Rottne H-8 - dominga.lt

Rottne H-8 - dominga.lt

Rottne H-8 - dominga.lt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SERVICE ACCESS<br />

Serviceability is an important factor during development work on all <strong>Rottne</strong> machines.<br />

Downtime can prove expensive for machine owners and good service access can significantly<br />

reduce the time needed for servicing, repairs and cleaning. <strong>Rottne</strong> H-8 is no exception<br />

in this respect. The entire engine compartment can be accessed easily by<br />

ti<strong>lt</strong>ing the engine hood back and the oil tanks to the side.<br />

Even the cab can be ti<strong>lt</strong>ed to the side during servicing work on hoses and blocks underneath<br />

the machine. The distribution box with fuses and relays, and computers, are well positioned<br />

for easy access when the right cab door is opened. A vacuum pump for the hydraulic<br />

system reduces oil spillage when replacing hoses, for example, and an electric pump makes<br />

a change or replenishing of hydraulic oil easier.<br />

TECHNICAL DATA<br />

ENGINE<br />

JOHN DEERE 4045 HF 485, Tier 3<br />

water-cooled turbocharged engine with intercooler<br />

Cylinder volume ...................................4.5 litres (274 in)<br />

Torque at 1400 rpm ............................645 Nm (476 lb ft)<br />

Output at 1800 rpm ............................116 kW<br />

Fuel tank ................................................260 litres (69 US gal)<br />

TRANSMISSION<br />

Fully hydrostatic with three gear stages and variable diff. lock<br />

Tractive force .........................................73 kN<br />

BRAKES<br />

Negative wet disc brakes in the wheel motors that are<br />

controlled proportionally via the brake pedal.Parking and<br />

emergency brake.<br />

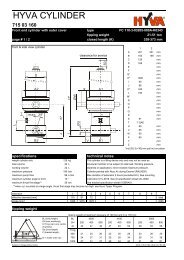

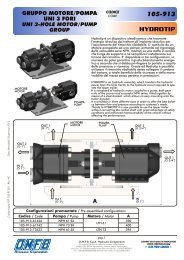

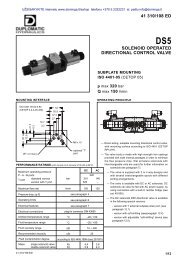

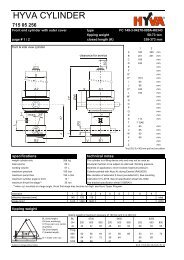

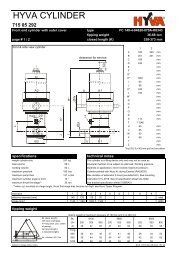

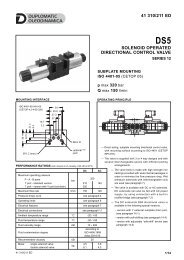

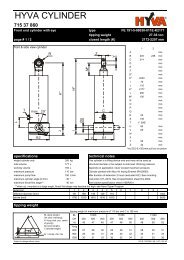

HYDRAULIC SYSTEM<br />

Fully independent systems for transmission<br />

and working hydraulics.<br />

Pump capacity ..................................230 litres (61 US gal) /1700 rpm<br />

Working pressure ........................25.0 Mpa (3410 psi)<br />

ELECTRICAL SYSTEM<br />

24-vo<strong>lt</strong> electrical system with <strong>Rottne</strong> D5 machine control system.<br />

Work lighting ..................................17 x 70 W<br />

CAB<br />

Spacious, vibration-proof safety cab (ROPS, FOPS as per ISO<br />

standard). Polycarbonate windows. Climate system with<br />

automatic control (ACC), sun blinds. Radio with CD player.<br />

Printer for measuring system integrated into ceiling panel.<br />

Noise level.......................................69 dBA<br />

LOADER<br />

RK 50<br />

Parallel knuckle boom loader with ti<strong>lt</strong>ing loader base and<br />

1.4 m extension.<br />

Automatic loader ti<strong>lt</strong> function ...–15°/+20°<br />

Lifting torque, gross/net................80 kNm/53 kNm<br />

(59000/39090 lbf ft)<br />

Torque ................................................12 kNm (8850 lbf ft)<br />

Angle of rotation .............................230°<br />

Reach ..................................................7 m (23 ft)<br />

EQUIPMENT<br />

Standard: Technical documentation. Radio with CD player.<br />

2 hand-held fire extinguishers. Toolkit. Sun blinds.<br />

Vacuum pump. Electric filling pump.<br />

Options: Engine/cab heater with heating coil for hydraulic tank.<br />

Sprinkler system. Green oil. Rear vision system. Xenon working<br />

light. Data calliper. Colour marking system, Orbitrol steering,<br />

Mobile telephone, Fluid-filled wheels, Stump spray treatment,<br />

GPS/GIS,