved with strategic planning and careful selection<br />

of training options. Success doesn’t come as a coincidence as it is a result of creative thinking, strategic<br />

vision and hard work. Our company has invested a great deal of time and effort in fine tuning a program<br />

that addresses our training and educational needs and, as of recent, the needs of the community.<br />

Back in 2001 Wayne Brothers embarked on the goal of establishing an educational plan for craft training.<br />

The program has now evolved to multiple training options such as carpentry, heavy equipment,<br />

layout, form systems, rigging operations, supervisory training, leadership and management, safety<br />

courses and many more. The courses are tailored to the cognitive needs as well as geographical requirements.<br />

Our effort has resulted in improved performance, higher employee retention and increased<br />

efficiency.<br />

Page 8

The goal for the near future is to develop a fully operational industrial park with training as a centerpiece<br />

where we can provide hands on training delivered with the same equipment that we use at our<br />

major job sites; as well as involving the craft skills and specialized methods used in large construction<br />

projects. Now with the combined effort of our company leadership and our partners we are closer and<br />

closer to reaching our goal. The Claude Wayne Building Institute, an initiative that grew from the need<br />

of providing the necessary skills for the community, is now about to come to fruition as a complete and<br />

well-designed major effort for the training options in the southeast.<br />

The future location of the Claude Wayne Building Institute will be adjacent to our new headquarters.<br />

This will turn our training facility into a wireless internet access site where we can also demonstrate<br />

and train on the specific communications and technological tools currently being used at constructions<br />

sites. The link between our Building Information Models (BIM) and the practical application is just one<br />

of the many training options that we will implement.<br />

We recognize the needs of our industry and we would like to contribute to the betterment of the families<br />

of those who work with their hands. We intend to accomplish this by providing effective and meaningful<br />

education related to heavy commercial construction at the beginning and subsequently expand to<br />

other trades, such as electrical, HVAC, plumbing, etc. Our commitment of Safely Exceeding Expectations<br />

and improving the communities where we live and work is our promise to our customers and to<br />

our workforce.<br />

Page 9

Cabela’s Retail Store<br />

By: John Vaughan, Project Manager<br />

Wayne Brothers Inc. was excited to be awarded the Turnkey building and site concrete packages for the<br />

Cabela’s Retail store located in Fort Mill, SC. CDI Contractors awarded us the contract and we were<br />

excited to be working for them again. This project was a little extra special because the site selected for<br />

the Cabela’s Retail store was the location of job #01 for Wayne Brothers when the company was established<br />

back in 1985. The “Outlet Marketplace” then later named “Plaza Fiesta Carolinas” was the first<br />

project for Wayne Brothers. It’s been interesting and entertaining hearing the stories from the folks at<br />

the office who were involved with that project 30 years ago. All the comments usually start and finish<br />

with “we’ve come a long way since then”.<br />

The Cabela’s Retail store had an very aggressive schedule and Wayne Brothers was usually able to better<br />

the dates on the schedule. The interior isle ways and other showcase areas in the store are exposed<br />

polished concrete. Our client and owner had very high expectations for the quality of the concrete floors<br />

in these areas. Wayne Brothers completed these high tolerance/high quality floors without any defects.<br />

The plaza site concrete pavement that extends the full length of the store was treated as Architectural<br />

concrete. This required a consistent medium broom finish and we also installed decorative beveled<br />

sawcuts in this area. It turned out great. Thanks to everyone involved who made this project a success.<br />

Page 10

Lacie Jones<br />

NEW BIM Engineer<br />

NEW HR Assistant<br />

Please welcome WBI’s new HR Assistant, Lacie<br />

Jones. Lacie is originally from Shelby, NC. She<br />

graduated from Crest High School and went on<br />

to graduate from Appalachian State University<br />

with a BS in Communications. Before WBI,<br />

Lacie was employed in Human Resources for 6<br />

years at an abrasives manufacturer. When not<br />

at work, she enjoys spending time on the lake<br />

with her fiancée and playing with their 4 dogs.<br />

NEW Senior Superintendents<br />

Congratulations to Jason Loucks, Ryan Shaw,<br />

Jason Thompson and Rick Adsit on their promotions<br />

to Senior Superintendent! Each of<br />

these employees have demonstrated excellence<br />

in leadership and performance throughout<br />

their careers at WBI. We are proud to offer this<br />

new opportunity to these deserving individuals!<br />

- Isaiah Wayne, Project Executive<br />

NEW Field Service Technician<br />

We are pleased to announce that Dicky Miller<br />

Dickey Miller has joined Wayne Brothers as a Field Service<br />

Mechanic. Dicky attended Clemson Diesel<br />

School and has experience working on a large variety of heavy equipment,<br />

including some work on cranes. Additionally, he has experience in fabrication<br />

work through his employment in the motorsports industry. During<br />

Dicky’s interview when asked his thoughts on customer service, he responded<br />

by saying “ I was taught the customer comes first. I work to make<br />

the customer happy. The customer is our bread and butter.” He went on to<br />

say he was raised with these beliefs by his dad in the family business. Initially,<br />

Dicky will be shadowing Jeff Ingle to learn about our organization.<br />

Welcome to WBI!<br />

We are very excited to announce the latest news in our WBIM department.<br />

As many of you know, we have been actively searching for a qualified<br />

BIM Engineer who fits well into our culture. Darren Thompson has<br />

elected to take on this challenge and advance his career path while leveraging<br />

his skills and knowledge from his time served as a project engineer.<br />

Darren will be working over the next month<br />

to train and hand-off his current project engineering<br />

duties, which will then allow him to<br />

fully submerge himself into the BIM training<br />

program. Please join us in congratulating Dar<br />

ren on this great news! My prediction is that<br />

with the addition of Darren, we will continue<br />

to see the number of projects impacted by BIM<br />

and the overall benefits of BIM grow rapidly in<br />

the next 6 months to 1 year.<br />

- Daniel Wayne, Director of Technology<br />

Darren Thompson<br />

Jason Thompson<br />

Jason Loucks<br />

Ryan Shaw<br />

Rick Adsit

An excavator loads a jaw crusher which feeds a screen, that produces three different sized materials,<br />

with multiple conveyors. The materials were used to replace manufactured wall blocks, purchased<br />

stone and engineered structural fill.<br />

Civil & Infrastructure Group Update<br />

By: Jim Rhodes, Civil & Infrastructure Group Manager<br />

WBI’s Civil and Infrastructure group (WBICI) recently started a project on site where the geo-tech<br />

report indicated the potential need for significant un-rippable rock removal. As WBICI went through<br />

the preconstruction process, minimal available soil borings were entered into our take-off software<br />

to determine the amount of rock on site and locations. Based on the info gathered, the engineer and<br />

owner were able to evaluate their needs and associated design in order to mitigate the amount of rock<br />

encountered before WBICI ever arrived on site.<br />

Once WBICI mobilized, the first order of business was to pre-drill the entire site and confirm the quantities<br />

that were derived from the geo-tech report. As is sometimes the case, it was found that many of<br />

the borings missed some the below existing grade rock due to the fact that the strata had many more<br />

peaks and valleys than would normally be seen on a similar site. This fact doubled the amount of expected<br />

rock on site. All of the rock was mapped and entered into the GPS site model that WBICI was<br />

P.12<br />

Two rock drills work in the background as an excavator loads a rock truck with overburden,<br />

prior to digging the previously blasted shot rock<br />

Page 12

An excavator loads a jaw crusher while sitting on a pile of shot rock<br />

using to build the project. This knowledge allowed the project team to re-evaluate plans on building the<br />

project and how best to mitigate cost as they related to rock, while pushing the schedule forward with<br />

as little impact as possible.<br />

The site was designed to balance so all the rock material was needed on site. To avoid the expense<br />

and need for import, the large quantity of rock was crushed onsite. This activity allowed the project to<br />

save what would have been an added cost to the project but it also allowed us to assess if there may be<br />

additional savings to offset the added rock costs. Segmented retaining walls were converted to gabion<br />

basket walls. Select fills and erosion control stone were processed on site. By adding a 3 way screen to<br />

the end of the crushing operation, the project team was able to make the gabion rock that was necessary<br />

for the basket walls, while at the same time production erosion control stone and select fill.<br />

In the end, WBI’s Civil and Infrastructure group was able utilize its technological expertise along with<br />

it site grading acumen to help the client reduce added costs, troubleshoot its design as it related to the<br />

existing rock and hold as close as possible to the original schedule once the course of action was determined.<br />

Wayne Brothers, Inc is proud to announce that Ryan Lindsey has<br />

been promoted to Project Manager in the Civil & Infrastructure<br />

Group. Ryan has worked with Wayne Brothers, in a PE/PMIT<br />

roll, since he was in a junior in college. We’re excited for, not<br />

only Ryan’s growth, but the opportunity it will provide for the<br />

Group and Company to grow as a whole. Please help us welcome<br />

Ryan into his new roll.<br />

- Jim Rhodes, Civil & Infrastructure Group Manager<br />

Ryan Lindsey<br />

Page 13

Jeff Ingle in the process of<br />

removing teeth from an<br />

excavator bucket.<br />

Air Carbon ARC Gouging<br />

By: Alan Goodman, Asset Manager<br />

Our shop recently purchased an “air carbon ARC gouging” torch to improve<br />

efficiency / productivity when we need to cut welds. Air carbon<br />

arc gouging works as follows - An electric arc is generated between<br />

the tip of a carbon electrode and the work piece. The metal becomes<br />

molten and a high velocity air jet streams down the electrode to blow<br />

it away, thus leaving a clean groove. The process is simple to apply<br />

and has a high metal removal rate, and gouge profile can be closely<br />

controlled.<br />

This tool dramatically reduces this time to remove weld as compared<br />

to the typical method of torching or grinding, plus the cut is very clean<br />

and the metal is not subjected to extremely high temperatures This<br />

tool could be compared to using a razor to precisely remove material.<br />

A new, high volume, 25 HP air compressor enabled us to take advantage<br />

of the gouging torch. Many thanks to Jerry Lambert and the shop<br />

technicians for bringing new tools and technology into the workplace.<br />

CAGC Pinnacle Award<br />

Congratulations to New Atlantic Contracting for winning the 2014 Carolinas AGC Pinnacle Award!<br />

They won “Best Building” for the UNCG Pedestrian Underpass. Wayne Brothers’ Grading Group is<br />

grateful to have been part of such a successful project. The joint project between UNCG and the NC<br />

Railroad Company was designed to provide a safer path for pedestrians and bicyclists as well as create<br />

a connection between the university’s core campus and the school’s massive mixed-use project along<br />

the Lee Street corridor. The most interesting and challenging part of the project was the open cut tunnel<br />

was excavated and built underneath three Norfolk Southern railroad tracks, without taking them out<br />

of service.<br />

Page 14

HR News<br />

BY: Lacie Jones, HR Assistant<br />

Weight Loss Challenge Winners!<br />

Congratulations to Ryan Barker who won the Company Weight Loss Challenge.<br />

Ryan lost a total of 25 pounds, and won a total of $400 for winning<br />

both the half point weigh-in and the final weigh-in. Also, Kudos to Barbara<br />

Turner who did a great job coming in second place and losing a total of 14.8<br />

pounds!<br />

World Health Day<br />

The World Health Organization recognizes April 7th of every year as<br />

Word Health Day. The theme of World Health Day 2015 is Food Safety.<br />

Did you know that 2 million deaths occur worldwide each year from contaminated<br />

food or drinking water? America being a developed country we tend to take for granted how<br />

safe our food is but it is always a good idea to make informed food choices and practice proper handling<br />

procedures.<br />

Monthly Wellness Newsletters<br />

Reminder that monthly wellness newsletters are posted on Yammer. Make sure you take a look at these<br />

as they contain good information on all types of wellness topics!<br />

Save the Date!<br />

Summer is right around the corner and weekends get booked early. Go ahead and put July 25, 2015 on<br />

your calendar for the WBI 2015 Annual Awards & Picnic. The event will be at The Quarry at Carrigan<br />

Farms from 5:00 pm – 9:30 pm. Plan now to come have fun and fellowship with some folks you may<br />

not get the opportunity to see very often. More information is coming soon!<br />

401k Beneficiaries<br />

We are currently performing an audit on 401K Beneficiaries. Due to marriages, divorces, deaths etc.<br />

most people’s forms need to be updated to their current beneficiaries. To ensure that we have the correct/current<br />

beneficiary we are requiring a new Designation of Beneficiary Form to be completed by<br />

everyone. Even if you think you have the correct beneficiaries listed please complete a new form. Just<br />

a few reminders on completing the form:<br />

- If you do not have the new Designation of Beneficiary form please contact Lacie and she can get you<br />

one.<br />

- If you are married your spouse must be listed as your primary beneficiary unless he/she consents to<br />

someone else being your primary. If your spouse does consent, the second page of the form must be<br />

completed and notarized.<br />

- If you are listing your spouse as your primary, or are not married I only need the first page of the form<br />

completed and signed.<br />

- If you are not currently contributing but have a balance in your 401k account we still need this form<br />

completed.<br />

- Superintendents please assist me in having your employees complete this form.<br />

- Please return this form to HR (Lacie) as soon as possible.<br />

- Summary Plan Descriptions are available for our Insurance and 401K. Please contact Lacie in HR if<br />

you would like a copy, and they are also available to view on the company server.<br />

- If you have any other questions about the forms, please feel free to contact Lacie 704-956-2268.<br />

Page 15

KUDOS!<br />

Davis Dahlbeck<br />

Galilea Cruz<br />

BABY CRUZ!<br />

Congratulations to the Cruz<br />

Family!! Juan and Ingrid Cruz<br />

had a baby girl, Galilea Cruz, on<br />

April 6, 2015. Galilea was born<br />

at 6:00 am at 21 ¼“ and weighing<br />

7 pounds. Mom and baby<br />

are doing great!<br />

BABY DAHLBECK<br />

Congratulations to the Dahlbeck Family!! Davis Joshua Dahlbeck was born<br />

Wednesday, January 28th, 2015 at 7:26 p.m weighing 8lbs, 7oz and 22.5 inches<br />

long . Mom and baby are doing great!<br />

I was recently made aware of an issue that a local high school (Northwest Cabarrus)<br />

track team was facing. The school had their track resurfaced and a concrete pad and<br />

pit poured for their pole vaulting runway this past off season. It was discovered a few<br />

weeks ago that the pit cast in the pole vaulting pad was incorrectly installed (it was<br />

out of square with the run way, it was 2.5” too shallow and the angles on the sides<br />

were incorrect). The team’s track season started two weeks ago and they had not<br />

been able to practice pole vaulting as a result of the issue with the pit.<br />

My wife (who is an assistant track coach there) asked if we had any ideas on how to<br />

repair the issue. This is where Scott, Rodney and Moises come in. The three of them<br />

took opportunity of a slow day for the finishers and went out to the track field to<br />

make the repairs for the team. It didn’t cost us a lot of time or money, but the impact<br />

that it made is huge. Now 6 or 8 high school kids can carry on with their pole vaulting<br />

practice and hopefully give them more opportunity to be successful this track<br />

season. Just another example of how we can use our skills and resources to make a<br />

positive impact on our community. -Daniel Wayne, Director of Technology<br />

KUDOS JEFF INGLE!<br />

I would like to share with you my thoughts on Field Mechanic Jeff. While I have not<br />

worked directly with Jeff, I have heard nothing but glowing reviews of his work. On<br />

every jobsite I go to I always hear praise about Jeff’s work ethic, willingness to work<br />

through lunch or late hours, and his overall spectacular attitude. I don’t know that<br />

I have ever seen Jeff not covered in grease, oil, or mud but he always seems to be<br />

cheerful. On behalf of myself and the grading group, I want to say thanks and we<br />

appreciate the work the equipment department does to keep us moving.<br />

- Josh Dahlbeck, Project Manager<br />

Thanks to all the grading crew working on the Pavilion job site for all your hard<br />

work. -Rick Adsit, Senior Superintendent<br />

Thank you to all our Grading Group training participants and instructors who are<br />

taking the time to learn, teach, question and grow themselves as well as each other.<br />

We can see the improvements in the Group due to everyone’s hard work.<br />

- Jim Rhodes, Civil & Infrastructure Group Manager<br />

Congratulations to New Atlantic, Bruce Ashworth and the entire project team for a<br />

job well done on the UNCG pedestrian Tunnel Project. The project won a well deserved<br />

AGC Pinnacle award. - Jim Rhodes, Civil & Infrastructure Group Manager<br />

WBI would like to thank all that contributing in any way to the Holiday Giving Back<br />

Program. Several employees suggested fellow co-workers or folks in the community<br />

that they knew had some special needs during this time of year. Employees<br />

donated money and WBI matched the contributions. The company also adding an<br />

additional contribution to the fund and all was distributed prior to the holidays. A<br />

total of $10,500 was distributed among five employees and four families from our<br />

community. One of the recipient’s husband passed away last year and left many<br />

doctor bills and medical expenses. She lives in a small trailer that is not underpinned.<br />

This causes her heating and electrical expenses to be more than she can<br />

afford. She struggles to make ends meet and does not have any family to help her.<br />

She received a check for $500 from WBI’s Christmas Giving to purchase materials<br />

for the underpinning of her home, and a local church covered the installation. She<br />

wanted to make sure everyone at WBI knew she was very thankful. After she was<br />

given the check she said “Now I won’t have to be cold anymore.” All recipients were<br />

very thankful and everyone should feel a sense of pride knowing you and WBI care<br />

about their employees and the community we live and work in!

Wayne Brothers, Inc.<br />

is NOW HIRING for the following positions:<br />

1- Finishing Superintendent, Charleston, SC<br />

4 - Concrete Finishers, Charleston, SC<br />

1- QA/QC Manager<br />

2 - Equipment Operator III, Davidson, NC<br />

3 - Civil & Infrastructure Group Laborers, Various Locations<br />

5 - Concrete Form Carpenters, Various Locations<br />

10 - Form Carpenter Helpers, Various Locations<br />

5 - Building Group Laborers, Various Locations<br />

4 - Internship, Summer Program, Davidson, NC<br />

Application Process<br />

Please go to:<br />

www.http://waynebrothers.com/Careers/ApplyOnline.aspx<br />

and complete an employment application.<br />

Or, you can visit our recruiting office at:<br />

357 Concrescere Parkway, Davidson, NC 28036<br />

Wayne Brothers, Inc. is a drug-free work environment and has a<br />

zero-tolerance policy. We drug screen prior to employment.<br />

Wayne Brothers, Inc. is an Equal Opportunity/Affirmative Action Employer.<br />

EOE/AA/m/f/vets/disabled