Annual Report 2012 - Latvijas Universitātes Cietvielu fizikas institūts

Annual Report 2012 - Latvijas Universitātes Cietvielu fizikas institūts

Annual Report 2012 - Latvijas Universitātes Cietvielu fizikas institūts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Flax and Hemp Fiber Functionalization Studies<br />

A. Lusis, E. Pentjuss, J.Gabrusenoks , R.Janeliukštis, L.Veļķere, J.Zandersons,<br />

J. Balodis<br />

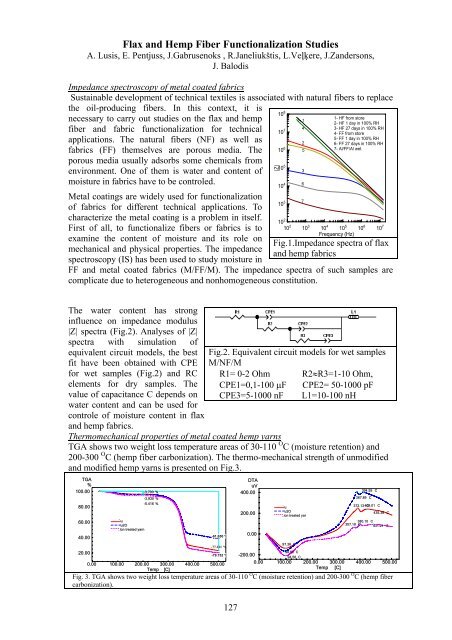

Impedance spectroscopy of metal coated fabrics<br />

Sustainable development of technical textiles is associated with natural fibers to replace<br />

the oil-producing fibers. In this context, it is<br />

necessary to carry out studies on the flax and hemp<br />

fiber and fabric functionalization for technical<br />

applications. The natural fibers (NF) as well as<br />

fabrics (FF) themselves are porous media. The<br />

porous media usually adsorbs some chemicals from<br />

environment. One of them is water and content of<br />

moisture in fabrics have to be controled.<br />

Metal coatings are widely used for functionalization<br />

of fabrics for different technical applications. To<br />

characterize the metal coating is a problem in itself.<br />

First of all, to functionalize fibers or fabrics is to<br />

examine the content of moisture and its role on<br />

mechanical and physical properties. The impedance<br />

spectroscopy (IS) has been used to study moisture in<br />

1<br />

4<br />

10 7<br />

2<br />

10 6<br />

10 5<br />

5<br />

3<br />

10 4<br />

10 3<br />

6<br />

7<br />

10 2<br />

10 2 10 3 10 4 10 5 10 6 10 7<br />

10 8 Frequency (Hz)<br />

FF and metal coated fabrics (M/FF/M). The impedance spectra of such samples are<br />

complicate due to heterogeneous and nonhomogeneous constitution.<br />

|Z|<br />

1- HF from store<br />

2- HF 1 day in 100% RH<br />

3- HF 27 days in 100% RH<br />

4- FF from store<br />

5- FF 1 day in 100% RH<br />

6- FF 27 days in 100% RH<br />

7- Al/FF/Al wet<br />

Fig.1.Impedance spectra of flax<br />

and hemp fabrics<br />

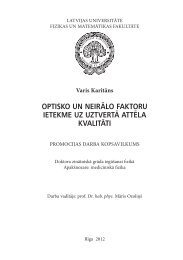

The water content has strong<br />

influence on impedance modulus<br />

|Z| spectra (Fig.2). Analyses of |Z|<br />

spectra with simulation of<br />

equivalent circuit models, the best<br />

fit have been obtained with CPE<br />

for wet samples (Fig.2) and RC<br />

elements for dry samples. The<br />

value of capacitance C depends on<br />

water content and can be used for<br />

controle of moisture content in flax<br />

and hemp fabrics.<br />

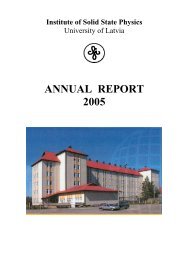

Thermomechanical properties of metal coated hemp yarns<br />

TGA shows two weight loss temperature areas of 30-110 O C (moisture retention) and<br />

200-300 O C (hemp fiber carbonization). The thermo-mechanical strength of unmodified<br />

and modified hemp yarns is presented on Fig.3.<br />

TGA<br />

%<br />

100.00<br />

80.00<br />

60.00<br />

40.00<br />

20.00<br />

Cu<br />

Cu2O<br />

Non treated yarn<br />

-3.700 %<br />

-3.930 %<br />

-5.416 %<br />

-61.650 %<br />

-77.121 %<br />

-79.752 %<br />

0.00 100.00 200.00 300.00 400.00 500.00<br />

Temp [C]<br />

Fig.2. Equivalent circuit models for wet samples<br />

M/NF/M<br />

R1= 0-2 Ohm R2≈R3=1-10 Ohm,<br />

CPE1=0,1-100 μF<br />

CPE3=5-1000 nF<br />

127<br />

DTA<br />

uV<br />

400.00<br />

200.00<br />

0.00<br />

Cu<br />

Cu2O<br />

Non treated yar<br />

97.36 C<br />

CPE2= 50-1000 pF<br />

L1=10-100 nH<br />

394.55 C<br />

367.89 C<br />

372.13 409.01 C C<br />

435.38 C<br />

380.10 C<br />

357.19 C<br />

431.21 C<br />

-200.00<br />

98.65 C<br />

94.56 C<br />

0.00 100.00 200.00 300.00 400.00 500.00<br />

Temp [C]<br />

Fig. 3. TGA shows two weight loss temperature areas of 30-110 O C (moisture retention) and 200-300 O C (hemp fiber<br />

carbonization).