December 2008 - Plumbing & HVAC

December 2008 - Plumbing & HVAC

December 2008 - Plumbing & HVAC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Pipes, Valves & Fittings<br />

Sizing circulators<br />

in hydronic systems<br />

By Art Irwin<br />

Pipe sizing and<br />

circulator sizing<br />

are critical<br />

for hot water heating<br />

systems. One<br />

must first ensure the<br />

piping is properly<br />

sized to carry the<br />

hot water from “A” to “B” or, in other<br />

words, from the heating boiler to the<br />

radiation via the piping system.<br />

There are, of course, hundreds of<br />

sizes of circulators, but it is important<br />

the circulator be properly sized to deliver<br />

the required number of BTU’s, carried<br />

in gallons of water per minute<br />

(gpm), to its destination. If the circulator<br />

is too large or too small, we get into<br />

velocity or noise problems, insufficient<br />

heat, cavitation and pump failure.<br />

There are two issues that must be<br />

addressed when sizing circulators. First,<br />

how many gallons per minute must the<br />

circulator pump to deliver the maximum<br />

heat?<br />

Item number two – what is the<br />

“head” or resistance the circulator must<br />

overcome? There a are a number of<br />

things that can cause “bumps in the<br />

road” – length of piping, elbows, tees<br />

and friction loss. (Refer to the chart at<br />

right for pipe carrying capacity in<br />

To obtain the required gallons per<br />

minute (GPM), divide the total Btu’s<br />

by 10,000:<br />

BTU Heat Loss = Gallons per minute.<br />

10,000<br />

Example:<br />

200,000 Btu/hr.= 20 Gal/Min.<br />

10,000<br />

Btu/h.)<br />

Determining pump head<br />

How do we determine the pump head?<br />

Here’s a quick way to do it. It’s not 100<br />

percent accurate, but close enough for<br />

quick sizing. We must take the total<br />

equivalent length, which means measuring<br />

to the most distant radiator from<br />

the boiler, and back, plus 50 percent,<br />

and multiply x .04<br />

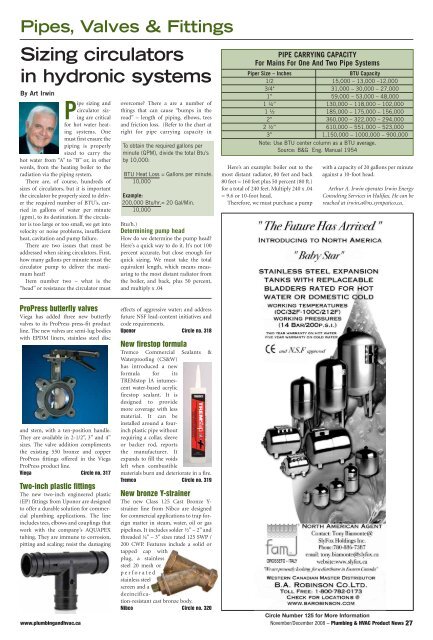

PIPE CARRYING CAPACITY<br />

For Mains For One And Two Pipe Systems<br />

Piper Size – Inches<br />

BTU Capacity<br />

1/2 15,000 – 13,000 –12,000<br />

3/4" 31,000 – 30,000 – 27,000<br />

1” 59,000 – 53,000 – 48,000<br />

1 ¼” 130,000 – 118,000 – 102,000<br />

1 ½ 185,000 – 175,000 – 156,000<br />

2” 360,000 – 322,000 – 294,000<br />

2 ½” 610,000 – 551,000 – 523,000<br />

3” 1,150,000 – 1000,000 – 900,000<br />

Note: Use BTU center column as a BTU average.<br />

Source: B&G Eng. Manual 1954<br />

Here’s an example: boiler out to the<br />

most distant radiator, 80 feet and back<br />

80 feet = 160 feet plus 50 percent (80 ft.)<br />

for a total of 240 feet. Multiply 240 x .04<br />

= 9.6 or 10-foot head.<br />

Therefore, we must purchase a pump<br />

with a capacity of 20 gallons per minute<br />

against a 10-foot head.<br />

Arthur A. Irwin operates Irwin Energy<br />

Consulting Services in Halifax. He can be<br />

reached at irwin.a@ns.sympatico.ca.<br />

ProPress butterfly valves<br />

Viega has added three new butterfly<br />

valves to its ProPress press-fit product<br />

line. The new valves are semi-lug bodies<br />

with EPDM liners, stainless steel disc<br />

and stem, with a ten-position handle.<br />

They are available in 2-1/2”, 3” and 4”<br />

sizes. The valve addition compliments<br />

the existing 550 bronze and copper<br />

ProPress fittings offered in the Viega<br />

ProPress product line.<br />

Viega Circle no. 317<br />

Two-inch plastic fittings<br />

The new two-inch engineered plastic<br />

(EP) fittings from Uponor are designed<br />

to offer a durable solution for commercial<br />

plumbing applications. The line<br />

includes tees, elbows and couplings that<br />

work with the company’s AQUAPEX<br />

tubing. They are immune to corrosion,<br />

pitting and scaling; resist the damaging<br />

effects of aggressive water; and address<br />

future NSF lead-content initiatives and<br />

code requirements.<br />

Uponor Circle no. 318<br />

New firestop formula<br />

Tremco Commercial Sealants &<br />

Waterproofing (CS&W)<br />

has introduced a new<br />

formula for its<br />

TREMstop IA intumescent<br />

water-based acrylic<br />

firestop sealant. It is<br />

designed to provide<br />

more coverage with less<br />

material. It can be<br />

installed around a fourinch<br />

plastic pipe without<br />

requiring a collar, sleeve<br />

or backer rod, reports<br />

the manufacturer. It<br />

expands to fill the voids<br />

left when combustible<br />

materials burn and deteriorate in a fire.<br />

Tremco Circle no. 319<br />

New bronze Y-strainer<br />

The new Class 125 Cast Bronze Y-<br />

strainer line from Nibco are designed<br />

for commercial applications to trap foreign<br />

matter in steam, water, oil or gas<br />

pipelines. It includes solder ½” – 2” and<br />

threaded ¼” – 3” sizes rated 125 SWP /<br />

200 CWP. Features in clude a solid or<br />

tapped cap with<br />

plug, a stainless<br />

steel 20 mesh or<br />

perforated<br />

stainless steel<br />

screen and a<br />

dezincification-resistant<br />

cast bronze body.<br />

Nibco Circle no. 320<br />

Circle Number 125 for More Information<br />

www.plumbingandhvac.ca November/<strong>December</strong> <strong>2008</strong> – <strong>Plumbing</strong> & <strong>HVAC</strong> Product News 27