You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

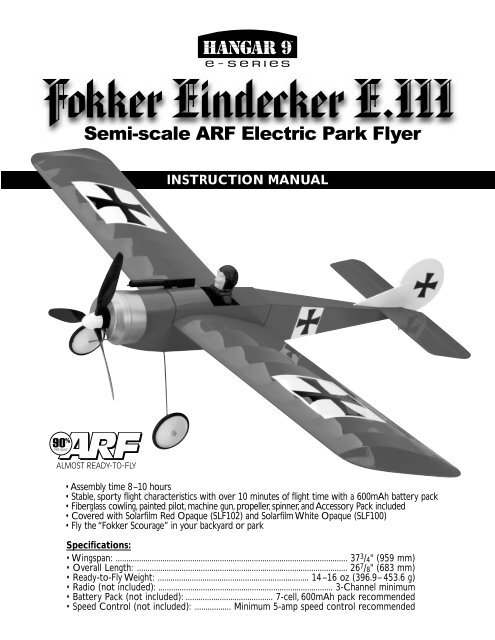

INSTRUCTION MANUAL<br />

• Assembly time 8–10 hours<br />

• Stable, sporty flight characteristics with over 10 minutes of flight time with a 600mAh battery pack<br />

• Fiberglass cowling, painted pilot, machine gun, propeller, spinner, and Accessory Pack included<br />

• Covered with Solarfilm Red Opaque (SLF102) and Solarfilm White Opaque (SLF100)<br />

• Fly the “<strong>Fokker</strong> Scourage” in your backyard or park<br />

Specifications:<br />

• Wingspan: ............................................................................................................. 37 3 / 4 " (959 mm)<br />

• Overall Length: ................................................................................................... 26 7 / 8 " (683 mm)<br />

• Ready-to-Fly Weight: ....................................................................... 14–16 oz (396.9–453.6 g)<br />

• Radio (not included): .................................................................................. 3-Channel minimum<br />

• Battery Pack (not included): ......................................... 7-cell, 600mAh pack recommended<br />

• Speed Control (not included): ................. Minimum 5-amp speed control recommended

Table of Contents<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Assembly Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Tools and Supplies Needed for Assembly . . . . . . . . . . . . . . . . 4<br />

Recommended Radio and Electronic Equipment . . . . . . . . . . . 4<br />

Applying the Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

Assembling the Wing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Fuselage Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Preparing the Tail Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Pushrod Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10<br />

Attaching the Tail Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Finishing the Cockpit Section . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Servo Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Installing the Landing Gear . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Installing the Battery Pack, Receiver, and Speed Control . . . . 14<br />

Propeller Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Prior to First Flight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Flight Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

AMA Safety Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

<strong>Fokker</strong> Eindecker Spare Parts List . . . . . . . . . . . . . . . . . . . . . 17<br />

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Introduction<br />

Congratulations! You have purchased the <strong>Hangar</strong> 9 E-Series<br />

<strong>Fokker</strong> Eindecker E.III, a high-quality, semi-scale electric ARF<br />

R/C park flyer of the famous fighter plane of World War I. Over<br />

2,000 <strong>Fokker</strong> Eindecker aircraft were produced during the First<br />

World War.<br />

The fast and maneuverable Eindecker began its military career as<br />

a scout aircraft. Later, when a synchronized machine gun that<br />

fired through the spinning propeller was added, the Eindecker<br />

introduced the world to the challenges and terror of aerial combat.<br />

The Eindecker soon became known as the “<strong>Fokker</strong> Scourge.”<br />

Two famous German aviators, Max Immelmann and Ernst Udet,<br />

flew the <strong>Fokker</strong> Eindecker in World War I.<br />

If you are able to successfully fly a trainer-type R/C airplane on<br />

your own, you should feel confident flying your electric <strong>Fokker</strong>.<br />

Smaller, lightweight park flyers like the <strong>Fokker</strong> Eindecker fly best<br />

in no wind or very light wind conditions.<br />

If you are a first time R/C pilot, seek the guidance of an experienced<br />

R/C pilot before flying your <strong>Fokker</strong>. Flying with a more<br />

experienced R/C flyer may prevent an unfortunate and untimely<br />

loss of your airplane, as well as prevent possible injury to you<br />

or spectators or damage to property.<br />

The hobby shop where you purchased this kit may be able to<br />

recommend a local R/C flying club that you could join. R/C flying<br />

clubs often have very experienced R/C pilots who are happy<br />

to provide guidance to less-experienced R/C pilots who would<br />

like to develop their flying skills. R/C flying clubs also have dedicated<br />

R/C flying sites, which are the best choices for flying any<br />

type of R/C aircraft.<br />

We hope your <strong>Hangar</strong> 9 E-Series <strong>Fokker</strong> Eindecker E.III brings<br />

you many hours of R/C flying enjoyment. Thank you for purchasing<br />

this <strong>Hangar</strong> 9 E-Series product.<br />

WARNING<br />

An R/C aircraft is not a toy! If misused, it can cause serious<br />

bodily harm and damage property. Fly only in open areas,<br />

preferably AMA (Academy of Model Aeronautics) approved flying<br />

sites. Follow all included instructions.<br />

Assembly Tips<br />

• Carefully read assembly instructions and inspect all parts<br />

prior to assembly.<br />

• In the assembly instructions, the left and right of the airplane<br />

refer to the left and right side as if you were stationed in<br />

the cockpit.<br />

• Use 12-minute epoxy, medium CA, and silicone sealant for<br />

model assembly. Moderate, but not excessive, amounts of<br />

adhesive are recommended. Remember to use what you need<br />

and no more. It is important to keep park flyers light.<br />

• Build your model on a solid, flat surface in a well lit and well<br />

ventilated location.<br />

• If you are an inexperienced builder, we recommend seeking<br />

the guidance of a more experienced model builder to help<br />

you assemble the kit.<br />

• If you encounter difficulty in any construction sequence,<br />

please contact one of our technicians at:<br />

Horizon Hobby, Inc.<br />

4105 Fieldstone Road<br />

Champaign, IL 67822<br />

(877) 504-0233<br />

www.horizonhobby.com<br />

3

Kit Contents<br />

Before assembly, carefully examine all kit contents. If any parts<br />

are missing or damaged, return the kit to the retailer where you<br />

purchased it. The following is a list of all the parts that should<br />

be included with your kit:<br />

• Fuselage with motor installed (1)<br />

• Cockpit section (1)<br />

• Wing halves (2)<br />

• Horizontal stabilizer/elevator (1)<br />

• Vertical stabilizer/rudder (1)<br />

• Fiberglass cowling (1)<br />

• 3-bladed propeller (1)<br />

• Spinner (1)<br />

• Landing gear legs (2)<br />

• Wheels (2)<br />

• Tail skid (1)<br />

• Pushrod tubes (2)<br />

• Wire pushrods (2)<br />

• Nylon bolts (4)<br />

• Control horns (2)<br />

• Axle collars (2)<br />

• 1.5 mm set screws (2)<br />

• Small Phillips head screws (4)<br />

• Plastic landing gear straps (2)<br />

• Wing joiner wire (1)<br />

• Elevator joiner wire (1)<br />

• Pilot (1)<br />

• Machine gun (1)<br />

• Decal sheet (1)<br />

• Small piece of Velcro ® tape<br />

attached to the bottom of the<br />

cockpit section<br />

• Assembly instructions (1)<br />

Tools and Supplies Needed (not included in kit)<br />

• Sharp hobby knife<br />

• Small rat-tail file<br />

• Needle-nose pliers<br />

• Wire cutters<br />

• Small Phillips-head screwdriver<br />

• Medium-sized flat-head screwdriver<br />

• 1.5 mm Allen wrench<br />

• Small piece of medium grade sandpaper<br />

• Ruler<br />

• 1 / 8 " drill bit<br />

• 12-minute epoxy<br />

• Rubbing alcohol<br />

• Medium CA<br />

• CA debonder<br />

• Clear silicone sealant<br />

• Double-sided servo tape<br />

• Velcro tape<br />

• Masking tape<br />

• Black felt-tipped pen<br />

• Clean soft towel<br />

• Small clean sponge<br />

• Liquid dishwashing detergent<br />

• 2 scraps of 1 / 8 " balsa sheeting measuring 1 / 4 " wide by 2" long<br />

Recommended Radio and Electronic Equipment<br />

(not included in the kit)<br />

We recommend the following airborne radio accessories to<br />

complete your <strong>Fokker</strong>.<br />

• The best choice for your airborne radio equipment would be<br />

the JR AirPac Micro(JRPF640), which combines two JR<br />

S241 Sub-Micro Servos and one JR R610 6-Channel<br />

FM Micro Receiver into one convenient package. Total<br />

weight for this three-piece package is just over one ounce.<br />

• Minimum 5-amp electronic speed control.<br />

• 7-cell, 270 to 600mAh battery pack.<br />

4

Applying the Decals<br />

Step1. Select a clean, flat surface for assembling your kit. Your<br />

building area should also be well lit and well ventilated.<br />

Step 2. Place a clean towel on your building surface. Place the<br />

left and right wing panels on the towel.<br />

Step 3. Mix a solution of water and a few drops of dishwashing<br />

detergent in a small bowl. Applying this mixture to the surface of<br />

the model before applying the decals allows the decals to be<br />

positioned and repositioned as necessary without having them<br />

stick to the surface of the model.<br />

Step 9. Remove the smaller Maltese cross and white field decal<br />

from the sheet. Apply the decal to the left side of the fuselage,<br />

3 1 / 8 " aft from the radio compartment. When the decal is in the<br />

desired position, gently smooth it out with a clean, dry cloth to<br />

remove any air bubbles. After the decal has dried, carefully trim<br />

any of the decal excess from the top and bottom of the<br />

fuselage with a sharp hobby knife.<br />

Step 4. Apply the soap and water solution liberally with a clean<br />

sponge to the outer half of the curved upper surface of the left wing.<br />

Step 5. Remove one large Maltese cross and white field decal<br />

from the sheet. Apply the decal to the upper surface of the left<br />

wing 8 1 / 2 " from the center and 1 1 / 8 " forward from the trailing<br />

edge. When the decal is in the desired position, gently smooth<br />

out the decal with a clean, dry cloth to remove any air bubbles.<br />

Step 10. Turn the fuselage over and repeat Step 8 and Step 9 to<br />

apply the decal to the right side of the fuselage. Set the<br />

fuselage aside.<br />

Step 11. Place the vertical stabilizer/rudder on the towel with<br />

the left side facing up. Apply the soap and water solution liberally<br />

with a clean sponge to the center of the left side of the rudder.<br />

Step 6. Repeat Step 4 and Step 5 to apply the large decal to the<br />

right wing. Set the wings aside.<br />

Step 12. Remove the small Maltese cross decal from the sheet<br />

and apply to the left side of the rudder. The cross should be centered<br />

on the rudder 1" from the top, 1" from the bottom, 1 / 8 " aft<br />

of the leading edge of the rudder and 1 / 2 " from the trailing edge<br />

of the rudder. When the decal is in the desired position, gently<br />

smooth out the decal with a clean, dry cloth to remove any<br />

air bubbles.<br />

Step 7. Place the fuselage on the towel with the left side<br />

facing up.<br />

Step 8. Apply the soap and water solution liberally with a clean<br />

sponge to the center of the left side of the fuselage.<br />

Note: Do not get the soap and water solution inside of<br />

the fuselage.<br />

Step 13. Turn the vertical stabilizer/rudder over and repeat<br />

Step 11 and Step 12 to place the decal on the right side of the<br />

rudder. Then set the vertical stabilizer/rudder aside.<br />

5

Assembling the Wing<br />

Step 1. Remove the towel and cover the building surface with<br />

wax paper or plastic food wrap to prevent glued parts from sticking<br />

to your building surface.<br />

Step 7. Raise the right wing 3 1 / 8 " for dihedral and support the<br />

raised right wing with a block of appropriate size.<br />

Step 2. Place the left and right wing panels over the wax paper<br />

or plastic food wrap.<br />

Step 3. Insert the V-shaped wing joiner wire into the plastic<br />

tube on both wings and test fit the wing halves together.<br />

Step 8. Ensure the wing halves maintain proper alignment<br />

and continue to be joined together while the epoxy cures.<br />

Masking tape can be used to help hold the wing together while<br />

the epoxy cures. Remove any excess epoxy with a clean cloth<br />

and rubbing alcohol.<br />

Step 4. Remove the wing joiner wire and rough up its surface<br />

with sandpaper prior to gluing.<br />

Note: Assembly of the wing is very critical. Please read the<br />

following assembly steps before completing.<br />

Step 9. Use a small rat tail file or drill to remove any excess<br />

epoxy from the holes for the wing attachment bolts. Ensure that<br />

the holes are circular and will accommodate the nylon wing<br />

attachment bolts.<br />

Step 10. Set the completed wing aside. Remove the wax paper<br />

or plastic wrap covering from the building surface.<br />

Step 5. Cover the left and right wing joiner ribs and the wing<br />

joiner wire with a moderate but not excessive amount of<br />

12-minute epoxy.<br />

Note: Keep the 2 holes for the wing attachment bolts free<br />

of epoxy.<br />

Step 6. Join the wing halves together. Ensure the left wing<br />

remains flat and does not move.<br />

6

Fuselage Preparation<br />

Step 1. Place the fuselage on the building surface with the left<br />

side facing up. Toward the aft end of the fuselage you will find a<br />

precut pushrod tube exit hole covered by the red Solarfilm. Use a<br />

sharp hobby knife to carefully remove the covering from the precut<br />

hole on the left side.<br />

Note: Please read Steps 5–8 on cowling installation<br />

before completing.<br />

Step 5. Place 12-minute epoxy in the bare rectangular-shaped<br />

area on the top of the fuselage and place the silver fiberglass<br />

cowling over it.<br />

Step 2. Turn the fuselage over so the right side is facing up.<br />

There is another precut pushrod tube exit hole in approximately<br />

the same position as there was on the left side of the fuselage.<br />

Repeat Step 1 to uncover the precut hole on the right side of<br />

the fuselage.<br />

Step 6. Correctly position the cowling on the fuselage before<br />

the epoxy cures. Look at the cowling on the nose of the airplane<br />

head-on. The cowling should be centered over the fuselage.<br />

Step 3. Turn the fuselage over so the bottom of the fuselage is<br />

facing up. Test fit the tailskid in the predrilled hole. Remove and<br />

rough sand the part of the tailskid inserted into the predrilled<br />

hole. Cover the sanded area of the tailskid with medium CA and<br />

install. Allow the adhesive to cure completely.<br />

Step 7. Hold the cowling in place and turn the fuselage over.<br />

The bottom of the cowling should be spaced 5 / 16 " from the front<br />

end of the fuselage.<br />

Step 4. Attach the cowling to the fuselage. Turn the fuselage<br />

over so the top of the fuselage is facing up.<br />

Step 8. Hold the cowling in place with masking tape until the<br />

epoxy cures completely.<br />

7

Preparing the Tail Surfaces<br />

Step 1. Remove the 2 control horns from the tree. Cut the 7 / 16 "<br />

flat section from the two control horns and discard. The 2<br />

remaining control horns with the flange and 1 / 8 " shaft will be<br />

installed on the rudder and elevator.<br />

Step 4. Test fit the rudder control horn in the hole on the rudder.<br />

It may be necessary to increase the diameter of the hole to<br />

get a proper fit for the rudder control horn.<br />

Step 5. Place wax paper or plastic food wrap on your<br />

building surface.<br />

Step 6. Glue the rudder control horn in place with medium CA.<br />

Note: The rudder control horn must be perpendicular<br />

(90 degrees) to the surface of the rudder and the thin<br />

edges of the control horn must be facing forward and<br />

aft. Allow the CA to cure completely and set vertical<br />

stabilizer/rudder aside.<br />

Step 2. Place the vertical stabilizer/rudder on a flat surface with<br />

the right side facing up. Mark the drill point for the rudder control<br />

horn 3 / 16 " in from the leading edge of the rudder and 3 / 16 "<br />

up from the bottom of the rudder.<br />

Step 7. Place the horizontal stabilizer/elevator on the building<br />

surface with the topside facing up. The top of the horizontal<br />

stab/elevator has a narrow, uncovered line where the vertical<br />

stabilizer attaches to it.<br />

Step 3. Hand drill the mark on the rudder with a 1 / 8 " drill bit.<br />

Carefully drill into the rudder with the drill bit between your<br />

thumb and fore finger.<br />

Step 8. Fold the elevators back over the top of the horizontal<br />

stabilizer. When the horizontal stab/elevator is facing up, the<br />

elevators easily fold back over the horizontal stab.<br />

Hold the elevators down flat against the horizontal stabilizer. A<br />

weight may be needed to hold the elevators flat.<br />

Note: Do not crush the horizontal stab/elevator with the weight.<br />

8

Preparing the Tail Surfaces<br />

CONTINUED<br />

Step 9. Test fit the elevator joiner wire into the elevator control<br />

surfaces. It may be necessary to widen the cut already made so<br />

the elevator joiner wire will fit properly.<br />

If more cutting is necessary for a proper fit, open the precut area<br />

wider with a very sharp hobby knife. Carefully fit the elevator<br />

joiner wire into the left and right elevators.<br />

Step 12. On the left elevator, (the front of the horizontal stabilizer<br />

facing you), mark 1 / 4 " in from the leading edge and 5 / 16 " in<br />

from the inside of the elevator for placement of the elevator<br />

control horn.<br />

Note: Do not cut into the red Solarfilm covering.<br />

Step 10. Glue the elevator joiner in place with medium CA.<br />

Step 13. Use a 1 / 8 " drill bit to hand-drill the mark made on the<br />

left elevator in the previous step. Try to keep the covering on the<br />

upper surface intact. Carefully drill into the rudder with the drill<br />

bit between your thumb and fore finger.<br />

Note: Be very careful when applying CA. Do not glue the elevator<br />

and horizontal stabilizer together. Allow adhesive<br />

to cure completely.<br />

Step 14. Test fit the elevator control horn on the left elevator. It<br />

may be necessary to increase the diameter of the hole to get a<br />

proper fit for the elevator control horn.<br />

Step 15. Glue the elevator control horn in the left elevator with<br />

medium CA or 12-minute epoxy.<br />

Note: The elevator control horn must be perpendicular<br />

(90 degrees) to the surface of the elevator and the thin<br />

edge of the control horn must be facing forward and<br />

aft. Allow the adhesive to cure completely.<br />

Step 11. Place the horizontal stab/elevator on a flat surface with<br />

the upper surface facing down and the leading edge of the horizontal<br />

stab facing you. The triangle-shaped uncovered area in the<br />

center of the horizontal stab should be facing up.<br />

9

Pushrood Installation<br />

Note: If you do not have any experience installing pushrods<br />

and radio equipment, we suggest seeking the guidance<br />

of an experienced modeler to help you through the<br />

following steps.<br />

Step 3. Hold the pushrod tube on the right approximately<br />

1 / 2 " in from the right side of the airplane. Apply medium CA to<br />

the sides of the pushrod tube where it meets the rear wing<br />

support crosspiece.<br />

Step 1. Install the white plastic rudder pushrod tubes in the<br />

fuselage. Run the first tube from the open hatch through the exit<br />

hole on the left side of the fuselage.<br />

Carefully use a hobby knife to guide the pushrod through the left<br />

exit hole. Use caution when using the hobby knife as a guide.<br />

Run the elevator pushrod tube through the fuselage and guide it<br />

through the right exit hole.<br />

Step 4. Hold the pushrod tube on the left approximately<br />

1 / 2 " from the left side of the airplane. Apply medium CA to the<br />

sides of the pushrod tube where it meets the rear wing<br />

support crosspiece.<br />

Step 5. Cut off the pushrod tubes so they are even with the forward<br />

edge of the rear wing support crosspiece.<br />

Note: Do not trim the pushrods or glue them in place.<br />

When the pushrod tubes are installed, they cross over inside the<br />

rear of the fuselage—as a result, the elevator servo will be<br />

installed on the right side of the fuselage and the rudder servo<br />

will be installed on the left side of the fuselage.<br />

Step 2. Pull the pushrod tubes forward in the radio compartment<br />

until the pushrod tubes extend a minimum 1 / 4 " from the<br />

exit holes. Apply medium CA around the pushrod tubes where<br />

they exit from the holes. Allow the CA to cure.<br />

Note: Do not get CA in the pushrod tubes.<br />

10

Attaching the Tail Surfaces<br />

Step 1. Attach the wing to the fuselage with 2 nylon wing bolts.<br />

Step 2. Prior to gluing the horizontal stabilizer to the fuselage,<br />

check its position relative to the wing. Viewed from the aft end of<br />

the fuselage, the horizontal stabilizer and wing should be parallel<br />

to each other.<br />

Step 3. Test fit the vertical stabilizer/rudder. Prior to gluing,<br />

ensure the horizontal and vertical stabilizers are perpendicular to<br />

each other.<br />

Note: The horizontal and vertical stabilizers must be kept<br />

perpendicular to each other when gluing. A 90-degree<br />

triangle can be used for proper alignment.<br />

When the horizontal stabilizer is in the correct position, apply<br />

medium CA to both sides of the horizontal stabilizer where it<br />

contacts the left and right sides of the fuselage. Allow adhesive<br />

to cure completely.<br />

Apply medium CA to both sides of the vertical stabilizer where it<br />

meets the top of the horizontal stabilizer. Allow adhesive to cure.<br />

Finishing the Cockpit Section<br />

Step 1. Glue the pilot and machine gun in place on the cockpit<br />

section with 12-minute epoxy. It may be necessary to sand the<br />

base of the pilot flat prior to gluing. Place the epoxy in the<br />

uncovered area and attach the appropriate pieces.<br />

Step 3. Test fit the cockpit section over the wing and remove.<br />

Note: Do not use CA to glue the pilot in place, as it will melt<br />

the pilot.<br />

Step 4. Turn the cockpit section over and separate the Velcro ®<br />

tape. Remove the backing from the Velcro tape. Place the Velcro<br />

on the wing center section so it will correspond with the Velcro<br />

on the on the bottom of the fuselage section.<br />

Step 2. Install the wing on the airplane with the 2 nylon bolts.<br />

Step 5. Place the cockpit section over the wing again. Ensure<br />

the two Velcro tapes adhere to each other so the cockpit section<br />

will remain securely in place on top of the wing. While the airplane<br />

is in flight.<br />

Step 6. Remove the cockpit section and wing from the fuselage.<br />

11

Servo Installation<br />

Step 1. Cut 1 / 8 " balsa sheeting scrap into two pieces, approximately<br />

1 / 4 " wide by 2" long.<br />

Step 2. Use medium CA to glue the two balsa scraps to the left<br />

and right sides of the radio compartment, 5 / 8 " up from the floor<br />

of the radio compartment and 3 1 / 4 " aft of the forward bulkhead.<br />

Step 5. Position the servo arms on the servos so they are<br />

90 degrees to the servos and pointing to the centerline of<br />

the airplane.<br />

Step 6. Slide the straight end of the wire pushrod into the<br />

rudder pushrod tube on the left side of the fuselage. Connect the<br />

Z-bend in the pushrod with the rudder servo on the left side of<br />

the radio compartment.<br />

Step 3. Test fit the rudder and elevator servos in the radio compartment.<br />

The servos should be in contact with the floor and the<br />

balsa strips installed on the left and right sides of the fuselage.<br />

Before installing the servos in the radio compartment, trim the<br />

3 servo arms that are not needed and install the servo arms on<br />

the servos. The servo arms should be toward the centerline of<br />

the fuselage.<br />

Step 7. Place the rudder control surface in the neutral position.<br />

You may need a small piece of masking tape to hold the rudder<br />

in the neutral position. Use a black felt tipped pen to mark the<br />

wire pushrod where it is even with the rudder control horn.<br />

Step 4. Use silicone sealant or servo tape to secure the 2 servos<br />

to the floor and left and right sides of the fuselage, approximately<br />

4" aft of the forward fuselage bulkhead.<br />

Note: Silicone sealant works best for keeping the servos fixed<br />

in position in the radio compartment.<br />

Note: Mark the pushrod wire accurately. A 90-degree bend<br />

will be made on this mark so the pushrod wire can<br />

connect with the rudder control horn.<br />

Step 8. On the mark made in Step 7, use the needle-nose pliers to<br />

make a 90-degree bend in the pushrod wire so it faces downward.<br />

12

Servo Installation<br />

Step 9. Cut the excess rudder pushrod wire and insert the<br />

rudder pushrod wire into the rudder control horn.<br />

CONTINUED<br />

Step 11. Place the elevator control surface in the neutral<br />

position. Use a black felt-tipped pen to mark the wire pushrod<br />

where it is even with the elevator control horn.<br />

Note: Mark the pushrod wire accurately. A 90-degree bend<br />

will be made on this mark so the pushrod wire can<br />

connect with the elevator control horn.<br />

Step 12. On the mark made in Step 11, use the needle-nose<br />

pliers to make a 90-degree bend in the pushrod wire so it<br />

faces outward.<br />

Step 10. Slide the straight end of the wire pushrod into the elevator<br />

pushrod tube on the right side of the fuselage. Connect the<br />

Z-bend in the pushrod with the elevator servo on the right side<br />

of the radio compartment.<br />

Step 13. Cut the excess elevator pushrod wire and insert the<br />

elevator pushrod wire into the elevator control horn.<br />

13

Installing the Landing Gear<br />

Step 1. Turn the fuselage over, taking care not to damage the<br />

vertical and horizontal stabilizers. Install the left and right<br />

landing gear legs into the pre-drilled holes on the bottom of<br />

the fuselage.<br />

Step 2. Secure each landing gear leg with a black plastic<br />

landing gear strap and two small Phillips head screws.<br />

Step 3. Install a wheel on the left and right landing gear legs.<br />

Place the axle collars on the left and right axle and secure in<br />

place by tightening the setscrews with a 1.5 mm Allen wrench.<br />

Installing the Battery Pack,<br />

Receiver, and Speed Control<br />

Note: Installation of the battery pack, receiver, and electronic<br />

speed control may vary due to size, weight, and personal<br />

preference for locating the components. These<br />

instructions should be used as a guide for installation<br />

and should not be considered to be the only way that<br />

the items can be successfully installed.<br />

Step 3. Use servo tape to secure the electronic speed control to<br />

the left fuselage wall approximately 1 / 2 " aft of the forward wing<br />

support and 1 / 2 " below the top of the radio compartment.<br />

14<br />

Step 1. Install the 7-cell battery pack in the forward section of<br />

the fuselage. Use Velcro ® tape to anchor the battery pack in place.<br />

Note: The battery pack is the heaviest electronic component<br />

installed in the radio compartment. The battery pack<br />

should be positioned so the center of gravity is 2"<br />

behind the leading edge of the wing.<br />

Step 2. Connect the leads of the electric motor to the electronic<br />

speed control.<br />

Note: Do not connect the battery lead to the electronic<br />

speed control.<br />

Step 4. Plug the leads from the rudder and aileron servos into<br />

the receiver. Ensure that the servo leads are plugged into the correct<br />

positions in the receiver.<br />

Step 5. Plug the lead from the speed control into the throttle<br />

position in the receiver.<br />

Step 6. Secure the receiver to the floor of the radio compartment<br />

with double-sided servo tape.<br />

Step 7. Hand drill a 1 / 16 " hole in a convenient location on either<br />

side of the fuselage for the receiver antenna. The receiver antenna<br />

can also be run over the edge of either side of the radio compartment<br />

and the wing placed over it.

Propeller Installation<br />

Step 1. Remove the “e”-clip and washer from the propeller<br />

shaft. Use a needle nose pliers to remove the e-clip. Do not lose<br />

the “e”-clip and washer.<br />

Step 2. Lubricate the propeller shaft with a small amount of oil.<br />

Step 3. Place the propeller on the shaft. Ensure the gear on the<br />

motor shaft meshes with the ring gear on the propeller. Place the<br />

washer on the propeller shaft followed by the “e”-clip.<br />

Step 5. Glue the spinner in place on the propeller with a few<br />

drops of CA.<br />

Step 4. Trim the excess plastic from the white plastic spinner<br />

with a sharp scissors and sharp hobby knife. Carefully cut the<br />

three rectangular-shaped notches in the spinner and test fit on<br />

the propeller.<br />

Prior to First Flight<br />

Step 1. Ensure that all electronic and radio equipment is properly<br />

installed and connected and that the battery is charged.<br />

Step 2. Attach the wing to the fuselage with two nylon wing bolts.<br />

Step 3. Attach the cockpit section to the wing.<br />

Step 4. Check the center of gravity. The center of gravity should<br />

be located 2" behind the leading edge of the wing.<br />

Step 5. Check for proper movement of the elevator, rudder and<br />

speed control. At standard rate, the control throws should be 3 / 8<br />

inch up and down for the elevator and 1 inch left and right for<br />

the rudder.<br />

Step 6. Range check your <strong>Fokker</strong> prior to the first flight, or the<br />

first flight after a repair. With the transmitter antenna retracted,<br />

walk 30 to 40 paces from the model. With the assistance of<br />

another person, check for the proper operation and movement of<br />

the control surfaces and speed control.<br />

Flight Safety<br />

1. Always take off and land into the wind.<br />

2. If you are an inexperienced R/C pilot, do not fly unless you<br />

have an experienced R/C pilot with you.<br />

3. Fly only in open areas free of obstructions and never fly over<br />

spectators. Your flying area should be clear of trees, buildings,<br />

and power lines.<br />

4. Never fly on or near a road with traffic. You may risk a collision<br />

with an automobile or you may distract a driver, which<br />

may cause an accident.<br />

5. Be sure to follow the AMA Safety Code following these<br />

instructions.<br />

15

AMA Safety Code<br />

Official AMA National Model Aircraft Safety Code<br />

Effective January 1, 1999<br />

Model flying MUST be in accordance with this Code in<br />

order for AMA Liability Protection to Apply<br />

General<br />

1. I will not fly my model aircraft in sanctioned events, air<br />

shows, or model flying demonstrations until it has been<br />

proven airworthy by having been previously, successfully<br />

flight tested.<br />

2. I will not fly my model higher than approximately 400 feet<br />

within 3 miles of an airport without notifying the airport operator.<br />

I will give right-of-way and avoid flying in the proximity of<br />

full-scale aircraft. Where necessary, an observer shall be utilized<br />

to supervise flying to avoid having models fly in the<br />

proximity of full-scale aircraft.<br />

3. Where established, I will abide by the safety rules for the flying<br />

site I use, and I will not willfully and deliberately fly my<br />

models in a careless, reckless, and/or dangerous manner.<br />

4. At all flying sites, a straight or curved line(s) must be established<br />

in front of which all flying takes place with the other<br />

side for spectators. Only personnel involved with flying the<br />

aircraft are allowed in front of the flight line. Flying over the<br />

spectator side of the line is prohibited, unless beyond the<br />

control of the pilot(s). In any case, the maximum permissible<br />

takeoff weight of the mode is 55 pounds.<br />

5. At air shows or model flying demonstrations, a single straight<br />

line must be established — one side which is for flying and<br />

the other side for spectators. Only those persons accredited<br />

by the contest director or other appropriate official as necessary<br />

for flight operations or as having duties or functions<br />

relating to the conduct of the show or demonstration are to be<br />

permitted on the flying side of the line. The only exceptions<br />

which may be permitted to the single straight line requirements,<br />

under special circumstances involving consideration of<br />

side conditions and model size, weight, speed, and power,<br />

must be jointly approved by the AMA President and the<br />

Executive Director.<br />

6. Under all circumstances, if my model weights over 20 pounds,<br />

I will fly it in accordance with Paragraph 5 of this section of<br />

the AMA Safety Code.<br />

7. I will not fly my model unless it is identified with my name<br />

and address or AMA number, on or in the model. (This does<br />

not apply to models flown indoors.)<br />

8. I will not operate models with metal-bladed propellers or with<br />

gaseous boosts, in which gases other than air enter their<br />

internal combustion engine(s); nor will I operate models with<br />

extremely hazardous fuels, such as those containing tetranitromethane<br />

or hydrazine.<br />

9. I will not operate models with pyrotechnics (any device that<br />

explodes, burns, or propels a projectile of any kind) including,<br />

but not limited to, rockets, explosive bombs dropped from<br />

models, smoke bombs, all explosive gases (such as hydrogen-filled<br />

balloons), ground mounted devices launching a<br />

projectile. The only exceptions permitted are rockets flown in<br />

accordance with the National Model Rocketry Safety Code or<br />

those permanently attached (as per JATO use); also those<br />

items authorized for Air Show Team use as defined by AST<br />

Advisory Committee (document available from AMA HQ). In<br />

any case, models using rocket motors as primary means of<br />

propulsion, are limited to a maximum weight of 3.3 pounds<br />

and a G series motor. (A model aircraft is an aircraft, with or<br />

without an engine, not able to carry a human being.)<br />

10. I will not operate any turbo jet engine (axial or centrifugal<br />

flow) unless I have obtained a special waiver for such specific<br />

operations from the AMA President and Executive Director<br />

and I will abide by any restriction(s) imposed for such operation<br />

by them. (This does not apply to ducted fan models using<br />

piston engines or electric motors.)<br />

11. I will not consume alcoholic beverages prior to, nor during,<br />

participation in any model operations.<br />

Radio Control<br />

1. I will have completed a successful radio equipment ground<br />

range check before the first flight of a new or repaired model.<br />

2. I will not fly my model aircraft in the presence of spectators<br />

until I become a qualified flier, unless assisted by an experienced<br />

helper.<br />

3. I will perform my initial turn after takeoff away from the pit or<br />

spectator areas, and I will not thereafter fly over pit or spectator<br />

areas, unless beyond by control.<br />

4. I will operate my model using only radio control frequencies<br />

currently allowed by the Federal Communications<br />

Commission. (Only properly licensed Amateurs are authorized<br />

to operate equipment on Amateur Band frequencies.)<br />

5. I will not knowingly operate an R/C system within 3 miles of a<br />

preexisting model club-flying site without a frequency sharing<br />

agreement with that club.<br />

6. I will not fly my model aircraft in any racing competition,<br />

which allows models over 20 pounds, unless that competition<br />

event is AMA sanctioned. (Competition is defined as any situation<br />

where a winner is determined.)<br />

7. Every organization racing event requires that all officials,<br />

callers, and contestants must properly wear helmets, which<br />

are OSHA, DOT, ANSL, SNELL, NOCSAE, or comparable standard<br />

while on the racecourse. In addition, all officials occupying<br />

safety cages must wear protective eyewear.<br />

16

<strong>Fokker</strong> Eindecker Spare Parts List<br />

Wing Replacement Kit (HAN9001)<br />

includes:<br />

• Left wing<br />

• Right wing<br />

• Wing joiner<br />

Fuselage Replacement Kit (HAN9002)<br />

includes:<br />

• Fuselage<br />

• Cockpit<br />

• Plastic pushrod tubes<br />

• Pushrods<br />

Note: Fuselage kit does not include the pre-installed motor.<br />

Tail Replacement Kit (HAN9003)<br />

includes:<br />

• Vertical stabilizer/rudder<br />

• Horizontal stabilizer/elevator<br />

Landing Gear Kit (HAN9004)<br />

includes:<br />

• (2) Landing gear legs<br />

• (4) Small Phillips head screws<br />

• (2) Plastic straps<br />

• (2) Axle collars<br />

• (2) Collar fasteners<br />

<strong>Fokker</strong> Eindecker Hardware Kit (HAN9005)<br />

includes:<br />

• Wing joiner wire<br />

• Tail skid<br />

• Elevator joiner wire<br />

• Control horns<br />

• (4) Nylon wing attach bolts<br />

• Velcro ® tape<br />

Individual Items:<br />

• <strong>Fokker</strong> Eindecker silver fiberglass cowling (HAN9006)<br />

• <strong>Fokker</strong> Eindecker German decal set—(2) wing decals, (2) fuselage decals, (2) rudder decals (HAN9007)<br />

• (2) 2 7 / 16 " diameter World War I era wheels (HAN9008)<br />

• Prepainted foam World War I German pilot, 2 1 / 8 " tall, base is 1 7 / 8 " wide (HAN9009)<br />

• Black plastic World War I era machine gun (HAN9010)<br />

• Black 3-bladed plastic propeller and white spinner with propeller shaft washer and “e”-clip (HAN9011)<br />

(The propeller is designed to fit the EXPERT 280 Power Unit motor.)<br />

EXPERT 280 Power Unit EXPERT (EXRE0280)<br />

• 280-size electric motor<br />

• 1:4 gear ratio reduction unit with brass pinion and bronze bearings<br />

• 230 mm diameter, black 3-bladed plastic propeller<br />

• White plastic spinner<br />

17

Glossary<br />

Center of Gravity (CG). The balancing point of an aircraft.<br />

Center Line. An imaginary line drawn through the center of the<br />

aircraft from the nose through the tail.<br />

Control Horn. The arm on the control surface that connects<br />

with the pushrod.<br />

Control Surfaces. The moveable parts on the wing and tail<br />

that cause the aircraft to roll (aileron), pitch (elevator), or<br />

yaw (rudder).<br />

Dihedral. The degree of angle (V-shaped bend) at which the<br />

wings intersect the plane is called dihedral. More dihedral gives<br />

an airplane more aerodynamic stability. Some small R/C airplanes<br />

and trainers with large dihedral dispense with ailerons<br />

and use only the rudder to control roll and yaw.<br />

Elevator. The hinged control surfaces connected to the horizontal<br />

stabilizer. The elevator controls the pitch of the airplane.<br />

Pulling the right control stick on the transmitter aft adjusts the<br />

elevator up and causes the airplane will climb. Pushing the right<br />

control stick on the transmitter forward adjusts the elevator down<br />

and causes the airplane to descend.<br />

Fuselage. The main body of an airplane.<br />

Horizontal Stabilizer. The horizontal surface of the tail that<br />

provides stability in flight. The elevator is connected to the horizontal<br />

stabilizer.<br />

Leading Edge. The front edge of a flying surface.<br />

Landing Gear. The wheel and gear assembly the airplane uses<br />

to land. It is attached to the bottom of the fuselage.<br />

NiCad. This abbreviation stands for Nickel Cadmium — the<br />

chemical compound used in rechargeable batteries.<br />

Pitch Axis. The horizontal plane on which an airplanes nose is<br />

raised or lowered. By moving the elevator, you can raise the airplanes<br />

nose above the pitch axis to climb or lower the nose<br />

below the pitch axis to descend.<br />

Roll Axis. The horizontal plane on which the airplanes wingtips<br />

are raised or lowered. The airplanes ailerons cause the airplane<br />

to roll left or right. On some smaller airplanes that do not have<br />

ailerons, application of the rudder control, combined with the<br />

wing dihedral, will cause the airplane to roll.<br />

Rudder. The control surface attached to the vertical stabilizer.<br />

The rudder controls the yaw of the airplane. Moving the left<br />

control stick of the transmitter left or right will cause the rudder<br />

to move left or right.<br />

Servo. The servo transforms your ground commands into physical<br />

adjustments of a control surface while the airplane is in flight.<br />

Servo Arm. A moveable arm or wheel that connects the servo<br />

to the pushrod. Also called a servo horn.<br />

Speed Control. An electronic device that functions as a throttle<br />

for an electric motor. A speed control controls the speed or rpm<br />

of an electric motor.<br />

Spinner. The nose cone that covers the propeller hub.<br />

Transmitter. The device used on the ground to transmit<br />

instructions to the airplane. Three transmitter modes are used in<br />

model airplanes. The most common is Mode II where the left<br />

stick controls the throttle and rudder and the right stick controls<br />

the elevator and aileron.<br />

Vertical Stabilizer. One of the tail surfaces that provides stability<br />

in flight. The rudder is connected to the vertical stabilizer.<br />

Wheel Collar. The round retaining piece that anchors wheels<br />

in place on the axle.<br />

Wing. The wing provides the primary lifting force on an airplane.<br />

Yaw Axis. The vertical plane through which the airplanes nose<br />

passes as it yaws to the left and right. Rudder controls movement<br />

about the yaw axis.<br />

Z-Bend. The end of a pushrod wire with a Z-shaped bend that<br />

connects to the servo.<br />

Pushrod. The rigid wire that transfers movement from the servo<br />

to the control surface.<br />

Receiver. The receiver unit in the airplane receives your signals<br />

from the ground transmitter and passes the instructions onto the<br />

airplanes servos.<br />

18

Note<br />

19

© Copyright 2000, Horizon Hobby, Inc. 877-504-0233<br />

www.horizonhobby.com