You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

PREFAC~<br />

II<br />

Eight volumes of compendiums containing important<br />

instructions and letters issued by Electrical (TRS) Dte. concerning<br />

Traction Rolling Stock have already been circulated. The last volume<br />

contained letters issued from Electrical (TRS) Dte. between from<br />

Jan. '09 td Dec. 1 09.<br />

This Volume IX in this series contains policy instructions issued<br />

by Railway Board on Traction rolling Stock from Jan., 2010 to Dec.,<br />

2010. Efforts have been made to compile important guidelines<br />

keeping the compendium concised. Any lapse or error in this volume<br />

may be brought to the notice of Secretary(Eiectricai}/RS, Railway<br />

Board for consideration during updates and review. Availability of<br />

this compendium with officials in all Electric Loco Shed, Divisional<br />

Head quarters, Workshops, Production Units and at Zonal<br />

Headquarters may be ensured.<br />

,)<br />

Dated :January, <strong>2011</strong><br />

{L.M. Sahore)<br />

Adviser Elect. (RS)<br />

Railway Board

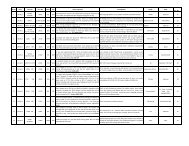

INDEX<br />

Railway Board/references (Traction Rolling Stock}<br />

S.No. Letter No. Dated Subject Page<br />

No.<br />

f--<br />

1. 2002/Eiect.(TRS)/113/13<br />

05.01.10 Extraction of data from ESMON at the time of 1<br />

accidents<br />

I<br />

2. 92/Eiect.(TRS)/138/5 Pt. Ill 08.01.10 Review of the periodicity of maintenance of electric 2<br />

locos.<br />

--<br />

3. 92/Eiect.(TRS)/138/5 Pt. Ill 08.01.10 Schemes for cooling of electronics on three phase 3<br />

electric locos.<br />

4. 2006/Eiect.(TRS)/441/11 Pt. 14.01.10 Healthiness of VHF sets given to loco pilots and 4<br />

guards.<br />

---<br />

97/elect.(TRS)/440/18/44(3-Ph) Pt. 18.01.10 Failures of traction housing and link flange/bolts in 5<br />

3-ph. Locos.<br />

r<br />

. 2008/Eiect.(TRS)/441/5 Pt. 24.02.10 Revised norms for UES for maintenance of 6<br />

conventional Ac elect. Locos.<br />

7. 2003/elect.(TRS)/440/1 Pt. 05.04.10 Integrity of BP & FP circuit on electric locomotives. 7<br />

----<br />

8. 2007 /Eiect.{TRS)/440/17 19.04.10 Condemnation of averaged electric locos 8<br />

---<br />

9. 2007 /Eiect.(TRS)/441/10 03.05.10 Upgradation/modification of single bottle VCBs type 9-16<br />

BVAC 25.10 (Older version) and BVAC 25.10 M07<br />

(Old) of Secheron design supplied by M/s BY to VCBs<br />

type BVAC 25.10.M07 {new).<br />

10. 2002/Eiect.(TRS}/441/4 Pt. 06.05.10 Report of the Committee on standardization of 17-18<br />

maintenance kits and rehabilitation I reconditioning<br />

policy for N-32 tap changer used on conventional<br />

electric locomotives.<br />

11. 2002/ Elect.(TRS)/441/4 Pt.<br />

I 17.05.10 Development of low frequency horn for elect Locos 19<br />

to prevent cattle run over.<br />

-- 12. 2010/Eiect.(Dev)/225/1 07.06.10 Review of working of RDSO -streamlining the policy 20-46<br />

of upgradation of vendors & agencies for vendors<br />

and agencies for vendor development.<br />

-<br />

13.<br />

TPWS on electric locos - installation and 47<br />

2004/Eiect.(TRS)/440/19<br />

09.06.10<br />

maintenance<br />

--<br />

14. 2009/Eiect.(TRS)/441/4 21.06.10 Assembly of new electric locos in workshops. 48-52<br />

15. 1<br />

2009/Eiect.(TRS)/441/4 11.08.10 Assembly of new electric locos in workshops. 53<br />

-<br />

Colours of ink to be used for notings and for sending 54-55<br />

~-~2007 /Eiect.(TRS}/225/10/Misc. 23.08.10<br />

communications.<br />

--- -<br />

17.<br />

2009/Eiect.(rRS}/113/2 29.09.10<br />

Completion of entries in drivers' competency and 56-57<br />

oio-data books.<br />

18.<br />

2008/Eiect.(TRS)/113/2(Fog Safe) 01.11.10<br />

Use of GPS based fogsafe device on electric 58-59<br />

locos/EMUs.<br />

:912009/Eiect.(TRS)/113/2 28.12.10 Use of mobile phones during train run 60<br />

l 20· Modification of headstock and cattle guard on 61-63<br />

2010/Eiect.(TRS)/113/1 29.12.10<br />

WAPS/WAP7 locos<br />

---- ---·<br />

***

•<br />

~ ~xtfjl•{ GOVERNMENT c)F INDIA<br />

~ +i'3tle1~ MINISTRY OF RAILWAYS<br />

~ ifr.t RAILWAY BOARD)<br />

No. 2002/Eiect.(TRS)/113/13<br />

New Delhi, Dated : 05.01.10<br />

·•<br />

General Managers (E:Iect.),<br />

Central Railway, Mumbai,<br />

East Central Railway, Hajipur<br />

Northern Railway, New Delhi·<br />

Southern Rallwav, Chennai<br />

South Eastern Railway, Kolkata<br />

South Western Railway, Hubli<br />

West Central Railway, Jabalpur<br />

Eastern Railway, Kolkata<br />

East Coast Railway, Bhubaneswar<br />

North Central Railway, Allahabad<br />

South Central Railway, Secunderabad<br />

South East Central Railway, Bilaspur<br />

Western Railway, Mumbai<br />

SUB : Extraction of data from ESMON at the time of accidents<br />

Ref: (i) Board's letter no. 2002/Eiect.(TRS)/113/13 Pt. dt. 09.11.09.<br />

(ii) Board's letter no. 2002/Eiect.(TRS)/113/13 dt. 25.11.02.<br />

Board , vide letter under ref. (i), had advised Zonal Railways to ensure<br />

availability of softwares for different types of ESMON in sheds/divisional offices for<br />

extraction of short term data from internal memory for analysis of various<br />

parameters and that a loco Inspector well conversant with data extraction should<br />

be available with lap top & data cable at the accident site for any data retrieval<br />

after the memory card has been taken off by safety organization.<br />

Despite of these instructions issued in Nov. '09, NCR was found wanting<br />

during the accidents occurred on 02.01.10 and data could not be extracted for<br />

more than 15 hrs in either of the accidents. This is being viewed seriously.<br />

It is once again emphasized that Zonal Railways should ensure availability<br />

of softwares of different types of ESMONs on laptop along with data cable at<br />

convenient locations and confirm to Board of the same within next 3 days.<br />

Also, a practice of extraction and evaluation of data from internal memory<br />

by a loco Inspector on a regular basis should be established in divisions<br />

immediately not only for sensitizing the organization but also to keep the<br />

records updated .<br />

~~<br />

S" .(. )(.<br />

(Kul Bhushan)<br />

Adviser Elect. (RS)<br />

Railway Board

'+rffa ti'

No.92/Eiect.(TRS)/l.38/5 Pt.lll<br />

New Delhi, dated : 08.01.2010<br />

Director General (Elect.)<br />

RDSO<br />

Manak Nagar<br />

LUCKNOW<br />

SUB : Schemes for cooling of electronics on three phase electric locomotives<br />

Ref: RDSO's letter no. EL/11.5.5/,5 dated 16.12.09<br />

RDSO, \/ide letter under reference, have proposed three schemes for<br />

nnnging ·ac\ .:, ·.ht: it?mperature ol eiectrunics Ot1 th ... ec ~~·~.dse ~0t·.:.;.s ·.. :.;.p~-c'.:~dg<br />

reliability. While: the proposal of providing Air Conditioning unit in machine room<br />

blower is being examined separately, Board (ML) have approved RDSO proposal<br />

for retrofitment modified cooling radiators in all existing three phase locos and<br />

to conduct trials with Thermo Electric Cooling Modules (TECM) in 5 WAG-9 locos<br />

from oldest lot.<br />

Accordingly, RDSO is advised to take the following action:<br />

{i) Zon

~ l"f;rr

'(~ toj·::Ut'l)<br />

No. 97/Eiect(TIRS}/440/18/44 (3·Ph) Ft. New Delhi, dated 1$.01.2010<br />

General Manager (Elect}<br />

Central Railway, Mumbc:1i<br />

East Central Railway, Hajipur<br />

Northern Railway, New Delhi.<br />

Chlttaranjan locomotive Work~, Chittaranjan<br />

South East Central Railway, Bilaspur<br />

South Central Railway, Vijayawada<br />

We!.t Central Railway, Jabalpur<br />

SUB :<br />

Ref : RDSO's letter no. EL/3.1.35112 dated 23.12.09<br />

Failures of traction housing and link flange/bolts hi 3 phase locos<br />

Zonal Railways have. been reporting failures of traction housing and link flange I<br />

bolts on 3~phase electric locos. RDSO studied the problem and issued SMI no. RDSO I<br />

2009/El/ SMI/0259 ( Rev'O') for maintenance of the traction link arrangement along with<br />

introduction of Ievei-I radiographic testing of the casting to ensure quality. Also a<br />

modification sheet no. MP.MOD.VL..06.38.09 ( Rev.OO) has been issued to modify traction ,<br />

link ammgemt:!nt which envisages change in CLW drawing no. 1209..01 ..113-002 Alt. 6 to<br />

obtain requisite clearance for proper tightening of 20 mrn dia bolts.<br />

CLW and Zonal Railways are to ensure the following:<br />

..<br />

(i) CLW to modify its drawing for traction housing incorporating grinding near<br />

the flange for getting adequate clearance for proper tightening and! fitment<br />

of 20 mm dia bolts in accordance with RDSO modification sheet no.<br />

MP.MOD.Vl-06.38.09 ( Rev._OO).<br />

Copy to:<br />

......<br />

All future procurements shall be made as per the revised CLW and with the<br />

specification for Ievei-I radiographic testing.<br />

(ii) CLW to ensure that all new locos being manufactured at CLW are<br />

equipped with traction housing I link complying to above drawings I<br />

specifications and modification to be cut-in on all new locos w.e.f. 01.04.3.0.<br />

(iii}<br />

{iv)<br />

CLW should ensure 100% check on the dimensions of flanges and traction<br />

tubes procured through trade. Welding of these parts to form traction bar<br />

should be done fixing them in proper jig I fixture so as to avoid any chances<br />

of misalignment. The welding so done sho.uid be checked thoroughly using<br />

ultrasonit testing facilities.<br />

'<br />

l.

'l-fR'G ~ GOVERNMENT OF INDIA<br />

~"R J=hHfll MINISTRY OF RAILWAYS<br />

(~ m RAILWAY BOARD)<br />

No. 2008/Eiect(TRS)/441/5 Pt.<br />

New Delhi, dated 24.02.2010<br />

General Manager (Elect)<br />

Central Railway, Mumbai<br />

East Central Railway, Hajipur<br />

Northern Railway, New Delhi<br />

Southern Railway, Chennai<br />

South Eastern Railway, Kolkata<br />

Western Railway, Mumbai<br />

Eastern Railway, Kolkata<br />

East Coast Railway, Bhubaneswar<br />

North Central Railway, Allahabad<br />

South Central Railway, Secunderabad<br />

South East Central Railway, Bilaspur<br />

West Central Railway, Jabalpur<br />

SUB : Revised norms for Unit Exchange Spares for maintenance of<br />

conventional ·Ac. electrk locos<br />

Ref : Railway Boards' letter no. 2005/Elect(TRS)/441/7 pt dated 28.04.08<br />

During CELEs' conferer1 :e held on ·22nd Jan'lO at Vijayawada, availability of<br />

Unit Exchange Spares (UESj of HS15250 A. TM armature on Zonal Railways Nas<br />

deliberated upon an .::1 it was :.Jnsensua!ly agreed that the 1~orms may be convenie1tly<br />

reduced to 5.0 %.<br />

The issue has been examined and Board ( ML) have approved the following<br />

norms for Unit Exchange Spares (UES) of HS15250 A TM armatures:<br />

-<br />

Sn. Equipment Existing norms % Revised<br />

-- ~ormsg<br />

1 TM armature (Hitachi) 7.5 5.<br />

Railways are a

'lHxo "iff~ GOVERNMENT OF INDIA<br />

~ l"j3jJ&J:!:l MINISTRY OF RAilWAYS<br />

~ ~RAILWAY BOARD)<br />

No. 2003/Eiect(TRS)/440/1 Pt.<br />

New Delhi, dated : 05.04.10<br />

General Manager (Elect)<br />

Central Railway, Mumbai<br />

East Central Railway, Hajipur<br />

Northern Railway, New Delhi<br />

Southern Railway, Chennai<br />

South Eastern Railway, Kolkata<br />

South Western Railway, Hubli<br />

West Central Railway, Jabalpur<br />

Eastern Railway, Kolkata<br />

East Coast Railway, Bhubaneswar<br />

North Central Railway, Allahabad<br />

South Central Railway, Secunderabad<br />

South East Central Railway, Bilaspur<br />

Western Railway, Mumbai<br />

SUB : Integrity of BP & FP circuit on electric locomotives<br />

Ref: (i) Board's letter of even number dated 19.11.09<br />

(ii) RDSO Maintenance Instruction no. MP.MI-138/88 of Feb. 1988<br />

With the introduction of air suspension springs on coaches as well as C::ontrol<br />

Discharge Toilet System (CDTS), importance of maintaining FP as per norms also has<br />

become important and critical.<br />

It has been given to understand that feed pipe circuit has been running isolated<br />

on certain locomotives.<br />

Zonal Railways are advised to identify such locos and ensure integrity of feed<br />

pipe circuit on all electric locomotives. Zonal Railways are also advised to ensure<br />

that BP & FP leakages are within the norms as prescribed by RDSO for different types<br />

of locomotives.<br />

\~/~<br />

------<br />

(Mohit Chandra)<br />

Dir. Elect. Engg. (RS)<br />

Railway Board<br />

e-mail: deers@rb.railnet.gov.in<br />

I<br />

I<br />

• f•o<br />

... 7<br />

···- -

'+ll«f '81(¢'1\! GOVERNMENT OF INDIA<br />

t(Yf ·Ji~n~~ MINISTRY OF RAILWAYS<br />

f~ ~RAilWAY BOARD)<br />

No. 2.007 /Eiect(TRS)/440/17<br />

New Delhi, dated : 19.04.2010<br />

General Manager (Elect)<br />

Central Railway, Mumbai<br />

East Central Railway, Hajipur<br />

Northern Railway, New Delhi<br />

Southern Railway, Chennai<br />

South Eastern Railway, Kolkata<br />

Western Railway, Mumbai<br />

Eastern Railway, l

,;<br />

,;·<br />

1fffif ~ GOVERNMENT OF INDIA<br />

tt1' ~.q MINISTRY OF RAILWAYS<br />

(t~ -~ RAILWAYBOARD)<br />

---_;;.<br />

::,·~·\0<br />

No. 2007/Eiect(TRS)/441/10 New Delhi, dated 03.05.2010<br />

General Manager (Elect.)<br />

Central Railway, Mumbai,<br />

East Centml Railway, Hajipur<br />

Northern Railway, New Delhi<br />

Southern Railway, Chennai<br />

South Eastern Railway, Kolkata<br />

Western Railway, Mumbai<br />

Eastern Railway, Kolkata<br />

East Coast Railway, Bhubaneswar<br />

North Central Railway, Allahabad<br />

South Central Railway, Secunderabad<br />

South East Central Railway, Bilaspur<br />

West Central Railway, Jabalpur<br />

SUB :<br />

Ref:<br />

Upgradation/modification of single bottle VCBs<br />

(Older version) and BVAC 25.10 M07 (Old) of Secheron<br />

M/s BT to VCBs type IBVAC 25.10. M07 (New)<br />

(i) RDSO's letter no. El/3.2.61/BT dated 08.12.09<br />

(ii) RDSO's letter no. ELJ;I.2.61/BT dated 16.10.09<br />

type BVAC 25.10<br />

design supplied by<br />

A techno economic proposal received from RDSO, vide letter under reference,<br />

recommending up-gradation I modification of single bottle VCBs type BVAC 25.10 (older<br />

version) and BVAC 25.10 M07 (old) of Secheron design single bottle VCB supplied by M/s BT<br />

to BVAC 25.10.M07 (New) has been examined.<br />

R[)SO has recommended the following improvements which would not only improve the<br />

reliability of these VCBs but would also reduce the recurring maintenance cost.<br />

(i) Use of simplified Electronic Control Unit (CMDE) by elimination of power<br />

resistors.<br />

(ii) Use of electro-mechanical relay in place of MOSFET & RC combination in place of<br />

OFF dE!Iay timer.<br />

(iii) Use of two 110 v DC coils instead of 12 V and 24 V coils.<br />

(iv) Use of fish bone design auxiliary contact switch in place of cam operated BBC<br />

auxiliary contacts<br />

(v) Use of air damping instead of hydraulic damping.<br />

(vi) Elimination of shoulder stop screw.<br />

(vii) Use of indigenous lndfos make pressure switch in place of Festa make pressure<br />

switch.<br />

RDSO has recommended undertaking above up gradation I modification through<br />

OEM (M/s BT) as per the scope of work at Annex 'A' and Annex 'B' and as per the price schedule<br />

and terms 8t conditions given below.<br />

(i)<br />

Moy'10<br />

!JJuradation of VCB of Model BVAC 25.10 MJ)7(old} to BVAC 25.10 M07(Newl to be<br />

YJ.:!dertaken in shed 11remises:<br />

(a) Price schedyle:<br />

-<br />

Sn. Description Amount (in Rs.)<br />

1-·--<br />

1 Price of replacement of components as per Rs. 70,000/·<br />

AnneK. A including dismantling,, cleaning,<br />

t~<br />

assennbly of components an~ testing of VCB.<br />

Service tax @ 10.30% Rs. 7,210/-<br />

Total<br />

Rs. 77,210/- (Rupees seventy seven<br />

thousand two hundred ten only)<br />

- -<br />

-9-· CD

(b)<br />

Term~ and conditions:<br />

T- Transportation No transportation is required as the modification Is to be<br />

undertaken at electric loco sheds.<br />

2 Completion Period-- The repairing work shall be completed in 90 days from the<br />

date of handing over to firm for repair in shed.<br />

3 Inspection Routine Inspection of the upgraded I modified Vacuum<br />

Circuit Breakers will be witnessed by the representative of Sr.<br />

DEE (TRS)/Dy.CEE of the concerned shed/workshl~p.<br />

·--<br />

4 Disposal of All released I removed assemblies I components of the VCB<br />

released/removed which are not reused for conversion shall be retained by the<br />

components/<br />

firm.<br />

assemblies of VCB;<br />

5 Warranty The upgraded/modified VCB shall be warranted for 12<br />

mCinths warranty for only replaced new parts from the date<br />

of modification of the VCB.<br />

----<br />

(ii) !.!1:1 gradation of \{~Bs .!.YR~ BVAC 254.Qlo!der v~n} to BVAC 25.10 M07 (New) to be<br />

undertaken in firm's (!r!!!lises_:<br />

(a)<br />

Price schech.de (ex-worlg}:<br />

--<br />

Sn. Descrip tion Amount (In Rs.)<br />

-------<br />

J. Price of re placement of components as Rs. 1,30,000/-<br />

per Annex • B inc! uding dismantling,<br />

cleaning, a. ssembly o f components and<br />

testing ofV CB<br />

2 Service tax @ 10.30% Rs. 13,390/-<br />

3 Total Rs. 1,43,390/- (Rupees one l

()<br />

The proposal has been examined and with the concurrence of associate finance,<br />

Board (ML) have decided that the single bottle VCBs of Secheron design type BVAC 25.10 (older<br />

version) <br />

I<br />

No. l007/Eiect(TRS)/441/10 New Delhi, dated 03.05.2010<br />

Copy to:<br />

FA & CAOs of Central, Eastern, East Central, East Coast, Northern, North Central,<br />

Southern, South Central, South Eastern, South East Central, Western and West Central Railways.<br />

Copy for information to :<br />

~16.~<br />

for Fina~ci4}ommissioner (Railways)<br />

Sr. EDSE, RDSO, Manak Nagar, Lucknow<br />

ED(PS &EMU), RDSO, Manak Nagar, Lucknow '<br />

Chief Electrical Engineer, Chittaranjan Locomotive Works, Chittaranjan<br />

Chief Electrical Engineer, Rail Coach Factory, Kapurthala<br />

Chief Electrical Engineer, Bharat Earth Mover Limited, Banglore<br />

May'10

•<br />

()<br />

Modification of VCB type BVAC 25.10 M07 (old) to VCB type BVAC 25.10 M07 (new}<br />

--<br />

c Cab!e with male contact HSBA-432659-RSOO 4 Nos. c<br />

\<br />

d Piug_ connector t:lumdy HSBA-440086-Pi l i d<br />

e Shrinkable boot Adaoter Bumdy HSBA-440086-P2<br />

1 e<br />

f Crimp contact female HSBA-440087-P2<br />

13 f<br />

~<br />

Scope of work<br />

Items to be replaced I modified<br />

Old Items<br />

Sr. No. Descri~tion Drawing No.<br />

Qty. Sr. No.<br />

1 Coil + Pipe's Cylinder SG-310063-R1<br />

1 1<br />

2 Solenoid Valve with Coil Assembly 3EYC-300012-R1<br />

1 2<br />

3 Aux. switch AM-400660-R 1<br />

10 3<br />

3a !Aux. switch CAM SG-310026-P2<br />

2 3a<br />

I<br />

4 CMDE 3EYC-300046-R 1<br />

i I 4<br />

Stud (For mounting CMDE) 3EYC-400231-P1<br />

2<br />

5<br />

5<br />

Stud (For mountiflg_ CMDE) 3EYC-400231-P2<br />

2<br />

6<br />

Wiring Harness consists of<br />

following major itmes.<br />

6<br />

a Radox cable 125 - 2 X 1 mm2 3EYC-4001 03-P2 2.6 Mtrs. a<br />

b Cable with male contact HSBA-432659-R 1100 17 Nos. b<br />

'---<br />

New items<br />

!Description<br />

!Coil + Pipe's Cylinder (of 110V DC) !<br />

!Solenoid Valve with Coil Assembly (Of<br />

(110V DC)<br />

DBTF type Aux Switch<br />

I<br />

Aux. switch CAM<br />

CMDE control Unit<br />

Stud (For Mountin~ CMDE)<br />

Wiring Harness consists of following' major<br />

itmes.<br />

Radox cable 125-2 X 1 mm2<br />

Cable with male contact<br />

Cable with male contact<br />

Plug connector Burndy_<br />

i<br />

Shrinkable boot Adapter Bumdy<br />

Crimp contact female<br />

i<br />

'<br />

Drawing No.<br />

3EYC-300056-R1<br />

3EYC-300053-R1<br />

3EYC-300057-R1<br />

3EYC-300058-R 1<br />

3EYC-300060-R1<br />

3EYC-400255-P 1<br />

3EYC-4001Q3.P2<br />

HSBA-432659-R1100<br />

HSBA-432659-R600<br />

HSBA-440086-Pt<br />

HSBA-440086-P2<br />

HSBA-440087 -P2<br />

I<br />

!<br />

Qty.<br />

1<br />

1<br />

Page 1 of 1<br />

Annex-A<br />

I<br />

I<br />

1<br />

1 I<br />

I<br />

1<br />

I<br />

4<br />

2.6 Mtrs.<br />

17 Nos.<br />

4Nos.<br />

1<br />

1<br />

13<br />

New Items to be added<br />

Sr. No. Description Drawing No.<br />

1 Bracket Complete 3EYC-400247-R1<br />

2 Spacer __ 3EYC-400248-P1<br />

3 M6 X 25 Hex. Soc.hd. Cap Screw MT -430956-P2008<br />

4 Plain washer Dia.6.6/12 MT -430827-P<strong>2011</strong><br />

5 Spring washer 86 MT -430197-P61 0<br />

6 HexNutM6 MT -430108-P2017<br />

7 Hex Nut MB MT -4301 08-P2018<br />

8 Plain washer 9/17 X 1.6 MT-430827-P2015<br />

9 Spring washer 88<br />

----<br />

MT -430197-P613<br />

-·-<br />

QtV.<br />

1<br />

1<br />

4<br />

8<br />

4<br />

4<br />

2<br />

2<br />

2<br />

.<br />

.. ~·<br />

ft difi<br />

-- --- . - . - --<br />

Sr. No. Description Drawing No.<br />

1 Support Plate (of Aux. switch NO) 3EYC-300030-P 1<br />

2 Support Plate {of Aux. switch NC) 3EYC-300031-P1<br />

3 Hex screw M5X20 3EYC-400126-P1~<br />

4 Beilevilfe Spring washer Dia;67i2 [M-1 '-430i5t~P1S ~-- _<br />

Qty.<br />

1<br />

1<br />

10<br />

to·<br />

---- --<br />

.Q~ ..<br />

~<br />

/4) ...._..._.

Page 1 of3<br />

Annex.'S'(<br />

0<br />

\<br />

~<br />

\JJ<br />

Scope of V\fork<br />

Modification of VCB type BVAC 25.10 to VCB type BVAC 25.10 M07 (new)<br />

Items to be replacl:!d I modified<br />

Old Items New ite~s I<br />

Sr. No. Descri!ltion Drawing_ No. (Qty. Sr. No. Description Drawing_ No. Qty. l<br />

1 Assembled Base with M12 Studs HSBA-433546-R2 . 1 1 Base Plate Assembly SG-31001D-R1 1J<br />

2 Air Tank Assembled SG-300083-R2 1 2 Air Tank Assembly : 3EYC-300043-R1 H<br />

3 Toggle Mechanism HSBA-331618-R1 1 3 Tooo!e Mect!anism Assembtv SG-310018-R1 1!<br />

4 0-ring 17.86 X 2.62 HSBA-432095-P26 1 4 0-ring 17.86 X 2.62 HSBA-432095-P26 1<br />

i 5 Cylinder with holding coil HSBA-432444-R1 1 5 Coil+ Pipe's Cylinder (of 110V DC) '3EYC-300056-R1 1<br />

I 6 iShock absorbers with nuts HSBA-433864-P2 10 6 Air Damper SG-310054-P1 1<br />

I 7 !Piston Pin HSBA-432431-P1 1 7 Pislon p;n SG-310053-P1 I 1<br />

' s ,Piston i HSBA-432425-?1 1 a Pision ·, SG-310055-Pi i<br />

I 9 Piston Ring HSBA-432435-P1 1 9 Piston segment ; SG-31 0079-P 1 0.29m<br />

10 CMDE Control Unit IHSBA-231389-R1 i 10 CMDE control Unit .3EYC-300060-R1 1<br />

I 11 Cable to Pressure switch & HSBA-433332-R1 &<br />

Radox cable 2 X 1 Sq.mm (For Pres~ure<br />

3.5m<br />

3EYC-400103-P2 3.5M<br />

Solenoid Valve HSBA-433333-R 1 1i SWitch Solenoid Valve) 1<br />

i 12 Protection Cover Assmmbled KSBA-331423-R1 1 12 Protection Cover SG-31 0046-P2 1<br />

I<br />

13 Elastic Washer 12.4/27.2X1.8 SAVA-330-6 8 13 Elastic Washer i2.4/27.2X1.8 9AVA-330-6 8<br />

14 Elastic Washer 8.2/16.2X1.4 9AVA-330-12 7 14 Elastic Washer 8.2f16.2X1.4 9AVA-330-12 10<br />

15 H .V.spring ring AS NB-335805-P511 2 15 H .V.spring ring A8 l NB-335805-P511 2<br />

I<br />

16 H.V.spring ring AS NB-335805-P509 2 16 H.V.spring ring A6<br />

NB-335805-P509 8<br />

17 Fillister hd screw M4 X 16 SADA-187-5 4 17 Fi!lister hd screw M4 X 16 I ' ·SAOA-187-5 4<br />

iB rtiiister ild screw M6 X 25 9AOA-187-26 2 18 F11!ister hd screw M6 X 25<br />

' I SADA-187-26 8<br />

19 Self tapping screw M3 X 6 GMN-316023-P1 078 4 19 Self lapping screw M3 X 6 ) GMN-316023-P1 078 4<br />

20 Solenoid Valve I3EYC-300012-R1 i<br />

20<br />

Solenoid Valve with Coil Assembly (o,f<br />

110VDCJ i<br />

3EYC-300053-R1 1<br />

21 Pressure regulator with filter HSBA-433890-?1 1 21 Pressure regulator with filter I HSBA-433890-R 1 1<br />

22 Pressure Switch 1 22 Pressure switch I 3EYC-400216-P1 1<br />

23 Operating rod + Bellows SG-3001 19-Ri 1 23 Operating rod + Bellows SG-300119-R2 1<br />

24 •0-Rinn HSBA-432579-P1 2 24 ,0-Ring I HSBA-432579-P1 2<br />

25 Anti Breaking screw_(M6 X20) SG-300120-P1 8 25 Anti Breaking screw (M6 X20) SG-300120-P1 8<br />

26 Elastic washer (6.1) 9AVA-330-11 10 26 Elastic washer {6.1) 9AVA-330-11 8<br />

27 0-ring HSBA-432095-P26 1 27 0-ring I HSBA-432095-P26 1<br />

28 CapG 3/8" HSBA-432531-Pi 2 28 CapG 3/8"<br />

: HSBA-432531-P1 2<br />

29 0-ring HSBA-432579·P1 1 29 0-ring ; HSBA-432579.?1 1<br />

30 O..Jing HSBA-432580-P 1 1 30 0-ring HSBA-432580-?1 1<br />

31 0-ring HSBA-432580-?2 1 31 0-rino HSBA-432580-P2 1<br />

32 ·Coupling rod with thread M1 0 SG-300125-P1 1 32 Coupling rod with 1hread M10 SG-300125-P1· 1<br />

33 Distance Piece HSBA-432433-P1 4 33 Distance Piece HSBA-432445-P1 2<br />

34 Washer HSBA-432539-P1 4 34 Washer HSBA-43.2539-Pi 4<br />

35 Needle bearing !HSBA-432623-P1 2 35 Needle becaring HSBA-432623-P1 2<br />

36 LockNutM10 9ADA-299-6 2 36 loci< Nut M10 9ADA-299-6 2<br />

37 Compression Spring HSBA-432463-P1 1 37 Compression Spring HSBA-432463-P1 1<br />

ruxiliary Contact BA 19 {5 NO) with<br />

i<br />

38 0- Rings & Auxiliary·Contact BA24 SG-300016-R1 & R2 2Sets I DBTF type Aux Switch 3EYC-300057 -R 1 1<br />

(5 Ncl'ffi.th 0- ~--- 38<br />

~<br />

~t\r<br />

@

Page2of 3<br />

Annex~·s· ( L-<br />

Q<br />

Modification ofVCB type BVAC 25.10 to VCB type BVAC 25.10 M07 (new)<br />

\<br />

-4:::-<br />

t<br />

;<br />

I<br />

I<br />

I<br />

I<br />

I<br />

I<br />

New Items to be added<br />

Sr. No. DescripUon Drawing No. qty. I<br />

1 Transfer Bleck: Assembly_ SG-310078-R1 1 I<br />

2 Protection Plate SG-3Hl044-P2 1 I<br />

3 Connecting Pioe SG-310059-P1 1 J<br />

I<br />

4 Distance Piece for toggle plate SG-310048-P1 4<br />

5 Jack head SG-310058-?1 1 I<br />

s Support Plate 3EYC-400235-P1 1<br />

7 Cable Binder 112 X 4.6 NB 1-402938-P203 a<br />

8 Pin Contact HSBA-440086-P3 1<br />

s Crimp contact Pin) HSBA-440087-P1 16<br />

10 Shim Washer Oia.12/24X0.1th HZN-451264-?0012 1<br />

11 Shim Washer Dia.12124X0.2th HZN-451264-P612 1 I<br />

12 Shim Washer Dia. i2i24X0.3th HZN451264-P1212 1<br />

1<br />

13 Shim Washer Dia.12124X0.5th HZN-451264-?2412 3<br />

'<br />

14 Elastic Washer6.1/142X1.4 SAVA-330-3 111<br />

15 Serrated washer SB GON-336152-?0422 4<br />

15 Serrated washer S10 GON-336152-P0423 1<br />

17 HexNU1M6 9ADA-299-4 4<br />

18 SShexnutM8 3EVC-400127 -P2 4<br />

19 Stud M8 {For Mounting CMOE) 3EYC-400255-P1 4<br />

20 Fi!lister hd screw M6 X 16 9AOA-187-24 2<br />

21 Fil!ister hd screw M8 X 50 9ADA-187-42 2<br />

22 Fillister hd screw M8 X 130 9ADA-i87-8130 4<br />

23 FiUister hd screw M10 X 160 9ADA-187-i0160 1<br />

24 Fillister hd screw M12 X 120136 3EHN-424021-P1014 4<br />

25 Cover Screw M8 X 20 SG-310047-Pi 4<br />

2& Screw Socket M6 NBT -40293R-P0013 3<br />

27 Cable lug 1 Sq.mm 3EYC-400026-P16 22<br />

28 Aux. switch CAM 3EVC-300058-R 1 1<br />

29 Bracket Complete 3EVC-400247-R1 1<br />

30 Spacer 3EYC-400248-P1 1<br />

31 MB X 25 Hex. Soc.hd. Cap Screw MT -430956-P2008 4<br />

32 Plain washer Dia.6.6112 MT -430827-P<strong>2011</strong> B<br />

33 Spring_ washer 86 MT-430197-P610 4<br />

34 HexNutM6 MT -430106-P2017 4<br />

35 HexNutM8 MT -430108-P2018 2<br />

36 Plain washer 9/17 X 1.6 MT -430827-?2015 2<br />

37 §Qring washer 88 MT -430197-P613 2<br />

~<br />

@

~------- ---------------.fter<br />

~<br />

Page3of3<br />

- Armex~'B' ~<br />

()<br />

Modification of VCB type BVAC 25.10 to VCB type BVAC 25.10 M07 (new}<br />

\<br />

vf<br />

modif" -.....--------<br />

Sr. No. Description Drnwing No.<br />

1 Connecting. PiQe SG-300055--?2<br />

2 0-Ring HSBA-432095-P27<br />

3 Nr Flow Regulator SG-300054-PI<br />

4 0-Ring HSBA-432095-P25<br />

5 0-Ring HSBA-432095-?28<br />

6 Cover for Holding coil HSBA-331407-P1<br />

7 Fiat Gasket HSBA-432551-P2<br />

8 Control Rod HSBA-433316-P1<br />

9 Stay8olt HSBA-433314-Pi<br />

10 Drive Screw HSBA-433491-P1<br />

11 Pusher HSBA-433315-Pi<br />

12 Fastener far AUx. Contact Spring HSBA-433889-PZ<br />

13 Tension Spring HSAB-433308-P 1<br />

14 Cable lug 1.5 Sg,mm 3EVC-400124-P1<br />

15 Distance Piece HSBA-432445-Pi<br />

16 Cap HSBA-432424-Pi<br />

17 Plate HSBA-432510-?1<br />

18 Hex Nut0.8d X M12 3EYC-400127-P3<br />

19 Elastic Washer 6.1 SAVA-330-11<br />

20 HexiloltM12 X 130<br />

1 9AVA-5945<br />

21 Hex Nut 0.8d X MS 3EYC-400127 -PZ<br />

22 Wedge washer 0.2 HSBA-433389-?1<br />

23 We{j~ washer 0.5 HSBA-433389-P2<br />

24 Wedge washer 1.0 HSBA-433389-?3<br />

25 Elastic washer 8.2 SAVA-330-4<br />

26 Fillister head screw iv18 X 70 9AOA-187-46<br />

27 Fillister head screw M6 X 30 9AOA-187-27<br />

28 F,illister head screw M8 X 140 NB-315840-P225<br />

29 Hex Screw MS X 14 :JEYC-400126-PS<br />

30 LocknutM4 9ADA-299-2<br />

31 Hex screw M4 X 30 3EYC-400126-P9<br />

32 Elastic washer 4.1 SAVA-330-100<br />

33 Flange screw M5 X 12 HSBA-433531-P2<br />

34 Conic head screw M6 X 16 SAVA-194-616<br />

Qty.<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

2<br />

I 1<br />

2<br />

2<br />

2<br />

2<br />

18<br />

2<br />

1<br />

2<br />

4<br />

2<br />

4<br />

6<br />

4<br />

4<br />

6<br />

4<br />

2<br />

2<br />

4<br />

2<br />

8<br />

4<br />

22<br />

2<br />

4<br />

::;;;~.<br />

~<br />

&

C1<br />

I l<br />

The list of Compc;·nents to be changed on conditional basis for VCB Upugradation.<br />

. I<br />

Sr.<br />

No.<br />

----·;-=-<br />

' I<br />

Desbrip tion<br />

' '<br />

~ ~<br />

!a tor<br />

or 25KV.<br />

ting Head.<br />

I Sleeve.<br />

5 ·Rear Hori:z:odtc:: !!·Sleeve.<br />

t--6"-,._:V.....;.;e;:,.;;;rt;.;_ic.~e~~~e<br />

..<br />

I<br />

7<br />

Assembled Vja<br />

S·witch Tube:.<br />

I<br />

. !<br />

!·<br />

cuum<br />

Drg .. No.<br />

HSBA~2313!96-R1<br />

HSBA-231305~R1<br />

HS8A-433486·R 1<br />

HSBA·331594~P1<br />

HSBA-331593-P1<br />

-<br />

HSBA-331677-P1<br />

HSBA-331624-R 1<br />

\ Unit Price (including·-<br />

'Qty. taxes & duties) in<br />

Rupees<br />

--<br />

1 Rs. 47,500. 00<br />

-<br />

1 Rs. 41,000.00<br />

1 Rs. 20,120.00<br />

1 Rs. 9,000.00<br />

1 i Rs. 7,850.00<br />

1 Rs. 10,800.00<br />

Rs'. 1,.20,000.00 '<br />

1<br />

- --<br />

1<br />

i<br />

I<br />

I<br />

! '<br />

~::..--:=...""=::::·. ~~==~<br />

I<br />

1<br />

1<br />

'<br />

===

~fRO *1\!l'< GOVERNMIENT Of INDIA<br />

~ T-f~ MINISTRY OF RAILWAYS<br />

(~ ~ RAILWAY BOARD)<br />

.,<br />

No.2002/Eie

(vi)<br />

The procedure for awarding of tende!r shaH be as under:<br />

{a)<br />

Separate tenders should be floated by the Railways for BT make and AAL<br />

(Ganz) make tap changers as per the respective scope of works<br />

defined by the Committee.<br />

(b) The total cost of reha~bilitation should be calculated on the basis of lump<br />

sum cost of items to be changed compulsorily ( List A ) together with<br />

40% of the total cost of variable I optional items (List B) and other<br />

charges and taxes etc. and the bidder quoting the lowest total cost of<br />

rehabilitation should be declared the lowest bidder.<br />

(c) There may be a possibility of incurring higher effective cost of<br />

rehabilitation due to mismatch of optional item pricing between the<br />

bidders and therefore a counter-offer shall be given for a total<br />

cost of rehabilitation worked out based on lump sum cost of items<br />

to be changed compulsorily (List A) together with lowest price for<br />

each item quoted by either bidder in variable I optional list (List 'B'<br />

items) and other charges and taxes etc. to the Ll bidder determined<br />

earlier for acceptance.<br />

(d)<br />

The tender may be awarded to Ll bidder at the cost determined in<br />

(c) above on acceptance.<br />

(vii)<br />

All other terms and conditions for repair and rehabilitation as given in<br />

Railway Board's letter no. 2000/Eiect (TRS)/132/1 Pt dated 17.09.01<br />

including limiting of the cost of rehabilitation of tap changers with in<br />

60% of the cost of new tap changer should be ensured by Zonal Railways.<br />

RDSO may take necessary action and advise all concerned accordingly.<br />

\------ ---~,,<br />

\('C~-(_~~<br />

' •· ·i<br />

(MOhitChandra}<br />

Dir. Elect. Engg. (RS)<br />

Railway Board<br />

e-mail: deers@rb.raifnet.gov.in<br />

..................<br />

rD~.<br />

C}§?<br />

May'lO

1fffi1 "ff{Q)R GOVERNMENT OF INDIA<br />

~

No.20 1 0/Eiect(Dev)/225/1<br />

Director General,<br />

RDSO, Manak Nagar,<br />

Lucknow.<br />

GOVERNMENT OF INDIA (BHARAT SARKAR)<br />

MINISTRY OF RAILWAYS (RAIL MANTRALAYAt.-<br />

(RAILWAY BOARD) ' .<br />

New Deihi - ·11 0001<br />

Dated:07 06 2010 ~( /J<br />

Sub: - Review of working of RDSO~ Streamlining the policy of up gradation of vendors &<br />

agencie~ for vendor development.<br />

Ref: - (i)ED/E&R's note no. 2009/E&R/3400i9 dt 29.12.09.<br />

(ii)CRB'S DO no. 2009/E&R/ROS0/0/1 dt 18.12.09.<br />

(iii)SrEDSE/RDSO letter no. EL!Sr. EDSE/Misc.dt 15.01.10<br />

(iv)DG/RDSO,OO.no. DG/CRP-9/AO/Mech dt. 27.01.10<br />

(v)DG/RDSO,DO.no. El/8.1.10/EM dt 25.0110<br />

i .. ·<br />

Pursuant to Hon'ble MR's directives, ED's committee of Railway Board reviewed the vendor<br />

approval work and the organizational structure of RDSO<br />

2.0 . Sr.EDSE/RDSO (member of ED's Committee) constituted an interhal committee of Directors of<br />

RDSO (Loco,TI, EMU,TLIAC and PS) to review it's list of vendors (Pt-1 & Pt-11) and furnished RDSO's<br />

recommendation vide ref.(iii) which have been examined in Railway Board and a considered view taken.<br />

3.0 Board (ML) have approved the following.<br />

3.1 items critical to the performance for Rolling Stock (Loco, EMU, TUAC) and Tl have been<br />

retained at RDSO.<br />

3.2 Revision is indicated in enclosed lists. Agencies responsible for vendor approval/development,<br />

item wise are also indicated.<br />

For such items which have now been transferred to Production Unit & Zonal Railways, the<br />

Specifications will continue to be controlled by RDSO.<br />

3.3 Quantities required for evaluation of performance before up gradation of vendors from Pt-11 to<br />

Pt-1 will be 10 to 15% of the annual requirements of production for rolling stock and for Railway<br />

Electrification.<br />

3.4 The period for monitoring the performance of different items will be one year except for the<br />

foil owmg 1 't ems f or w r uc · h. 1t would be 2 ~ears.<br />

--·-------..·--·---·<br />

S.N. Item Description<br />

.~.....-~--·----------~-----<br />

1 All types of bearings<br />

-<br />

2 Main Transformer for Locomotives/EMUs<br />

3 All types of cables _<br />

4 Computer Controlled/Micro[!rocessor based Brake system for Electric Locos/EMUs<br />

5 Rubber com12onents for transmission systems·<br />

6<br />

--<br />

IGBT!IGCT/GTO based traction converter, auxilfar~ converter for rolling stock.<br />

7 ·Asynchronous Traction Motors.<br />

8 Vehicle Electronics/Control Unit for electric rolling stock.<br />

··-----~~.·-··~~<br />

3.5 RDSO's list of vendors (Pt-1 & II) will be monitored by Railway Board on half yearly (April &<br />

October} basis. Feedback in proforma enclosed shall be given by respective EDs/Sr EDs of RDSOfor<br />

these it(:;)ms. , . . \) .<br />

' ..<br />

_ . _ _Annexure~!! ~ 7 }2..<br />

(to leiter no. No.201 0/Elect(Oev)/225/1 dt.07 .06.201 O)<br />

list showing Revision in vendor__Q_QRroval authority of RDSQ controlled items<br />

Electric locomotive<br />

,-·<br />

---------------~-- -· ···------------ ---·--·--.. --.-~<br />

SN ITEM SPECIFICATION Agency for<br />

vendor<br />

developrrrent,<br />

--~-·------------- post revision --<br />

(a) (b) .(c) (e)<br />

---<br />

Thin Walled Cables for ELRS/SPEC/ELC/0019, RDSO<br />

Conventional locomotives. & Rev0-2002<br />

1 EMUs<br />

Chemical curing process _______<br />

---~----·--···-·--------- --------------------- ··-<br />

2 Electron Beam Irradiation ELRS/SPEC/ELC/00 19, RDSO .<br />

curing process<br />

Rev0-2002<br />

r---- --------·---·"'-~·--· -·- ·-------·---------!----------------·········<br />

3 Thin Walled Cable for 3- Single Core Cable RDSO<br />

_phase locomotives CL W /ES/3/0458<br />

1--· ..<br />

----·-·-----~--------<br />

Multi Core Cable<br />

RDSO<br />

CL W /ES/3/0459<br />

- -------------·-·<br />

4 Single Core & Multi Core<br />

a) Elastomeric Cables (for E-14/01 (Rev.2} 1993 RDSO<br />

loco & EMU}<br />

(part I & II)<br />

b) HRPVC cables (for EMUs & E-14/0 1 (Rev.2) 1993 RDSO<br />

coaches)<br />

part Ill<br />

""<br />

5 Zero Halogen Low Smoke E:..14/04 (Rev.l) 1998 RDSO<br />

Cables<br />

-- 6 CARBON BRUSH . ELRS/SPEC/CB/ 0027 RDSO<br />

TM HS-1050Er &TM HS l5250A Rev '0' of Sept.-2003 RDSO<br />

7 Earth return brush for ------ RDSO<br />

HSl 050Er & HSl5250A TM.<br />

_<br />

8 MCPA Type CRC~ 150- .<br />

CLW<br />

ALL. TYPES OF ROLLER & BAlL<br />

RDSO<br />

...<br />

BEARtNGS<br />

9 . Bearing. for traction _motor NtJ-'330 & NH:-3{2 RDSO<br />

type HS H)SOEr'/HS 152s'OA ...<br />

. . . . -·<br />

10 Auxilior Machine bearings<br />

_,_ __<br />

,.<br />

RD('O ...;) ..<br />

· (inciUdihg -~-phase<br />

-- 11 Locomotive).<br />

suspension bearing for RDSO<br />

. Hilochi/TA0:..659 Traction<br />

Motor<br />

t!

··-t<br />

l-s·~;_:;;i~-9~---t~r ·.4:-t~-;n~~~m · 9~-c;~- ··<br />

1 case of WAP 5<br />

.,<br />

-.. 2·5 --M-ai~--Gea-r·G·e-~~Tn9- -- ----------------- ·- --- --t: 5585-48-::: i-_ s-58'51-o --- --·· ----Rosa-----<br />

26-- --i'ilterm-ediatec8-cir-5e-arin9- -- __ M ______ 4321-~fsl\·--·-=:·,-- M - ·-·- R-r.Ss·o-·-----<br />

432111<br />

--- ~ii''' ~~-~-i on_b,ea~~-2-=--~~~-~-~~~~~-~==~~--~ !1~~~-?3_'_--:.. _:____: ... =:~-.~:~-.: __-___:_ -_· ·:___ .::-- ::· __ ~ps5?,~-~=~--<br />

28 Gears & Pinions (other than RDSO Spec. No. MP- CLW<br />

3 phase Locomotives) 0~2800-09 Rev 0.2 of<br />

June 2005<br />

-----r--- --------------~- ---------------- --------------<br />

29 Transformer Main (TFP) CLW/ES/T-22/M RDSO<br />

5400 KVA<br />

------ ----- --------------------·--·---------------- ----------- -- -------------·-------------------------- -- -- .. -- ---- ·-- ------------------<br />

30 Transformer Tank for 3-phase CLW /ES/3/SK-l /0507 RDSO<br />

locomotives<br />

&CLW/ES/3/SK-<br />

2/0507<br />

-----r------------------------------------ r--- . -------~------ -----------------<br />

31 Cable Head termination ELRS/SPEC/BL/0003 RDSO<br />

, system {Rev. 1), and Amend<br />

Vertical Take--off type 1 Dec. 08<br />

32--- T~type cable·-- Head specificati0-;--------N'o:·-----·-----R-oso ______<br />

termination system.<br />

CL W /ES/3/0251<br />

Alt.- B<br />

--~-- ----------------If-------------------- ---------------<br />

33 Rectifier block complete. CLW/ES/R-31 of CLW CLW<br />

I<br />

. ·v<br />

!-------- ----+-------------------+--~-------------J<br />

Devices. (diodes). -do- CLW<br />

1------'-------'-----..:......-~--. -~-- 1----·---,-------------r----------·-<br />

Fuses -do- CLW<br />

t-------i---,----------------+-------------+----.. --.----J<br />

34 Vacuum Circuit Breaker No; CLW/ES/C 47 RDSO<br />

(single bottle<br />

single bottle<br />

~--~~-----·~-----------~~~--~---~·~-------~<br />

35 TAP CHANGER CLW/ES/T~28 or RDSO<br />

ELRS/SPEC/ GR/ 0039<br />

(Rev.O)<br />

36 TAP CHANGER N'-'32 OEM Pt. No. -/RDSO RDSO<br />

COMPONENTS<br />

Drg.No.<br />

37 Bevel G.~ar<br />

___·A 1924/M 1924/SKEL- RDSO<br />

4611.<br />

38 Toothe.d·Segment A4540-2/SKEL-46-l2 ROSO<br />

r---r-----~~~~~-----~~---<br />

39· Car;n Sha·ff; Complete . A5150/SKEL-46l3· RDSO<br />

40 Spur Ge~r A6101 /SKEL-4614 ' RDSO<br />

~---~----~=-~-~--~--~~~~-----~~--~.-<br />

41 Intermediate Gear A61 03'a/SKEL-46l5 RDSO<br />

r--t~----~~~--------~~---<br />

42 Spur Gear A6ll 0-1 /SkEL-4616. RDSO<br />

43 Spur Gear A6-3l3/SKEL-46l7 RDSO<br />

44<br />

-~~------~------~<br />

Pinion A640 l-1 /SKEL-46 l 8 RDSO<br />

45<br />

--~---~-----~-~-r~--~----~~--r-~----~<br />

Bevel Gear S 1408/ /G 1408/SKEL.. RDSO<br />

3<br />

4619<br />

' ... ;; .<br />

. ·-, ..

phase locomotives<br />

T -- -.... --- . -- - ---- -. -~-<br />

i<br />

64 Spheribloc ··· ···· ··1 ·Roso72oo7/'E~i~/srE:c:: ··- -·- -RDso<br />

...... I [~0 5--~-~~\;':.~9.:_ ---· --·-. --- - ·- - -- - ---- . . -<br />

65 Elastic Ring RDS0/2007 /El/SPEC RDSO<br />

/0053 Rev.'O'<br />

---··-- f---··-·---·-· -- -···-····--·-------------·---·-·· .... ··-··--··-···· ····- ----------·-·-·--·----------···· --- ----·-··· -····· .... - ----------·-····-····- ...... .<br />

Rt Jhher Ccn-npclnenb lor RDSO 1<br />

Brake system for of 3-phose<br />

locomotives<br />

------· - -----···-···--·----··· -------------····------·-···--·----·--------------- --·-···-----------·-·- ······ ...<br />

66 Rubber Components/Kits for RDSO<br />

_____ -~-70-~_r:_ake_~ste_m_____________________-________ . _ ___________________________ .___________ ... __ ··-·· . J<br />

67 Rubber Components/Kits for RDSO - j<br />

~-~l------c<br />

__ c ___ ~ __ s_ys_t~!'l___________________________ __ .. _____ ·---------·--------··-- .... ___ ,_ ·····-------·---·-·--·. ______ ---·-····-----·· ____ ..... _<br />

68 Brake System for 3-phase RDSO<br />

locomotives<br />

--- ------~------------·-·-·····-···- ----· r-------------·---------·-- ··-- -----····-· -·· ·-· ·i<br />

69 (a) Main Compressor for CLW I ES I C-34 M RDSO<br />

Conventional Locomotive<br />

1000 LPM<br />

1----------1-------------~-------····-- -------·-------------------·-------······<br />

70 (b) Main Compressor for CLW I ES I 3/0100 RDSO<br />

WAG9/WAP5/ WAP7 Alt.'C'<br />

1--------t- ··-·------1-----~------+--------------<br />

71 Twin Beam head light ELRS/SPEC/PR/0024 CL W<br />

(Rev.' 1') Sept.2004<br />

---t------~------------1_____:__.-----'------'---·-- r-----------·--<br />

72 DC-DC converter for head ELRS/SPEC/DC-DC CL W<br />

light<br />

Converter/0021 (Rev<br />

• 1') Sept. 2004<br />

r-----:-::---r-:--------------'-------+----~- ------J-----------<br />

73 LED based flasher light ELRS/SPEC/LFL/00 17 CL W<br />

(Rev.'l ')Sept. 2004<br />

1-----+----'---------------+....:___--,----=----------'-----'--------,.---r--·-. --~<br />

74 LED based marker light ELRS/SPEC/PR/0022 CL W<br />

(Rev '1 f} Ocf.-2004<br />

~--~--4--------~<br />

Pantographs<br />

CLW<br />

..<br />

··.· .... '<br />

75 Pantographs forFreight<br />

Locos (/\C applicqtion)<br />

RDS0/2008/EL/SPEC/<br />

0069 . ·Rev ,'O' _dated<br />

20,~6.200$· and<br />

Am·end . -l<br />

. 31.12~08· .·<br />

76<br />

. ····. Pantograph fC>t Possenger CLW'/'t.S/P~5 Al.t.'f'<br />

Locos for AC appl!caHon.<br />

77 Spar~ for AM 12 or IR.Ol or<br />

PAN, 01 type·Pantogrdph<br />

Dtd<br />

RDSQ/2008/EL/SPEC/<br />

0066 ReV.'O' doted<br />

20.6.2008 and<br />

Amend 1 Dtd<br />

~-~----~---~-~-L----<br />

5<br />

·CLW<br />

CLW<br />

CLW

_,<br />

_________.....__________ .. ___ , ____, .....<br />

--~------·-·-...-----·---~---··-··- ·--··-·· ......... ........ . ..... __ -----··-""'''"'--···<br />

89 Motor for Scavenge blower f~DSO Spec No. CLW<br />

(TM) E-10/3/09 (Motor) ,<br />

ABB drg no.<br />

3GYN490209<br />

CLW /ES/3/0021<br />

--r----------------·-·--·-------------r------------------·----·----·-- .... ---·--------~·····-·-··<br />

90 Motor for Traclion Molot RDSO Spec t'-lo. CLW<br />

Blower. E-10/3/09 (Motor) ,<br />

ABB drg no. HCBX-<br />

605-115<br />

CLW/ES/3/0019<br />

------- ··----·------- -·-·---~-----<br />

91 Motor for compressor RDSO Spec No. CLW<br />

., E-10/3/09 (Motor),<br />

ABB drg no.<br />

HXP200MLD6<br />

CL W /ES/3/0100/ A<br />

... -<br />

92 Oil Pump for Converter ROSO Spec No .. CLW<br />

E-1 0/3/ l 0,<br />

ABB drg no.<br />

3EHP585770R0003<br />

CLW/ES/3/0107<br />

--<br />

93 Oil Pump for Transformer ROSO Spec No. CLW<br />

·----·-·----·---~-~-~~<br />

. .. ---~~-<br />

E-10/3/10,<br />

ABB drg no.<br />

HBTB585513R276l<br />

CLW/ES/3/0106<br />

94 Silicon Rectifier high capacity CLW/ES/R- CLW<br />

for WAG7/WAP4Loco 33/FCLW /ES/8 14 for<br />

..<br />

Conventional<br />

Rectifier<br />

ELRS/Spec /RS/0030<br />

"'··. Dec.03With Amnd<br />

No. 3 Ot 06.8.08 for<br />

· Compact Rectifier<br />

95 .·. Magnetfram$ f.qr Hitochii · RDSO for<br />

Trdcti6n Motor' qnd t A.O 659<br />

HI.TACH(fm<br />

....<br />

· .ar~difs assembly,<br />

TAO no new<br />

solJ,rce need<br />

• components,.<br />

to IDe<br />

'<br />

devetopedJ<br />

..<br />

7

·---- ...... , ........ --·------ ................... .<br />

103 TM 4939 AZ<br />

/ 104 TM MB 3080A<br />

105<br />

-~-··-·-... ····---·····-·----~..---- .. -···········-····· ·-- --··· -·· .... ---·······-----···--·- ·•· ...-. . -····<br />

TM HS-15256 & 15556 (for ECoR<br />

WAG6B & C)<br />

-·~--~-- ......·-----·-----...........-.... ~----------· ......... ·---·--. ............. .......... .... .... .. ................... - .................................... ·-· . .. ·-~--............._<br />

106 TM-LJM-450-2 (for WAG6A). ECoR<br />

107 Earth return brush lor TA0-659 CR<br />

TM<br />

108 Bearings for traction motor NU-328 & NH-318<br />

RDSO<br />

TA0~-659<br />

·-.......... -~--------............................................................ ·----· f--·--·--·-----·--·--·-----··--.. ·-------------- ........ .... --- " .............................. ~ ..... ..<br />

l 09 TA0-659 Traction Motor RDSO Spec No. E- CR<br />

complete<br />

7/20 of Sepi. '97 and<br />

Amend 1 to 4<br />

c--~ ---------~---------.. ~--·--------·-----·---·-·-- ..····--·-"·--·-·-·""'""' ____, ______ ........ - - .............,_, ----~ .... .<br />

110 TA0-659 Stator Assly. -do- CR<br />

Complete with coils<br />

---- -----------··--·------..------ - ........................- .......___..... c .....................---·--1---·· ....... ----·------....- ......<br />

111 TA0-659 Armature -do- CR<br />

1------ ---~----------·---·----- r---------·-------·-·---------1--· _____ .._________,____<br />

112 Armature Power & Equaliser -do-- C R<br />

1-----<br />

Coils (lnsulategjJ_g_r_TA<br />

__ 0_··6 __ 5_9·---l---------------- __________________<br />

113 Potted single section field SKEL-4540 & SKEL-4541 CR<br />

coil forT A0-659<br />

------------------ 1----------------------------------------<br />

114 Modified Brush holder Mod. Sheet<br />

assembly for TA0-659 No.ELRS/MS/WAM4/0 CR<br />

traction motors.<br />

216of 12.2.99 & its<br />

Amend no 1 to 5.<br />

-----l-----------<br />

115 Modified Brush holder M.S. WAM4/l96 of<br />

Revolving Ring assembly for . Dec. 96<br />

TM TA0-659<br />

CR<br />

116 Commutator Assly. _ CL W drg. No.<br />

.. 2'fWD.092.078 Al.t. 4 ..<br />

117 ForgedArmQture head .·RDSO Drg. Nos,....,<br />

.. .· . ;'SKEL"'"" 453·7 & 4538<br />

118 TM Armoture $haft Forgings. Alsfhom-Drg:.No. TR ·<br />

· · · · · . : 6.o2s2oo (Maferta~- EN~ .<br />

· 119- lmpregni;ltfng Varnish for TM_<br />

Armature T AQe-659<br />

:· 120 • Anti-frackingVarnish TM<br />

TA0~659-<br />

, 121 MicaBondtng varnish for<br />

GMS/ GMGS tape & GMGS<br />

9<br />

'""··--~.::::;:; Q .,, ..<br />

2{? to ~S~9'70J · . ..<br />

CR<br />

CR<br />

CR<br />

Rosa·<br />

RDSO<br />

RDSO<br />

t?<br />

.... ..

l .... .... .... ............ .¥7(7<br />

5588/403.404 & 406<br />

I .•.. ·- -· .... ...... . .. . . ·~· ' ..<br />

137 Epoxy Compound f·-!EW--823 A0256, ALT--2 RDSO --I<br />

(2 Cornponents)<br />

I<br />

I<br />

5588/237 &238<br />

...... -l<br />

138 i) Finishing Varnish TVA-1410 A0209 RDSO<br />

.... _______ ..:2~?8 I 4Q_! ___ ···-----·---·--·······-·-------·-···· ..._.... ___ ... ----·-----·-········ ···---- ______._. .... .. ._<br />

.... . ___ .... .. ... .. ...... _J<br />

139 ii) Thinner-S-1 l 0 5588/409 AO 152 RDSO<br />

140 Solvent less Epoxy Resin AO 108 RDSO<br />

HEW-502(2 components)<br />

5575/017& 019<br />

------ ·----------·-··-···"·"·-·----·--····-· ......... ------·-···-- .......................... ...... ........ . .. --- ··-·--····--··-··---· ··---··---<br />

141 i) Synthetic Varnish WSY-285 A0205, ALT-1 RDSO<br />

5588/220<br />

.....____ --------~---------·-------···-·---------- ... ...... ------------------· ....... " ....._...._....................... -----·---·------------·-·---<br />

142 ii) Thinner S-30, 5588/234 A015l RDSO<br />

----- _________..___ ··----·-··---------------------·-·- ----···-··--------·-···· --- ............ ........... ....... .... ----··--·--·----·-----·--·--·<br />

143 Alkyd Varnish Wl-294 A0175, ALT-1 RDSO<br />

5535/005<br />

c----------------------------------------- --···---------------------------------------·-c--·---------···-·-·-<br />

144 i)Finishing Varnish WSY- A0201, ALT-1 RDSO<br />

101 (Core), 5528 /025<br />

1------.....jl- ·---- --------------------------------·------~----·----------<br />

145 ii) Thinner S-30, 5588/234 A0151 RDSO<br />

------- .. -+-------..-----------1---------<br />

146 Lubricant KS-707 5588/246 A0119 Alt-1 RDSO<br />

I--- - ---------r-------------<br />

147 i) Finishing Varnish WSY- A0204, ALT-2 RDSO<br />

195R (Commutator),<br />

5565/078<br />

r---~r----------~-------~~-------------------r-- --<br />

148 iiJThinner.S-110,5588/409 A0152 RDSO<br />

149 i}Silicon RubberTube A025l, ALT-B RDSO<br />

(ST110 DG) 5565/819<br />

J------:-1---'---·<br />

150 H}Silicon Rubber Tube (ST 170 RDSO<br />

DG) 5580/104 .·<br />

151 Wedge 552,2/069 lOS. 784-157, Alt C RDSO<br />

F.0006<br />

152. Flexible Mka . Sheet MP~60'" . A0268, AL T- 1<br />

' FCZ, 5522/005,~ 00~ ..<br />

RDS6<br />

, 153 Glass mica Sheet GU-:-Fl' .. A0269,ALT-C<br />

RDSO<br />

5522/012<br />

154 Semi _cured Ceramic: Sheets.~ A0235, ALT-5<br />

RDSO<br />

SCQ-H 5588/202; &. 5586/202<br />

1-~t----~--.....:.._.,..._.:_~~-'---~-t--~~·~--~.,-~-~---f-.,------:-l<br />

·.155 Glass backed uniform Mica A0270, ALT ... 5 RDSO<br />

Sheet·GUA-CN~3<br />

5588/206<br />

ll

'---------··· ______________ ,, __________ ~ --<br />

.... i<br />

f ........... ·--·- ..•···<br />

' Size: 2x 600x5rn length<br />

I"<br />

5588/241<br />

·- --·-·--···- ...._,_________ -~·---·--·· .. --------·· .. .. -··-- ... ........... ··----------··-· ----<br />

I<br />

··---- .,<br />

173 Article II. Protective i. CL.W /ES/R-27 1 CLW<br />

(QLM, QRSI, QOA, QOP, (or latest version)<br />

Q30, QE, QF)<br />

·-1-74-- ·· sequence·----~c;-46~···c;·49-:--o52. ··ccw/E:s/R-:27- -- ·- l -cLw · ·- ---<br />

______ owe Et_::_:l ....·------~------ ........ J?r. ...!~test ~-~!_s~on._L _ j -·------·-· _·--· __<br />

175 Article Ill. Time Delay CLW /ES/R-27 1 CLW<br />

________ IQ44 -~ Q 1 ~8) ________________________ _lC?! .. ~~!est ~_ersJ?n) ... j ___________ -·. ___<br />

176 (QTD 105 & QTD 106) CLW/ES/R-1 I CLW<br />

-1-77 (Q48) ____ --.. ~-- __ .. _____________ -- ----- . 2{-£/:~;R~~~f;;?~-t~si 1-- . (j\_ji -------<br />

I<br />

~-- ---------------·------------------ _____ --~~~ionL______________ .. _ -,-- -------·--- ___ -·-<br />

178 Signalling (QV60 - 64, CLW/ES/R2/J CLW<br />

QVLSOL and Q-51}<br />

(or latest version)<br />

1--1-7-9--+-T--ra---c-ti-o-~~v'\oto-;: Protection ________ -c-L·w JESJR-zT_____ -- ··· 1 ------cLw·-·------<br />

(QD, Q20)<br />

(or latest version)<br />

------------ ---------------·-- -----------------··-·-"-"" .. ----------·-------<br />

180 QCVAR CLW ES/R2/J CLW<br />

~(('%<br />

I<br />

I<br />

i<br />

·''' ·.<br />

.. , ·.<br />

181 a. Air Flow ____ relay-- {QVMT:-· ~~:/:;;R~~;Ion) ·-··· --j···-- CLW -----<br />

QVRH&QVSL}<br />

(or latest version)<br />

1--18-2---+--b. Air Flow relay (QVSI) ---~do- ---·----- -----CLW~-~<br />

.... ~·---- ~-<br />

183 Oil Flow (QPH) CLW SPEC. CLW<br />

(or latest version)<br />

-·----+----<br />

184 Oil for 3-phase locomotives IEC: 296 Clause liA RDSO<br />

-<br />

185 Article IV.SL<br />

CLW SPEC ---N-0--.+--C-LW-,---<br />

4TES.075.001 (or latest<br />

version)<br />

r---r---------------~-----~-~--~--------+------· ----<br />

186 SJ CLW SPEC No. CLW<br />

4TES.l33.00l 9or<br />

latest version}<br />

187 ·Notch Indicator ECIL's make Ptno ClW ...<br />

r---~-~~--~~~~~~~~--~--~~--~-4~~-<br />

188 ·· DigJfal'npfch indie:;otQ(_ . ELRS/SPEC/DNI'/0032 CLW<br />

(Rev.'O'} Aug·2~ __ 04~· --+--'------_,.<br />

,._ -~-<br />

189 c ll& C.ontacfors CL W/ES/C-l5 clw:<br />

· (or latest version}<br />

~-~~~~~~--~<br />

190 : MVMT (H Class}<br />

. RDSO Spec· No. ~--10 CLW<br />

/3/08 CLW/ES/B-<br />

14/C.<br />

r---r-~~----------~~--~--~--------------~~~---~,~<br />

191 MVRH (H Class} RDSO Spec No.E-10 CLW<br />

/3 I 08 CLW/ES/B-<br />

14/C.<br />

ll

Annexure-Ill<br />

(to letter no. No.201 0/Eiect(Dev)/225/1 dt.07 062010)<br />

List_ showing .fS.evision in . .Y:~ndQ.L9J2illOval__g_uthority_QLRDSO -~on trolled items<br />

Electrical Multipl~ Units<br />

--·-¥•- --·-··------·------·-····------······-----··-------------··-·---- ·------- ----~---· --------------<br />

S.No ITEM ---------·-·-----------~-·-----.<br />

Agency for vendor<br />

development, post<br />

revision<br />

r-------- ·------- -· -·- -----··--··-~~~--~-~------------------~- ..-- ---·-------------------------<br />

EMU TRANSFORMER<br />

-- -------------------------··----------<br />

1. Power Transformer for EMU 1000/1550 KVA RDSO<br />

f---.-· ·----~---------------1--------·-------<br />

TRACTION MOTOR<br />

..<br />

·-----~------·------------------------ --------····-----·-------- -~---<br />

2. 4303 AZ {BHEL)/C1005(CGL) RDSO<br />

,..,.<br />

-- .. ------------------ ..... --·---- ___________ ---~<br />

LUBRICANTS<br />

----- ____..__-<br />

-----~------------------------ ------·-~-~-_,...<br />

ARMATURE BEARING GREASE<br />

.. -------·----------·-----<br />

3.. Trod ion Motor 253 BX/ 4601 of BHEL RDSO<br />

--<br />

RDSO<br />

AZ<br />

r----- --------- -------.........--<br />

AXLE SUSP-ENSION BEARING OIL<br />

-- ---~-----<br />

5. (a) TDK 5620 A I BHEL 3701 AZ RDSO<br />

---··------ ··---··-·-- --<br />

6. (b) 253 BX I 4601 AZ RDSO<br />

----<br />

GEAR CASE OIL<br />

7. (a) 133 AY 13601 AZ RDSO<br />

-<br />

8.· (b) TDK 5620 I BHEL 3701 AZ RDSO<br />

9. {c) 253 BX /4601 AZ RDSO<br />

10. (d)} 4303AZ/C 1005 RDSO<br />

11. Led based taillight ROSO<br />

Rubber and metal bonded rubber<br />

components for EP brake sysi·em<br />

12. For M/s WSF make Brake Equipments<br />

. . .<br />

RDSO<br />

13. · For M/s ESCORTS make Brake Equipments RDSO<br />

, TRACTION MOTOR<br />

' . ·,. r:·' •<br />

;<br />

14. 253 BX /.4601 Az RDSO<br />

. 15. 133 A Y l 3-M> 1 AZ RDSO<br />

. . . . . .<br />

16. TDK 5620A/ 37£11 AZ (BHEL).··· . :-<br />

RDSQ<br />

17. Alstom TM4ERA-l858A for 3-phasE? EMU' WR<br />

·.· .18. BHEL TM Dty\KT 53/42 for 3~phase i:MU CR<br />

19'. Axle-Cap & Gem Case·and Suspension: tube ICF<br />

20.<br />

Bolts·.<br />

-<br />

Plain Sleeve Bearing for 253 BXI4601AZ RDSO<br />

21. Voltage regulator for EMUs ' ICF/RCF<br />

/1<br />

l<br />

--<br />

I<br />

>; 7( 7

-·<br />

i lnlerrupter 25 kV Single Pole (voccum) poie ! RDSO<br />

27<br />

mounted<br />

-----·· ············-··-·· -··· ____,.____ ·--------------------- .. -- .---..--.. ·-·- ---- ,._.. ,....... ·•···· ---------- ,.,____________________ ... ----~- ----·- -- ··- .. -- ... ·-· ·- ..<br />

Single pole Motorized Isolators for l~oilwcw Electric RDSO<br />

28<br />

lroction<br />

····-·· ---------------- -~--- .. ··---- --. --- .... ------ -- ~--- -- ----- ~ ... --- ... -- ··- ·······------- .-----<br />

Double pole Motorized Isolators for Railway RDSO<br />

29<br />

Electric traction<br />

... -----.... ·--------- ,.________________.......,.......___ ------ ----·--·--· .. -- ·----- ~ ·---------· .---------~-------..---- ........ ... .. . .. - . -·· .-- ... --. ..---- -- ~--·-"-~---- ····-·· .<br />

Joint less Grooved Copper Contact Wire ( 107sq<br />

RDSO<br />

30<br />

----------- _Q:!_!_~!_l____________________ -<br />

Joint less Grooved Copper Contact Wire (150, RDSO<br />

31<br />

mrn 2 l<br />

r----···--- - --· ------------·-·---·----·-----·------------·----···-------- --· ·-- ----------- -------- ·----------- ---· ·--- --.<br />

Joint less Grooved Copper Contact Wire ( 193 RDSO<br />

32<br />

mm2l ·<br />

-=~~-~~-~~~~~~a~:'~co~~er-:o~::~r~.~:J~s~== •..._<br />

Uninsulated Cadmium copper catenary wire ( 65 RDSO<br />

34<br />

----------- __?_g_:____r:nm} -----·-·--·---···---------------------·-----------..----··-- ·-·- ----·-·--------· -·-- -·---·-·<br />

Uninsulated Cadmium copper catenary wire ( RDSO<br />

35<br />

129 sq. mmJ _ ------···-··---···- ------··---·-<br />

36 Uninsulated Cadmium copper catenary wire (242 RDSO<br />

-----~q__mrn) ____ _ -------~------------"!--------···-·-..<br />

Uninsulated Cadmium copper catenary wire ( RDSO<br />

37<br />

-------+ 323 sq. mm} ___________-:----------+----·--<br />

Control & relay panel for TSS with all numerical<br />

38<br />

RDSO<br />

relay<br />

--------·-·-----1r-------<br />

- --<br />

39 Control & relay panel for TSS<br />

----------+----R_D_SO-=---------<br />

40 Control & relay panel for capacitor ban~-----------+-R--'--D_S:....O::;._._ ___-l<br />

Parallelogram type static distance protection RDSO<br />

41<br />

~------~-- relay<br />

Control & relay pane! for capacitor bank with all RDSO<br />

42<br />

1--------, numerical relay --------+-----------1<br />

43 Numerical relay for feeder protection module RDSO<br />

44 Numeric relay for feeder protection with 3 zone RDSO<br />

---+------1<br />

45 Synchro check relay for Mumbai qrea RDSO<br />

46 Reverse power flow relay for Murnbai area RDSO<br />

. 47 IDMT & Definite time OCR for Mumbai area : RDSQ<br />

48 . L v bus bar diffrential protection relaY RDSO . ----1<br />

f----,-_5 - 0<br />

49.: HV bus par diffrentlalprotecHon reloy · .·.RDSO<br />

-.~r:-N::--.-u--'--rn:;_;:e:;_;:r.i-'-c;o._a;;:;.:l--'--ty=;-p:.:..:e.;;.._·::c...:d:.:..:if:.::...:fe:..:.:..r...ce:.:..:n-=-tia:...::_-:....::lr;:_:_e:..::la:.:..:V:......:, m...;:;· ·C:,:o;;;.J.d'-u-le-_--fo--r--_,_----+-'-'-R:;_;:D:....;s:_o~;;..;<br />

__ ..,......__,..,_~transformer<br />

prqtection · · ·<br />

-~~-~~~~--~--~----+-~--7<br />

51 Differentialrelqy for transrortn€9r protection · RDSO .·<br />

52<br />

IDMT ,·oef time· & REF numerical relay module for RDSO<br />

transformer protection · . . · . .<br />

53,· Static type tDMT reiay for trc.msfqrrner protecHon RDSO<br />

54 Static type REF relay for transformer ,· RDSO<br />

55 . • Delta-! re!o'L_'-· __,...-.-,------.......,---,.--------- -~-·_R_D_so...C..--'--'--1<br />

56 Ponto flashover relay · RDSO<br />

r-·----~-------~~~--~-~------~~-~----------·-r--------~<br />

57 Over current relay for capacito.r bank RPSO<br />

17 lrM<br />

T

High precision thermo vision camera for OHE RDSO<br />

r------~m~o_n_it~o~ri_n~QU~P.~to~1~20~k~m~p~h------------------+-----------<br />

Corrosion Resistant Paint System<br />

RDSO<br />

132kV XLPE unde~n_:,_:d::;;.·_ -=-ca=b:..::le=-------------+-R~D__;s:___;o::....____;__---J<br />

T ensile load testing Machine for insulators , RDSO<br />

54 MV A, 220/2x27 kV, 50Hz, ONAN Scott- RDSO<br />

connected traction power transformef ---,--~-----,.·~<br />

21.6 MVA. 132/2x27 kV 50Hz, ONAN Sing!e Phase RDSO<br />

fraction power transformer · ·. ·<br />

.8· MVA, 54/27 kV, 50 Hz Auto Transformer· RDSO<br />

25 kV Double Pole SF6 Circuit Breaker.. RDSO<br />

.• 2.5 kV Double Pole SF6 Interrupter · · ·. RDSO .<br />

. 25 kV Double Pole Vacuum Interrupters ~ ...;,..---O-~___,r--R,.._,;D=-S=-0=-··-____,.,...--!<br />

Delfo,-1 type fault seledive relay.<br />

· RDSO<br />

.Parallelogram type static distance protection<br />

reloy<br />

Series. capacitor.<br />

Shunt capacitor<br />

Control and Relay panel.<br />

Micro computer SCAbA system<br />

19<br />

RDSO<br />

RDSO<br />

RDSO<br />

'· ·,<br />

':

),<br />

-;,, I<br />

Annexure~V<br />

(to letter no. No.201 0/Eiect(Dev)/225/1 dt.07 06 201 O)<br />

list showing Revision in vendor approval authority of RDSO. controlled items<br />

T . l' hr d A. C dT<br />

- rotn lq 1nq on 1r- on 11onmq ·-¥·--···---·-···--~---·····-- ····-·------~-~--" ·-------------~- ---- ···-··--·~-<br />

S.No. ITEMS Agency for<br />

vendor<br />

development,<br />

·-----·-~-- ·-· ·-·---·--------········· ....... ____ __ .. ____ R~_:>L~~yi~i-~'l .._<br />

.....___<br />

BATTERIES<br />

- ·----·---------- r---<br />

Battery for TR-D Application<br />

-<br />

1 Lead Acid 40Ah -LM ZR/PUs/CORE<br />

-------·-- ------~----~~-------<br />

2 Lead Acid 40Ah -LM ZR/PUs/CORE<br />

~·-·----- ------....~~---------------- ----~--<br />

3 Lead Acid 200Ah --LM ZR/PUs/CORE<br />

r------ -----~----·----------- ··--·--·-·-<br />

4 Lead Acid 200Ah -LM ZR/PUs/CORE<br />

r-----~--- ···---·-------·---·-·---<br />

Battery for Air-conditioning<br />

- --~------·----- ~--------<br />

5 525 Ah RDSO<br />

--- ·------~----~------ ----·---<br />

6 800Ah RDSO<br />

-----<br />

7 450Ah (MG AC Coaches) RDSO<br />

--· --·---·----<br />

Mono Block Pump for Water Raising - --<br />

8 0.5 HP self priming mono block pump for ICF/RCF<br />

water raising purpose in lR coaches.<br />

--<br />

9 Railway Carriage Fan (llOV AC/DC) ICF/RCF<br />

...<br />

--'-:<br />

·.<br />

10 Flat Belt for Train Lighting. ZRs<br />

Brush less Alternator with Rectifier<br />

Regulator along with Belt Tensioning<br />

Device<br />

l 1 3/4.5 KW 24/30V. ZR<br />

Inverter up to 10 kVA<br />

12 Bulk.lnverter 2.5 KV A 110 V DC/230 V AC ICF/RCF<br />

13 .2.5 KVA 110 VDC/230 V AC ICF/RCF<br />

J4 2.5 KVA,.llOVD.C/HOVAC ICF/RCF<br />

15<br />

:<br />

5kVA ,llOV<br />

..<br />

DC/230VAC ICF/RCF<br />

16 lOkV A Inverter · tCF/RCF<br />

'.<br />

.•<br />

• Ba-tfery Charg¢r<br />

.·<br />

..<br />

17 . Arnafgarri_Qted Trqnsformer {Battery RDSO<br />

·.·Charger).<br />

l8 ·. Battery Chorg.er Unlt:Precaoling ICF/RCF/ZR<br />

· · Trc:msformer<br />

19 · Boftery Chdrger Unit fCF/RCF<br />

FRP Tray for Battery Boixes<br />

20' FRP Gloss Tray for Battery Boxes for Non ZR/ICF/RCF<br />

21.<br />

~fY0<br />

--

13 •low t\~llirJI('Il0/11 c ic•,J(J 1\cicf Hof/c>t}l /. 1 ><br />

Ail tor locomollve'> (1>/'CfJ Contoiner)<br />

.14 rlolfery for £lv11 1~ 90 Ah (I M} (Pe('fl<br />

Container)<br />

Battery for train lighting<br />

4 s ? 10 Ah<br />

46 I /0 AH ( l I OV} in fJFl CP Conlo/ner<br />

- -·-<br />

Battery for Air-conditioning<br />

-- --~ --·- -- .<br />

47 650/11 OOAh VRLA<br />

ERRU<br />

;.f8 FRRU fo1 4.5 k\ 1 \/ Allernotor<br />

49<br />

I H

~,,<br />

1"'\.lttiCAUSC- ti' I<br />

(to letter r)o. No.2010/Eiect(Dev)/225/i dt07 06.2010)<br />

list showing Revision in vendor agproval authority of ROSO controlled item~<br />

Energy Mana~_ement Directorat~ _ __ __ __ ______________ _ _ _ _ __ -~---~- _____ _<br />

S. N. Items to be transferred to Railways Agency for<br />

vendor<br />

development,<br />

post revision<br />

1---------------- -------------------- -------------------------------- ----------------------------------------- ---------- ----------------- -------------<br />

1 Double capped tubular T-5 Fluorescent lamps, T-- ZR<br />

5 luminaire & Electronic ballast<br />

------------ -----------------------------·--------- ------------ -------------------------------------- ------ -- ----- ·--------------------------<br />

2 Power saver in lighting system. ZR<br />

---·-·-··---··--·--··-·-------------------------·"·-·----'"--····-.....---....-·--·-·---~-------·-·<br />

·--·-·-···----~-<br />

3<br />

----<br />

Energy saver cum intelligent motor controlled for ZR<br />

AC induction motors.<br />

------------------------------------------------------------------------------------ ------ - -------------------- ---~- .J<br />

Lj Grid connected solar generating system of I 0 KWp, 25 ZR I<br />

KWp,30 KWp, 50 KWp & 100 KWp capacity.<br />

5<br />

---------"'··---~ ·--~----~-----~------·-------~--····-<br />

Stand alone wind + solar photovoltaic hybrid ZR<br />

generating system level crossing gates.<br />

----- . ------ -,------------------------------ ------------ ------ -- ------------------------··-···" ----- -------------------------------------<br />

6 LED Signage. ZR<br />

------------------ --•----------------------------------- ------------------------ ----- -- ------------------------. --·-- ----- - ----- ------ ----- -----------<br />

7 t\~anufacture & supply of 11/33 KV XLPE ZR<br />

underground cable. (May-- 2009)<br />

-----'--·----- ---------- - ------- ----------------~-----------<br />

8 Manufacture & supply of upto 11 OOV XLPE cable. ZR<br />

----------~--~-· ------- ----------------------------<br />

9 Stand-Alone Solar Photovoltaic LED based street ZR<br />

lighting system.<br />

r-----------<br />

.. _______ _,. .... --··- .. - ---·-~-- -------···-·---·-.<br />

10 Solar based water heating system<br />

1-----+--------- -----=--------------<br />

11 Energy efficient LED based luminaire unit for street<br />

1---------------+--...::.._ light _________________ and platform lighting. _<br />

12 Centralized air Ventilation with air coolers of<br />

waiting room and departure lounge at the station<br />

l---------1---__;::;__<br />

13 Integrated Renewable energy system based<br />

power supply arrangement<br />

ZR<br />

------------<br />

ZR<br />

ZR<br />

--------+-----~<br />

14 Integrated solar photovoltaic based power ZR<br />

supply system lighting loads for Electric Loco<br />

Sheds & Workshops.<br />

------''---------- --------+--------<br />

15 Manufacture & Supply of Solar Cooker. ZR<br />

---------+----------4<br />

16 Maintenance free earth for electrical installation. ZR<br />

1------------+-------<br />

17 Uninterrupted Power Supply ZR<br />

-----t------.---rZR<br />

18 Water Mist &compressed air foam ype F1re<br />

--~---1-E_x_t_in--=g:.....u_is_h_e_r____ ~-------<br />

19 LED based pit light ZR<br />

1----------+-<br />

20 LED based tunnel light ZR<br />

------~~------·---<br />

21 LED based facade light ZR<br />

1--------·--+-<br />

22 Energy Meters for vendors ZR<br />

l_u_se __ ~-=--___;_;._----t--ZZRR -----~<br />

: __ 2_3 __ +_En_--e_r-=g:...:..y_M_e_t_e_r_s_fo_r_r_e_s_id_e_n_1-i_a __<br />

24 · Building Management system -~<br />

25<br />

26<br />

Data logger _____ _ --~--__.__-?:__ZRR_----~-- j_<br />

DG sets with AMF panels _ _ __ _<br />

-25-<br />

._/ 4.! - !1fpf

L---------·-----·-<br />

~ ~ GOVERNMENTOFINDIA<br />

~ ~ MINISTRY OF RAILWAYS<br />

~ mt RAILWAY BOARD)<br />

No. 2004/Eiect(TRS}/440/19<br />

General Manager (Elect),<br />

Central Railway, Mumbai<br />

East Central Railway, Hajipur<br />

Northern Railway, New Delhi<br />

North Eastern Railway, Gorakhpur<br />

North Western Railway, Jaipur<br />

South Central Railway, Secunderabad<br />

South East Central Railway, Bilaspur<br />

Western Railway, Mumbai<br />

New Delhi, dated 09.06.:Z010<br />

Eastern Railway, Kolkata<br />

East Coast Railway, Bhubaneswar<br />

North Central Railway, Allahabc:1d<br />

North East Frontier Railway, Guwahatl<br />

Southern Railway, Chennai<br />

South Eastern Railway, Kolkata<br />

South Western Railway, Hubli<br />

West Central Railway, Jabalpur<br />

SUB : TPWS on electric locos • l111stallation and maintenance<br />

Ref : (i) Rly Boards' letter no. 2005/SIG/TPWS/Dli-AGC/Vol-11 dated 02.06.201.0<br />

(il) Rly Boards' letter of even no. dated 02.06.2010<br />

Board (Ml) have decided that installation and maintenance of 'on board'<br />

equipment for TPWS shall be undertaken by Electrical department for which ilOSO<br />

has been advised to define infrastructure/maintenance facilities required in sheds I<br />

trip sheds and lay down maintenance schedules in consultation with the OEM,<br />

specifying the periodicity. RDSO has ctlso been advised to frame training modules<br />

for maintenance and running staff in consultation with OEM.<br />

Board (Ml) have decided that for further implementation of TPWS on IR,<br />

while overall control and coordination of the project shall be exercised by CSTE on<br />

the Zonal Railways, the tender schedule pertaining to 'on board' equipment and<br />

its installation shall be executed by the CEE of the Railway or authority nominated<br />

by him. The D&G charges shall be apportioned according to ratio of costs of<br />

'on board' equipments & installation and track side equipments & installations<br />

including supply & installation of all required Signaling equlpments including relays,<br />

cables etc' between CEE and CSTE respectively.<br />

Accordingly, CEE's of Zonal Railwavs are advised to coordinate with CSTEs and<br />

ensure inclusion of provision for creation of infrastructure I maintenance facilities in<br />

sheds I trip sheds along with training aspects of maintenance & running staff in the<br />

tender schedule. Proper apportionment .of D&G charges and creation of adequate<br />

organization should also be ensured .<br />

~<br />

(Mohit Chandra)<br />

Dir. Elect Engg. (RS)<br />

Railway Board<br />

e-mail: deers@rb.railnet.gov.in<br />

Jllft'IO<br />

....,,.,.,,.,.. L:J-.-7·~ ·-;.- ..··

~lRcr -~Hlx GOVERNMENT OF INDIA<br />

·'tn lf?ircl

)<br />

Suggestions for JQint Procedure Order {JPO)<br />

:J<br />

r -Sf____ D_r_a._ft_J_P_O_s_u_b_m_i._tt_e_d __ b_y_c_tw ________________._s_u_gg_e_s~-io_n_s_____ nt----1--~-ith-as<br />

been decided by Rly--. 8-d-.-t-ha_t_A_s--s-ly-. o_f_n_e_w-+-lt_h_a_s-be_e_n-de-c-id-e·-d-by_R_ly-.--8-d- . ...;,th--a-t_a_ssembly of<br />