Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

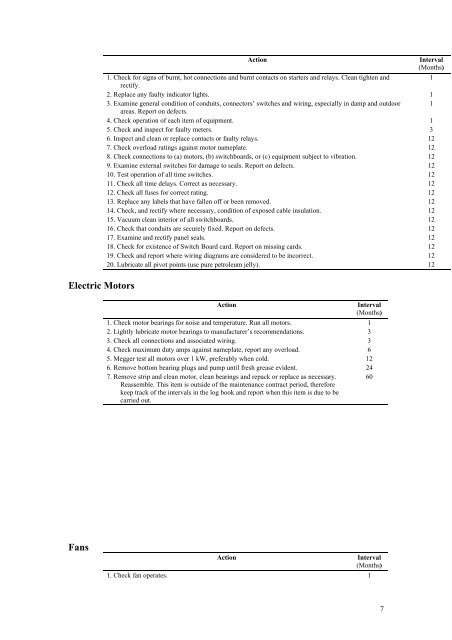

Electric Motors<br />

Action<br />

Interval<br />

(Months)<br />

1. Check for signs <strong>of</strong> burnt, hot connections <strong>and</strong> burnt contacts on starters <strong>and</strong> relays. Clean tighten <strong>and</strong><br />

1<br />

rectify.<br />

2. Replace any faulty indicator lights. 1<br />

3. Examine general condition <strong>of</strong> conduits, connectors’ switches <strong>and</strong> wiring, especially in damp <strong>and</strong> outdoor 1<br />

areas. Report on defects.<br />

4. Check operation <strong>of</strong> each item <strong>of</strong> equipment. 1<br />

5. Check <strong>and</strong> inspect for faulty meters. 3<br />

6. Inspect <strong>and</strong> clean or replace contacts or faulty relays. 12<br />

7. Check overload ratings against motor nameplate. 12<br />

8. Check connections to (a) motors, (b) switchboards, or (c) equipment subject to vibration. 12<br />

9. Examine external switches for damage to seals. Report on defects. 12<br />

10. Test operation <strong>of</strong> all time switches. 12<br />

11. Check all time delays. Correct as necessary. 12<br />

12. Check all fuses for correct rating. 12<br />

13. Replace any labels that have fallen <strong>of</strong>f or been removed. 12<br />

14. Check, <strong>and</strong> rectify where necessary, condition <strong>of</strong> exposed cable insulation. 12<br />

15. Vacuum clean interior <strong>of</strong> all switchboards. 12<br />

16. Check that conduits are securely fixed. Report on defects. 12<br />

17. Examine <strong>and</strong> rectify panel seals. 12<br />

18. Check for existence <strong>of</strong> Switch Board card. Report on missing cards. 12<br />

19. Check <strong>and</strong> report where wiring diagrams are considered to be incorrect. 12<br />

20. Lubricate all pivot points (use pure petroleum jelly). 12<br />

Action<br />

Interval<br />

(Months)<br />

1. Check motor bearings for noise <strong>and</strong> temperature. Run all motors. 1<br />

2. Lightly lubricate motor bearings to manufacturer’s recommendations. 3<br />

3. Check all connections <strong>and</strong> associated wiring. 3<br />

4. Check maximum duty amps against nameplate, report any overload. 6<br />

5. Megger test all motors over 1 kW, preferably when cold. 12<br />

6. Remove bottom bearing plugs <strong>and</strong> pump until fresh grease evident. 24<br />

7. Remove strip <strong>and</strong> clean motor, clean bearings <strong>and</strong> repack or replace as necessary. 60<br />

Reassemble. This item is outside <strong>of</strong> the maintenance contract period, therefore<br />

keep track <strong>of</strong> the intervals in the log book <strong>and</strong> report when this item is due to be<br />

carried out.<br />

Fans<br />

Action<br />

Interval<br />

(Months)<br />

1. Check fan operates. 1<br />

7