METHOD STATEMENT Gas Systems - Vital Energi

METHOD STATEMENT Gas Systems - Vital Energi

METHOD STATEMENT Gas Systems - Vital Energi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

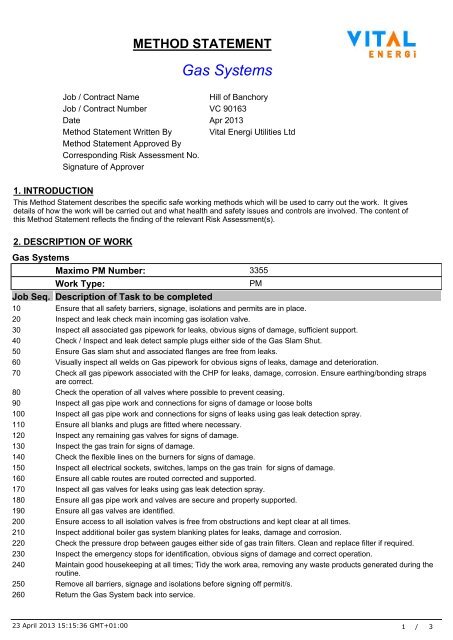

<strong>METHOD</strong> <strong>STATEMENT</strong><br />

<strong>Gas</strong> <strong>Systems</strong><br />

Job / Contract Name<br />

Hill of Banchory<br />

Job / Contract Number VC 90163<br />

Date Apr 2013<br />

Method Statement Written By <strong>Vital</strong> <strong>Energi</strong> Utilities Ltd<br />

Method Statement Approved By<br />

Corresponding Risk Assessment No.<br />

Signature of Approver<br />

1. INTRODUCTION<br />

This Method Statement describes the specific safe working methods which will be used to carry out the work. It gives<br />

details of how the work will be carried out and what health and safety issues and controls are involved. The content of<br />

this Method Statement reflects the finding of the relevant Risk Assessment(s).<br />

2. DESCRIPTION OF WORK<br />

<strong>Gas</strong> <strong>Systems</strong><br />

Maximo PM Number: 3355<br />

Work Type:<br />

PM<br />

Job Seq. Description of Task to be completed<br />

10 Ensure that all safety barriers, signage, isolations and permits are in place.<br />

20 Inspect and leak check main incoming gas isolation valve.<br />

30 Inspect all associated gas pipework for leaks, obvious signs of damage, sufficient support.<br />

40 Check / Inspect and leak detect sample plugs either side of the <strong>Gas</strong> Slam Shut.<br />

50 Ensure <strong>Gas</strong> slam shut and associated flanges are free from leaks.<br />

60 Visually inspect all welds on <strong>Gas</strong> pipework for obvious signs of leaks, damage and deterioration.<br />

70 Check all gas pipework associated with the CHP for leaks, damage, corrosion. Ensure earthing/bonding straps<br />

are correct.<br />

80 Check the operation of all valves where possible to prevent ceasing.<br />

90 Inspect all gas pipe work and connections for signs of damage or loose bolts<br />

100 Inspect all gas pipe work and connections for signs of leaks using gas leak detection spray.<br />

110 Ensure all blanks and plugs are fitted where necessary.<br />

120 Inspect any remaining gas valves for signs of damage.<br />

130 Inspect the gas train for signs of damage.<br />

140 Check the flexible lines on the burners for signs of damage.<br />

150 Inspect all electrical sockets, switches, lamps on the gas train for signs of damage.<br />

160 Ensure all cable routes are routed corrected and supported.<br />

170 Inspect all gas valves for leaks using gas leak detection spray.<br />

180 Ensure all gas pipe work and valves are secure and properly supported.<br />

190 Ensure all gas valves are identified.<br />

200 Ensure access to all isolation valves is free from obstructions and kept clear at all times.<br />

210 Inspect additional boiler gas system blanking plates for leaks, damage and corrosion.<br />

220 Check the pressure drop between gauges either side of gas train filters. Clean and replace filter if required.<br />

230 Inspect the emergency stops for identification, obvious signs of damage and correct operation.<br />

240 Maintain good housekeeping at all times; Tidy the work area, removing any waste products generated during the<br />

routine.<br />

250 Remove all barriers, signage and isolations before signing off permit/s.<br />

260 Return the <strong>Gas</strong> System back into service.<br />

23 April 2013 15:15:36 GMT+01:00 1 / 3

3. LOCATION / ASSET OF WORK<br />

Location<br />

Asset<br />

GASSYSTEM<br />

4. Access Arrangements<br />

Give details of any special access or egress arrangements that will be used.<br />

5. Licence<br />

If a licence is required for this work, give details of licence required, who holds it and where a copy of this licence is<br />

stored e.g. Asbestos, C.O.R.G.I. Registration.<br />

23 April 2013 15:15:36 GMT+01:00 2 / 3

23 April 2013 15:15:36 GMT+01:00 3 / 3