2 & 3 Flute Aluminum Cutters

2 & 3 Flute Aluminum Cutters

2 & 3 Flute Aluminum Cutters

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

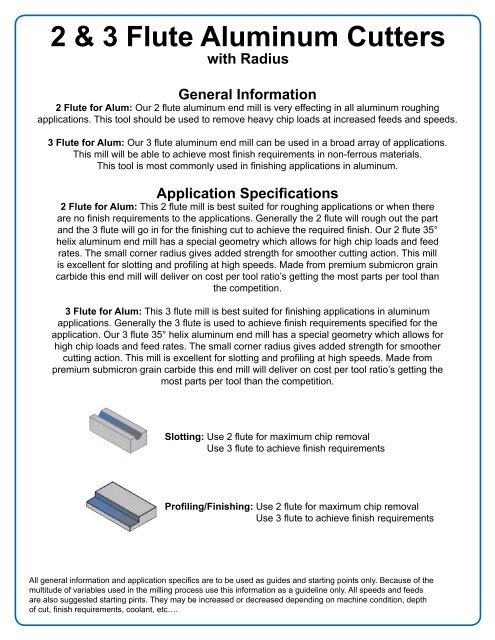

2 & 3 <strong>Flute</strong> <strong>Aluminum</strong> <strong>Cutters</strong><br />

with Radius<br />

General Information<br />

2 <strong>Flute</strong> for Alum: Our 2 flute aluminum end mill is very effecting in all aluminum roughing<br />

applications. This tool should be used to remove heavy chip loads at increased feeds and speeds.<br />

3 <strong>Flute</strong> for Alum: Our 3 flute aluminum end mill can be used in a broad array of applications.<br />

This mill will be able to achieve most finish requirements in non-ferrous materials.<br />

This tool is most commonly used in finishing applications in aluminum.<br />

Application Specifications<br />

2 <strong>Flute</strong> for Alum: This 2 flute mill is best suited for roughing applications or when there<br />

are no finish requirements to the applications. Generally the 2 flute will rough out the part<br />

and the 3 flute will go in for the finishing cut to achieve the required finish. Our 2 flute 35°<br />

helix aluminum end mill has a special geometry which allows for high chip loads and feed<br />

rates. The small corner radius gives added strength for smoother cutting action. This mill<br />

is excellent for slotting and profiling at high speeds. Made from premium submicron grain<br />

carbide this end mill will deliver on cost per tool ratio’s getting the most parts per tool than<br />

the competition.<br />

3 <strong>Flute</strong> for Alum: This 3 flute mill is best suited for finishing applications in aluminum<br />

applications. Generally the 3 flute is used to achieve finish requirements specified for the<br />

application. Our 3 flute 35° helix aluminum end mill has a special geometry which allows for<br />

high chip loads and feed rates. The small corner radius gives added strength for smoother<br />

cutting action. This mill is excellent for slotting and profiling at high speeds. Made from<br />

premium submicron grain carbide this end mill will deliver on cost per tool ratio’s getting the<br />

most parts per tool than the competition.<br />

Slotting: Use 2 flute for maximum chip removal<br />

Use 3 flute to achieve finish requirements<br />

Profiling/Finishing: Use 2 flute for maximum chip removal<br />

Use 3 flute to achieve finish requirements<br />

All general information and application specifics are to be used as guides and starting points only. Because of the<br />

multitude of variables used in the milling process use this information as a guideline only. All speeds and feeds<br />

are also suggested starting pints. They may be increased or decreased depending on machine condition, depth<br />

of cut, finish requirements, coolant, etc….

<strong>Aluminum</strong> <strong>Cutters</strong><br />

Speeds & Feeds 2 <strong>Flute</strong><br />

Chip load per tooth<br />

Material SFM 1/8" 1/4" 1/2" 1"<br />

<strong>Aluminum</strong> Alloys 900-1500 .0010 .0025 .0050 .0095<br />

Brass 300-500<br />

Bronze 300-500<br />

Copper 500-1200<br />

Plastic .0015 .0030 .0060 .0120 600-1200 .0015 .0030 .0060 .0120

<strong>Aluminum</strong> <strong>Cutters</strong><br />

Speeds & Feeds 3 <strong>Flute</strong><br />

Chip load per tooth<br />

Material SFM 1/8" 1/4" 1/2" 1"<br />

<strong>Aluminum</strong> Alloys 900-1500 .0010 .0025 .0050 .0095<br />

Brass 300-500<br />

Bronze 300-500<br />

Copper 500-1200<br />

Plastic .0015 .0030 .0060 .0120 600-1200 .0015 .0030 .0060 .0120