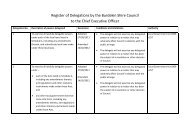

Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

Service, Maintenance and Repairs of Council's Airconditioning ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1. Check <strong>and</strong> record, as applicable:-<br />

a. Discharge temperatures. 1<br />

b. Discharge pressures. 1<br />

c. Refrigerant flow temperatures. 1<br />

d. Refrigerant return temperatures. 1<br />

2. Check sump heater operation when unit is <strong>of</strong>f. Report on defects. 1<br />

3. Check oil level. Report on defects. 1<br />

4. Check for undue vibration <strong>of</strong> unit or pipes. Rectify as required. 1<br />

5. Check oil pressure. Report on defects. 1<br />

6. Check liquid refrigerant charge flow in sight glass (where fitted) for moisture or<br />

1<br />

shortage <strong>of</strong> gas. Report on defects.<br />

7. Check motor <strong>and</strong> drive. Report on defects. 1<br />

8. Check vibration mountings. Report on defects. 1<br />

9. Check operation <strong>of</strong> recycle <strong>and</strong> between stage timers. 1<br />

10. Check switchboard to ensure tight terminals <strong>and</strong> correct operation. 1<br />

11. Check for refrigerant leaks. Rectify as required. 1<br />

12. Change oil <strong>and</strong> flush crankcase sump. 12<br />

13. Change driers. 12<br />

14. Clean strainers <strong>and</strong> scale trap. 12<br />

15. Change filters. 12<br />

16. Check solenoids electrically. Report on defects. 12<br />

17. Check alignment <strong>of</strong> coupling <strong>and</strong> check rubbers for wear. Replace as necessary. 12<br />

18. Remove heads <strong>of</strong> water cooled condensers <strong>and</strong> oil coolers <strong>and</strong> clean tubes. Check 12<br />

<strong>and</strong> report on corrosion.<br />

19. Have necessary inspections carried out on condensers <strong>and</strong> evaporators. 12<br />

20. Set unit to work <strong>and</strong> prove correct operation. 12<br />

21. Prove correct operation <strong>of</strong> all safety controls. 12<br />

22. Lubricate <strong>and</strong> grease all points <strong>and</strong> linkages. 12<br />

23. Replace cathodic protection in condenser (if fitted). 12<br />

Storage Vessels<br />

Daily <strong>Service</strong> Feed <strong>and</strong> Expansion Tanks<br />

Action<br />

Interval<br />

(Months)<br />

1. Check operation <strong>of</strong> float valve or other controls. 1<br />

2. Repair any leaks in tank or at pipe fittings. 1<br />

3. Clean out drip trays, <strong>and</strong> ensure drains are clear. 6<br />

4. Clean water <strong>and</strong> sludge from daily service tanks for fuel oil. 12<br />

Vibration Isolation<br />

Action<br />

Interval<br />

(Months)<br />

1. Inspect vibration isolators. 3<br />

2. Check for damaged isolators <strong>and</strong> incorrect settings on jacking bolts. 3<br />

3. Check that machine isolators are not short-circuited by electrical conduits, guards, 3<br />

debris etc.<br />

4. Ensure mounts are clear <strong>of</strong> oil or water. 3<br />

5. Check that flexible connections are installed correctly. 3<br />

11