Machine Manual - Production Tool Supply

Machine Manual - Production Tool Supply

Machine Manual - Production Tool Supply

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

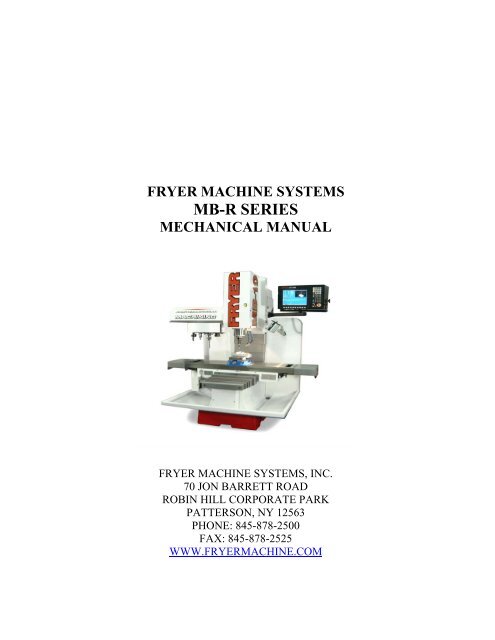

FRYER MACHINE SYSTEMS<br />

MB-R SERIES<br />

MECHANICAL MANUAL<br />

FRYER MACHINE SYSTEMS, INC.<br />

70 JON BARRETT ROAD<br />

ROBIN HILL CORPORATE PARK<br />

PATTERSON, NY 12563<br />

PHONE: 845-878-2500<br />

FAX: 845-878-2525<br />

WWW.FRYERMACHINE.COM

MECHANICAL DRAWINGS....................................................................................................................................................3<br />

HEAD ASSEMBLY..................................................................................................................................................................4<br />

Z AXIS COLUMN ....................................................................................................................................................................5<br />

Z AXIS RAM.............................................................................................................................................................................6<br />

X AXIS TABLE ........................................................................................................................................................................7<br />

X AXIS BALL SCREW ............................................................................................................................................................8<br />

Y AXIS SADDLE .....................................................................................................................................................................9<br />

Y AXIS BALL SCREW ..........................................................................................................................................................10<br />

TOOL CHANGER ..................................................................................................................................................................11<br />

BED AND COLUMN .............................................................................................................................................................12<br />

COUNTER WEIGHT..............................................................................................................................................................13<br />

RETENTION KNOBS ............................................................................................................................................................14<br />

maintenance MB R SERIES 2 OF 14

MECHANICAL DRAWINGS<br />

maintenance MB R SERIES 3 OF 14

HEAD ASSEMBLY<br />

maintenance MB R SERIES 4 OF 14

Z AXIS COLUMN<br />

maintenance MB R SERIES 5 OF 14

Z AXIS RAM<br />

maintenance MB R SERIES 6 OF 14

X AXIS TABLE<br />

maintenance MB R SERIES 7 OF 14

X AXIS BALL SCREW<br />

maintenance MB R SERIES 8 OF 14

Y AXIS SADDLE<br />

maintenance MB R SERIES 9 OF 14

Y AXIS BALL SCREW<br />

maintenance MB R SERIES 10 OF 14

TOOL CHANGER<br />

maintenance MB R SERIES 11 OF 14

BED AND COLUMN<br />

maintenance MB R SERIES 12 OF 14

COUNTER WEIGHT<br />

maintenance MB R SERIES 13 OF 14

FRYER PART NUMBERS<br />

CAT 40<br />

TOL-5450<br />

BT 40<br />

TOL-5456<br />

CAT 50<br />

TOL-5454<br />

NOTE:<br />

IF THRU COOLANT IS NEEDED, PLEASE CALL FOR PROPER<br />

PART NUMBER<br />

RETENTION KNOBS<br />

maintenance MB R SERIES 14 OF 14

FRYER MACHINE SYSTEMS<br />

ELECTRICAL &<br />

PROCEDURES MANUAL<br />

ANILAM 3000 CONTROL<br />

FRYER MACHINE SYSTEMS, INC.<br />

70 JON BARRETT ROAD<br />

ROBIN HILL CORPORATE PARK<br />

PATTERSON, NY 12563<br />

PHONE: 845-878-2500<br />

FAX: 845-878-2525<br />

WWW.FRYERMACHINE.COM<br />

Electrical manual 3000.doc 1 OF 38 4/30/07

SAFETY RULES.........................................................................................................................................................................3<br />

STARTUP PROCEDURE FOR FRYER MB SERIES MILLS..............................................................................................4<br />

UNPACK MACHINE.....................................................................................................................................................................4<br />

LINE VOLTAGE CHECK................................................................................................................................................................4<br />

MACHINE POWER-UP PROCEDURE ..............................................................................................................................................4<br />

VOLTAGE CHECKS (ALL VOLTAGES +/- 10%): ...........................................................................................................................5<br />

ADDITIONAL CHECKS:................................................................................................................................................................5<br />

STARTUP REPORT - ANILAM 3000 CONTROL.................................................................................................................6<br />

INITIAL START-UP QUALITY SURVEY.............................................................................................................................6<br />

MB-R SERIES ELECTRICAL DRAWINGS...........................................................................................................................8<br />

PANEL LAYOUT.....................................................................................................................................................................9<br />

3000 OPTIONS .......................................................................................................................................................................10<br />

3000 OPTIONS .......................................................................................................................................................................11<br />

3000 OPTIONS .......................................................................................................................................................................12<br />

MB Q SERIES ELECTRICAL DRAWINGS.........................................................................................................................13<br />

PANEL LAYOUT...................................................................................................................................................................14<br />

3000 OPTIONS .......................................................................................................................................................................16<br />

3000 OPTIONS .......................................................................................................................................................................17<br />

ANILAM ELECTRICAL DRAWINGS..................................................................................................................................18<br />

3000 CABLE LAYOUT..........................................................................................................................................................19<br />

CABINET WIRING DIAGRAM............................................................................................................................................20<br />

CONSOLE WIRING DIAGRAM...........................................................................................................................................21<br />

MB SERIES M CODES............................................................................................................................................................22<br />

MAINTENANCE SCHEDULE................................................................................................................................................23<br />

ADJUSTMENTS FOR ANILAM 3000 CONTROL ..............................................................................................................24<br />

SETUP AND TESTING..........................................................................................................................................................25<br />

YASKAWA GPD 315 SPINDLE DRIVE................................................................................................................................26<br />

-BALDOR VECTOR SPINDLE DRIVE PARAMETERS-....................................ERROR! BOOKMARK NOT DEFINED.<br />

INSTRUCTIONS FOR SETTING PARAMETERS...............................................ERROR! BOOKMARK NOT DEFINED.<br />

ANILAM 3000 SOFTWARE UPDATE INSTRUCTIONS ...................................................................................................29<br />

ANILAM 3000 SERVICE PROCEDURE FOR SAVING CONFIGURATION FILES.....................................................30<br />

RENISHAW TOOL PROBE INSTALLATION ..................................................................................................................................31<br />

DIAGNOSTICS OF ANILAM MB PLC.................................................................................................................................32<br />

ANILAM HARD DRIVE INSTALLATION ..........................................................................................................................33<br />

LOADING IPI FILE .................................................................................................................................................................35<br />

USER SETUP FOR ANILAM NETWORKING....................................................................................................................36<br />

FRYER OPTIONAL CHILLER INSTRUCTIONS...............................................................................................................38<br />

Electrical manual 3000.doc 2 OF 38 4/30/07

SAFETY RULES<br />

READ BEFORE OPERATING MACHINE<br />

1. PREVENT LOOSE CLOTHING, HAIR, JEWELRY FROM CONTACTING SPINDLE<br />

2. NEVER: CHANGE TOOLS, HANDLE SPINDLE, CHANGE PARTS OR PERFORM WORK<br />

ON MILL UNLESS CNC IS IN EMERGENCY STOP OR TOOL CHANGE MODES<br />

3. ALWAYS WEAR EYE PROTECTION WHEN OPERATING MILL.<br />

4. DO NOT OPERATE MILL WITHOUT AXIS MOTOR COVERS OR AXIS WAY COVERS IN<br />

PLACE.<br />

5. DO NOT PLACE OBJECTS OR HANDS BETWEEN COLUMN AND TABLE/SADDLE<br />

ASSY, UNLESS CNC IS IN EMERGENCY STOP POSITION.<br />

6. DO NOT MODIFY EQUIPMENT WITHOUT APPROVAL FROM FRYER MACHINE<br />

SYSTEMS. DOING SO MAY VOID YOUR WARRANTY.<br />

7. ELECTRICAL ENCLOSURES CONTAIN HIGH VOLTAGE. DISCONNECT EQUIPMENT<br />

FROM POWER SOURCE BEFORE OPENING CABINETS.<br />

8. CHECK LUBRICANT FILL LEVELS BEFORE OPERATING.<br />

9. DO NOT OPERATE POWER DRAWBAR UNIT WHILE SPINDLE IS IN MOTION.<br />

10. EMERGENCY STOP MILL WHEN NOT IN USE<br />

11. KEEP VISES, CLAMPS, FIXTURE OR WORKPIECE FROM EXTENDING BEYOND BACK<br />

EDGE OF TABLE.<br />

12. TURN OFF POWER IF:<br />

POWER PROBLEMS DEVELOP<br />

IN THE EVENT OF ELECTRICAL STORMS.<br />

AMBIENT TEMPERATURES EXCEED 105 DEGREES FARENHEIT.<br />

Electrical manual 3000.doc 3 OF 38 4/30/07

STARTUP PROCEDURE FOR FRYER MB SERIES MILLS<br />

WITH ANILAM 3000 MK CONTROLLERS<br />

Unpack <strong>Machine</strong><br />

1. Remove plastic wrap. Carefully inspect for any damage.<br />

2. Install leveling pads and level machine. (This is usually the responsibility of the rigger or customer)<br />

3. Remove Wooden counterweight SPIKE at top of machine.<br />

Assistance will be necessary to perform the following steps:<br />

4. Using a socket or suitable wrench (Pliers are not recommended) turn the Z<br />

ballscrew clockwise from the top of the screw enough to remove wooden shipping block on table. Be careful not<br />

to let the ratchet/wrench slip backwards.<br />

5. Turn the ratchet/wrench counter clockwise until counterweight chains are taut, and counterweight bar<br />

is free.<br />

6. Remove counterweight bar. At this time you must remove the ratchet/wrench otherwise serious damage could<br />

occur.<br />

7. Install the Z-Axis motor and drive belt, and any other items that may have been removed for shipping purposes.<br />

8. Check that front panel with swivel arm is clear of Z-Axis head motion.<br />

Line voltage check<br />

1. Verify 220/440vac. (+/- 10%) is wired to the main disconnect correctly.<br />

2. Verify 110vac plug is in a 20 amp minimum dedicated receptacle, or the warranty will be voided.<br />

3. The breaker for the 110vac must be a high magnetic breaker. An example is a Square D PN:Q0BHM-20<br />

4. Check all wire connections, relays, contacts and plugs to be sure nothing has become loose. If so, reseat or<br />

tighten before turning on main power.<br />

5. All voltage checks should be recorded on the STARTUP REPORT form.<br />

<strong>Machine</strong> power-up procedure<br />

1. The electrical cabinet door should remain open until this startup is completed. The switch on the back of the<br />

console (MANUAL/AUTO) should be in the AUTO position.<br />

2. Turn on the main disconnect switch on the electrical cabinet to power up 220/440vac. A pair of pliers may be<br />

used to turn the disconnect rod ¼ turn CW.<br />

3. On the side of the electrical cabinet, the switch marked CONTROL POWER (0/1) should be in the 1 position to<br />

power up 110vac.<br />

4. Press F10 to continue, press ENTER to boot into software.<br />

5. Rotate the E-stop button CW, then press SERVO RESET to engage servo drives.<br />

Electrical manual 3000.doc 4 OF 38 4/30/07

Voltage checks (All voltages +/- 10%):<br />

1. Check for +160VDC at the large blue capacitor in the electrical cabinet.<br />

2. Check for 110VAC at the Corcom EMI line filter in the electrical cabinet.<br />

3. Check for +5VDC between pins 1 & 4 (common) on the P2 connector of the power supply in the console.<br />

4. Check for +12VDC between pins 8 & 4 (common) on the P2 connector of the power supply in the console.<br />

5. Check for –12VDC between pins 11 & 4 (common) on the P2 connector of the power supply in the console.<br />

6. Check for +5VDC between pins 1 & 3 (common) on the P2 connector of the power supply in the electrical<br />

cabinet. Refer to the Panel Layout drawing for more detail.<br />

7. Check for +15VDC between pins 6 & 3 (common) on the P2 connector of the power supply in the electrical<br />

cabinet. Refer to the Panel Layout drawing for more detail.<br />

8. Check for –15VDC between pins 5 & 3 (common) on the P2 connector of the power supply in the electrical<br />

cabinet. Refer to the Panel Layout drawing for more detail.<br />

9. Check for +24VDC at the 24volt power supply (blue & yellow wires). Refer to the Panel Layout drawing for<br />

more detail.<br />

Additional Checks:<br />

1. Make sure way surfaces are receiving sufficient oil from pump.<br />

2. Make sure air pressure to power drawbar unit (if so equipped) is set at 85psi minimum.<br />

All information should be recorded on a Fryer <strong>Machine</strong> Startup Form with any unusual conditions<br />

listed and returned to Fryer <strong>Machine</strong> Service Dept. If any problems are encountered or if you<br />

have any questions, please contact FRYER MACHINE SYSTEMS Service Department at (845)<br />

878-2500.<br />

Electrical manual 3000.doc 5 OF 38 4/30/07

STARTUP REPORT - ANILAM 3000 Control<br />

CUSTOMER: ____________________________________________DATE:____________________<br />

MODEL #: ____________________ SERIAL #: _________________ CONTROL SN#: ____________________<br />

DISTRIBUTOR: _______________________________ SERVICE TECH: _________________________________<br />

SHOPCONTACT:___________________________TITLE:__________________________________<br />

ATTENTION:<br />

ITEMS CAN BECOME LOOSE DURING SHIPPING CAUSING A LOSS OF CONNECTIONS. THIS MAY RESULT IN<br />

IMPROPER MACHINE FUNCTION AND/OR DAMAGE TO THE MACHINE OR COMPONENTS. BEFORE INITIAL<br />

POWER-UP:<br />

• TIGHTEN ALL SCREWS AND ELECTRICAL CONNECTIONS IN THE ELECTRICAL CABINET .<br />

• CHECK TO ENSURE THAT ALL ELECTRICAL COMPONENTS ARE PROPERLY SEATED AND SECURED.<br />

70 Jon Barrett Road<br />

Robin Hill Corporate Park<br />

Patterson, N.Y. 12563<br />

Phone: (845) 878-2500<br />

Fax: (845) 878-2525<br />

E-mail: service@fryermachine.com<br />

ELECTRICAL CONNECTIONS AND COMPONENTS CHECKED: _________<br />

COMPUTER POWER SUPPLY (+5, +/- 12 VDC) (in consol)<br />

SERVO POWER SUPPLY (+5, +/-15 VDC)<br />

+5 VDC: ________ P2-1 +5 VDC: ___________ P2-1<br />

+12 VDC: ________ P2-8 +15 VDC: ___________ P2-6<br />

• -12 VDC: ________ P2-11 -15 VDC: ___________ P2-5<br />

(COMMON P2-4)<br />

(COMMON P2-3)<br />

24VDC POWER SUPPLY- 24VDC: ________<br />

220/440 VAC (MAIN DISCONNECT)<br />

L1-L2 _________ L2-L3 _________ L1-L3 _________ L1-GND _________ L2-GND _________ L3-GND _________<br />

110 VAC (CORCOM LINE FILTER) 110VAC _________ 160 VDC (DRIVE BUS CAPACITOR) 160VDC_________<br />

WAYLUBE: PRESENT AT X, Y & Z BOX WAY SURFACES: __________<br />

AIR PRESSURE: _________PSI<br />

HOUR METER READING ______________<br />

INITIAL START-UP QUALITY SURVEY<br />

At Fryer <strong>Machine</strong> Systems, we strive to continuously improve the quality of our products and services.<br />

As a qualified machine tool technician, your feedback is an essential part of this ongoing process.<br />

Please take a moment to fill out the following information. It will be greatly appreciated.<br />

Please circle the appropriate response (1=worst, 5=best) for each question. Feel free to add any comments.<br />

INITIAL IMPRESSIONS<br />

Was machine received in satisfactory condition? ................................................................Yes No<br />

If no, what was lacking?<br />

____________________________________________________________________________<br />

Electrical manual 3000.doc 6 OF 38 4/30/07

MACHINE SERIAL NO.______________________<br />

DATE ____________<br />

Please rate the overall appearance of the machine: ...........................................................1 2 3 4 5<br />

Comments:<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

PERFORMANCE<br />

Please rate the mechanical systems of the machine: ..........................................................1 2 3 4 5<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

Please rate the electrical systems of the machine: ..............................................................1 2 3 4 5<br />

Comments:<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

SERVICE<br />

Were there any problems with the machine during start-up? ...............................................Yes No<br />

If yes, please list:<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

What issues, if any, are still outstanding?<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

Was our Service Dept. helpful during the start-up? Please rate us:.....................................1 2 3 4 5<br />

GENERAL<br />

Would you recommend this machine to others?................................................................... Yes No<br />

Why?<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

____________________________________________________________________________<br />

ADDITIONAL COMMENTS:<br />

________________________________________________________________________<br />

________________________________________________________________________<br />

________________________________________________________________________<br />

Electrical manual 3000.doc 7 OF 38 4/30/07

MB-R SERIES ELECTRICAL DRAWINGS<br />

Electrical manual 3000.doc 8 OF 38 4/30/07

PANEL LAYOUT<br />

Electrical manual 3000.doc 9 OF 38 4/30/07

Ω−<br />

3000 OPTIONS<br />

Electrical manual 3000.doc 10 OF 38 4/30/07

3000 OPTIONS<br />

Electrical manual 3000.doc 11 OF 38 4/30/07

3000 OPTIONS<br />

Electrical manual 3000.doc 12 OF 38 4/30/07

MB Q SERIES ELECTRICAL DRAWINGS<br />

Electrical manual 3000.doc 13 OF 38 4/30/07

PANEL LAYOUT<br />

Electrical manual 3000.doc 14 OF 38 4/30/07

FRYER MB PART LIST<br />

DRAWING REF. – PANEL LAYOUT<br />

SERIES B<br />

ITEM PART NO. PART NAME QTY SPECIFICATION<br />

1 DRV-1010 SPINDLE DRIVE 1<br />

2 CMB-2320 SERVO CONTROL BOARD 1<br />

3 MSE-1930 24VDC POWER SUPPLY 1<br />

4 MSE-1950 5/15VDC POWER SUPPLY 1<br />

5 DRV-1185 SERVO DRIVE BOARD 3<br />

6 SWT-5190 DISCONECT SWITCH 1<br />

7 MSE-1016 CORCOM FILTER 1<br />

8 MSE-1185 OMRON RELAY 24VDC 2<br />

9 MSE-1954 BRIDGE RECTIFIER 1<br />

MISC. ITEMS NOT IN DRAWING<br />

SCA-1010 COUPLED QUILL SCALE 1<br />

SWT-5014 MICRO SWITCH 4<br />

MSE-1460 AIR FILTER 1<br />

MTR-3050 AXIS MOTOR W/ CABLE 3<br />

SWT-5180 OVERRIDE SWITCH 2<br />

SWT-5200 E-STOP BUTTON 1<br />

SWT-5170 E-STOP BLOCK 1<br />

CMB-2168 FLOPPY DRIVE 1<br />

CMD-2164 HARD DRIVE (PART STORAGE) 1<br />

CMB-2290 F-KEY STRIP 1<br />

CMB-2280 MAIN KEY BOARD (3000 CONTROL) 1<br />

CMB-2286 MAIN KEY BOARD (5000 CONTROL) 1<br />

Electrical manual 3000.doc 15 OF 38 4/30/07

3000 OPTIONS<br />

Electrical manual 3000.doc 16 OF 38 4/30/07

3000 OPTIONS<br />

Electrical manual 3000.doc 17 OF 38 4/30/07

ANILAM ELECTRICAL DRAWINGS<br />

Electrical manual 3000.doc 18 OF 38 4/30/07

DWG REF.#302008516<br />

3000 CABLE LAYOUT<br />

Electrical manual 3000.doc 19 OF 38 4/30/07

DWG REF.#302008517<br />

CABINET WIRING DIAGRAM<br />

Electrical manual 3000.doc 20 OF 38 4/30/07

DWG REF. #D000775<br />

CONSOLE WIRING DIAGRAM<br />

Electrical manual 3000.doc 21 OF 38 4/30/07

MB SERIES M CODES<br />

M00 Program stop<br />

M01 Optional stop(Optional hardware is required)<br />

M02 End of program and rewind<br />

M03 Spindle clockwise (an “s” code must also be present to specify RPM)<br />

M04 Spindle counter-clockwise (an “s” code must also be present to specify RPM)<br />

M05 Spindle stop<br />

M06 Turn off spindle and does tool change( a “T” number must be present to specify tool requested)<br />

M07 Mist coolant on(optional)<br />

M08 Flood coolant on(optional)<br />

M09 Mist and flood coolant off<br />

M10 Optional indexer interface, will cause cycle start on indexer and wait for finish pulse<br />

M11 Spare “M” function turns on output bit 0<br />

M12 Spare “M” function turns off output bit 0<br />

M9293x1 will display following error on screen<br />

ATC M-CODES<br />

M12<br />

M13<br />

M14<br />

M15<br />

M16<br />

M50<br />

M51<br />

M52<br />

M53<br />

M54<br />

M55<br />

M58<br />

M59<br />

M61<br />

MISC MCODE OFF (CHIP AUGER OR BRAKE ETC)<br />

U BRAKE ON<br />

U BRAKE OFF<br />

W BRAKE ON<br />

W BRAKE OFF<br />

SPINDLE ORIENT<br />

ORIENT OFF<br />

ATC CAROUSEL IN<br />

ATC CAROUSEL OUT<br />

DRAWEAR ON<br />

DRAWEAR OFF<br />

ATC INDEX FWD<br />

ATC INDEX REV<br />

HOME ATC<br />

Electrical manual 3000.doc 22 OF 38 4/30/07

MAINTENANCE SCHEDULE<br />

FRYER MB SERIES MILLING MACHINES<br />

fill oil cups 1<br />

fill lube pump 2<br />

fill drawbar lube 3<br />

grease head 4<br />

grease drawbar 5<br />

check coolant level<br />

change coolant 6<br />

check head tram<br />

check machine level<br />

check gibs<br />

check backlash<br />

check belt tension<br />

daily weekly monthly 3 months 6 months yearly as req’d.<br />

X<br />

check servo cabinet<br />

and console fans,<br />

clean filters<br />

replace servo cabinet<br />

and console filters 7 X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

1 -Mobil Velocite #10 (ISO VG 22) or equivalent<br />

2 -Mobil Vactra #2 (ISO 68) or equivalent<br />

3 -Break-Free Synthetic Air <strong>Tool</strong> Oil (5W) or equivalent<br />

4 -Mobil 1 Universal Synthetic Grease (ISO VG 220) or equivalent<br />

5 -Mobil XHP 220 Special Moly Grease or equivalent<br />

6 -Valenite Turn Tech Blue Metalworking Fluid or equivalent<br />

7 -See Anilam <strong>Manual</strong><br />

Electrical manual 3000.doc 23 OF 38 4/30/07

ADJUSTMENTS FOR ANILAM 3000 CONTROL<br />

FOR MB MACHINES<br />

PART 1<br />

GLENTEK SMA 7215-2 DRIVE CARD PRESETS<br />

1. E-stop machine in the middle of its travel X-Y-Z. Make sure parameters for DSP motion are as follows:<br />

DSP Motion Gain Tables:<br />

(All axis)<br />

FEED RAPID NO MOTION<br />

Kp 10 7 10<br />

Ki 0 0 5<br />

Kd 10 10 10<br />

Kf 0 0 0<br />

Il 0 0 10<br />

Ds 5 2 5<br />

2. Turn power off.<br />

3. Disconnect the J1 connector on all drive cards.<br />

4. Set DVM to thousand OHMs scale. Connect black lead to the J2-1 common test lead on drive card. This<br />

is the common to set all potentiometers.<br />

5. Adjust as follows: (NOTE: Look at diagram on side of drive card for correct position)<br />

TEST POINT ADJUST POTOTENTIOMETER OHM VALUE<br />

J2-1 (Common)<br />

J2-2 (Signal Input)<br />

J2-3 (Tach Input)<br />

J2-4 (Diff Sig Gain) (1) Diff Gain 0 or Full CCW<br />

J2-5 (Signal Gain) (2) Sig Gain 2.18K<br />

J2-6 (Tach Gain) (4) Tach 4.60K<br />

J2-7 (Comp) (5) Comp 3.40K<br />

(6) Fldbk Full CW (20 turn pot)<br />

(7) ILIM Full CW (20 turn pot)<br />

LOOP GAIN<br />

Full CW ( 1 turn pot)<br />

6. For your reference, DIP switch settings should be:<br />

ON (Towards circuit board) 1-5-6-7-9<br />

OFF(Away form circuit board) 2-3-4-8-10<br />

7. Reconnect all J1 connectors.<br />

Electrical manual 3000.doc 24 OF 38 4/30/07

PART II ADJUSTMENTS FOR ANILAM 3000/5000 CONTROL ON MB MACHINES – MOTION<br />

SETUP AND TESTING<br />

8. Once the drives are pre-adjusted, turn on power to machine, make sure all axis are in the middle of their<br />

travel. Go to machine setup and disable home requirement.<br />

9. Go to motion setup and testing.<br />

10. Leave drives off.<br />

11. Press axis you wish to test (X or Y or Z).<br />

12. Press balance, this will cause the DSP board to output 0 mV and START.<br />

13. Inside the CRT box is the DSP board. Set your DVM to mV scale, connect the black lead to the Glentek<br />

drive card you are setting at the J2-1 test point (common) and the red lead to J2-2 test point (Signal<br />

Input). Adjust the appropriate POT on the DSP board (labeled on card) to obtain 0 mV.<br />

14. Now you can remove the DVM leads. Press manual and then turn on the drives , then go to balance. On<br />

the screen under the “X-Y-Z” readout is an “F”. Adjust the balance POT (3) on the Glentek drive card for 0<br />

feed rate. This will stop the axis from drifting.<br />

15. Now press manual to cancel the balance test.<br />

16. Press signal gain to activate the signal gain test. It will ask for a time period = 2, and press start. This will<br />

cause the control to output .9 VDC and the axis will move positive and negative.<br />

17. Adjust the signal gain POT on the appropriate Glentek drive card to obtain 10% of the rapid feed rate<br />

(usually 20 IPM).<br />

18. Press manual and you are done with the test. Repeat steps 11 through 18 until all axis are adjusted.<br />

Electrical manual 3000.doc 25 OF 38 4/30/07

YASKAWA GPD 315 SPINDLE DRIVE<br />

PARAMETERS FOR MILLS<br />

TO RUN MACHINE IN LOCAL MODE:<br />

1. Turn servos on.<br />

2. Make sure the spindle is off<br />

3. The run light should be blinking on the PC7 drive<br />

4. Press the “ DSPL “ key 5 times so the “ LO/RE “ is illuminated in red.<br />

5. Use the “ ∧ ” or “ ∨ ” arrow buttons to display “ Lo “<br />

6. Press the “DSPL “ key to illuminate “F/R”, use the “ ∧ ” or “ ∨ ” arrows to select forward or reverse spindle rotation.<br />

7. Press the “ DSPL “ key to illuminate “FREF”<br />

8. Press the “RUN” button and adjust the min/max knob to desired frequency (RPM)<br />

PROCEDURE TO PROGRAM PC7 PARAMETERS:<br />

1. Turn the drives on<br />

2. Make sure the spindle is off<br />

3. The run light should be blinking on the PC7 drive<br />

4. Press the “ DSPL “ key 6 times until “PRGM” is illuminated in red<br />

5. Use the “ ∧ ” or “ ∨ ” arrow buttons to select the parameter that must be edited<br />

6. Press “ DATA/ENTER “ key to view the value of the parameter<br />

7. This parameter can now be changed with the “ ∧ ” or “ ∨ ” arrow buttons<br />

8. Once the change has been made press the “ DATA/ENTER “ key. The display will change to display the parameter<br />

number (ex. “ N001 “ )<br />

9. Repeat this procedure for all parameters that must be modified.<br />

TO INITIALIZE ALL PARAMETERS: (Warning this will reset all parameters in the PC7)<br />

1. Follow the above procedure to set parameter N001=10<br />

2. Once N001 is set recheck the value it should equal 1, this confirms that all parameters have been reset to factory default<br />

3. Change the parameters specified below: (Warning do not change any other values!)<br />

N001=4<br />

N002=1 (Vector control mode)<br />

N011=Depends on the machine. Standard machines settings MB15=150 , MB14=121<br />

This sets the maximum frequency to limit the RPM of the machine. To accurately set this:<br />

Follow the procedure above to run the machine in Local mode.<br />

Press the “ DSPL “ button once to move the green light to “ FOUT “<br />

Adjust the Min/Max knob to make the display reads 60 HZ ±.5<br />

Use a tachometer and record the RPM<br />

Use this formula to calculate the RPM / HZ= recorded rpm / 60 HZ<br />

Now divide the maximum RPM desired by the RPM/HZ this is the value that should be entered for N011.<br />

N019=3 (Accel time may have to be increased if fault occurs during accel to max speed.)<br />

N020=3 (Decel time may have to be increased if fault occurs during decel from max speed to stop)<br />

N022=2 (Emergency stop decel time)<br />

N036=(motor rated current-read motor tag) MB15/16=20 MB11/14=14 *440 VAC use ½ values<br />

N037=1<br />

N052=19<br />

N058=3 ( ZERO SPEED )<br />

NO59=1 (DURING RUNNING)<br />

N092=1<br />

N096=2<br />

N106=2.7<br />

N107=( 220VAC=.235) (440VAC= .924)<br />

N110=(MB15/16=59) (MB11/14=39)<br />

4. When complete make sure unit is in “rE” (remote mode) press “DSPL” until “FREF”is illuminated.<br />

Dip switch settings: SW1=NPN SW2= 1=off 2=off<br />

Refer to manual for any further information.<br />

Electrical manual 3000.doc 26 OF 38 4/30/07

BALDOR H2 VECTOR SPINDLE DRIVE PARAMETERS<br />

MB-10<br />

Instructions for setting parameters and tuning drive.<br />

1. Make sure the software version is 1.06 or newer. If it is not update to the latest software version.<br />

2. Make sure motor is securely bolted down, as the auto tuning will cause the motor to rotate.<br />

3. In order to set the parameters press the program button, use the up-down arrow keys to cursor to the correct parameter<br />

level. Once the correct parameter is selected press enter this will enter into this parameter. Use the right arrow key to<br />

go to the next parameter. Press enter to modify the parameter, use the left and right arrow key to select the digit and<br />

the up and down key to change the value. Once the correct value is displayed press enter to save the change. Press<br />

status to exit the parameter edit field.<br />

4. Set the following parameters:<br />

LEVEL 2 BLOCKS →DRIVE CONFIGURE →FACTORY SETTINGS=1-YES<br />

LEVEL 2 BLOCKS→DRIVE CONFIGURE→SPEED UNITS=1-RPM<br />

LEVEL 2 BLOCKS→DRIVE CONFIGURE→POWER INPUT=2-THREE PHASE<br />

(Note: use single phase only if ordered.)<br />

=0-SINGLE PHASE<br />

LEVEL 2 BLOCKS →DRIVE PROTECT→OVERLOAD=0-FAULT<br />

LEVEL 2 BLOCKS→MISCELLANEOUS→HOMING SPEED=200RPM.<br />

SPEEDS 2-15=0<br />

LEVEL 2 BLOCKS→MISCELLANEOUS→HOMING OFFSET=1024 (Note: change this value to adjust spindle orient<br />

position)<br />

LEVEL 2 BLOCKS→MOTOR CONTROL→CONTROL TYPE=2-CLOSED VECTOR<br />

LEVEL 2 BLOCKS→MOTOR DATA→MOTOR RATED VOLT=220(see motor tag)<br />

LEVEL 2 BLOCKS→MOTOR DATA→MOTOR RATED AMP=22(see motor tag)<br />

LEVEL 2 BLOCKS→MOTOR DATA→MOTOR RATED SPEED=1750(see motor tag)<br />

LEVEL 2 BLOCKS→MOTOR DATA→MOTOR RATED FREQ=60(see motor tag)<br />

LEVEL 2 BLOCKS→MOTOR DATA→ENCODER COUNTS=1024(see encoder)<br />

LEVEL 2 BLOCKS→BRAKE ADJUST→RESISTOR OHMS=15(check resistor)<br />

LEVEL 2 BLOCKS→BRAKE ADJUST→RESISTOR WATTS=1000(check resistor)<br />

LEVEL 1 BLOCKS→INPUT SETUP→OPERATING MODE=14-BIPOLAR<br />

LEVEL 1 BLOCKS→INPUT SETUP→COMMAND SOURCE=2-ANALOG IN2<br />

LEVEL 1 BLOCKS→OUTPUT SETUP→DIGITAL OUTPUT1=8-AT ZERO SPEED<br />

LEVEL 1 BLOCKS→OUTPUT SETUP→DIGITAL OUTPUT2=25-AT POSITION<br />

LEVEL 1 BLOCKS→OUTPUT SETUP→RELAY OUTPUT1=17-FAULT<br />

LEVEL 1 BLOCKS→OUTPUT SETUP→ZERO SPEED SET POINT=50<br />

LEVEL 1 BLOCKS→PRESET SPEED 1=200RPM<br />

LEVEL 1 BLOCKS→RAMP RATES→ACCEL TIME 1=5 SEC<br />

LEVEL 1 BLOCKS→RAMP RATES→DECEL TIME 1=7 SEC<br />

5. Once these values are set enable the drive by either commanding a M50 on the Anilam control or placing a jumper<br />

wire on the Baldor terminal strip between J2-8 and J3-21. Then put the drive in local mode.<br />

LEVEL 2 BLOCKS→AUTOTUNE→ONE STEP TUNING=1-YES. Follow the directions on the BALDOR screen. This will go through the auto<br />

tuning procedure which will run the motor and set parameters automatically.<br />

6. Once the auto tuning is complete set :<br />

LEVEL 2 BLOCKS→DRIVE LIMITS→MAXIMUM OUTPUT SPEED=6000 ( if this requires a higher spindle<br />

speed change this parameter)<br />

7. Remove temporary jumper and put drive in remote mode, install all covers.<br />

Electrical manual 3000.doc 27 OF 38 4/30/07

NOTES<br />

NOTE 1: The drive must be programmed for maximum RPM through the control. Cycle the drive forward and reverse<br />

allowing the spindle to obtain the extreme RPM ranges, if an error occurs during accel or decel the appropriate value should be<br />

enlarged.<br />

NOTE 2: The homing offset (LEVEL 2 BLOCKS→MISCELLANEOUS→HOMING OFFSET) is used only on machines<br />

equipped with Automatic <strong>Tool</strong> Changers. This will be adjusted from its original factory set value of 1024. After doing an<br />

M50 (orient spindle) command, adjust accordingly to correct the spindle home position.<br />

NOTE 3: Auto-tune values are set by following the instructions above. No manual entry is required.<br />

Electrical manual 3000.doc 28 OF 38 4/30/07

Anilam 3000 software update instructions<br />

1. Press E-stop and plug in an external keyboard<br />

2. Press F10 exit<br />

3. Press clear then type password “Z48” ↵ (enter)<br />

4. Now you are in DOS at the C:\P3M prompt *<br />

5. Type “cd..” ↵ You will now be in the root directory c:\<br />

6. Type “md old”↵ This will create an old directory<br />

7. Type “cd P3M” (*) This will return you to the P3M directory<br />

8. Type “copy *.* c:\old”↵ This will copy all files to the old directory for backup purposes. If there is a<br />

problem with the software installation you can get your machine back to original operating software<br />

by copying all the files in the old directory back to the P3M directory. To do this type “cd..”↵ - “cd<br />

old” - “copy *.* c:\P3M” say yes to overwrite files. Power down to restore when completed copying<br />

files.<br />

9. Now you can install the software update disk . (If you received the software via E-mail please copy<br />

all attached files to a clean 3.5” disk ) Type “a:”↵<br />

10. Type “install”↵ this will start the installation process follow the directions on the screen.<br />

11. Once you have completed the installation process and your machine is functioning properly you must<br />

backup your configuration file onto the floppy disk in the electrical cabinet (usually mounted on the<br />

door). See the Anilam manual for directions.<br />

* When updating a 5000 control the directory is c:\P5M<br />

Electrical manual 3000.doc 29 OF 38 4/30/07

ANILAM 3000 Service Procedure for Saving Configuration files.<br />

Copy Configuration<br />

This feature enables the user to make copies of the configuration and save the copies to a floppy<br />

diskette.<br />

NOTE: FRYER MACHINE recommends that you copy your Configuration file before any changes<br />

are made to the system. Such as, software updates, backlash adjustments, console swap etc. (↵<br />

= ENTER)<br />

1. Go to the Software Options Menu.<br />

2. #2 Setup Utility ↵<br />

3. #3 Utilities ↵<br />

4. #2 Copy Configuration ↵<br />

5. Enter the password Z48 ↵<br />

6. Highlight A: to copy the configuration to a floppy diskette. The configuration will be saved as<br />

A:\P3MCFG.CFG ( 3000 ) OR A:\P5MCFG.CFG ( 5300 )<br />

Restore from Copy<br />

Use this feature to restore a copy of the configuration from the A drive (A:\P3MCFG.CFG) and<br />

save it as the new configuration file.<br />

NOTE: If you restore your configuration file from a copy or a backup you will need to reboot when<br />

the system prompts to do so. You will prompt for an automatic reboot.<br />

1. Go to the software Options Menu.<br />

2. #2 Setup Utility ↵<br />

3. #3 Utility ↵<br />

4. #3 Restore From Copy ↵<br />

5. Enter the password Z48 ↵<br />

6. Highlight A: to restore the configuration from a floppy diskette. The configuration will be<br />

restored from A:\P3MCFG.CFG ( 3000 ) OR A:\P5MCFG.CFG ( 5300 )<br />

Print configuration<br />

Use this feature to save a copy of the configuration to diskette as a text file. P3CFG.TXT ( 3000 )<br />

OR P5CFG.TXT ( 5300 ) may then be taken to desktop P.C. and printed as a readable text file.<br />

1. Go to the Software Options Menu.<br />

2. #2 Setup Utility ↵<br />

3. #3 Utility ↵<br />

4. #6 Printer Configuration ↵<br />

5. #2 Text File (A:) ↵<br />

6. F1 Yes Print Anilam 3000 M/MK CNC VER.XXX to A:\P3MCFG.TXT? OR 5300 M/MK CNC<br />

VER. XXX TO A:\ P5MCFG.TXT?<br />

Electrical manual 3000.doc 30 OF 38 4/30/07

Renishaw <strong>Tool</strong> Probe Installation<br />

This will assist you in setting up and installing your Renishaw TS-27R tool probe on your Fryer milling machine with Anilam<br />

control. Make sure you read the instruction manual that came with the Renishaw probe and the Anilam manual pertaining to<br />

probing cycles.<br />

The probe has been pre-wired and tested on the Fryer machine at the factory. The manuals also can be downloaded in PDF<br />

format from either Renishaw.com or Anilam.com Installation should be completed at the customer’s facility. Follow these<br />

basic instructions referring to the manufacturers manuals for further details:<br />

1. Find a suitable mounting location for the probe ( most common is the far right hand corner of the table ) The probe<br />

should be mounted with the stylus pointing up and towards the left, this will exit the cable to the right. The Stylus<br />

should be approximately ½ the largest tool diameter used from the positive limit in x axis and at the rearmost t-slot(as<br />

long as it is a couple inches from the y limit). A t-nut can be used to mount the probe base with a ½-13 socket head<br />

cap screw. Make sure the cable will not interfere with anything during machine operation.<br />

2. Once the probe is securely mounted tram the probe within .0002” perpendicular and parallel to the machine slides.<br />

See Renishaw installation manual for further details.<br />

3. Follow the Anilam instructions to set the parameters according to your installation.<br />

4. Now you will need a tool with a known diameter to preset the tool presetter. You should use the Anilam G150 or tool<br />

probe calibration cycle. See the Anilam manual for further details.<br />

5. Once the G150 cycle is accomplished a G53 fixture offset should be activated and set to the top of the part so that all<br />

other tool to be set with the G151 cycle will be referenced to the top of the part.<br />

Electrical manual 3000.doc 31 OF 38 4/30/07

Diagnostics of Anilam MB PLC<br />

Refer to the Anilam <strong>Manual</strong>-Integral Programmable Intelligence User’s Guide for more information, included is the<br />

page on “Viewing the IPI Monitor” for your reference.<br />

An example of the input and output bits:<br />

Can 0 input bit 0<br />

Can 0 input bit 1<br />

Can 0 input bit 2<br />

Can 0 input bit 3<br />

Can 0 input bit 4<br />

Can 0 input bit 6<br />

Can 0 input bit 7<br />

Can 0 input bit 8<br />

Can 0 output bit 0<br />

Can 0 output bit 1<br />

Can 0 output bit 2<br />

Can 0 output bit 3<br />

Can 0 output bit 4<br />

Can 0 output bit 5<br />

Can 1 input bit 0<br />

Can 1 input bit 1<br />

Can 1 input bit 2<br />

Can 1 input bit 3<br />

Can 1 input bit 4<br />

Can 1 input bit 5<br />

Can 1 input bit 6<br />

Can 1 input bit 7<br />

X axis Home Switch 0=on trip dog 1=off trip dog (nc switch)<br />

Spindle drive fault 0=drive ok 1=spindle drive fault<br />

Y axis Home Switch 0= on trip dog 1=off trip dog (nc switch)<br />

Low Way Lube 0=low lube level 1=good oil level (no float switch)<br />

Z axis Home Switch 0=on trip dog 1=off trip dog (nc switch)<br />

Index complete cycle<br />

Spindle zero speed 0=spindle on 1=spindle not running<br />

Spindle in orient position 0=not orient 1=spindle in orient position<br />

Spare M-code M11=on M12=off<br />

Indexer start command (enables wait state)<br />

Mist coolant 1=on M7 0=off M9<br />

Spindle Enable 1=run the spindle or orient (power to spindle motor)<br />

Spindle Orient 1=orient the spindle for tool changeM50 0=off M51<br />

Flood coolant 0=off M9 1=on M8<br />

Drawbar off switch 0=tool not clamped 1=tool clamped (no sw on dbar air cyl)<br />

Drawbar on switch 0=tool locked 1=tool released (no switch on dbar air cyl)<br />

Low air pressure switch 0=low air pressure 1=good air pressure (no switch)<br />

ATC carousel in under spindle 0=not in 1=under spindle (no prox switch)<br />

ATC carousel out 0=not out 1=normal position (no prox switch)<br />

ATC Geneva drive prox 0=at pocket 1=not at pocket (no prox switch)<br />

ATC home prox 0=not at home pocket 1=at pocket 1 (no prox switch)<br />

<strong>Manual</strong> <strong>Tool</strong> in/out button on head 0=not pressed 1=pressed(no momentary sw)<br />

Can 1 output bit 0<br />

Can 1 output bit 1<br />

Can 1 output bit 3<br />

Can 1 output bit 4<br />

ATC index direction<br />

ATC index 1=spin the ATC geneva drive motor M58 or M59<br />

ATC carousel in under head M52=1 move under head 0=retract M53<br />

Drawbar on 1=drawbar on to release the tool (also airblast on)M54=off M55<br />

Electrical manual 3000.doc 32 OF 38 4/30/07

MATERIALS REQUIRED:<br />

-Hard Drive<br />

-<strong>Machine</strong> Parameter Disk<br />

-Blank, Formatted 3.5” Floppy Disk<br />

ANILAM HARD DRIVE INSTALLATION<br />

PROCEDURE:<br />

1. Install the hard drive into the control. Depending on the machine model, the hard drive will be located<br />

either in the operator console or the computer chassis in the electrical cabinet.<br />

2. If you received a DSP and/or keyboard chip with your new software, please install it following the<br />

directions provided with the chip(s).<br />

3. Plug a standard keyboard into the control. Start the computer. If the computer boots into the Anilam<br />

software, proceed to Step 3. Otherwise, proceed as follows: During the initial boot sequence, enter the<br />

BIOS setup menu by pressing the key specified by the message “press __ to enter setup” (usually or<br />

). You will need to enter the “Main” or “Standard CMOS Setup” menu. Now you must auto-detect<br />

the hard drive. Due to variations in the BIOS versions used by Anilam, it is difficult to provide one exact<br />

procedure to cover all controls. Call for assistance if you run into any problems. NOTE: For non-Pentium<br />

computers using large hard drives, check the auto-detected information for “no. of heads”. If this field<br />

says 16, it needs to be changed to 15. Highlight the field with the cursor and use the minus key to<br />

change. Now proceed to the “Exit” menu. Choose “Save changes and exit”- if prompted, answer “Y”<br />

.<br />

4. The computer should reboot and start the Anilam software. Press until you get to the Software<br />

Options menu. Press +. When prompted for the password, type the password corresponding to<br />

your control from the list below, followed by .<br />

-“Y10” for 1100 controls<br />

-“SERVICE” for 1400 controls<br />

-“Z48” for 3X00 5X00 controls<br />

5. You should see a black screen with the DOS prompt:<br />

-S1100\> for 1100 controls<br />

-S1400\> for 1400 controls<br />

-P3M\> for 3X00 controls<br />

-P5M\> for 5X00 controls<br />

6. Insert the machine’s original parameter disk into the floppy drive.<br />

7. Type “cd\” . Then, type “A:” . Then, type:<br />

“COPY *.* C:\_____” , inserting the directory name that corresponds to your control from the list<br />

below:<br />

S1100 for 1100 controls<br />

S1400 for 1400 controls<br />

P3M for 3X00 controls<br />

P5M for 1100 controls<br />

This will copy your original parameter file and machine files into the control software. If you are asked,<br />

“File exists, replace?” Press . You should get a<br />

“_ file(s) copied” message.<br />

8. Now you will need to re-install the Anilam software onto the hard drive in order to update the parameter<br />

file. To do this, insert the Anilam software disk into the floppy drive and reboot the computer. The<br />

Anilam software installation utility should start automatically (If it does not, type “A:\install”). Follow the<br />

prompts on the screen, performing a normal software installation.<br />

9. At the end of the software installation, remove the floppy disk and press to reboot the computer. It<br />

should boot from the hard drive and automatically start the Anilam software. The machine should be<br />

ready to run. Test the machine to ensure that it is functioning properly.<br />

Electrical manual 3000.doc 33 OF 38 4/30/07

Once you are satisfied with the machine’s operation, you will need to make a new parameter disk. To do<br />

this, perform the following procedure:<br />

For 3X00 and 5X00 Controls:<br />

Press in the E-stop button and exit the CNC software .<br />

Use the cursor to highlight #2, Setup Utility, press .<br />

Go to #3, Utilities, press .<br />

Go to #2, Copy Configuration, press .<br />

Enter the password “Z48”, .<br />

Go to A:, press .<br />

When copying is complete, remove the floppy disk and store it in a safe place.<br />

Press until you get back to the Software Options menu.<br />

Go to Control Software, press .<br />

10. You are done! If you need help, please call our Service Department at (845) 878-2500.<br />

Electrical manual 3000.doc 34 OF 38 4/30/07

Loading IPI file<br />

Anilam 3000 Control<br />

This procedure goes through a step by step process to put a new PLC program into the hard drive of the<br />

machine in the P3M directory. Then you must compile the file through the IPI interface section. The<br />

“particular plc file.DBO” is________________________ the file made for your machine on the floppy<br />

disk with the .DBO extension.<br />

Do the following steps from the main screen (<strong>Manual</strong>) with the drives off:<br />

(F2) program<br />

(F8) display<br />

keep pressing (F8) until ..\ is in the upper left of the screen<br />

move cursor to (..\) (enter)<br />

cursor to (p3m\) or (p5m) (enter)<br />

(F7) log<br />

cursor to (A:) (enter) (make sure the floppy is in the drive)<br />

move cursor to (particular plc file .DBO)<br />

(MBMENG.TXT) (enter) this is the message file (optional)<br />

(F9) utilities<br />

cursor to (copy) (enter)<br />

cursor to (c:) (enter) *this will copy file to machines hard drive<br />

(F7) log<br />

cursor to (c:) (enter)<br />

(F10) exit<br />

get back to the main screen (manual)<br />

(F10) exit *this will exit out of the cnc software<br />

cursor to (2.setup utility) (enter)<br />

cursor to (1.builder setup) (enter)<br />

cursor to (3.prog. I/O interface)<br />

enter password (IPI) (enter)<br />

cursor to (2.select program) (enter)<br />

cursor to (particular plc file .DBO) (enter) *this is the program loaded from the disk<br />

cursor to (4.load) (enter) *this will compile file<br />

(F10) exit two times.<br />

you are now done with the installation so keep exiting back to the cnc software saving the changes. If<br />

you get an error of block 90 not found during a tool change, you must power down to eliminate this error,<br />

this may take more than one reboot cycle.<br />

Make sure you put the floppy disk in a safe place.<br />

Electrical manual 3000.doc 35 OF 38 4/30/07

User Setup For Anilam Networking<br />

Upon receiving your Fryer machine networking will be setup for TCPIP protocol. We only support this method of<br />

networking. If you need to use a different protocol, like Novel, the system will need to be reconfigured. For those using TCPIP<br />

you will only need to edit two files to configure to your network. The proticol.ini and system.ini files are located in the c:\net<br />

directory. Below are examples of these files.<br />

You will first boot up your machine and get to the control software menu. At this point, you will need<br />

to plug in an external keyboard and press the escape key. A password box will now be displayed. The password<br />

is Z48. Once you type in the password press enter and you will be in Dos. To edit the files you can use XTG<br />

utility that is installed in your machine. Once you are exited the Anilam software and at the c:\> prompt, type<br />

XTG and then press enter. This will get you into the XTG dos utility. To use this software the cursor keys will<br />

move the highlighted box. The enter key will access the highlighted box which must be a directory. Once you are<br />

in the proper directory select the file you wish to edit and press the letter “E” then enter to edit the file. Once you<br />

finished editing press the “ESC” key and then select “save file and quit”.<br />

Proticol.ini – in the C:\net directory<br />

[network.setup]<br />

version=0x3110<br />

netcard=smc9000,1,SMC9000,1<br />

transport=tcpip,TCPIP<br />

lana0=smc9000,1,tcpip<br />

[TCPIP]<br />

NBSessions=6<br />

SubNetMask0=255 255 255 0<br />

defined by the network tech.<br />

IPAddress0=100 100 100 2<br />

defined by the network tech.<br />

DisableDHCP=1<br />

DriverName=TCPIP$<br />

BINDINGS=SMC9000<br />

LANABASE=0<br />

[protman]<br />

DriverName=PROTMAN$<br />

PRIORITY=MS$NDISHLP<br />

[SMC9000]<br />

DriverName=SMC9X$<br />

Interrupt=9<br />

IOBase=0x300<br />

MaxTransmits=1<br />

System.ini – in the C:\net directory<br />

[network]<br />

sizworkbuf=1498<br />

filesharing=yes<br />

printsharing=yes<br />

autologon=yes<br />

computername=MINIMILL<br />

defined by network tech.<br />

lanroot=C:\NET<br />

username=MINIMILL<br />

defined by network tech.<br />

workgroup=CNC<br />

defined by network tech.<br />

reconnect=yes<br />

dospophotkey=N<br />

lmlogon=1<br />

logondomain=CNC<br />

defined by network tech.<br />

preferredredir=full<br />

autostart=full<br />

maxconnections=8<br />

[Password Lists]<br />

*Shares=C:\NET\Shares.PWL<br />

MACHINE=C:\NET\MACHINE.PWL___________delete this line, the next boot-up<br />

will allow you to store a new network password.<br />

Electrical manual 3000.doc 36 OF 38 4/30/07

FURTHER INSTRUCTIONS<br />

Once the two files are edited and stored turn off the main disconnect switch wait 30 seconds and turn<br />

back on to reboot the system.<br />

1. Watch closely the boot process once you see “starting MS-DOS” hold down F8 key on keyboard. This will ask<br />

you yes or no for each line of the autoexec file. You will answer yes (type the letter “y” and ↵) to each question<br />

until the line that asks you to type your username.<br />

2. Type “network administrator supplied user name” for username and when asked for the password enter “network<br />

administrator supplied user password” press the enter key. When prompted to create a password list for this<br />

username type “y↵” and when asked to confirm password re-enter “network administrator supplied user<br />

password” press the enter key.<br />

3. When prompted for a domain password enter “domain password supplied by the network administrator” and<br />

press the enter key. This will create a stored password file in the system.ini<br />

4. Continue to enter “y” (type the letter “y” and ↵) for each line of the Autoexec file until the line that states<br />

“c:\touch\elodev ####,#,…” type “n↵” for the rest of the questions. You will then be at the c:\>_ (c prompt).<br />

5. At the C:\>_ type “netshare.exe↵” This will bring up a blue window, instructions how to maneuver the cursor are<br />

on the bottom of the screen.<br />

6. Type in the SHARE NAME as “network administrator supplied sharename” this is the name of the CNC control.<br />

7. Type in the PATH as “c:\user”<br />

8. Move cursor to SHARE and press↵. This should put the name and path in the current share window if everything<br />

is done correctly.<br />

9. Exit Netshare<br />

10. Type “cd net↵”<br />

11. Type “net↵” This will bring up a blue window, instructions on how to maneuver the cursor are on the bottom of<br />

the screen. Sometimes you will not see where the cursor is, so just keep using the tab button until you can change<br />

the value you desire.<br />

12. DRIVE should be already set at G: if not type it in.<br />

13. Type in the PATH as “network administrator supplied path”<br />

14. Make sure the box for reconnect on startup is “x” ed.<br />

15. Move the cursor to connect and press↵<br />

16. Repeat steps 12-16 to map additional drives. Now you can exit net.exe and reboot the machine<br />

17. You now should be completed with the installation. Verify that you can see the machine on the network and<br />

make sure that you have drive G and any other mapped drive listed when you are in Program and log (use the<br />

shift key ) If you cannot see drive G you may have to repeat step 12 through 16.<br />

Notes on NT systems<br />

1. Limits of Microsoft DOS client 3.0 do not allow for digital signatures.<br />

2. Using windows XP the network neighborhood GUI (Graphic User Interface) will not allow explorer to access a<br />

DOS shared drive. The workaround is done by using the command prompt (under start-programs-accessoriescommand<br />

prompt) type: “net use (drive letter): \\ (computer name) \ (share name) “ then enter . Example: net use<br />

M: \\machine\test. On DOS systems it may take some time to map.<br />

3. Microsoft 2003 server requires all machines on the network to have digital signing. In order for the CNC to<br />

function with this, the digital signing must be turned off, which would cause a security issue. In order to work<br />

around this problem the machine can be mapped to a intermediary that has an XP operating system. This can be<br />

done by using the command prompt (under start-programs-accessories-command prompt) type: “net use (drive<br />

letter): \\ (computer name) \ (share name) “ then enter . Example: net use M: \\machine\test. On DOS systems it<br />

may take some time to map.<br />

Electrical manual 3000.doc 37 OF 38 4/30/07

Fryer Optional Chiller Instructions<br />

Used on all optional high speed spindles and automatic gearbox<br />

INSTALLATION: The chiller has been wired and tested at the factory. The reservoir is filled with ISO#32 spindle oil. At<br />

installation check the level at the tank sight glass and top off as necessary. The ambient temperature to run the chiller must be<br />

between 41°-104° Fahrenheit (5-40°Celsius). The working range of the chiller is between 77°-95° Fahrenheit (25-35° Celsius).<br />

The factory preset is to run at 77° F. This is the optimal setting for most applications. The chiller must be located in a clean<br />

dry area with good ventilation and level.<br />

WIRING: The chiller is pre-wired at the factory. Incoming 3 phase power is applied at terminals R-S-T. Ground is connected<br />

to E. Terminals 93 and 95 are fault contacts going back to the CNC control. Terminals 224 and 225 are the remote start inputs.<br />

Do not turn the chiller off or on with the on switch on the chiller operator panel. This will bypass the remote on from the CNC<br />

and cause an alarm on the CNC.<br />

ADJUSTMENT: The display on the chiller normally shows the oil temperature. To adjust the preset temperature when the<br />

refrigeration will cycle on press the left arrow button. The display will now show the preset value. This should be set at 25°<br />

Celsius (77°Fahrenheit). Use the right and left arrow keys to adjust. Wait for 5 seconds and the display should revert back to<br />

displaying the liquid temperature.<br />

TROUBLESHOOTING:<br />

1. Alarm on CNC control “Spindle chiller alarm”: Look at the chiller for any alarms. If the display is blank press the<br />

ON button on the chiller. If there still is no display check the fuses in the CNC electrical cabinet (normally fuses D1-<br />

D2_D3).<br />

2. If there is an alarm displayed on the chiller,here is a brief listing:<br />

AL-1 REV: Phase failure or out of phase, The is not three phase present or line is out of phase. Switch any two lines<br />

at the terminal strip in the chiller R-S or T. Check the fuses in the CNC cabinet.<br />

AL-2 PUMP: The pump motor is not functioning properly.<br />

-Check that there is no obstruction in lines<br />

-Reverse red and white wire of thermal relay 51P in chiller<br />

-Replace pump<br />

-Add recirculating oil to the reservoir<br />

-Adjsut the oil pressure switch to .3kgf/cm2 under .5-.8cmHg<br />

-Reset the thermal overload<br />

AL-3 COMP: The compressor motor is not functioning properly.<br />

-Reset the thermal overload<br />

-Replace the compressor<br />

AL-4 RA: Temperature probe of the room is not functioning properly<br />

-Replace the RA room temperature probe<br />

AL-5 RO: Temperature probe of oil is abnormal<br />

-Replace the RO liquid temperature sensor<br />

AL-6 OT: The cooling oil is overheating<br />

-Shut down the coller and wait until the temperature drops to acceptable levels.<br />

-Recharge Freon.<br />

-Check level of oil<br />

MAINTENANCE:<br />

-Clean the filter net periodically as required.<br />

-Replace oil as required and make sure there is no blockage in the lines.<br />

Electrical manual 3000.doc 38 OF 38 4/30/07