Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

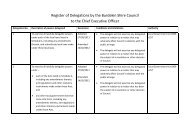

4. Check isolation at pipe hangers, repair as necessary. 12<br />

Packaged A/C Plant<br />

Pipe work<br />

Action<br />

Interval<br />

(Months)<br />

1. Inspect plant for physical damage <strong>and</strong> make good. 1<br />

2. Check all components are secure. Rectify as required. 1<br />

3. Check operation through heating <strong>and</strong> cooling sequence. Report on defects. 1<br />

4. Check insulation is secure. Report on defects. 1<br />

5. Check drains <strong>and</strong> drip tray are clear. Clean as required. 1<br />

6. Check refrigerant charge through site glass where fitted. 1<br />

7. Lubricate in accordance with Manufacturer’s recommendation. 1<br />

8. Record on/<strong>of</strong>f coil temperatures. 6<br />

9. Fit set <strong>of</strong> gauges to refrigerant circuit, record readings. 12<br />

10. Check <strong>and</strong> adjust refrigerant charge, record readings. 12<br />

11. Clean air cooled condenser coils, examine for damage, comb as necessary. 12<br />

12. Simulate loading <strong>of</strong> compressor. Check operation <strong>of</strong> control stages. 12<br />

13. Clean inlet side <strong>of</strong> evaporator coil. 12<br />

14. Remove equipment where maintenance is not possible in situ, replace after<br />

12<br />

maintenance.<br />

15. Clean water cooled condensers, check for corrosion. 12<br />

16. Check casing for corrosion, clean dry <strong>and</strong> make good. 12<br />

17. Check for broken frame supports or missing or loose bolts. Report on defects. 12<br />

18. Check for icing on coil <strong>and</strong> investigate if necessary. Report on defects. 12<br />

19. Check operation <strong>of</strong> defrost systems <strong>and</strong> devices. 12<br />

Pipe work - Refrigeration<br />

Action<br />

Interval<br />

(Months)<br />

1. Check for frosting; adjust gas charge or TX control valve setting if necessary. 1<br />

2. Check temperature (<strong>and</strong> pressure drop where possible) across refrigerant drier. 1<br />

3. Check operation <strong>of</strong> solenoid valves <strong>and</strong> TX valves. 1<br />

4. Check all pipes <strong>and</strong> valves for leaks using a detector. Rectify as necessary. 6<br />

5. Check that pipes <strong>and</strong> gauges are securely fixed. Report on defects. 6<br />

6. Check operation <strong>of</strong> all manual valves. Ensure that all valve caps have copper seal 12<br />

rings fitted.<br />

7. Test <strong>and</strong> reset TX valve superheat settings. 12<br />

8. Check operation <strong>of</strong> solenoid valves. 12<br />

9. Clean all strainers. 12<br />

Plant Rooms<br />

Action<br />

Interval<br />

(Months)<br />

1. Remove all waste materials, rags, old media <strong>and</strong> the like. 1<br />

2. All machinery to be wiped down <strong>and</strong> left in clean <strong>and</strong> tidy condition. 1<br />

3. Maintain floors in clean state by occasional mopping with detergent. 1<br />

4. Replace lamps as necessary <strong>and</strong> maintain fittings in clean condition. 1<br />

5. Ensure all drains are clear. 1<br />

6. Check that fresh air inlets are not blocked with stored materials <strong>and</strong> that cleaning 1<br />

equipment, <strong>and</strong> other odorous materials are not stored in fresh air plenums.<br />

7. Advise on remedial painting or other building work required. 12<br />

9