Essar Steel

Essar Steel

Essar Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

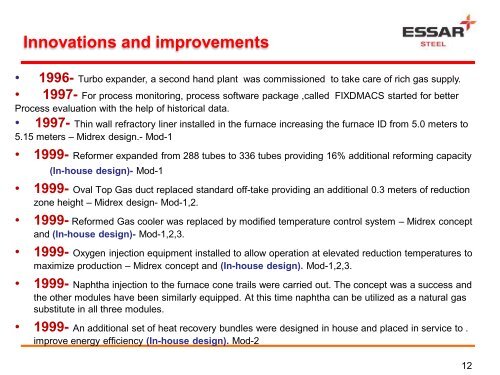

Innovations and improvements<br />

• 1996- Turbo expander, a second hand plant was commissioned to take care of rich gas supply.<br />

• 1997- For process monitoring, process software package ,called FIXDMACS started for better<br />

Process evaluation with the help of historical data.<br />

• 1997- Thin wall refractory liner installed in the furnace increasing the furnace ID from 5.0 meters to<br />

5.15 meters – Midrex design.- Mod-1<br />

• 1999- Reformer expanded from 288 tubes to 336 tubes providing 16% additional reforming capacity<br />

(In-house design)- Mod-1<br />

• 1999- Oval Top Gas duct replaced standard off-take providing an additional 0.3 meters of reduction<br />

zone height – Midrex design- Mod-1,2.<br />

• 1999- Reformed Gas cooler was replaced by modified temperature control system – Midrex concept<br />

and (In-house design)- Mod-1,2,3.<br />

• 1999- Oxygen injection equipment installed to allow operation at elevated reduction temperatures to<br />

maximize production – Midrex concept and (In-house design). Mod-1,2,3.<br />

• 1999- Naphtha injection to the furnace cone trails were carried out. The concept was a success and<br />

the other modules have been similarly equipped. At this time naphtha can be utilized as a natural gas<br />

substitute in all three modules.<br />

• 1999- An additional set of heat recovery bundles were designed in house and placed in service to .<br />

improve energy efficiency (In-house design). Mod-2<br />

12