How To Build A Spray-In-Place Concrete Fence - Monolithic

How To Build A Spray-In-Place Concrete Fence - Monolithic

How To Build A Spray-In-Place Concrete Fence - Monolithic

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

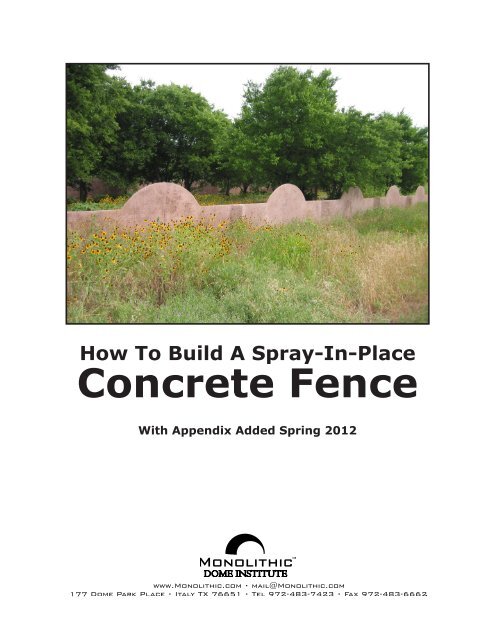

<strong>How</strong> <strong>To</strong> <strong>Build</strong> A <strong>Spray</strong>-<strong>In</strong>-<strong>Place</strong><br />

<strong>Concrete</strong> <strong>Fence</strong><br />

With Appendix Added Spring 2012

<strong>How</strong> <strong>To</strong> <strong>Build</strong> A <strong>Spray</strong>-<strong>In</strong>-<strong>Place</strong><br />

<strong>Concrete</strong> <strong>Fence</strong><br />

Before<br />

After<br />

A spray-in-place concrete<br />

fence adds a beautiful<br />

touch to any yard. Not<br />

only does it delineate, but<br />

the fence also give a beautiful<br />

backdrop to landscaping.<br />

This fence by this<br />

home in Italy, Texas varies<br />

from six to four feet tall.<br />

Disclaimer. All of the information given in this booklet is to the best of our knowledge factual and useful. The engineering data<br />

given is from practical experience. Any person building these fences is advised to have each particular fence engineered by a professional<br />

engineer competent in this type of endeavor. The engineering will of necessity take into account the soil bearing, snow loads,<br />

wind loads, seismic values, etc.

Step 1<br />

Design the <strong>Fence</strong> Layout<br />

Where is the property line?<br />

Whenever a fence is built, it<br />

should be ascertained where the property<br />

line is, or at least, exactly where<br />

the fence is to be constructed.<br />

If the fence is between two property<br />

owners it is best to have an agreement<br />

on what the fence is to be like,<br />

how it should be laid out, and who is<br />

to pay for and install it.<br />

The laws on fences vary from<br />

state to state, so if you don’t get an<br />

absolute agreement with your neighbor,<br />

it is probably best that you check<br />

with an attorney to see what your legal<br />

options are.<br />

After locating and marking the<br />

property lines decide with the neighbors<br />

on the best fence layout. This is<br />

doubly important if the fence is to be<br />

zigzag.<br />

During planning remember to<br />

design the layout so it does not hinder<br />

future plans, remodeling, or expansions.<br />

For instance, if there is no exit<br />

to the back lot and some day you want<br />

to build a swimming pool there, you<br />

will find it very difficult to go through<br />

the concrete fence. Therefore, a gate<br />

would be in order.<br />

<strong>Fence</strong>s perform many functions,<br />

not the least is to “keep them out<br />

and us in.” “Them” can be critters,<br />

people, wind, snow drifts. “Us” usually<br />

consists of the residents and the<br />

pets of the home.<br />

An appropriate fence height<br />

The property line must be determined, agreements<br />

between neighbors must be reached,<br />

and a plan decided on before construction<br />

can begin.<br />

The zigzag fence is superior to the straight line fence. Notice the zigzag fence only requires<br />

a fence post every 16 feet, while the straight line fence requires a post hole every 8 feet.<br />

3

needs to be established. Here again<br />

it is wise to check your local city<br />

ordinances. <strong>In</strong> many places a fence<br />

over three feet tall in the front of the<br />

house is not allowed. <strong>In</strong> other places<br />

a fence has a maximum height in the<br />

back of eight feet. You will find the<br />

fence ordinances vary everywhere in<br />

between. Normally a six foot fence<br />

is acceptable for everything but front<br />

yards, where they may be hazardous<br />

to motorists, especially on a corner lot.<br />

The best choice is get the rules.<br />

The spray-in-place concrete fence<br />

is amazingly versatile. There are many<br />

creative options for layout and design.<br />

On a straight line fence<br />

(right) the wind pressure<br />

and vibration can often<br />

enlarge the post holes and<br />

eventually push the fence<br />

over or snap the posts at<br />

ground level.<br />

Because of the zigzag,<br />

pressures act very differently<br />

on this fence (below)<br />

from those of a straight<br />

fence. The 2” thick fence<br />

with a one foot offset<br />

zigzag acts as if it were a<br />

two foot thick fence. Pressures<br />

applied act to turn<br />

over the fence rather than<br />

to break it off at ground<br />

level. It is much more<br />

stable<br />

Straight <strong>Fence</strong> vs. Zigzag<br />

First you will want to decide<br />

whether or not to build a straight fence<br />

or one with a zigzag. Both types of<br />

fences, the straight line and the zigzag,<br />

have advantages. You must decide<br />

which of the two fences is most appropriate<br />

for your application.<br />

The Straight <strong>Fence</strong> — Advantages<br />

The straight line fence is the traditional<br />

fence. It obviously can follow<br />

precisely along given property lines,<br />

and is utilized in most neighborhoods.<br />

The straight fence has a series<br />

of posts, in line, all standing vertically.<br />

These posts acting together, in<br />

concert, keep the fence standing and<br />

prevent it from tipping over, even<br />

when loads are applied, such as: high<br />

winds, some one backing into it, or<br />

something piled against the fence.<br />

A straight fence has the advantage<br />

of taking the least amount of land and<br />

being an exact delineator between two<br />

properties.<br />

The Straight <strong>Fence</strong>—Disadvantages<br />

The straight fence’s main disadvantage<br />

is strength. Expansion and<br />

4

Well laid-out plan for a zigzag fence (above). It would be even better if the ends of the fence<br />

by the driveway had doubled fence posts, a box (see drawing page 5), or a turn to give greater<br />

stability and a more finished look.<br />

contraction is more severe especially<br />

for long straight runs of fence. Twice<br />

as many posts need to be installed<br />

because they are all that hold it up.<br />

The posts need to be a little larger in<br />

diameter and be deeper in depth.<br />

Consider wind pressure: A wind<br />

blowing 100 miles per hour against<br />

a vertical fence will push with 50<br />

pounds per square foot against the<br />

fence. If the fence is six feet tall that<br />

means there is 300 pounds of push<br />

per foot down the length of the fence.<br />

The taller part of the fence has a<br />

lever action against the ground which<br />

increases its propensity to roll over.<br />

<strong>In</strong> other words, the taller the post<br />

the more leverage it exerts. This 300<br />

pound push is considered in average<br />

three feet above the ground. If the<br />

posts are eight feet apart and we have<br />

an average of 300 pounds of push,<br />

that equals 2400 pounds of push on<br />

one fence post.<br />

That fence post must be able to<br />

resist snapping off at ground level and<br />

the post hole must resist enlarging to<br />

prevent turn over at ground level. If<br />

the hole starts to enlarge even a little<br />

bit, the fence tends to pound the hole<br />

larger and larger as the wind hits it<br />

and backs off over and over again. A<br />

fence that can withstand being tipped<br />

over from a one-time push may fail to<br />

the buffeting of an intermittent wind.<br />

It is therefore very important that the<br />

post be larger in diameter and set deep<br />

enough to withstand this turn over at<br />

the ground line.<br />

The Zigzag <strong>Fence</strong> — Advantages<br />

The zigzag fence is much stronger<br />

and more durable than a straight<br />

fence. It will stand up to expansive<br />

soils, wind loads and expansion and<br />

contraction much better than a straight<br />

fence. It proves interesting by being<br />

Note the forms set up for shotcreting (left).<br />

This four-foot high fence is zigzagged one<br />

foot off center each way. Surprisingly, when<br />

completed one hardly notices the zigzags<br />

in this fence. The posts have already been<br />

poured. The bracing must resist wind until<br />

the fence is sprayed and solid.<br />

5

zigzagged, forming pockets for planting<br />

trees and shrubs. It can be taller<br />

without significantly increasing post<br />

size.<br />

A zigzag fence is a stronger fence<br />

because of the zigzag. It acts as if it<br />

were a wide fence. Note on the diagram<br />

(see page 3) the pressures act on<br />

a zigzag fence vastly differently from<br />

those of a straight fence.<br />

When pressure is applied against<br />

the top of the fence it tries to turn the<br />

fence over. The posts certainly prevent<br />

some turn over, but mostly they prevent<br />

the fence from sliding sideways.<br />

It is far easier to prevent a fence from<br />

sliding sideways than it is to prevent<br />

it from turning over. <strong>In</strong> order to turn<br />

over the zigzag fence the wind must<br />

pick up one whole side of the zigzag.<br />

The amount of zig (off set from<br />

center) determines how much pressure<br />

will have to be applied before the<br />

forward post can lift and bend over<br />

against the back post. <strong>In</strong> other words,<br />

the ability of the forces to hold against<br />

pressure is much greater as the “zigs”<br />

increase.<br />

If the zigzagging is 2 feet every<br />

16 feet the fence behaves as if it were<br />

a two-foot wide fence. Air pressure<br />

working against the fence is doing<br />

more to lift the high side of the fence<br />

than it is to turn over the fence. The<br />

zigzag fence is enormously strong.<br />

The zigzag fence is a very pretty<br />

fence, besides being very structural.<br />

Small alcoves can have benches<br />

placed in them. Trees and plantings<br />

look great set in the enclosures of the<br />

insets.<br />

The zigzag also acts as an expansion<br />

joint at each change of direction,<br />

providing greater flexibility in<br />

expansion/contraction situations. The<br />

amount of the zig can be varied. A<br />

four-foot fence many only need twelve<br />

to eighteen inches of zigzag. A six to<br />

eight foot fence might be better with<br />

eighteen inches to two feet of zigzag.<br />

The zigzag fence can easily be<br />

built eight, ten, twelve feet high. The<br />

straight fence is best kept at lower<br />

heights. The zigzag fence gets along<br />

very easily with posts 16 foot on<br />

Above, an eight foot fence constructed for<br />

the Christmas Festival in Waxahachie, Texas<br />

has walls connected to the fence to delineate<br />

booths. More importantly, they significantly<br />

add to the strength of the fence.<br />

Anytime an adornment or offset can be<br />

added strength will be added to the fence.<br />

This straight line fence has small offset<br />

every eight feet and finishes with a decorative<br />

and strengthening box at the end of the<br />

fence.<br />

6

This particular fence starts with twelve feet<br />

straight, then a two foot deep triangle on<br />

the right, then twelve straight feet of fence,<br />

then a two foot deep triangle to the left, and<br />

continues with alternating triangular niches.<br />

These niches create wonderful landscaping<br />

opportunities for benches, roses, anything.<br />

This fence acts as a 4 foot thick fence. It is<br />

extremely stable under all conditions.<br />

There are few limitations to creative design.<br />

One could build a variation of the above<br />

using square offsets instead of triangles. The<br />

fence can be built serpentine. The spray-inplace<br />

concrete fence allows for the imagination<br />

to run wild.<br />

center. The straight fence should have<br />

posts 8 foot on center.<br />

The Zigzag <strong>Fence</strong> — Disadvantages<br />

The zigzag fence takes up a little<br />

more space. If you want a zigzag<br />

fence the neighbors must absolutely<br />

determine where the fence posts are<br />

going to go. <strong>To</strong> be fair the posts<br />

should zigzag across the property line<br />

so that each of the parties have the<br />

same amount of property taken up by<br />

the fence itself. It takes a little more<br />

layout. It is somewhat nontraditional.<br />

Summary of the Principle Difference<br />

The major difference in the<br />

strength dynamics of these two fences<br />

is — what it will take to knock the<br />

fence down.<br />

The straight line fence is held in<br />

place by the soil. Force against the<br />

fence does two things. One, it tries<br />

to snap the post off. But, the concrete<br />

post is very strong. Secondly,<br />

it tries to make the post hole bigger.<br />

Force acting against the top of the<br />

fence forces it to rock back and forth,<br />

enlarging the hole. The fence, to a<br />

certain extent, is only as strong as the<br />

soil.<br />

For the zigzag fence the dynamics<br />

are totally different. It is not a soil<br />

issue, or snapping off of the posts.<br />

Here, force acting against the fence<br />

tries to tip the fence over. The posts<br />

serve mainly to keep the fence from<br />

sliding sideways in the soil -- the<br />

fence itself is the strength. A zigzag<br />

fence that zigs one foot off center one<br />

way and zags one foot off center the<br />

other acts as if it were a two foot thick<br />

fence.<br />

Soil Considerations: Moving Ground<br />

Many parts of the United States<br />

have expansive soil. This means that<br />

when the ground gets wet it expands<br />

and when it dries out it contracts.<br />

Where we are here in Italy, Texas,<br />

it is extremely bad. The contraction<br />

will pull all of the dirt away from a<br />

post, or it may lift the post, or in the<br />

case of the concrete fence, it may try<br />

to lift the fence.<br />

If you are building in that type of<br />

soil condition, we suggest again that<br />

you very seriously look at the zigzag<br />

fence. If you don’t look at a zigzag<br />

fence, then look at a very sizable size<br />

post. The four foot high fence would<br />

have a three foot deep post. An eight<br />

foot high fence would have a four to<br />

five foot deep post. The straight line<br />

fence should have at least an eight<br />

inch post. The zigzag fence could get<br />

by with a six-inch post and in all cases<br />

it doesn’t need to be especially deep,<br />

three feet would be just right.<br />

If the soils persist in moving the<br />

fence around, then you can dig the<br />

soil out from under the length of the<br />

fence and that should stop. I am hesitant<br />

to dig out from under the fence<br />

in most areas because that invites animals<br />

to dig under the fence. <strong>In</strong> most<br />

places there is not going to be enough<br />

expansion or contraction to bother the<br />

fence itself. You should just monitor<br />

it and if it looks like it is going to be<br />

a problem then dig out half of the soil<br />

out from under it, or two thirds, or all<br />

of it if you need to.<br />

7

The <strong>To</strong>p of the <strong>Fence</strong><br />

The top of the fence in general<br />

should be delineated. This can be as<br />

simple as a 2” x 2” runner along the<br />

top of the form or can have an interesting<br />

pattern fastened to the forms as<br />

illustrated.<br />

As the fence is sprayed the concrete<br />

is shot up underneath this top<br />

finish board so there is a place to stop.<br />

The imagination can be free on how<br />

to finish the top. It could be made to<br />

look like a picket fence, it could be<br />

made to have a flat top, or it could be<br />

let run wild and have an organic look.<br />

Corners, <strong>In</strong>clines, and more...<br />

This fence is marvelously versatile.<br />

The corners can be square,<br />

angled or rounded. On an incline the<br />

fence can come down in steps or can<br />

follow the slope of the hill. The fence<br />

easily spans ditches because of its<br />

strength. It is simple to vary the height<br />

of the fence for privacy or a favorite<br />

view.<br />

The top of the fence can have any desired finished shape. Likewise the fence itself is<br />

extremely versatile. On an incline it can come down in steps or follow the slope of the hill.<br />

8

Step 2<br />

<strong>In</strong>stall <strong>Fence</strong> Posts<br />

The next step in building either of<br />

the fences is installing the fence posts.<br />

Measuring The Layout<br />

Pull a string along the property<br />

line to delineate it. Measure carefully<br />

the distances along the string and from<br />

the string for the proper zigzag or<br />

other pattern.<br />

The post should be poured up flush with the ground level or 1/2” to 2” above the ground level,<br />

then insert three vertical bars of #3 rebar. The fence post above is the thickness and depth for<br />

a zigzag fence. <strong>Fence</strong> posts poured in a zigzag pattern (below).<br />

Determine The Post<br />

Size And Distance<br />

The posts are obviously key to the<br />

fence standing up. The size must be<br />

large enough to restrain movement in<br />

the soil. If the fence posts are in line<br />

they must be larger than for the zigzag<br />

fence.<br />

The size of the post is best determined<br />

by the type of the soil. If the<br />

soil is sand and not prone to loosing<br />

while wet, a 6 inch fence post may<br />

be all that is needed. More than likely,<br />

the fence post should be 8 inches<br />

in diameter. If the soil is subject to<br />

flooding and not much strength when<br />

wet, the post may need to be built 12<br />

inches in diameter.<br />

If the soil doesn’t have some good<br />

side to side holding characteristics<br />

then a straight fence is probably not<br />

the best to build. The zigzag fence<br />

may be used here, but may be even<br />

increased to 3 foot zigzag on 16 feet.<br />

The post hole is then of not much<br />

importance, a 6 inch or 8 inch post<br />

hole would be fine.<br />

The post for the straight fence<br />

should be eight feet apart and for the<br />

zigzag fence they can be twelve to<br />

sixteen feet apart.<br />

<strong>In</strong>stalling The Post<br />

Care must be taken to fill the post<br />

9

hole to the top with concrete. The<br />

concrete of the upper part of the post<br />

must rest securely on that poured in<br />

the hole.<br />

<strong>In</strong>to the near center of the post<br />

should be placed three vertical bars of<br />

#3 rebar, extending up to the top of<br />

the fence. They should be arranged<br />

in a flattened triangle along the line of<br />

the fence. If the fence is higher than<br />

eight feet the rebar should probably be<br />

changed to #4 bar and the post holes<br />

may need to be increased to 18 inches<br />

in diameter for the straight fence; 8<br />

inches will still be fine for the zigzag<br />

fence.<br />

The post should be poured up flush with the ground level or slightly above ground level<br />

(above) with three vertical bars placed near center. Using a the side discharge door of a<br />

<strong>Monolithic</strong> <strong>In</strong>tegrator SL30 (below) makes filling the post holes astoundingly quick and easy.<br />

10

<strong>Place</strong> the forms vertical and two to three inches off the center of the post. Note (above)<br />

the rebar coming out of the hardened concrete post are arranged in a flattened triangle.<br />

Waferboard, 2” x 4”s, and stakes for bracing (below) provide easy and inexpensive formwork<br />

for this four foot tall fence.<br />

Step 3<br />

Form The <strong>Fence</strong><br />

The forms can be made of virtually<br />

anything that will hold still.<br />

We have found a light framework<br />

of 2” x 4” faced with 7/16 inch thick<br />

waferboard makes inexpensive forming<br />

for this fence.<br />

If the fence is only four feet tall,<br />

the waferboard can be laid down<br />

horizontally. If it is six to eight foot<br />

tall then the waferboard must be stood<br />

on end.<br />

These form boards are called<br />

single side forms. One side of the<br />

forms we will call “off side” that is<br />

the side where we are going to do the<br />

least amount of spraying. It is the side<br />

for the bracing. The “near side” is the<br />

11

side that we are going to do the spraying<br />

against. It needs to be the least<br />

obstructed side.<br />

The next step is to set the form<br />

boards on the off side of the work<br />

area.<br />

Coat the form on the near side<br />

with a concrete release agent. This<br />

release agent is often called form oil.<br />

Many times it is nothing more than<br />

diesel fuel. Form oil can be purchased<br />

at any concrete accessory supply<br />

house.<br />

Putting Up the Forms<br />

After applying the form oil stand<br />

up the single side forms.<br />

<strong>Place</strong> the formwork so that it is<br />

vertical and passes immediately adjacent<br />

to the post tops, approximately<br />

two to three inches off the center of<br />

the post.<br />

The fence must be perfectly<br />

straight up and down (plumb) and it<br />

should be square at the corners with<br />

bracing of 2” x 4” and stakes to hold<br />

it still. Brace the form well enough to<br />

be able to withstand normal winds and<br />

some abuse, but the concrete is not<br />

going to add any significant pressure.<br />

These photos are of the off side.<br />

You can see the temporary wafer<br />

board, braces, and stakes in place.<br />

Options<br />

This is an extremely simple<br />

system. The pieces can be made in<br />

modules to be moved in four foot or<br />

eight foot sections.<br />

If the fence length is short, you<br />

probably need to form the entire<br />

length of the fence.<br />

If you are building a long fence,<br />

form and spray part of the fence.<br />

After the second spraying of concrete<br />

you can generally move the forms<br />

and start a new section while you are<br />

finishing up old section.<br />

Brace the form well enough to be able to withstand normal winds and some abuse (above).<br />

The formed offset (below) gives two benefits — a decorative finish to the end of the fence<br />

and extra strength to the straight wall.<br />

12

(Above) Drill small holes above and below the rebar through the form boards. Fasten the first<br />

layer of rebar by wiring it to the off side. The rebar should be lightly attached to these forms<br />

so that it doesn’t wave and wiggle. Keep the rebar square and neat. It takes about 4 attaching<br />

points per 20 foot length of rebar.<br />

Step 4<br />

Attach The Rebar<br />

Now that the forms are in place,<br />

plumbed and staked, we can put the<br />

rebar in place. The rebar should be #3<br />

(3/8 inch diameter) and run approximately<br />

18 inches each way.<br />

<strong>In</strong> general the first layer of rebar<br />

is the horizontals, but it can be either<br />

the horizontal or verticals. Fasten the<br />

first layer of rebar by drilling a small<br />

hole on each side of the rebar through<br />

the form boards. Then push a tie wire<br />

through the holes and twist it tight in<br />

the back. It takes about 4 attaching<br />

points per 20 foot length of rebar. The<br />

rebar should be tightly attached to<br />

these forms so that it doesn’t wave and<br />

wiggle.<br />

When it is time to remove the<br />

forms cut the wires on the off side<br />

which will free the form.<br />

The top rebar should be about two<br />

inches below the top of the concrete.<br />

The bottom should be about two<br />

inches above the bottom of the concrete<br />

and then spread out the rebar<br />

in-between, evenly, but not to exceed<br />

eighteen inches.<br />

The vertical rebar can then be<br />

applied over the horizontal rebar and<br />

fastened with wire ties. These should<br />

also be spaced evenly but not to<br />

exceed eighteen inches.<br />

The post is the structural key.<br />

Center the rebar so it fastens into the<br />

rebar of the fence. Make sure there is<br />

a reasonable diameter to the size of the<br />

post as it comes out of the ground. It<br />

can be thinned to the thickness of the<br />

fence in the first 2 to 3 feet above the<br />

ground. The rebar from the fence posts<br />

is spaced about three inches apart and<br />

attached to the horizontal rebar.<br />

Left is a 6’ tall zigzag fence formed with rebar<br />

attached, ready for shotcreting. Only a section<br />

of the fence is formed, the remainder will<br />

be four feet tall and formed later. At the fence<br />

posts there are three lengths of vertical out<br />

of the post rebar spaced 3” apart instead of<br />

one rebar every 18”.<br />

13

<strong>Place</strong> the rebar 15” to 18” on center. Determine<br />

the distance by spacing the rebar<br />

evenly between the post. <strong>In</strong> general the horizontal<br />

rebar is placed first, but the first layer<br />

of rebar can be either the verticals or horizontals.<br />

The forms are up with the vertical rebar in<br />

place. Note the single 2” x 4” brace on<br />

the near side of the form so there is a minimal<br />

amount of obstruction for the shotcreter.<br />

Once the horizontal rebar is in place the concrete<br />

spraying can commence.<br />

The rebar should be evenly spaced but not<br />

to exceed 18 inches apart, and come up to<br />

two inches from the top of the fence and two<br />

inches from the bottom of the fence.<br />

14

Step 5<br />

Applying the Shotcrete<br />

The next step is applying the<br />

shotcrete. This requires a working<br />

understanding of cement, shotcreting,<br />

aggregate and your options.<br />

Types of Portland Cement<br />

<strong>In</strong>gredients for a fence: sand, cement, water,<br />

ad mixture, and colorant for the final coat.<br />

The <strong>Monolithic</strong> <strong>In</strong>tegrator SL30 attached to<br />

a skid loader is “self-bucketing” and easy to<br />

load up with sand.<br />

Type I. Normal Portland Cement.<br />

Use this general all purpose<br />

portland cement. It is available at<br />

most lumber yards and cement supply<br />

stores. Following is the long explanation.<br />

It is here for those who wish to<br />

know more.<br />

This is a general purpose cement<br />

suitable for all uses when the special<br />

properties of the other types are not<br />

required. It is used in pavement and<br />

sidewalk construction, reinforced<br />

concrete buildings and bridges, railway<br />

structures, tanks and reservoirs,<br />

sewers, culverts, water-pipe, masonry<br />

units, soil-cement mixtures, and for all<br />

uses of cement or concrete not subject<br />

to special sulfate hazard or where the<br />

heat generated by the hydration of the<br />

cement will not cause an objectionable<br />

rise in temperature.<br />

Type II. Modified Portland Cement<br />

This cement has a lower heat of<br />

hydration than Type I and generates<br />

heat at a slower rate. It is mixed with<br />

Type I in some locations. It will work<br />

well if available.<br />

Air Entraining Portland Cement.<br />

There are three types of airentraining<br />

portland cement corresponding<br />

to Types I, II, and III. <strong>In</strong><br />

these cements very small quantities<br />

of certain air-entraining materials are<br />

incorporated by intergrinding them<br />

with the clinker during the manufacturing<br />

process. They have been developed<br />

to produce concrete resistant to<br />

severe frost action and to effects of<br />

applications of salt to pavements for<br />

snow and ice removal.<br />

15

<strong>Concrete</strong> made with these cements<br />

contains minute, well-distributed and<br />

completely separated air bubbles.<br />

The bubbles are so minute it is estimated<br />

there are many billions of them<br />

in a cubic foot of the concrete. The<br />

entrained air is reflected in reduced<br />

weight of the fresh concrete. Best<br />

results are obtained when the air content<br />

is approximately 5% to 8%.<br />

Shotcrete Terms<br />

Shotcrete<br />

Shotcrete is a process by which<br />

concrete is air placed usually on a<br />

vertical or an overhead surface. Shotcrete<br />

is made from a mixture of sand,<br />

cement and water which is pumped<br />

through a hose to the nozzle. At the<br />

nozzle air is injected to break up and<br />

actually apply the concrete. Shotcrete<br />

is also called wet gunning or wet<br />

placed concrete.<br />

Gunite<br />

Gunite is a term for a patented<br />

process by which sand and cement<br />

are mixed together and transported<br />

down a hose with a large volume of<br />

air to the nozzle. At the nozzle water<br />

is injected to create the proper moisture<br />

to set the concrete. Gunite is also<br />

called dry gunning or dry gunned air<br />

placed concrete. Generally the sand<br />

and cement are mixed on the job site.<br />

Gunite takes approximately three<br />

times as much air as shotcrete. It will<br />

have about twice as much rebound.<br />

Two bags of cement are dumped into the<br />

mixer.<br />

The hydraulic power from the skid loader is<br />

what powers the mixing (guard removed for<br />

picture).<br />

Rebound<br />

Whenever air placed concrete,<br />

either wet or dry process, is sprayed<br />

the surface will reflect or bounce back<br />

a certain amount. We have found it<br />

to be 10% with wet gunning and 20%<br />

with dry gunning. The rebound can<br />

vary substantially from these numbers<br />

depending on the situation and opera-<br />

16

tor’s experience.<br />

<strong>Concrete</strong> Strengths<br />

Normally shotcrete is much<br />

stronger than conventional concrete<br />

because of several factors. First more<br />

cement is used in the mix. Also the<br />

impaction created by the air tends to<br />

drive out the larger air spaces thus<br />

providing a somewhat denser product.<br />

Usually shotcrete will have a compressive<br />

strength of more than 4,000 psi.<br />

The concrete strength depends<br />

greatly on the aggregate, the amount<br />

of cement and the amount of water.<br />

The concrete is being poured over the front<br />

of the <strong>Monolithic</strong> <strong>In</strong>tegrator SL30 <strong>Concrete</strong><br />

Mixer into the MudSlinger EHP 1500 concrete<br />

pump (above). The mixer also has a<br />

side gate for letting smaller amounts out<br />

(below), such as would be needed for filling<br />

post holes. The side dump is demonstrated<br />

below.<br />

Aggregate<br />

The best aggregate for shotcrete<br />

is a very even gradation from 3/8 to<br />

nearly nothing. If any of the sizes are<br />

left out that size must be replaced by<br />

the cement creating a much harder<br />

mixture to pump and work with.<br />

Rarely in the United States do we find<br />

nice, even graded aggregate. Aggregate<br />

that has been crushed is also<br />

much harder to work with than river or<br />

natural aggregates. The jagged edges<br />

of the crushed aggregate tend to hang<br />

up in the pumping process. Rarely do<br />

we find an even graded aggregate. So<br />

generally we have to make the best<br />

with what we can find in the locality.<br />

Mix Water<br />

Wherever possible the water/<br />

cement ratio needs to be held at .4 to<br />

.45. This creates an extremely strong,<br />

workable concrete. Sometimes additional<br />

water must be used to create<br />

a pumpable mix. This is done most<br />

often when some of the aggregate is<br />

off-size or cracked. Theoretically the<br />

slump test will give you an indication<br />

of the water cement ratio. <strong>How</strong>ever,<br />

with 3/8 minus aggregate slump tests<br />

are very unreliable.<br />

Slump Test<br />

The slump test is performed by<br />

filling an inverted cone with concrete,<br />

then removing the cone and measuring<br />

the distance the concrete slumps from<br />

the original height. A slump test is an<br />

17

extremely valid measurement for concrete<br />

in the 5, 6 sack range with 3/4 or<br />

larger aggregate.<br />

Compressive Strength Tests<br />

Compressive strengths in the<br />

conventional concrete industries are<br />

performed by breaking cylinders that<br />

have been filled and set aside for that<br />

purpose. A good correlation between<br />

a series of cylinders is about 20%.<br />

Unfortunately shotcrete doesn’t test<br />

very well in cylinders unless they<br />

are special shotcrete cylinders which<br />

are hard to come by. The most valid<br />

system for testing shotcrete seems to<br />

be the Windsor probe or spraying a 2”<br />

thickness that is later cubed and tested.<br />

Cubed tests and Windsor Probe<br />

tests are generally quite comparable.<br />

The Windsor Probe is much easier as<br />

it is simply a matter of firing a bolt<br />

with a predetermined charge into the<br />

concrete and measure the depth of<br />

penetration. It is somewhat destructive<br />

in that there’s a small hole left<br />

with a bolt sticking out of it. Cubed<br />

tests are totally nondestructive unless<br />

they are taken as cores. The major<br />

problem with cubed tests is always<br />

the question -- was the concrete cured<br />

under exactly the same conditions that<br />

are in the facility itself.<br />

<strong>Concrete</strong> Thickness<br />

Every endeavor is made to make<br />

concrete the proper thickness. This<br />

thickness is gauged by the amount of<br />

embedment on the steel and by the<br />

experience of the nozzleman. It is<br />

further checked and corroborated by<br />

the calculations of the volumes needed<br />

for the project. <strong>In</strong> general, however,<br />

the thickness is less important than<br />

properly embedding all of the reinforcing<br />

steel.<br />

When 1/2 inch to 3/4 inch of concrete<br />

covers the rebar on both sides, it<br />

is thick enough.<br />

The MudSlinger GHP1500 concrete pump is<br />

an ideal size for building fences. This is a<br />

very simple pump and can be driven by running<br />

an air compressor.<br />

Safe Operations and Practices<br />

The use of appropriate safety equipment<br />

is required. This includes face shields, or<br />

safety goggles, respiratory protection (as<br />

needed) and waterproof gloves. Wet concrete<br />

will “burn” unprotected skin. Shoes<br />

should be water proof and provide physical<br />

protection to the wearer. The first layer of<br />

shotcrete should be about 1/2 to 3/4 of one<br />

inch. After it is set, a second coat can be<br />

applied to bury the rebar.<br />

18

<strong>To</strong> Mix or Not to Mix<br />

The shotcrete is placed in layers. The first layer is left for several hours or overnight to gain<br />

strength. Then the second layer can be applied, then, of course, the third layer. By the time<br />

the second and third layers are in place the fence will be very strong.<br />

Do you want to use ready-mix or<br />

mix on-site? <strong>In</strong> order to use readymix<br />

you will need a larger pump and<br />

will want to have more of the fence<br />

formed. Mixing on-site has advantages,<br />

such as ease of pouring the<br />

fence posts and convenient scheduling.<br />

Obviously, if the job uses thousands<br />

of yards of concrete, a ready<br />

mix plant is the only way to go for<br />

ordering shotcrete. But for the small<br />

jobs using the small pumps, we suggest<br />

you consider mixing on site.<br />

Mixing on-site with small mixers<br />

must be well organized. The mixers<br />

can be a Porta-mix mounted on a skid<br />

loader, or a plaster mixer, or small line<br />

concrete mixer. The biggest advantage<br />

of on-site mixing is the ability to<br />

control the speed and delivery. There<br />

is nothing worse than waiting a few<br />

hours for the ready-mix truck and then<br />

immediately having a breakdown that<br />

prevents unloading it.<br />

Shown above the first layer of concrete is in place. There are places where some of the<br />

concrete sloughed off. These places will be easily filled in with the second layer of concrete.<br />

Shotcrete Mix Design<br />

Mix Design for 1/3 cubic yard<br />

Shotcrete mix design varies from<br />

job to job due to different types of<br />

materials and other conditions. <strong>How</strong>ever,<br />

following is a mix design that<br />

works well in most areas.<br />

Cement — 188 lb. Two sacks of<br />

standard Type I or II or I-II Portland<br />

cement. This is what the lumber yard<br />

will carry. It is not mortar mix.<br />

Water — about 80 lbs. (10 gallons.)<br />

Water must be clean (potable).<br />

19

This will vary from job to job and<br />

must be adjusted. The water in the<br />

aggregate will cause a difference in<br />

the amount of water needed. Adjust to<br />

a proper slump. 2” to 6” as needed.<br />

<strong>Concrete</strong> Sand — 690 lbs. (Ten, 5<br />

gallon buckets is a good approximate<br />

measure).<br />

Pea rock — 140 lbs. (Two, 5<br />

gallon buckets.) The amount of pea<br />

rock is adjusted per gradation of the<br />

sand. If the sand is high in larger<br />

aggregate the pea rock may be left out.<br />

If it is low, then more may be needed.<br />

This is a place to start for maximum<br />

strength. The total of the sand and<br />

pea rock should equal the 830 pounds<br />

(twelve, 5 gallon buckets). Usually,<br />

the pea rock is left out of the final<br />

coats to provide a smoother finish.<br />

Kel-Crete — use 2 oz. minimum<br />

per batch. Try up to four ounces per<br />

batch. Adjust between for the best<br />

results. We normally use 2.5 ounces.<br />

Add the Kel-Crete additive in with<br />

the water for easier dispersion. If the<br />

Kel-Crete is not added, another 1/3 of<br />

a bag of cement should be added.<br />

Nylon fibers — use 1/3 lb. Per<br />

batch. These are the best fibers we<br />

have found for what we are doing.<br />

<strong>To</strong>tal weight of this batch will be<br />

about 1,100 pounds.<br />

The nozzleman applies the second layer of<br />

shotcrete. One can see that the rebar is<br />

being buried with this second layer. The<br />

fence is now approximately one and a half<br />

inches thick. The rebar needs to be scraped<br />

or ridges will be left. Do not apply all the<br />

shotcrete at one time. Cover the fence then<br />

go back and do it again. After a section<br />

sets for even a short time it can often be<br />

resprayed.<br />

(Below) The nozzle should be held perpendicular<br />

to the work or slightly pointed up as<br />

shown on page 22. Never, never spray down<br />

with only one exception — spraying the base<br />

footing of the fence.<br />

<strong>Spray</strong> the Shotcrete<br />

The posts are obviously key to the<br />

fence standing up. The size must be<br />

large enough to restrain movement in<br />

the soil. If the fence posts are in line<br />

they must be larger than for the zigzag<br />

fence.<br />

The concrete of the upper part<br />

of the post must rest securely on that<br />

poured in the hole.<br />

Blow and clean any material off<br />

the top of the lower portion before<br />

shotcreting the upper portion.<br />

And be sure and spray onto the<br />

top of the post immediately (first) to<br />

prevent rebound or other materials<br />

20

After the forms are removed spray another 3/4 inch to both sides of the fence. After this has<br />

cured a few hours finish the fence with a 1/4 inch thick coat of concrete with colorant added.<br />

One can choose to finish with the gray concrete and stain it or just leave it gray. This final<br />

coat can be etched to simulate rock, brick or block finish.<br />

The fence is now structurally strong. It needs one more layer to even it up and then the<br />

final layer of colorant.<br />

to accumulate between the layers of<br />

concrete.<br />

Once all of the form work and<br />

rebar are in place a light coating of<br />

concrete is sprayed onto the form<br />

through the rebar.<br />

The placing of the concrete is<br />

simple when done right. Apply the<br />

concrete as evenly as possible at all<br />

times. This helps in keeping the thickness<br />

correct.<br />

The shotcrete is started at the<br />

bottom. The entire footing (top of<br />

posts) should be covered first with a<br />

thick layer that extends about 1 foot<br />

up the wall. This is to make sure<br />

that the concrete on the footing is<br />

good concrete and not just shotcrete<br />

rebound.<br />

This first layer of concrete<br />

includes the nylon fibers to make the<br />

mix stick better. The idea is to cover<br />

the plywood completely and to build<br />

up some on the rebar.<br />

It is not necessary that this first<br />

run of concrete be very thick. If it is<br />

working very well and sticking well,<br />

then go ahead and put a 1/2 to 3/4 inch<br />

on it. If all you can get to stick is a<br />

1/4 of an inch, that is fine.<br />

Let this concrete set over night,<br />

or until there is approximately 600 psi<br />

strength. This concrete will be tough,<br />

but it still can be scratched with a key.<br />

If the weather is inclement let the concrete<br />

set for two days. If the concrete<br />

is going to be subjected to severe rain<br />

or frost it will need to be covered. If<br />

it is real cold then it will need to be<br />

heated between the covering and the<br />

concrete surface.<br />

The next day spray the fence<br />

again with concrete, bringing the total<br />

thickness up to about an inch and a<br />

half. This may take two spray sessions.<br />

Often it can be sprayed twice<br />

the second day.<br />

<strong>Build</strong> the fence out, embedding<br />

the rebar very thoroughly. Care<br />

should be taken to scrape the rebar<br />

after each spraying of the concrete so<br />

it does not have a large build up on it.<br />

The rebar needs to be embedded<br />

in the concrete with about a 1/2 to 3/4<br />

inch of cover. The spraying process<br />

the second day doesn’t need to get it<br />

21

out to full thickness because we are<br />

going to spray one more time with the<br />

colored concrete. The second day it is<br />

a good idea to have most of the thickness<br />

finished up. You don’t want to<br />

spend a lot of time with colored concrete<br />

trying to cover up missed places.<br />

Note: It is very difficult to judge<br />

the depth of sprayed concrete as it is<br />

being applied. A 1” layer can look<br />

very much like a 1/8” layer. <strong>To</strong> be<br />

sure of a uniform build up of thickness,<br />

a very uniform spraying pattern<br />

should be followed. This pattern can<br />

vary according to the nozzleman, but<br />

it should be consistent. <strong>To</strong> insure<br />

proper thickness, check the depth<br />

gauges.<br />

It is important to use good shotcrete<br />

techniques when shooting around<br />

rebar, that is, shoot from close enough<br />

to the bar and with enough force that<br />

the concrete cannot build up on the<br />

face of the bar but closes around it<br />

from the back.<br />

After the fence has set overnight,<br />

gently, and I use the word gently,<br />

remove the forms, clean them, and<br />

move them on to get ready for another<br />

section of fence.<br />

The Last Coat<br />

The concrete can now be applied<br />

to both sides of the fence. This last<br />

coat of concrete to the front side and<br />

the complete coating on the back side<br />

should be done with a half to three<br />

quarter inch covering.<br />

This spray of approximately 1/2 to<br />

3/4 inch of concrete on the form side<br />

is to protect the rebar.<br />

The fence will harden up considerably<br />

over the first thirty days. It is<br />

very helpful if it can be kept damp<br />

within that same thirty day period.<br />

This can be done by hanging cloth or<br />

burlap over the fence and spraying<br />

water on it from time to time during<br />

the day. It is extremely important that<br />

the fence be kept moist during periods<br />

of direct sun, hot sun, and dry winds.<br />

The fence can be protected by coating<br />

with a concrete sealer available from<br />

the concrete accessory supplier.<br />

With the forms removed from the back, and<br />

the third coat applied, the fence is now ready<br />

for the finish coat of colored concrete. This<br />

is the time to consider etching the fence to<br />

look like a rock wall.<br />

Here can be seen the layering of the fence.<br />

The fence on the left has two layers of shotcrete<br />

and the forms have been stripped. The<br />

section on the right still has forms in place,<br />

some of which has been sprayed with the<br />

first layer of concrete.<br />

22

Final color coat sprayed is on the left. Note<br />

the position of the nozzleman for proper<br />

spraying. The nozzle should be held perpendicular<br />

to the work or slightly pointed<br />

up as shown both above and below. Never,<br />

never spray down with only one exception —<br />

spraying the base footing of the fence.<br />

It is a good idea to keep the fence moist,<br />

as with any concrete, as it goes through its<br />

curing phase. If possible the fence should<br />

be kept wet for up to 30 days or a concrete<br />

curing compound can be used. These compounds<br />

can be purchased from a concrete<br />

accesory store.<br />

Color<br />

The colorant will give a pleasing<br />

color to the finished concrete fence.<br />

<strong>Spray</strong> a quarter inch of colored concrete<br />

on both sides to produce the final<br />

finish.<br />

If the final coat of shotcrete has<br />

colorant in it, the fence is now finished<br />

other than the moisture cure.<br />

There is nothing that says that the<br />

gray is not beautiful. Gray colored<br />

concrete will eventually get white and<br />

become very pretty.<br />

The final spraying of concrete<br />

may be held up until the entire fence is<br />

finished with gray concrete so that the<br />

color can be the same from one end of<br />

the fence to the other.<br />

The coloring in concrete is always<br />

a little bit tricky. It is difficult to get a<br />

true match from one batch to another.<br />

The batches tend to interfere with each<br />

other. They seem to get more water<br />

or something in one than they do in<br />

the other, but after a period of a few<br />

weeks it can be noticed that the fence<br />

tends to equal out to one color.<br />

An option, a very valid option, is<br />

to spray out the full thickness of the<br />

concrete in the gray and then use a<br />

concrete stain. Most reputable paint/<br />

concrete shops have concrete stain. It<br />

is not a paint, it is a stain. It soaks<br />

into the concrete and will give you a<br />

permanent color finish.<br />

If a really nice finish is desired,<br />

the stain is probably the safest way to<br />

go.<br />

23

This 8-foot tall, 800-foot long fence is for the annual Bethlehem Revisited program in Waxahachie,<br />

Texas. The fence encloses a half a block. It has concrete posts and wing walls to<br />

provide lateral stability. These fence/walls can be built very cost effectively. The walls are<br />

two-inches thick, except at the posts where they are three and a half inches thick. Without<br />

colorant it is a beautiful gray.<br />

24

Appendix<br />

<strong>In</strong> the past 20+ years, we have<br />

gained significant know-how in<br />

building spray-in-place concrete<br />

fences. This Appendix adds to that<br />

knowledge.<br />

Zigzags: Experience has taught<br />

us the importance of zigzags. They<br />

make a difference in strength, versatility,<br />

expansion and contraction.<br />

Zigzags can be symmetrical,<br />

moving back and forth an extra<br />

foot on each side of the property<br />

line, every 16’. Half as many posts<br />

are needed with zigzag fence.<br />

Or they can be even more<br />

ornamental. The fence can run<br />

straight down the property line for<br />

12’, then have a short zigzag that<br />

creates a planter box or a place for<br />

a yard bench.<br />

First do the one side and then<br />

do the other. If these are 4’ long,<br />

zig it 2’, first to one side and then<br />

to the other. You can imagine the<br />

stability this gives a fence and<br />

makes it very beautiful. Obviously<br />

neighbors need to agree on the<br />

fence, but it really creates a highlight<br />

for both properties.<br />

Basalt Reinforcing: We have<br />

learned to use basalt reinforcing.<br />

Basalt is another name for lava<br />

rock. Reinforcing made of basalt<br />

is twice as strong as steel and --<br />

most importantly -- it won’t rust.<br />

The number one cause of concrete<br />

failure is rusting rebar. Water soaks<br />

through the concrete’s pores and<br />

eventually rusts the rebar. As the<br />

rusts grows, it explodes the concrete.<br />

Protecting the rebar is one of<br />

the concrete’s major functions.<br />

Using basalt reinforcing has made<br />

a dramatic difference in the ability<br />

to build the fence. We suggest<br />

you use the basalt fabric. We call<br />

it a fabric. It has about a one-inchsquare<br />

spacing each direction, and<br />

we can take this and put it directly<br />

into the concrete as we spray.<br />

We first spray a 1/2” to 3/4”<br />

of concrete on the fence forming.<br />

See the basalt webbing being installed. Simple, fast and permanent for flower boxes or<br />

fences.<br />

Simple zig zag fence with colorant is 1 3/4 to 2 inches thick and six feet tall.<br />

After it sets up, we spray about<br />

another 1/2”. Then we just gently<br />

push the reinforcing into that concrete.<br />

After it sets up to where it is<br />

relatively solid, we spray the next<br />

1/2” or 3/4” of concrete to finish<br />

the fence.<br />

At this point we have many<br />

options: We can peel the form<br />

work off and spray a light touch<br />

on the backside, or we can just<br />

leave it alone and do a hand trowel<br />

on either side, but in most cases<br />

we are done.<br />

Now is the time to decide what<br />

to do about the fence color-wise.<br />

<strong>Concrete</strong> can have colorant mixed<br />

in with it. But if you have ever<br />

sprayed concrete, you know it’s<br />

super tough to make the same mix<br />

with each batch and get the same<br />

color. And the color in the concrete<br />

is less expensive and will stay that<br />

color virtually forever.<br />

We also can recommend coating<br />

the fence with something like<br />

H&C <strong>Concrete</strong> Stain. This stain<br />

seems to last forever and is gor-<br />

25

The zig zag prevents trouble ith the black clay soil. <strong>Fence</strong> is permanent.<br />

geous and self-cleaning. The fence<br />

looks sharp and new for years.<br />

The thickness described here is<br />

1½” to 2” thick. Unless that fence<br />

will be subjected to heavy loads or<br />

heavy banging, that is all the fence<br />

you will ever need. <strong>In</strong> fact, it’s<br />

certainly stronger than any wood<br />

fence. And because we can keep it<br />

thin, we use less material and do<br />

the job quicker, simpler and less<br />

expensively.<br />

As part of this Appendix, we<br />

can also tell you that you can<br />

use #2 steel rebar in the fence, as<br />

described in the book. I would<br />

move the bars closer to 15” on<br />

center -- or you could even go to<br />

12”. Number 2 rebar is not readily<br />

available, but it can be used. But<br />

if you use steel rebar you have to<br />

keep the fence well coated to prevent<br />

rusting.<br />

If you are using steel rebar, be<br />

sure you have about 2” of cover<br />

on each side of the rebar to protect<br />

it from water. Or you have to<br />

paint the fence to protect it. <strong>To</strong> do<br />

a really good job of painting the<br />

fence, you need something beside<br />

the concrete stain. You need something<br />

like silicone or first class<br />

acrylic that stops water migration.<br />

We strongly recommend that<br />

you use basalt reinforcing. The<br />

rebar coming up out of the posts<br />

can still be steel, but it is even<br />

better if it’s basalt as well. Basalt<br />

rebar can be purchased at the same<br />

places as the webbing.<br />

26