Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

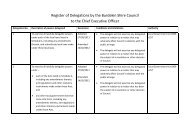

Chillers<br />

Action<br />

Interval<br />

(Months)<br />

1. Check action <strong>of</strong> chilled water <strong>and</strong> condenser water flow switches. 1<br />

2. Check TX valve <strong>and</strong> superheat. 6<br />

3. Check operation <strong>and</strong> calibration <strong>of</strong> chilled water temperature controller to maintain the designed<br />

12<br />

temperature.<br />

4. Check setting <strong>and</strong> operation <strong>of</strong> chilled water, low temperature safety thermostat, record trip temperature. 12<br />

5. Check pressure drop (water side) in both chiller <strong>and</strong> condenser <strong>and</strong> compare with data plate. 12<br />

6. Clean in-line strainers, replace or repair thermal insulation. Re-establish vapour seal around equipment. 12<br />

7. Clean chiller tubes <strong>and</strong> slug dose after refilling. 24<br />

8. Non-demountable chillers shall be cleaned with chemical cleaner <strong>and</strong> the system refilled <strong>and</strong> slug dosed. 24<br />

9. Isolate chiller vessel from chilled water piping, drain. After service refill system. 24<br />

10. Remove insulation <strong>and</strong> water boxes, clean. Fit new gaskets. 24<br />

Coils<br />

Condensers<br />

Coils – cooling<br />

Action<br />

Interval<br />

(Months)<br />

1. Check coils, clean algae <strong>and</strong> slime as required. 1<br />

2. Inspect drain trays <strong>and</strong> test drains. Clean as required. 1<br />

3. Check for leaks on coils <strong>and</strong> connections <strong>and</strong> repair as required. 6<br />

4. Vent water coils. 6<br />

5. Inspect coils for dirt build up <strong>and</strong> clean as necessary. 6<br />

6. Inspect coils for fin damage <strong>and</strong> comb if necessary. 12<br />

7. Examine coil to ensure internal sections are not blocked. 12<br />

8. Check temperatures across coil, adjust as necessary. Record result. 12<br />

9. Inspect feed <strong>and</strong> expansion tank <strong>and</strong> piping. 12<br />

Condensers - Air Cooled<br />

Action<br />

Interval<br />

(Months)<br />

1. Check <strong>and</strong> service fans, motors, drives <strong>and</strong> controls as per appropriate instruction sheet. 1<br />

2. Adjust belts. 1<br />

3. Remove dirt <strong>and</strong> debris from fan inlet screen. 1<br />

4. Inspect coils for build up <strong>of</strong> dirt <strong>and</strong> clean out as necessary. Clean by hosing. 1<br />

5. Inspect protective finish, repair as necessary. 12<br />

6. Check operation <strong>and</strong> settings <strong>of</strong> any control dampers. 12<br />

7. Inspect fan drives for correct rotation. 12<br />

8. Inspect propeller fans for correct position in cone <strong>and</strong> check that the retaining screw is tight. 12<br />

9. Inspect installation to ensure free air flow. 12<br />

3