Processed feed pea and canola meal for blue shrimp diets

Processed feed pea and canola meal for blue shrimp diets

Processed feed pea and canola meal for blue shrimp diets

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2. Material <strong>and</strong> methods<br />

( )<br />

L.E. Cruz-Suarez et al.rAquaculture 196 2001 87–104 89<br />

2.1. Diets<br />

A lot of commercial dry <strong>pea</strong>s P. satiÕum composed of mixed Canadian prairie<br />

varieties was processed to prepare the respective <strong>meal</strong>s. Whole <strong>and</strong> dehulled <strong>pea</strong>s were<br />

pin-milled to produce raw flours, WRA <strong>and</strong> DRA, respectively. Portions of these flours<br />

were preconditioned Ž Wenger model 2 DDC.<br />

<strong>and</strong> extruded with a co-rotating twin screw<br />

extruder Ž Werner <strong>and</strong> Pfleiderer ZSK-57.<br />

through 1r4 in. round hole dies at a product<br />

temperature reaching 1458C at the die plate, <strong>and</strong> pressure ranging between 620 <strong>and</strong> 740<br />

psi. The extruder screw was 147 cm long with a lengthrdiameter ratio of 24:1. The<br />

material was fed into the conditioner at a rate of 90.9, 93.6 <strong>and</strong> 113.6 kgrh <strong>for</strong> whole<br />

<strong>pea</strong>s, dehulled <strong>pea</strong>s <strong>and</strong> <strong>canola</strong> <strong>meal</strong>, respectively, <strong>and</strong> water was injected at a rate of 4.5<br />

lrh. The material was then dried in a fluid bed dryer at 1108C <strong>and</strong> pin milled to produce<br />

whole <strong>and</strong> dehulled extruded <strong>meal</strong>s Ž WEX <strong>and</strong> DEX, respectively .. Commercial <strong>canola</strong><br />

<strong>meal</strong> was similarly extruded <strong>and</strong> ground Ž CEX .. Another portion of whole <strong>pea</strong>s was<br />

tempered to 14% moisture <strong>and</strong> processed using infrared cooking, reaching a temperature<br />

of 1208C. The heat-treated Ž micronized.<br />

<strong>pea</strong>s were subsequently rolled to produce a<br />

flake <strong>and</strong> then milled into a fine powder Ž WMI .. The proximate composition <strong>and</strong> effects<br />

of heat treatment on starch gelatinization in the <strong>pea</strong> <strong>meal</strong>s are presented in Table 1.<br />

Isonitrogenous <strong>and</strong> isoenergetic Ž gross energy.<br />

experimental <strong>diets</strong> <strong>for</strong> the growth trial<br />

were <strong>for</strong>mulated to contain 30% of the test <strong>meal</strong>s, <strong>and</strong> to meet the nutrient requirements<br />

Ž Akiyama et al., 1991. with proteinrenergy ratios Ž Cruz-Suarez ´ et al., 2000.<br />

recommended<br />

<strong>for</strong> <strong>shrimp</strong> Ž Table 2 .. The test <strong>pea</strong> <strong>meal</strong>s were included in the experimental <strong>diets</strong><br />

1 to 5 to replace a portion of a soybean <strong>meal</strong> <strong>and</strong> wheat flour mix Ž1:3 parts,<br />

respectively.<br />

in the practical control diet 7. In test diet 6, extruded <strong>canola</strong> <strong>meal</strong> replaced<br />

a portion of soybean <strong>meal</strong>, fish <strong>meal</strong> <strong>and</strong> wheat Ž 1:2:3 parts, respectively ..<br />

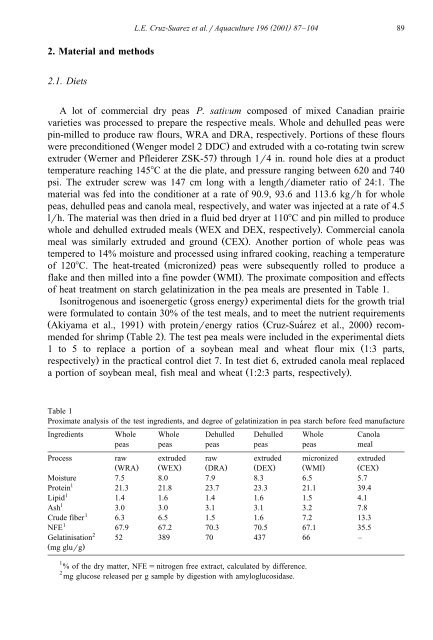

Table 1<br />

Proximate analysis of the test ingredients, <strong>and</strong> degree of gelatinization in <strong>pea</strong> starch be<strong>for</strong>e <strong>feed</strong> manufacture<br />

Ingredients Whole Whole Dehulled Dehulled Whole Canola<br />

<strong>pea</strong>s <strong>pea</strong>s <strong>pea</strong>s <strong>pea</strong>s <strong>pea</strong>s <strong>meal</strong><br />

Process raw extruded raw extruded micronized extruded<br />

Ž WRA. Ž WEX. Ž DRA. Ž DEX. Ž WMI. Ž CEX.<br />

Moisture 7.5 8.0 7.9 8.3 6.5 5.7<br />

1<br />

Protein 21.3 21.8 23.7 23.3 21.1 39.4<br />

1<br />

Lipid 1.4 1.6 1.4 1.6 1.5 4.1<br />

1<br />

Ash 3.0 3.0 3.1 3.1 3.2 7.8<br />

1<br />

Crude fiber 6.3 6.5 1.5 1.6 7.2 13.3<br />

1<br />

NFE 67.9 67.2 70.3 70.5 67.1 35.5<br />

2<br />

Gelatinisation 52 389 70 437 66 –<br />

Ž mg glurg.<br />

1 % of the dry matter, NFEsnitrogen free extract, calculated by difference.<br />

2 mg glucose released per g sample by digestion with amyloglucosidase.