Rottne H-8 - dominga.lt

Rottne H-8 - dominga.lt

Rottne H-8 - dominga.lt

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ROTTNE H8<br />

A SMALL HARVESTER WITH GREAT QUALITIES<br />

H8

CLEANER ENGINE<br />

<strong>Rottne</strong> H-8 has a powerful new 4-cylinder<br />

tier 3 diesel engine. It easily satisfies emission<br />

requirements for modern industrial engines.<br />

The new engine has been named Power Tech<br />

Plus and it has, among other things, 4-valve<br />

technology, a Common Rail injection system and<br />

a variable turbocharger. This technology and<br />

electronic means of control enables the power<br />

curve and torque to be adapted to the optimum<br />

rpm range for harvesters, which means that the<br />

harvester can be operated at a lower working<br />

engine speed.<br />

Compared with its predecessor, the new engine<br />

also produces a much more rapid response,<br />

less vibrations, a lower noise level and most<br />

importantly lower fuel consumption.<br />

EFFECTIVE THINNING HARVESTER<br />

Fantastic overview and visibility.<br />

<strong>Rottne</strong> H-8 is an ideal harvester for stand operated<br />

thinning, and with various working route system<br />

options it can handle strip road distances of up to 35<br />

metres without manual intermediate zone felling.<br />

The two-part chassis with an articulated joint in the<br />

centre produces precise tracking, and when combined<br />

with its levelling capabilities, this harvester becomes<br />

extremely flexible and easy to drive when working on<br />

a secondary road out in the stand.<br />

An optional rear vision system with a camera mounted<br />

on the back of the cab gives the operator a better<br />

overview. When reversing, pictures from the camera<br />

are automatically displayed on the D5 display.<br />

RK 50 is a parallel acting loader with a 1.4 metre<br />

extension and ti<strong>lt</strong> function for the turntable.<br />

The loader is thus extremely flexible and versatile<br />

in dense thinnings.

LARGE AND COMFORTABLE CAB<br />

The spacious and comfortable cab with its large windows<br />

affords the operator an excellent view of the entire working<br />

area. The ergonomically designed operator station has wel<strong>lt</strong>hought-out<br />

instrument panels to the side and in front of the<br />

operator's seat, which has air suspension and is equipped<br />

with Airvent. The infinitely adjustable armrests feature integrated<br />

lever panels with function keys used for controlling<br />

the head during felling and processing.<br />

The computer screens for the D5 machine control system<br />

and the D5 measuring system, are both colour displays with<br />

a touch screen function. They are positioned low down in<br />

front of the operator so as not to interrupt the field of view.<br />

An efficient air conditioning system with ACC ensures that<br />

the operator always has fresh air and a comfortable cab<br />

temperature.<br />

A lot of equipment is kept in the cab, and there are plenty of<br />

boxes and storage compartments for equipment that needs<br />

to be carried as part of the operator's day-to-day work.<br />

ROTTNE H-8<br />

EGS 405<br />

THE HEAD<br />

EGS 405 is a well-tested head of conventional design with two feed<br />

rollers of steel or solid rubber, two pairs of moving delimbing knives<br />

and a saw unit with automatic chain tensioning.<br />

The compact design and low weight make it ideal for use in all<br />

types of thinning stand. The head has a short frame and it is<br />

possible to control the upper and lower delimbing knives and<br />

wheel arms separately.<br />

These factors together with the heads high tractive force provide<br />

excellent conditions for processing bent and difficu<strong>lt</strong> to delimb<br />

hardwood. Colour marking and stump spray application equipment<br />

are available as option.<br />

WELL DESIGNED<br />

<strong>Rottne</strong> H-8 has a narrow and compact chassis with a swing arm<br />

system that gives the machine unique terrain handling qualities.<br />

The four wheel arms have a large swing movement, which means<br />

levelling can equal out both lengthways and sideways inclines, as<br />

well as give good ground clearance in stony and uneven terrain.<br />

The pendulum arm system minimises the amount of space needed<br />

for the harvester and improves weight distribution and stability so<br />

that felling and processing can be performed at full reach even to<br />

the side.<br />

The hydraulic system, which is load-sensing, has a large<br />

pump capacity and provides the loader and head with distinct<br />

and rapid movements. The flexible parallel loader RK 50<br />

has a good reach and a lifting force ideally suited to<br />

the head weight.

ROTTNE-H8<br />

A SMALL HARVESTER WITH<br />

HUGE POTENTIAL<br />

Several evaluation studies have shown<br />

that stand-operating harvesters produce<br />

the most consistent resu<strong>lt</strong>s during<br />

mechanical thinning. <strong>Rottne</strong> H-8 has all<br />

the qualities required to ensure successful<br />

thinning using secondary roads in the<br />

stand.<br />

The pendulum arm system means that<br />

the machine width is always maintained,<br />

even when the ground is uneven or you<br />

encounter an obstacle. The operator sits<br />

in a cab offering superb all-round visibility,<br />

while hydrostatic operation and precise<br />

tracking make this small yet flexible<br />

harvester even more versatile and easy to<br />

move forwards or backwards with great<br />

precision.<br />

It is easier to select the right tree when<br />

the operator is never more than 6-7 metres<br />

from the trees to be felled and the<br />

risk of damage to standing forest is also<br />

reduced considerably more than if thinning<br />

were to be performed from a strip<br />

road 10-12 metres away.<br />

When the harvester is equipped with a<br />

system for GPS/GIS, the forwarder operator<br />

can access tract maps with working<br />

routes and timber volumes per strip<br />

road to ensure that everything is being<br />

collected. The landowner can also access<br />

detailed information about thinning for his<br />

forest management plan.<br />

ROTTNE-8

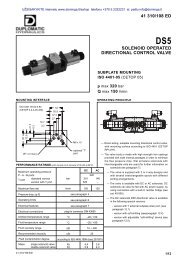

ROTTNE D5<br />

The machine control system <strong>Rottne</strong> D5, which is based on<br />

CAN bus technology, controls and monitors the engine,<br />

transmission, loader, and head. D5 comprises a main computer,<br />

a 7” colour touch screen, and a number of nodes set out<br />

on the machine close to the function to be controlled.<br />

The main computer communicates by means of a CAN bus cable<br />

linked to all the nodes. The operator can adjust settings for the<br />

loader, transmission and engine, monitor pressure, temperatures<br />

and fluid levels and perform troubleshooting using the display<br />

(touch screen) on an adjustable arm slightly forward of the operator.<br />

Alarms are indicated by visual and audible signals and are displayed<br />

in clear text on the display.<br />

ROTTNE D5 MEASURING SYSTEM<br />

A new generation of measuring system with the designation <strong>Rottne</strong><br />

D5 is currently replacing the old D4 system. This is based on new<br />

technology and the hardware is the same as in the machine control<br />

system D5.<br />

The software for the bucking system uses the same calculation<br />

algorithms as D4, but in D5 the operating screen looks different, has<br />

more settings options and is generally more user-friendly.<br />

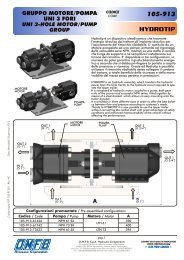

ROTTNE RK 50<br />

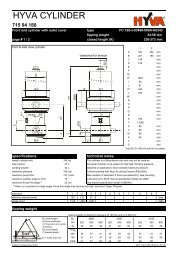

ROTTNE<br />

120"<br />

Min. 3060<br />

500×26,5<br />

8"-39"<br />

200-1000<br />

500×26,5<br />

23"<br />

Min. 595<br />

55"<br />

Max. 1390<br />

70"<br />

1775<br />

55"<br />

Max. 1390<br />

81"<br />

2050<br />

222"<br />

5632<br />

94"<br />

2378<br />

108"<br />

2737<br />

Ritn. nr. 30045<br />

2004-03-12 MJÖ<br />

329" inch<br />

8369 mm

SERVICE ACCESS<br />

Serviceability is an important factor during development work on all <strong>Rottne</strong> machines.<br />

Downtime can prove expensive for machine owners and good service access can significantly<br />

reduce the time needed for servicing, repairs and cleaning. <strong>Rottne</strong> H-8 is no exception<br />

in this respect. The entire engine compartment can be accessed easily by<br />

ti<strong>lt</strong>ing the engine hood back and the oil tanks to the side.<br />

Even the cab can be ti<strong>lt</strong>ed to the side during servicing work on hoses and blocks underneath<br />

the machine. The distribution box with fuses and relays, and computers, are well positioned<br />

for easy access when the right cab door is opened. A vacuum pump for the hydraulic<br />

system reduces oil spillage when replacing hoses, for example, and an electric pump makes<br />

a change or replenishing of hydraulic oil easier.<br />

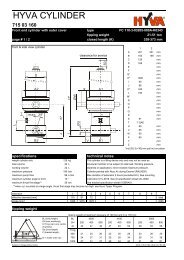

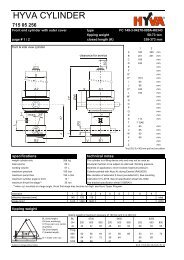

TECHNICAL DATA<br />

ENGINE<br />

JOHN DEERE 4045 HF 485, Tier 3<br />

water-cooled turbocharged engine with intercooler<br />

Cylinder volume ...................................4.5 litres (274 in)<br />

Torque at 1400 rpm ............................645 Nm (476 lb ft)<br />

Output at 1800 rpm ............................116 kW<br />

Fuel tank ................................................260 litres (69 US gal)<br />

TRANSMISSION<br />

Fully hydrostatic with three gear stages and variable diff. lock<br />

Tractive force .........................................73 kN<br />

BRAKES<br />

Negative wet disc brakes in the wheel motors that are<br />

controlled proportionally via the brake pedal.Parking and<br />

emergency brake.<br />

HYDRAULIC SYSTEM<br />

Fully independent systems for transmission<br />

and working hydraulics.<br />

Pump capacity ..................................230 litres (61 US gal) /1700 rpm<br />

Working pressure ........................25.0 Mpa (3410 psi)<br />

ELECTRICAL SYSTEM<br />

24-vo<strong>lt</strong> electrical system with <strong>Rottne</strong> D5 machine control system.<br />

Work lighting ..................................17 x 70 W<br />

CAB<br />

Spacious, vibration-proof safety cab (ROPS, FOPS as per ISO<br />

standard). Polycarbonate windows. Climate system with<br />

automatic control (ACC), sun blinds. Radio with CD player.<br />

Printer for measuring system integrated into ceiling panel.<br />

Noise level.......................................69 dBA<br />

LOADER<br />

RK 50<br />

Parallel knuckle boom loader with ti<strong>lt</strong>ing loader base and<br />

1.4 m extension.<br />

Automatic loader ti<strong>lt</strong> function ...–15°/+20°<br />

Lifting torque, gross/net................80 kNm/53 kNm<br />

(59000/39090 lbf ft)<br />

Torque ................................................12 kNm (8850 lbf ft)<br />

Angle of rotation .............................230°<br />

Reach ..................................................7 m (23 ft)<br />

EQUIPMENT<br />

Standard: Technical documentation. Radio with CD player.<br />

2 hand-held fire extinguishers. Toolkit. Sun blinds.<br />

Vacuum pump. Electric filling pump.<br />

Options: Engine/cab heater with heating coil for hydraulic tank.<br />

Sprinkler system. Green oil. Rear vision system. Xenon working<br />

light. Data calliper. Colour marking system, Orbitrol steering,<br />

Mobile telephone, Fluid-filled wheels, Stump spray treatment,<br />

GPS/GIS,

ROTTNE H-8

<strong>Rottne</strong> Industri AB<br />

www.rottne.com