LEADING EDGE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

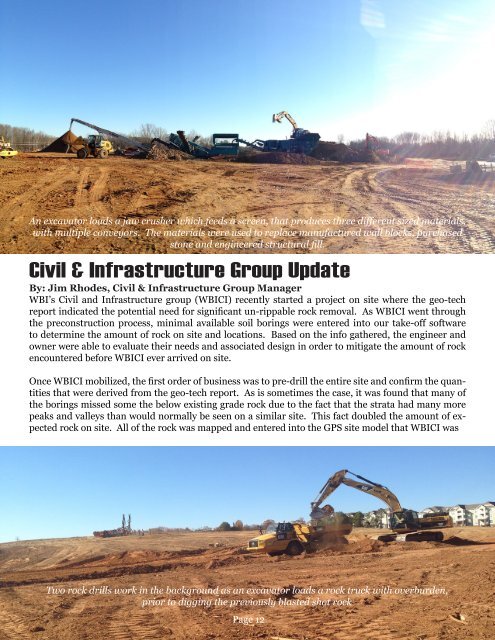

An excavator loads a jaw crusher which feeds a screen, that produces three different sized materials,<br />

with multiple conveyors. The materials were used to replace manufactured wall blocks, purchased<br />

stone and engineered structural fill.<br />

Civil & Infrastructure Group Update<br />

By: Jim Rhodes, Civil & Infrastructure Group Manager<br />

WBI’s Civil and Infrastructure group (WBICI) recently started a project on site where the geo-tech<br />

report indicated the potential need for significant un-rippable rock removal. As WBICI went through<br />

the preconstruction process, minimal available soil borings were entered into our take-off software<br />

to determine the amount of rock on site and locations. Based on the info gathered, the engineer and<br />

owner were able to evaluate their needs and associated design in order to mitigate the amount of rock<br />

encountered before WBICI ever arrived on site.<br />

Once WBICI mobilized, the first order of business was to pre-drill the entire site and confirm the quantities<br />

that were derived from the geo-tech report. As is sometimes the case, it was found that many of<br />

the borings missed some the below existing grade rock due to the fact that the strata had many more<br />

peaks and valleys than would normally be seen on a similar site. This fact doubled the amount of expected<br />

rock on site. All of the rock was mapped and entered into the GPS site model that WBICI was<br />

P.12<br />

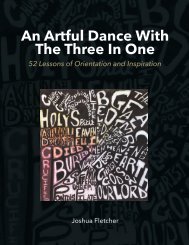

Two rock drills work in the background as an excavator loads a rock truck with overburden,<br />

prior to digging the previously blasted shot rock<br />

Page 12