SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

SOW Attachment D Epoxy Coating System Used on Hangar Floor

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

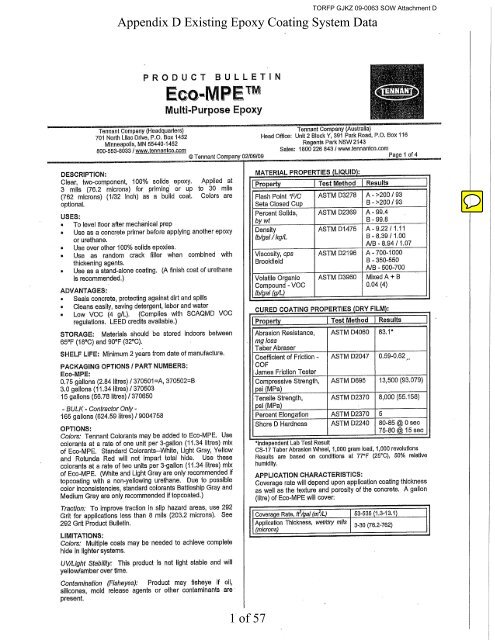

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data1 of 57

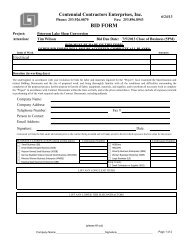

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data2 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data3 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data4 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data5 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data6 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data7 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data8 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data9 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data10 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data11 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data12 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data13 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data14 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data15 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> Data16 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTENNANT COATINGSFor First Impressi<strong>on</strong>s That Last• Protect your investment• Enhance your image• Make your floors easier to clean and maintain17 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTrust in the knowledge andexpertise that come from 135years of floor-care leadership.The architect of floor care: Tennant.For over 135 years, Tennant Company has been the industryleader in flooring experience, knowledge, and expertise. Part ofthat leadership has come from creating durable, high-performancec<strong>on</strong>crete coatings that, together with Tennant equipment, makefloors easier to clean and maximize your results.Tennant coatings protect and enhance floors with superiorresults. They repair cracks and chips, save m<strong>on</strong>ey by reducingmaintenance, and add tracti<strong>on</strong>, safety, and light reflectivity.“[Our coated floor] is actuallythere for <strong>on</strong>e reas<strong>on</strong> and that’sto impress our customers, to letthem know that we take qualityvery, very seriously.”– Packaging Corporati<strong>on</strong> of AmericaTENNANT COATINGS HELP YOU:Make an impact <strong>on</strong> your facility’s overall imageTennant coatings create a world-class impressi<strong>on</strong> with customers,visitors, partners, and prospective clients.Create easy-to-maintain floorsTennant coatings protect your floors from dust, dirt, chemicals,and traffic, making them easier to clean and maintain.Specify the right soluti<strong>on</strong> the first time, every timeFrom the widest range of coating soluti<strong>on</strong>s, to the deepest baseof technical knowledge, Tennant delivers unsurpassed quality, anestablished reputati<strong>on</strong>, and unwavering support.2800.228.494318 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataChoose the safest, most user-friendly,compliant coatings in the industry:the Tennant Eco-Advantage.®The Tennant Eco-Advantageis ideal for the growing“green building” movement.Eco-Advantage coatings provide the durability, high performance,and outstanding results expected from all Tennant coatings.Eco-COATINGS ARE:Virtually odor-freeNo shutdown is required and sensitive stock is protected asEco-Advantage coatings have such a low odor, they can beapplied during normal business hours.Envir<strong>on</strong>mentally friendlyReduced solvent means less evaporati<strong>on</strong> and c<strong>on</strong>taminati<strong>on</strong>,and this is what makes an Eco-Advantage coating <strong>on</strong>e of themost envir<strong>on</strong>mentally friendly in the industry.User-friendlyEco-coatings are the most straightforward way to coat your floors.From the first call for a site survey, to the easy, simple preparati<strong>on</strong>and applicati<strong>on</strong>, to complete after-sale support, TennantEco-coatings are user-friendly and envir<strong>on</strong>mentally friendly.VOC compliantComplies with U.S. Federal VOC regulati<strong>on</strong>s.19 of 57www.tennantfloorcoatings.com 3

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTennant coatings deliver the widest range of soluti<strong>on</strong>s to meetvirtually any flooring need.WAREHOUSING AND DISTRIBUTIONHigh-traffic areas demand a high-wear soluti<strong>on</strong>, and theheavy-wheeled nature of warehousing is ideal for high-trafficcoatings systems.• Loading docks• Main traffic aisles• Storage areasMANUFACTURINGThe key flooring c<strong>on</strong>siderati<strong>on</strong>s for a manufacturing facilityare abrasi<strong>on</strong> resistance and slip-and-fall preventi<strong>on</strong>. <str<strong>on</strong>g>Coating</str<strong>on</strong>g>soluti<strong>on</strong>s like Eco-PT250 and Eco-Shop<strong>Floor</strong> hold up wellin the most abusive, punishing manufacturing envir<strong>on</strong>ments.• Factories• Assembly lines• Loading docks• Machine shopsAVIATIONHighly image-c<strong>on</strong>scious aviati<strong>on</strong> facilities are involved with thestorage and maintenance of aircraft, and typically need a highglosscoating that is easy to clean and delivers high light reflectivity.Chemical resistance to Skydrol® and jet fuel, slip resistance,and weight durability are critical.• Assembly areas• <strong>Hangar</strong>s• Maintenance• Military bases4800.228.494320 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataFrom tracti<strong>on</strong>-enhancing systems to the innovative InstaCure®+,there’s a soluti<strong>on</strong> that’s right for you.COMMERCIALFrom automotive showrooms to clubhouse staging areas,coating soluti<strong>on</strong>s like Eco-DFS, Eco-DQS, and Tennant MMAhelp to make a world-class impressi<strong>on</strong> with customers, visitors,partners, and prospective clients.• Auto dealerships• Retail outlets• Sporting facilities• Airport c<strong>on</strong>courses• Hotel lobbiesFOOD AND BEVERAGE PROCESSINGMeat and poultry processing plants are good examples ofsolvent-sensitive envir<strong>on</strong>ments requiring a coating soluti<strong>on</strong>like Eco-ProTekt that delivers bacterial and thermal resistance.• Lockers• Chemical storage facilities• Pulp and paper• Bottling plants• PharmaceuticalINSTITUTIONALFrom schools with high foot traffic, to hospitals with high bacterialresistance standards, coating soluti<strong>on</strong>s for instituti<strong>on</strong>s includeEco-DFS, Eco-DQS, InstaCure®+, and Tennant MMA.• Universities• Hospitals• Pris<strong>on</strong>s• Kitchens• Schools• Sports facilities21 of 57www.tennantfloorcoatings.com 5

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataHigh-wear soluti<strong>on</strong>s for high-traffic areas.Eco-ECT / Eco-EDEStatic C<strong>on</strong>trol <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g>sHigh Traffic <str<strong>on</strong>g>System</str<strong>on</strong>g>High-Protecti<strong>on</strong> <str<strong>on</strong>g>System</str<strong>on</strong>g>Eco-PT 250C<strong>on</strong>crete Restorati<strong>on</strong> <str<strong>on</strong>g>System</str<strong>on</strong>g>• Prevent equipment damage fromstatic electricity by maintainingstatic c<strong>on</strong>trol.• Withstand wear better than ESDcarpeting or tile.IDEAL FOR: electr<strong>on</strong>ics and automotiveassembly, clean rooms,electr<strong>on</strong>ics service and repair areas,and aviati<strong>on</strong> manufacturing.• Maximum durability and chemicalresistance to protect against damagefrom industrial use.• Ensure l<strong>on</strong>g-lasting results fromsuperior impact, abrasi<strong>on</strong>, andwear resistance.IDEAL FOR: main traffic aisles inmanufacturing and warehousing,loading docks, aviati<strong>on</strong> hangars,and maintenance facilities.• Built to handle heavy loads inmain traffic aisles and loadingdocks, decreasing the need forcostly c<strong>on</strong>crete repair.• Designed to help repair or rebuilderoded floors.IDEAL FOR: main traffic aisles,loading docks, manufacturingareas, and eroded floors.AUTOMOTIVE ASSEMBLY PAPER MANUFACTURING HEAVY MANUFACTURING6800.228.494322 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataThe highest-quality epoxies, urethanes, and coatings deliveringthe highest-performing results.InstaCure® / InstaCure®+Same-Day Traffic <str<strong>on</strong>g>System</str<strong>on</strong>g>Cured floors immediately ready for foot traffic.Eco-Shop <strong>Floor</strong>High-Performance Shop <strong>Floor</strong> <str<strong>on</strong>g>System</str<strong>on</strong>g>Eco-ProTektFood-and-Beverage Overlay <str<strong>on</strong>g>System</str<strong>on</strong>g>• To coat floors with virtually nooperati<strong>on</strong>al shut-down, same-dayInstaCure® is the soluti<strong>on</strong>. WithInstaCure®, floors are quicklycoated, instantly cured, andimmediately ready for foot andvehicular traffic.• Coat surfaces from bare andpreviously coated c<strong>on</strong>crete tounglazed and vinyl tile.IDEAL FOR: main traffic aisles,producti<strong>on</strong> floors, warehouses,and retail and service areas.• Maximum chemical resistanceand tracti<strong>on</strong> c<strong>on</strong>trol to maximizesafety and reduce maintenancecosts with extremely durableEco-HTS 100 topcoat.• Provides excellent slip resistance,even under wet c<strong>on</strong>diti<strong>on</strong>s, creatinga safer workplace.IDEAL FOR: service, repair, heavymaintenance shops, and traffic ways– especially where wet floors mayexist.• Protect against abrasi<strong>on</strong>, chemicals,impact, thermal shock, andbacterial growth.• NSF certified.• Withstands thermal variati<strong>on</strong>s from-330°F to +240°F.IDEAL FOR: food, beverage, andpharmaceutical facilities, cosmeticmanufacturing, rendering plants,and other facilities requiring highsanitizati<strong>on</strong>.MAIN-TRAFFIC AISLES FIRE STATIONS FOOD AND BEVERAGE23 of 57www.tennantfloorcoatings.com 7

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataFrom start to beautiful finish, Tennant will support you everystep of the way.Eco-DFSDecorative Flake <str<strong>on</strong>g>System</str<strong>on</strong>g>Eco-DQSDecorative Quartz <str<strong>on</strong>g>System</str<strong>on</strong>g><strong>Hangar</strong> <strong>Floor</strong>Soluti<strong>on</strong>Aviati<strong>on</strong> <str<strong>on</strong>g>System</str<strong>on</strong>g>Tennant MMARANDOM FLAKEBROADCASTTROWELED FINISHBROADCAST• Achieve high-performingand l<strong>on</strong>g-lasting coatingresults, while maintainingthe aesthetic value ofyour design.• Project a quality imagethrough Tennant’sdecorative flake system,available in random andfull blends.IDEAL FOR: schools,universities, pharmaceuticals,automotive dealerships,museums, sporting facilities,supermarkets, c<strong>on</strong>venti<strong>on</strong>centers, and airports.• Create a clean, safe, andattractive facility with atextured and slip-resistantbroadcast surface or asmooth troweled finish.• Combine the aestheticsrequired for a commercialenvir<strong>on</strong>ment with theperformance of anindustrial floor.IDEAL FOR: schools,universities, pharmaceuticals,automotive dealerships,museums, sporting facilities,super markets, c<strong>on</strong>venti<strong>on</strong>centers, and airports.• Resistant to punishingindustrial traffic, Skydrol,®jet fuels, and otherindustrial chemicals.• Enhance and protect yourc<strong>on</strong>crete hangar floorswhile increasing overalllight reflectivity.IDEAL FOR: aviati<strong>on</strong> hangars,military aviati<strong>on</strong>, and aviati<strong>on</strong>manufacturing.• Create an attractive, l<strong>on</strong>glastingfloor in <strong>on</strong>e day.Each coat cures in lessthan an hour.• Combine the aestheticsrequired for a commercialenvir<strong>on</strong>ment with theperformance of anindustrial floor.IDEAL FOR: schools,universities, pharmaceuticals,automotive dealerships,museums, sporting facilities,super markets, c<strong>on</strong>venti<strong>on</strong>centers, and airports.AUTO MUSEUM CONVENTION CENTERS, AIRPORTS HANGARS CONVENTION CENTERS, AIRPORTS8800.228.494324 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataPut the experience and expertise of Tennant coatings towork for you.Epoxies repair damage and provide a sound base for topcoats, making floors easier to clean.Eco-MPE | Multi-Purpose <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g>Eco-MPE is a high-performance, two-comp<strong>on</strong>ent epoxy.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONmulti-purpose primer and build coat for thinmilsystems or a broadcast coat, stand-al<strong>on</strong>ecoating, indoor repair of mildly eroded c<strong>on</strong>cretehigh gloss,smooth textureclear, plusstandard andcustom colorsgood/goodacid etch,shot blast,grindsmooth tomild erosi<strong>on</strong>Eco-PT 250 | Power Trowel <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> Overlay ResurfacerA nominal, 1/4-inch, 100% solids, power-troweled system.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONrestorati<strong>on</strong> of large eroded areas,main traffic aisles, loading docksgloss with orangepeel textureneutral, plusstandard andcustom colorsgood/goodshot blastmild tosevere erosi<strong>on</strong>Eco-MVR | Moisture Vapor ReducerPrimer for new c<strong>on</strong>crete.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONc<strong>on</strong>crete that is less than 1 year oldwith Moisture Vapor Emissi<strong>on</strong> rates up to10lbs/1000 square feet in 24hrsn/a must betop coatedclearn/a must betop coatedshot blastsmooth tomild erosi<strong>on</strong>Urethanes create floors that are easier to clean and maintain.Eco-HTS 100 | Satin Urethane TopcoatA premium, 100% aliphatic urethane, Eco-HTS 100 combines aluminum oxide, ceramics,and an abrasi<strong>on</strong>-resistant polymer.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONloading docks, main traffic aisles,warehouses, all heavy-traffic areassatin finish withslight textureclear, plusstandard andcustom colorssuperior/superioracid etch orsand, primesmoothEco-HPS® 100 | Gloss Urethane TopcoatA proprietary, high-performance, single-comp<strong>on</strong>ent, 100% aliphatic urethane.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONaircraft hangars, high-profile areas,showrooms, manufacturing areashigh-gloss,smooth textureclear, plusstandard andcustom colorssuperior/superioracid etch orsand, primesmoothEco-CTO | Cementitious Trowel OverlayEco-CWO | Cementitious Workable OverlayEco-CFO | Cementitious Flowable OverlayFor resurfacing eroded, interior c<strong>on</strong>crete floors in areas that are often wet and exposed torapid temperature changes.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONfood and beverage processing,pharmaceutical and cosmetic manufacturing,rendering plants25 of 57satin andtexturedred, dark andlight gray,beigegood/superiorshot blastmild tosevere erosi<strong>on</strong>www.tennantfloorcoatings.com 9

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataChoose urethane coatings for superior performance at thelowest cost over time.Eco-TCU | Thick-Coat UrethaneHigh-solids, two-comp<strong>on</strong>ent 100% aliphatic urethane to seal quartz and flake.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONaircraft hangars, high-profile areas,showrooms, manufacturing areashigh-gloss,from texturedto smoothclear, plusstandard andcustom colorsgood/superiorshot blastsmooth tomild erosi<strong>on</strong>WearGuard-ITS | Gloss Urethane TopcoatOne-comp<strong>on</strong>ent, moisture-cured urethane applicable in either <strong>on</strong>e or two coats.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONaisles, display areas,producti<strong>on</strong> areas, warehousesgloss withslight textureclear, plusstandard andcustom colorsgood/goodacid etch orsand, primesmoothMaintain your floors with sealers, crack and joint repair, and quickly cured coatings.Eco-Hard-N-Seal | C<strong>on</strong>crete Hardener and SealerA water-based sodium silicate soluti<strong>on</strong> used to harden both old and new c<strong>on</strong>crete floors.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONfactories, warehouses, foodandodor-sensitive areasneutral transparent N/A scrub smoothEco-PJS® | Polyurea Joint FillerA two-comp<strong>on</strong>ent, semi-rigid polyurea joint filler.APPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONfilling c<strong>on</strong>trol, c<strong>on</strong>structi<strong>on</strong>, andc<strong>on</strong>tracti<strong>on</strong> joints, filling wandering cracksgloss finish,smooth texturedark gray N/A chase joints clean edgesEco-UVS / Eco-UVC | InstaCure®+ Soluti<strong>on</strong>An instantly curing product applied directly to c<strong>on</strong>crete or tile.APPLICATIONScommercial, pharmaceutical, medical,and educati<strong>on</strong>APPEARANCEsatin finish withslight texture UVSor smoothglossy UVCCOLORTennant MMA | One Hour Cure Applicati<strong>on</strong>Save time and m<strong>on</strong>ey by refreshing your floor's appearance with minimal interrupti<strong>on</strong>.clearABRASION/CHEMICAL RESISTANCEgood/goodSURFACEPREP METHODacid etchor sandSURFACE ATAPPLICATIONsmoothAPPLICATIONSAPPEARANCECOLORABRASION/CHEMICAL RESISTANCESURFACEPREP METHODSURFACE ATAPPLICATIONcommercial, pharmaceutical, medical,and educati<strong>on</strong>satin texture quartz or flake good/good shot blastsmooth tomild erosi<strong>on</strong>10800.228.494326 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataChoices that make your Tennant coating complete.GlossA gloss coating delivers the highestvisual impact, the best light reflecti<strong>on</strong>,and the smoothest finish. It isnot recommended for heavy-trafficareas.Retenti<strong>on</strong>Many coatings will yellow overtime. To prevent this, choose a100% aliphatic formula specificallydesigned to resist yellowing.ColorCustom colors are often selected toreflect pers<strong>on</strong>al tastes, to coordinatewith a dominant facility color, or tohide poor substrate appearance.Tennant’s <strong>on</strong>-site lab can matchalmost any preferred color.Slip ResistanceHelp protect against slip-and-fallaccidents by choosing a coatingor coating additive that increasestracti<strong>on</strong>. Silica and quartz are mostpopular.Chemical Resistance<strong>Floor</strong>s subject to toxic chemicalspills, battery acid, or similar highlydestructive acids require the specialprotecti<strong>on</strong> of our best chemicalresistantcoatings.Abrasi<strong>on</strong> ResistanceHeavy-wheeled traffic areas, aviati<strong>on</strong>hangars, and other envir<strong>on</strong>mentswith extremely large and heavyequipment require an extremelydurable topcoat.27 of 57www.tennantfloorcoatings.com 11

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTennant offers the industry’s most complete and integrated floor-care soluti<strong>on</strong>s tohelp you create a cleaner, safer envir<strong>on</strong>ment for employees, guests and customers.A floor-care system of high-performing Tennant coatings, sweepers, and scrubbers will:Maximize your floor’s natural life;––––Minimize your maintenance and repair costs;––––Create a world-class impressi<strong>on</strong> that reflects your highest standards;––––Protect your floors from the wear of heavy equipment, harsh chemicals, and extremetemperatures.For help specifying the right flooring soluti<strong>on</strong> for your specific envir<strong>on</strong>ment, please callour technical experts toll-free at 800.228.4943 anytime day or night.TennantP.O. Box 1452Minneapolis,MN U.S.A.55440Call toll-free: 800-228-4943, day or nightFax: 763-513-1829www.tennantfloorcoatings.comEmail: info@tennantco.com28 of 571250-47 <str<strong>on</strong>g>Coating</str<strong>on</strong>g>s Product Guide 4/10©2010 Tennant and Nobles are registered trademarks of Tennant Company, whose products are sold and serviced through Tennant Sales and Service Company, as well as through distributors.

Appendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DTennant <str<strong>on</strong>g>Coating</str<strong>on</strong>g>s Usage Guide Best Better GoodMARKETSDecorative<str<strong>on</strong>g>System</str<strong>on</strong>g>sHighPerformance<str<strong>on</strong>g>System</str<strong>on</strong>g>sWearGuardUrethane<str<strong>on</strong>g>System</str<strong>on</strong>g>sCementitiousOverlay<str<strong>on</strong>g>System</str<strong>on</strong>g>sStaticC<strong>on</strong>trol<str<strong>on</strong>g>System</str<strong>on</strong>g>sResurfacers &Restorati<strong>on</strong><str<strong>on</strong>g>System</str<strong>on</strong>g>sSame-Day<str<strong>on</strong>g>System</str<strong>on</strong>g>Shop <strong>Floor</strong><str<strong>on</strong>g>System</str<strong>on</strong>g>sChemicalResistant<str<strong>on</strong>g>Epoxy</str<strong>on</strong>g><str<strong>on</strong>g>Epoxy</str<strong>on</strong>g><str<strong>on</strong>g>System</str<strong>on</strong>g>sSealer<str<strong>on</strong>g>System</str<strong>on</strong>g>sAutomotive Dealer• Service Bay• Drive Through• Show <strong>Floor</strong>• RestroomAviati<strong>on</strong>• <strong>Hangar</strong> <strong>Floor</strong>• Maintenance Area• Avi<strong>on</strong>ics Room• Office & LobbyChemicalCommercial/Retail• Walkway• Lobby• Restroom• WarehouseCosmeticsElectr<strong>on</strong>icsFood & BeverageInstituti<strong>on</strong>al• Walkway• Lobby• Kitchen• Restroom• WarehouseManufacturingPharmaceuticalWarehouse29 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataColor Selecti<strong>on</strong> Guide“[Our coated floor] is actually there for <strong>on</strong>e reas<strong>on</strong> and that'sto impress our customers, to let them know that we take qualityvery, very seriously.”— Packaging Corporati<strong>on</strong> of AmericaTENNANT COATINGSFor First Impressi<strong>on</strong>s That Last30 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataEco-DFS Decorative Flake <str<strong>on</strong>g>System</str<strong>on</strong>g>Project a quality image through Tennant’s decorative flake system, available in random and full flake blends.StandardFlake BlendsCustom blends areavailableCheckerboardStormEvergreenTweedTornadoSolidFlake ColorsChoose any flake colorcombinati<strong>on</strong> to createthe customized lookyou wantAdobe BeigeAutumn BrownCany<strong>on</strong> RedCocoa BrownCrest GreenPeachDove GrayDusk BlueEggshell WhiteFawnForest GreenGoldMarina BlackMedium GrayMilkweedMint GreenOlivePatio RedPowder BlueRoseWhisper GrayBrownBurgundyDark BlueHunter GreenOrangePrimary YellowRedTrue BlueRandomFlake SampleBlendsAvailable in all standardand custom colorsColors are close approximati<strong>on</strong>s. Please call for samples.31 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataEco-DQS Decorative Quartz <str<strong>on</strong>g>System</str<strong>on</strong>g>Combine the aesthetics required for a commercial envir<strong>on</strong>ment with the performance of an industrial floor.StandardBlendsCustom blends areavailableBlack CherryCinnam<strong>on</strong> TwistCranberry RedNorthwoods GreenSandst<strong>on</strong>eSt<strong>on</strong>e GrayTwilight BlueWild PlumStandardSolidsChoose any quartzcolor combinati<strong>on</strong> tocreate the customizedlook you wantBlackBluePlumBrownCayman GreenCoral RoseRedGreenPeachTanGreyBuffWhiteSmokeTrowelGradeBlackBlueCayman GreenRedWhiteColors are close approximati<strong>on</strong>s. Please call for samples.32 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataStandard ColorantsThe colors as printed are close approximati<strong>on</strong>s and should not be used for specificati<strong>on</strong> purposes. Actual product may vary int<strong>on</strong>e and texture. C<strong>on</strong>sult your Tennant representative for actual colored sample panels.GlossRegal BlueSmoke BlueIvy GreenRotunda RedTile RedYellowSandy BeigeBattleship GrayMedium GrayCanada GrayLight GrayBlackWhiteSatinRegal BlueSmoke BlueIvy GreenRotunda RedTile RedYellowSandy BeigeBattleship GrayMedium GrayCanada GrayLight GrayBlackWhiteTennantP.O. Box 1452Minneapolis, MN U.S.A. 55440Call toll-free: 800.553.8033In Quebec call: 514.335.6061Fax: 763.540.1437www.tennantfloorcoatings.comEmail: info@tennantco.comBV-COC-940655For 135 years, high-performing Tennant flooring soluti<strong>on</strong>s including coatings, sweepers, and scrubbershave been used to minimize maintenance and repair costs and maximize a floor's natural life.Please call our technical experts toll-free at 800.228.4943 anytime day or night.33 of 57Printed in USA. 5/08 Material #1250-56©Copyright 2007 Tennant and Nobles are registered trademarks of Tennant Company, whose products are sold and serviced through Tennant Sales and Service Company

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DatabeforeafterEco-HTS 100 100 g/L SATIN URETHANE TOPCOATHigh-wear protecti<strong>on</strong> for high-traffic areas• INCREASED APPEARANCE – N<strong>on</strong>-yellowing formula comes in avariety of UV-stable colors• DURABLE – Proprietary three-comp<strong>on</strong>ent formula withstands highvolume,heavy-wheeled traffic areas• ENVIRONMENTALLY SAFE – Low odor formula, virtually solventfree,and ideal for odor-sensitive envir<strong>on</strong>ments• VOC COMPLIANT – Eco-HTS 100 meets all current VOC regulati<strong>on</strong>sin North America for industrial maintenance coatingsPart of theFamily:Low Odor No noxious fumes; will not c<strong>on</strong>taminate odor-sensitive inventory.Envir<strong>on</strong>mentally Friendly Reduced solvent means less evaporati<strong>on</strong> and less waste.User Friendly Can be applied during normal business hours—no shutdown required.VOC Compliant Meets the Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency VOC regulati<strong>on</strong>s.TENNANT COATINGSFor First Impressi<strong>on</strong>s That Last34 of 57

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataWear Life of <str<strong>on</strong>g>Coating</str<strong>on</strong>g> ProductsCURING MEMBRANESFLOOR PAINTSEPOXIESOIL-MODIFIED URETHANESMOISTURE-CURED URETHANESECO-HTS 100ABRASION RESISTANCEBased <strong>on</strong> relative mil loss, Eco-HTS 100 has a l<strong>on</strong>ger wear life.Eco-HTS 100 SnapshotAPPEARANCE:Satin finish with slight textureCOLOR:Clear, plus standard and custom colorsTRACTION:Increase slip resistance with Tennant’s grit additivesVOC COMPLIANCE: Very low VOC, 86 g/LABRASION RESISTANCE: SuperiorCHEMICAL RESISTANCE: SuperiorUV STABILITY: 100% aliphatic formula; n<strong>on</strong>-yellowing*APPLICATIONS: Aisles, loading docks, repair shops, hangars andother high-traffic areasINSTALLATION: Customer or c<strong>on</strong>tractor applied*Over the normal life of the coating.100 g/L Colors – 100 g/L areas require 100 g/L colorants; please c<strong>on</strong>tact Tennant for current available selecti<strong>on</strong>. All n<strong>on</strong> 100 g/L areas see standard colorants.Standard Colors – These colors are close approximati<strong>on</strong>s; please c<strong>on</strong>tact Tennant for product samples. Custom colors are also available.WHITE BLACK LIGHT GRAY CANADAGRAYChemical Resistance Properties1 day 7 dayAcids, Inorganic 10% Hydrochloric Acid E E30% Hydrochloric Acid(Muriatic) E E10% Nitric Acid E E50% Phosphoric Acid E G37% Sulfuric Acid(Battery Acid) E EAcids, Organic 10% Acetic Acid E E10% Citric Acid E EOleic Acid E EAlkalies 10% Amm<strong>on</strong>ium Hydroxide E E50% Sodium Hydroxide E ESolvents (Alcohols) Ethylene Glycol (Antifreeze) E EIsopropyl Alcohol E EMethanol E ESolvents (Aliphatic) d-Lim<strong>on</strong>ene E EJet Fuel (JP-4) E EGasoline E EMineral Spirits E ESolvents (Aromatic) Xylene E ESolvents Methylene Chloride P P(Chlorinated)Solvents Methyl Ethyl Ket<strong>on</strong>e (MEK) E E(Ket<strong>on</strong>es & Esters) Propylene Glycol MethylEther Acetate (PMA) E EMiscellaneous 20% Amm<strong>on</strong>ium Nitrate E EChemicals Brake Fluid E EBleach E EMotor Oil (SAE30) E ESkydrol® 500B E ESkydrol® LD4 E E20% Sodium Chloride E E1% Tide® Laundry Soap E E10% Trisodium Phosphate E EBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Skydrol® is a registered trademark of Solutia, Inc. Tide® is a registered trademark of Proctor and Gamble.E = Excellent (No Adverse Effect)G = Good (Limited Adverse Effect or Staining)F = Fair (Moderate Adverse Effect)P = Poor (Unsatisfactory)MEDIUM BATTLESHIP SANDY BEIGE YELLOWGRAYGRAYPhysical/Performance PropertiesMATERIAL PROPERTIES (LIQUID)Property Test Method ResultsFlash Point, °F (°C) ASTM D3278 Part A: >200 (93)Seta Closed Cup Part B: >200 (93)Percent Solids, by weight ASTM D2369 Part A: 99.35Part B: 59.23Part C: 100A+B+C = 94.00Density, lb/gal (kg/L) ASTM D1475 Part A: 9.56 (1.15)(A/B) Part B: 9.54 (1.15)Part C: 33.00 (3.96)A+B+C = 11.93 (1.43)Shelf Life2 years from date of manufactureViscosity, cps ASTM D2196 A+B+C = 700-800BrookfieldVolatile Organic Compound ASTM D3960 Mixed: A+B+C(VOC) lb/gal (g/L) 0.71 (86)CURED COATING PROPERTIES (DRY FILM)Property Test Method ResultsAbrasi<strong>on</strong> Resistance, mg loss ASTM D4060* 18.0Taber AbraserCoefficient of Fricti<strong>on</strong> (COF)** ASTM D2047 0.63James Fricti<strong>on</strong> TesterDry Film Thickness, mils3.0 (1 coat)Tensile Strength, psi (kPa) (resin <strong>on</strong>ly) ASTM C2370 6,250 (43,088)Percent El<strong>on</strong>gati<strong>on</strong> (resin <strong>on</strong>ly) ASTM D2370 6König Hardness (3 mil film) (resin <strong>on</strong>ly) 171.3APPLICATION CHARACTERISTICS (1 GALLON)PropertyResultsCoverage Rate, ft 2 /gal 500Applicati<strong>on</strong> Thickness, wet mils3.2 (1 coat)*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>s.**To improve tracti<strong>on</strong> in slip hazard areas, use Tennant 291 Grit.See 291 Grit Product Bulletin for more informati<strong>on</strong>.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F, 50% relative humidity.TILE RED ROTUNDA IVY GREEN SMOKE BLUE REGAL BLUEREDTennant701 North Lilac DriveMinneapolis, MN 55422 USAtel: +1-763-540-1315fax:+1-763-513-2144www.tennantco.comemail: info@tennantco.comA floor-care system of high-performing Tennant coatings, sweepers,and scrubbers will maximize your floor's natural life, minimize yourmaintenance costs and create a world-class impressi<strong>on</strong>.35 of 571250-74 Eco-HTS 100 9/08©2008 The Tennant Company logo and other marks designated with the symbol "♦" are registeredtrademarks of Tennant Company, Inc., in the United States and/or other countries. The marks designatedwith "TM" are trademarks of Tennant Company that are not yet registered in the United States.

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataEco-MPEMULTI-PURPOSE EPOXYHigh-performance soluti<strong>on</strong>• EASY TO USE – Self-leveling formula allows easy applicati<strong>on</strong>• PROVIDES A HIGH-QUALITY LOOK – High-gloss finish improvesthe appearance over c<strong>on</strong>crete-based fillers• LOW ODOR – Perfect for odor-sensitive stock and envir<strong>on</strong>ments• MULTI-PURPOSE – Primer and build coatPart of theFamily:Low Odor No noxious fumes; will not c<strong>on</strong>taminate odor-sensitive inventory.Envir<strong>on</strong>mentally Friendly Reduced solvent means less evaporati<strong>on</strong> and less waste.User Friendly Can be applied during normal business hours—no shutdown required.VOC Compliant Meets the Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency VOC regulati<strong>on</strong>s.TENNANT COATINGSFor First Impressi<strong>on</strong>s That Last36 of 57

<str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> Cure TimesEco-MPETORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataHOURSECO-MPESTANDARD EPOXIESAPPEARANCE:COLOR:TRACTION:High-gloss finish with smooth textureClear, plus standard and custom colorsIncrease slip resistance with Tennant’s line of grit additivesVOC COMPLIANCE: Eco-MPE: Very low VOC; 4 g/LCURE TIME:APPLICATIONS:INSTALLATION:Eco-MPE: 18 hours under normal c<strong>on</strong>diti<strong>on</strong>sEco-MPE: Multi-purpose primer and build coatEco-MPE: Professi<strong>on</strong>al applicati<strong>on</strong> suggested;special equipment requiredStandard Colors – These colors are close approximati<strong>on</strong>s; please c<strong>on</strong>tact Tennant for product samples. Custom colors are also available. See product bulletin for any restricti<strong>on</strong>s <strong>on</strong> colorant use.WHITE BLACK LIGHT GRAY CANADAGRAYMEDIUM BATTLESHIP SANDY BEIGE YELLOWGRAYGRAYTILE RED ROTUNDA IVY GREEN SMOKE BLUE REGAL BLUEREDChemical Resistance PropertiesAcids, Inorganic 10% Hydrochloric Acid E E(Muriatic) 30% Hydrochloric Acid E G10% Nitric Acid E G50% Phosphoric Acid F F37% Sulfuric Acid GG(Battery Acid)Acids, Organic 10% Acetic Acid G F10% Citric Acid GGOleic AcidG FAlkalies 10% Amm<strong>on</strong>ium Hydroxide E E50% Sodium Hydroxide E ESolvents Ethylene Glycol (Antifreeze) E G(Alcohols) Isopropyl Alcohol F PMethanolF FSolvents d-Lim<strong>on</strong>ene GG(Aliphatic) Jet Fuel (JP-4) E EGasolineGGMineral SpiritsE ESolvents (Aromatic) Xylene F FSolvents(Chlorinated) Methylene Chloride P PSolvents Methyl Ethyl Ket<strong>on</strong>e (MEK) P P(Ket<strong>on</strong>es & Esters) Propylene Glycol Methyl F FEther Acetate (PMA)Miscellaneous 20% Amm<strong>on</strong>ium Nitrate E EChemicals Brake Fluid F FBleachE EMotor Oil (SAE30)E ESkydrol® 500BF FSkydrol® LD4F F20% Sodium Chloride E E1% Tide® Laundry Soap E E10% Trisodium Phosphate E EBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Skydrol® is a registered trademark of M<strong>on</strong>santo. Tide® is a registered trademark of Proctor and Gamble.E = Excellent (No Adverse Effect)G = Good (Limited Adverse Effect or Staining)1-7 dayF = Fair (Moderate Adverse Effect)P = Poor (Unsatisfactory)Physical/Performance PropertiesMATERIAL PROPERTIES (LIQUID) ECO-MPEProperty Test Method ResultsFlash Point, °F (°C) ASTM D3278 Part A: >200 (93)Seta Closed Cup Part B: >200 (93)Percent Solids, by weight ASTM D2369 Part A: 99.4Part B: 99.8Density, lb/gal (kg/L) ASTM D1475 Part A: 9.22 (1.11)Part B: 8.39 (1.00)Mixed: 8.94 (1.07)Shelf Life2 yearsViscosity, cps ASTM D2196 Part A: 700-1000Brookfield Part B: 350-550Mixed: 500-700Volatile Organic Compound ASTM D3960 Mixed: A+B(VOC) lb/gal (g/L) 0.04 (5)CURED COATING PROPERTIES (DRY FILM) Eco-MPEProperty Test Method ResultsAbrasi<strong>on</strong> Resistance, mg loss ASTM D4060* 83.1Taber AbraserCoefficient of Fricti<strong>on</strong> (COF)** ASTM D2047 0.59–0.62James Fricti<strong>on</strong> TesterCompressive Strength, psi (kPa) ASTM D695 13,500 (93,150)Tensile Strength, psi (kPa) ASTM D2370 8,000 (55,200)Percent El<strong>on</strong>gati<strong>on</strong> ASTM D2370 5Shore D Hardness ASTM D2240 80-85 @ 0 sec75-80 @ 15 secUV/Light StabilityAPPLICATION CHARACTERISTICSPropertyWill yellow or amber over timeResultsCoverage Rate, ft 2 /gal 53-535Applicati<strong>on</strong> Thickness, wet mils 3-30*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>s.**To improve tracti<strong>on</strong> in slip hazard areas, use Tennant 292 Grit.See 292 Grit Product Bulletin for more informati<strong>on</strong>.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F, 50% relative humidity.Tennant701 North Lilac DriveMinneapolis, MN 55422 USAtel: +1-763-540-1315fax:+1-763-513-2144www.tennantco.comemail: info@tennantco.comA system of high-performing Tennant coatings, sweepers, andscrubbers will maximize your floor's natural life, minimize yourmaintenance costs and create a world-class impressi<strong>on</strong>.37 of 571250-99 Eco-MPE 12/08©2008 The Tennant Company logo and other marks designated with the symbol "®" are registeredtrademarks of Tennant Company, Inc., in the United States and/or other countries. The marks designatedwith "TM" are trademarks of Tennant Company that are not yet registered in the United States.

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataBeforeAfterBeforeAfterEco-PT 250POWER-TROWEL EPOXY OVERLAYRESURFACERThe proven soluti<strong>on</strong> for restoring eroded c<strong>on</strong>crete• ECONOMICAL – Avoids costly floor replacement and reducescleaning maintenance costs• EASY TO CLEAN – Protects against dirt, spills and wear• PERFECT FOR LARGE AREA RESTORATION – Handles heavyloads in main traffic aisles and loading docksPart of theFamily:Low Odor No noxious fumes; will not c<strong>on</strong>taminate odor-sensitive inventory.Envir<strong>on</strong>mentally Friendly Reduced solvent means less evaporati<strong>on</strong> and less waste.User Friendly Can be applied during normal business hours—no shutdown required.VOC Compliant Meets the Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency VOC regulati<strong>on</strong>s.TENNANT COATINGSFor First Impressi<strong>on</strong>s That Last38 of 57

Eco-PT 250 SnapshotAPPEARANCE:COLOR:TRACTION:Gloss finish, orange peel textureNeutral, plus standard and custom colorsIncrease slip resistance with Tennant’s line of grit additivesVOC COMPLIANCE: Solvent-free; 0.0 VOCPERFORMANCE:APPLICATIONS:INSTALLATION:TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataRestore a High-Quality Look—Over a Weekend.This nominal, 1/4-inch, 100 percent solids, power-troweled system c<strong>on</strong>sists of Eco-MPE primer; Eco-PT 250 resurfacer; and Eco-PT or Eco-HT topcoat,which is required to seal the surface. It’s recommended for large area restorati<strong>on</strong> of eroded c<strong>on</strong>crete, such as main traffic aisles and loading docks.High compressive strength; exceeds c<strong>on</strong>creteRestorati<strong>on</strong> of large eroded areasProfessi<strong>on</strong>al applicati<strong>on</strong> and special equipment requiredNOTE: Eco-PT 250 must be topcoated with Eco-PT or Eco-HT topcoat to seal the surface.Standard Colors – These colors are close approximati<strong>on</strong>s; please c<strong>on</strong>tact Tennant for product samples. Custom colors are also available. See product bulletin for any restricti<strong>on</strong>s <strong>on</strong> colorant use.WHITE BLACK LIGHT GRAY CANADAGRAYMEDIUM BATTLESHIP SANDY BEIGE YELLOWGRAYGRAYTILE RED ROTUNDA IVY GREEN SMOKE BLUE REGAL BLUEREDChemical Resistance PropertiesUnpigmented Eco-PT topcoat1 day 7 dayAcids, Inorganic 10% Hydrochloric Acid E E30% Hydrochloric Acid E E(Muriatic)10% Nitric Acid E G50% Phosphoric Acid F P37% Sulfuric Acid G G(Battery Acid)Acids, Organic 10% Acetic Acid F P10% Citric Acid E GOleic Acid G FAlkalies 10% Amm<strong>on</strong>ium Hydroxide E E50% Sodium Hydroxide E ESolvents (Alcohols) Ethylene Glycol (Antifreeze) E EIsopropyl Alcohol F FMethanol F FSolvents (Aliphatic) d-Lim<strong>on</strong>ene E EJet Fuel (JP-4) E EGasoline E GMineral Spirits E ESolvents (Aromatic) Xylene F FSolvents Methylene Chloride P P(Chlorinated)Solvents Methyl Ethyl Ket<strong>on</strong>e (MEK) P P(Ket<strong>on</strong>es & Esters) Propylene Glycol Methyl F FEther Acetate (PMA)Miscellaneous 20% Amm<strong>on</strong>ium Nitrate E EChemicals Brake Fluid F FBleach G GMotor Oil (SAE30) E ESkydrol® 500B F PSkydrol® LD4 F P20% Sodium Chloride E E1% Tide® Laundry Soap E E10% Trisodium Phosphate E EBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Skydrol® is a registered trademark of M<strong>on</strong>santo. Tide® is a registered trademark of Proctor and Gamble.Physical/Performance PropertiesMATERIAL PROPERTIES (LIQUID)Property Test Method ResultsPercent Solids, by weight ASTM D2369 100Volatile Organic Compound ASTM D3960 0 (0)(VOC) lb/gal (g/L)CURED COATING PROPERTIES (DRY FILM)Property Test Method ResultsCoefficient of Fricti<strong>on</strong> (COF)** ASTM D2047 0.60-0.63James Fricti<strong>on</strong> Tester(with 2 coats of Eco-PT topcoat)Coefficient of Thermal Linear ASTM D696 1.97 x 10 5Expansi<strong>on</strong>, mm/mm/ºCComprehensive Strength, psi (kPa) ASTM C579 10,000 (69,000)Flexural Strength, psi (kPa) ASTM D790 3,700 (25,530)Flexural Modulas of Elasticity, ASTM D790 1.8 x 10 6 (1.2 x 10 7 )psi (kPa)Heat Deflecti<strong>on</strong> Temperature ASTM D648 60ºC @ 264 psi load66ºC @ 66 psi loadIzod Impact Strength, lb/in (N/m) ASTM D256 0.26 (45.53)Tensile Strength, psi (kPa) ASTM C307 1,690 (11,660)UV/Light StabilityAPPLICATION CHARACTERISTICSPropertyEco-PT 250Will turn yellow or amber over timeResultsCoverage Rate, ft 2 (3 bag mix) 56-70Applicati<strong>on</strong> Thickness, inches 1/4” - 3/16”Eco-PT or Eco-HT TopcoatCoverage Rate, ft 2 /gal 200-300Applicati<strong>on</strong> Thickness, wet/dry mils5-8 per coatNOTE: Chemical Resistance and Physical/Performance Properties are based <strong>on</strong> the three-part productinstallati<strong>on</strong> of Eco-MPE, Eco-PT 250 and Eco-PT or Eco-HT topcoat.E = Excellent (No Adverse Effect)G = Good (Limited Adverse Effect or Staining)F = Fair (Moderate Adverse Effect)P = Poor (Unsatisfactory)*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>s.**To improve tracti<strong>on</strong> in slip hazard areas, Tennant 292 grit can be added to the PT topcoat.See 292 Grit Product Bulletin for more informati<strong>on</strong>.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F, 50% relative humidity.Tennant701 North Lilac DriveMinneapolis, MN 55422 USAtel: +1-763-540-1315fax:+1-763-513-2144www.tennantco.comemail: info@tennantco.comBV-COC-94065539 of 57A floor-care system of high-performing Tennantcoatings, sweepers, and scrubbers will maximizeyour floor's natural life, minimize your maintenancecosts and create a world-class impressi<strong>on</strong>.1250-80 Eco-PT250 9/08©2008 The Tennant Company logo and other marks designated with the symbol "®" are registeredtrademarks of Tennant Company, Inc., in the United States and/or other countries. The marks designatedwith "TM" are trademarks of Tennant Company that are not yet registered in the United States.

TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataEco-RCE Eco-RCE/F Eco-RCE/M RAPID CURE EPOXIES• REDUCE DOWNTIME – Eco-RCE, RCE/F and RCE/M featurefaster cure times for a faster return to business operati<strong>on</strong>• PRIME AND BUILD FLOORS – Use as a c<strong>on</strong>crete primeror build coat to level floors• EASY TO USE – Self-leveling formulas enable easy applicati<strong>on</strong>for higher profile and mechanically prepared floorsPart of theFamily:Low Odor No noxious fumes; will not c<strong>on</strong>taminate odor-sensitive inventory.Envir<strong>on</strong>mentally Friendly Reduced solvent means less evaporati<strong>on</strong> and less waste.User Friendly Can be applied during normal business hours—no shutdown required.VOC Compliant Meets the Envir<strong>on</strong>mental Protecti<strong>on</strong> Agency VOC regulati<strong>on</strong>s.TENNANT COATINGSFor First Impressi<strong>on</strong>s That Last40 of 57

Eco-RCE, RCE/F, RCE/M SnapshotTORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataCOLOR:VOC COMPLIANCE:WALK-ON TIME:APPLICATIONS:INSTALLATION:RCE, RCE/F, RCE/M – clear, Tennant 100 SeriesColorants, or full broadcast decorative flake orquartz into membrane.< 2 g/L.RCE, RCE/F: 4 hours under normal circumstances.RCE/M: 5 hours under normal circumstances.Multi-purpose primer and build coat.Professi<strong>on</strong>al applicati<strong>on</strong> recommended; specialequipment required. RCE, RCE/F arec<strong>on</strong>tractor-<strong>on</strong>ly product offerings.Physical/Performance PropertiesMATERIAL PROPERTIES (LIQUID)RCE, RCE/FRCE/MProperty Test Method Results ResultsFlash Point, °F (°C) ASTM D3278 Part A: >200 (93) Part A: >200 (93)Seta Closed Cup Part B: >200 (93) Part B: >200 (93)Percent Solids, by weight ASTM D2369 Part A: 99.9 Part A: 99.9Part B: 99.9 Part B: 99.8Density, lb/gal (kg/L) ASTM D1475 A/B (RCE): 9.04 (1.09) A/B: 9.10 (1.09)A/B (RCE/F): 9.06 (1.09)Viscosity, cps ASTM D2196 Part A: 250-650 Part A: 700-1000Brookfield Part B: 100-450 Part B: 350-550A/B: 250-450 A/B: 500-700Volatile Organic Compound ASTM D3960 Mixed A+B: 0.01 (0.82) Mixed A+B: 0.01 (1.15)(VOC) lb/gal (g/L)CURED COATING PROPERTIES (DRY FILM)RCE, RCE/FRCE/MProperty Test Method Results ResultsAbrasi<strong>on</strong> Resistance, mg loss ASTM D4060* NA 83.1*Taber AbraserCompressive Strength, psi (kPa) ASTM D695 NA 13,500 (93,150)Tensile Strength, psi (kPa) ASTM D2370 5,200 (35,880) 7,000 (48,300)Percent El<strong>on</strong>gati<strong>on</strong> ASTM D2370 4 5Coefficient of Fricti<strong>on</strong> (COF)** ASTM D2047 NA 0.5**Shore D Hardness ASTM D2240 80-85 @ 0 sec 80-85 @ 0 sec75-80 @ 15 sec 75-80 @ 15 secAPPLICATION CHARACTERISTICSRCE, RCE/FRCE/MProperty Test Method Results ResultsCoverage Rate Range, ft 2 /gal 80-535 53-535Applicati<strong>on</strong> Thickness, wet/dry mils 3-30 3-30*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>s.**After cleaning floor with auto scrubber.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F, 50% relative humidity.TennantP.O. Box 1452Minneapolis,MN U.S.A.55440800-553-8033In Quebec call: 514.335.6061Fax: 763.540.1437www.tennantco.cominfo@tennantco.comA system of high-performing Tennant coatings, sweepers, and scrubberswill maximize your floor's natural life, minimize your maintenancecosts and create a world-class impressi<strong>on</strong>.41 of 571250-63 Eco-RCE, RCE/F, RCE/M 7/08©2008 Tennant and Nobles are registered trademarks of Tennant Company, whoseproducts are sold and serviced through Tennant Sales & Service Company.

PRODUCT BULLETINEco-HTS 100Satin Urethane TopcoatTORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataTennant Company (Headquarters)Tennant Company (Australia)701 North Lilac Drive, P.O. Box 1452Head Office: Unit 2 Block Y, 391 Park Road, P.O. Box 116Minneapolis, MN 55440-1452Regents Park NSW 2143800-553-8033 / www.tennantco.comSales: 1800 226 843 / www.tennantco.com© Tennant Company 03/17/10 Page 1 of 4DESCRIPTION:High solids, three-comp<strong>on</strong>ent, aliphatic, moisture-cureurethane applied over an epoxy primer or used to recoat anexisting epoxy or urethane floor.USES:• Designed for loading docks, main traffic aisles and areasthat call for light stability with a satin appearance.ADVANTAGES:• Lasts twice as l<strong>on</strong>g as standard urethanes; up to fourtimes as l<strong>on</strong>g as standard epoxies• Light stable, satin-finish maintains fresh look in trafficaisles• Resists Skydrol®, jet fuels and other industrial chemicals• Low VOC (5 g/L). (Complies with SCAQMD VOCregulati<strong>on</strong>s. LEED credits available.)STORAGE: Materials should be stored indoors between65ºF (18ºC) and 90ºF (32ºC).SHELF LIFE: Two years from date of manufacture.PACKAGING OPTIONS / PART NUMBERS:Eco-HTS 100:1.09 gall<strong>on</strong>s (4.13 litres) / 90026175.5 gall<strong>on</strong>s (20.82 litres) / 9002621OPTIONS:Colors: All 100 Series Colorants may be added toEco-HTS 100. 100 Series colorants must be used if VOC ofthe mix needs to be 200 / 93B - >200 / 93ASTM D2369 A - 99.35B - 59.23C- 100.00A+B+C = 94.00ASTM D1475 A - 9.56 / 1.15(A/B)B - 9.54 / 1.15C- 33.00/3.96A+B+C=11.93 /1.43ASTM D2196 A+B+C=700-800ASTM D3960CURED COATING PROPERTIES (DRY FILM):Mixed A+B+C0.04 (5)Property Test Method ResultsAbrasi<strong>on</strong> Resistance,mg lossTaber AbraserCoefficient of Fricti<strong>on</strong> -COFJames Fricti<strong>on</strong> TesterDry Film Thicknessmils (micr<strong>on</strong>s)Tensile Strength,psi (MPa) (resin <strong>on</strong>ly)Percent El<strong>on</strong>gati<strong>on</strong>(resin <strong>on</strong>ly)König Hardness(3 mil / 76.2 micr<strong>on</strong> film)(resin <strong>on</strong>ly)ASTM D4060* 18ASTM D2047 0.633.0 (1 coat)(76.2)ASTM D2370 6,250 (43.092)ASTM D2370 6ASTM D4366 171.3*CS-17 Taber Abrasi<strong>on</strong> Wheel, 1,000 gram load, 1,000 revoluti<strong>on</strong>sBased <strong>on</strong> independent lab testing of Eco-HTS.Results are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F (25°C), 50% relativehumidity.APPLICATION CHARACTERISTICS:A gall<strong>on</strong> (litre) of Eco-HTS 100 will cover:Coverage Rate, ft 2 /gal (m 2 /L) 500 (12.3)Applicati<strong>on</strong> Thickness,wet mils (micr<strong>on</strong>s)3.2 (81)1 coatResults are based <strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s at 77°F (25°C), 50% relativehumidity.42 of 57

CHEMICAL RESISTANCEUNPIGMENTED - ECO-HTS 100 1 Day 7 DaysAcids, Inorganic10% Hydrochloric Acid E E30% Hydrochloric Acid (Muriatic) E E10% Nitric Acid E E50% Phosphoric Acid E G37% Sulfuric Acid (Battery Acid) E EAcids, Organic10% Acetic Acid E E10% Citric Acid E EOleic Acid E EAlkalies10% Amm<strong>on</strong>ium Hydroxide E E50% Sodium Hydroxide E ESolvents (Alcohols)Ethylene Glycol (Antifreeze) E EIsopropyl Alcohol E EMethanol E ESolvents (Aliphatic)d-Lim<strong>on</strong>ene E EJet Fuel - JP-4 E EGasoline E EMineral Spirits E ESolvents (Aromatic)Xylene E ESolvents (Chlorinated)Methylene Chloride P PSolvents (Ket<strong>on</strong>es & Esters)Methyl Ethyl Ket<strong>on</strong>e (MEK) E EPropylene Glycol Methyl Ether Acetate(PMA)E EMiscellaneous Chemicals20% Amm<strong>on</strong>ium Nitrate E EBrake Fluid E EBleach E EMotor Oil (SAE 30) E ESkydrol® 500B E ESkydrol® LD4 E E20% Sodium Chloride E E1% Tide® Laundry Soap E E10% Trisodium Phosphate E EBased <strong>on</strong> 1-day and 7-day spot testing <strong>on</strong> c<strong>on</strong>crete.<str<strong>on</strong>g>Coating</str<strong>on</strong>g> cured 2 weeks prior to testing.Legend:E - Excellent (No Adverse Effect) - Recommended.G - Good (Limited Adverse Effect) - Use for short-term exposure<strong>on</strong>ly.F - Fair (Moderate Adverse Effect) - Not recommended.P - Poor (Unsatisfactory) - Little or no resistance to chemical.Note:Reduced chemical resistance and increased staining ispossible in pigmented versi<strong>on</strong>s of this system.Tide ® is a registered trademark of Proctor and Gamble.Skydrol ® is a registered trademark of M<strong>on</strong>santo.TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataIMPORTANT:READ AND FOLLOW ALL PRECAUTIONS ANDINSTRUCTIONS BEFORE PROCEEDING.PRELIMINARY FLOOR INSPECTIONSCHECK THE CONCRETE: C<strong>on</strong>crete must be structurallysound and free of curing membrane, paint or other sealer. Ifyou suspect that the c<strong>on</strong>crete has been previously sealed,call Tennant Company, technical support for furtherinstructi<strong>on</strong>s.CHECK FOR MOISTURE: C<strong>on</strong>crete must be dry beforeapplicati<strong>on</strong> of this floor coating material. C<strong>on</strong>crete moisturetesting must occur. Calcium chloride testing or in-situ relativehumidity testing is recommended. Readings must be below3 pounds per 1,000 square feet (1.5 kg per 150m 2 ) over a24-hour period <strong>on</strong> the calcium chloride test or below 75%relative internal c<strong>on</strong>crete humidity. Test methods can bepurchased at www.astm.org, see ASTM F1869 or F2170,respectively or follow manufacturer's instructi<strong>on</strong>s.NOTE: Although testing is critical, it is not a guaranteeagainst future problems. This is especially true if there is novapor barrier or the vapor barrier is not functi<strong>on</strong>ing properlyand/or you suspect you may have c<strong>on</strong>crete c<strong>on</strong>taminati<strong>on</strong>from oils, chemical spills or excessive salts.CHECK THE TEMPERATURE AND HUMIDITY: <strong>Floor</strong>temperature and materials should be between 65°F (18°C)and 90°F (32°C). Humidity must be less than 80%. DO NOTcoat unless floor temperature is more than five degrees overthe dew point.APPLICATION EQUIPMENT• Protective clothing• Jiffy ® Mixer Blade[Tennant Part No. 08643-1 (small unit) or08643-5 (large unit)]• Slow speed drill (500 rpm or less)• Roller Assembly• Shed Resistant, 3/8" (10mm) Nap Rollers• Applicati<strong>on</strong> Tray• Disc machine• 60 grit sandpaper[Tennant Part No. 65449]• 80 grit sandpaper[Tennant Part No. 65450]ASSEMBLE EQUIPMENT: Clean roller with tape to removeany residual lint.PREPARATIONDetergent scrub and rinse with clean water to removesurface dirt, grease, oil and c<strong>on</strong>taminants.JOINTS: Depending <strong>on</strong> the preference of the facility owner,joints may or may not be filled. If the joints are filled, n<strong>on</strong>movingjoints, i.e. c<strong>on</strong>tracti<strong>on</strong> or c<strong>on</strong>trol joints, can be hardfilled with thickened, 100% solids epoxy or with a semi-rigidjoint filler such as Eco-PJS or Eco-EJF. C<strong>on</strong>structi<strong>on</strong>joints less than <strong>on</strong>e inch wide may also be filled withEco-PJS. Isolati<strong>on</strong> or expansi<strong>on</strong> joints must be filled with aflexible material designed for this purpose. <str<strong>on</strong>g>Coating</str<strong>on</strong>g> appliedover filled joints will crack if there is c<strong>on</strong>crete movement.Eco-HTS100 © Tennant Company 03/17/10 Page 2 of 443 of 57

Appendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataRECOATEco-HTS 100 may be used to coat over an existing epoxy orurethane in sound c<strong>on</strong>diti<strong>on</strong>. <strong>Floor</strong> must be sandedthoroughly with 80 grit paper/60 grit screen prior to recoating.If sanding a high wear urethane, use 60 grit paper as the fillerin high wear urethanes will wear down the paper very quickly.Change the paper every 200 sq. ft. (18.6 m 2 ) so abrasivestays sharp.We recommend thorough sanding with a swing-type buffer sothat multiple scratch marks cause an obvious gloss loss <strong>on</strong>all areas (depressi<strong>on</strong>s will remain shiny), and the floor isuniformly dulled. The ability to see individual scratch marksis an indicati<strong>on</strong> that sanding is not adequate. Scrub withdetergent and rinse with clean water before coating.BARE CONCRETE APPLICATION - PRIMERECO-HTS 100 MUST BE APPLIED OVER A TENNANT100% SOLIDS EPOXY PRIMER. (See appropriate epoxyproduct bulletin for applicati<strong>on</strong> instructi<strong>on</strong>s.)EPOXY MUST BE THOROUGHLY SANDED ANDCLEANED PRIOR TO APPLICATION OF ECO-HTS 100unless Eco-HTS 100 can be applied within the recoatwindow. The window is 24 hours for floor temperatures65°F-90°F (18°C-32°C).APPLICATION – COATINGPREMIX PART A FOR 3 MINUTES USING A JIFFY®MIXER BLADE with slow speed drill. POTLIFE: Mix <strong>on</strong>lyenough material which can be used in a two-hour period.NOTE: Once opened, this material cannot be resealed forlater use.COLORS: Premix Tennant Colorants (100 series colorantsmust be used to achieve 100 g/L VOC) before adding toEco-HTS 100 to ensure uniform color. Add colorant toEco-HTS 100 A.POUR PART C INTO PART A while mixing. NOTE: Thematerials in this c<strong>on</strong>tainer are not blended. The entireamount MUST be added.CONTINUE TO MIX AND ADD PART B.MIX FOR 3 MINUTES using a Jiffy® mixer blade and slowspeed drill. Pour into applicati<strong>on</strong> tray.APPLY ECO-HTS 100 at the rate of 500 sq. ft. per gall<strong>on</strong>(12.3 m 2 /L) with a 3/8" (10 mm) nap roller. For properappearance and development of physical properties, it iscrucial that material is not applied above or below this rate.Dip the roller in the coating and lightly roll out excess in theapplicati<strong>on</strong> tray. Apply two 8-10 foot (2.4-3.0 meter) l<strong>on</strong>gpaths <strong>on</strong> the c<strong>on</strong>crete, making <strong>on</strong>e stroke left to right and <strong>on</strong>eright to left. Rewet the roller and apply two more pathsadjacent to the first pair. Rewet roller and apply a third pairadjacent to the sec<strong>on</strong>d.SPREAD THE MATERIAL evenly with V-shaped crosspasses.MAKE SURE THE FLOOR HAS JUST ENOUGH COATINGTO COVER EVENLY. Excess material could cause the floorto blister, especially in high humidity. Insufficient material willcause the floor to look n<strong>on</strong>-uniform.LEVEL THE AREA with straight passes that cross the initialmaterial paths. These final strokes will reduce roller marks.If the appearance is not satisfactory, reroll the area.REMIX THE MATERIAL in the tray occasi<strong>on</strong>ally (with theroller) to prevent settling of the Part C (filler).NOTE: When multiple applicators are used to apply material,inc<strong>on</strong>sistencies between areas may result. To ensure amore uniform finish, an individual outfitted with spike shoesmay finish by pushing or pulling a roller across all applicatorareas.ALLOW COATING TO DRY 24 HOURS at 75°F (24°C), 50%relative humidity before opening to light traffic. Allow moretime at low temperatures, low humidity or for heavier traffic.Full coating properties take 14 days to develop.TECHNICAL SUPPORTFor any preparati<strong>on</strong> or applicati<strong>on</strong> questi<strong>on</strong>s, please callTennant technical support at 800-228-4943 ext. 6075 (1800226 843 Aust).DISPOSALDispose in accordance with federal, state and localregulati<strong>on</strong>s.PLEASE SEE MATERIAL SAFETY DATASHEET (MSDS) FOR SAFETY ANDPRECAUTIONS.USE PRODUCT AS DIRECTED.KEEP OUT OF THE REACH OFCHILDREN.Eco-HTS100 © Tennant Company 03/17/10 Page 3 of 444 of 57TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> D

MAINTENANCE GUIDELINESAllow floor coating to cure at least <strong>on</strong>e weekbefore cleaning by mechanical means (e.g.,sweeper, scrubber, disc machine).Care: Proper maintenance will increase the life and helpmaintain the appearance of your new Tennant floor coating.Sweep and scrub your new coating regularly, as dirt and dustare abrasive and can quickly dull the finish, decreasing thelife of your coating. Remove spills quickly as certainchemicals may stain and could possibly permanently damagethe finish.Use soft nyl<strong>on</strong> brushes or white pads <strong>on</strong> your new floorcoating. Polypropylene or abrasive bristle (Tynex®)brushes can cause premature loss of gloss.Detergent: Tennant has a full range of detergents--generalpurpose to heavy duty--for your cleaning needs. Forassistance in determining which detergent is right for yourfacility or for additi<strong>on</strong>al technical informati<strong>on</strong> call: 800-553-8033 US (1800 226 843 Aust).Cauti<strong>on</strong>: Avoid scratching or gouging the surface. All floorcoatings will scratch if heavy objects are dragged across thesurface.Do not drop heavy or pointed items <strong>on</strong> the floor as this maycausing chipping or c<strong>on</strong>crete popouts in the case of a weakcap.Rubber tires can permanently stain the floor coating fromplasticizer migrati<strong>on</strong>. Plexiglass® between the tire and thefloor coating can prevent discolorati<strong>on</strong>.Rubber burns from quick stops and starts can heat thecoating to its softening temperature, causing permanentmarking.Repair: Repair gouges or scratches or chip outs as so<strong>on</strong> aspossible to prevent moisture or chemical c<strong>on</strong>taminati<strong>on</strong>.TORFP GJKZ 09-0063 <str<strong>on</strong>g>SOW</str<strong>on</strong>g> <str<strong>on</strong>g>Attachment</str<strong>on</strong>g> DAppendix D Existing <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g> <str<strong>on</strong>g>Coating</str<strong>on</strong>g> <str<strong>on</strong>g>System</str<strong>on</strong>g> DataCONDITIONS OF SALE AND LIMITATION OFWARRANTY AND LIABILITYThis warranty applies to all Specialty Surface <str<strong>on</strong>g>Coating</str<strong>on</strong>g>s, withthe following excepti<strong>on</strong>s: Eco-Hard-N-Seal,Eco-EDP (Electrostatic Dissipative Primer),Eco-EDE (Electrostatic Dissipative <str<strong>on</strong>g>Epoxy</str<strong>on</strong>g>), and SDS(Static Dissipative <str<strong>on</strong>g>System</str<strong>on</strong>g>). These products have a separatewarranty policy.Tennant Company warrants its Specialty Surface <str<strong>on</strong>g>Coating</str<strong>on</strong>g>s tobe free from defective manufacture, improper formulati<strong>on</strong>,and defective ingredients. Warranty covers replacement ofmaterials <strong>on</strong>ly.THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHERWARRANTIES EXPRESSED OR IMPLIED, INCLUDING,BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OFMERCHANTABILITY AND FITNESS FOR A PARTICULARPURPOSE.In no event shall Tennant or Seller be liable for anyincidental, c<strong>on</strong>sequential, or special damages arising out ofthe use of Tennant Specialty Surface <str<strong>on</strong>g>Coating</str<strong>on</strong>g>s. THE ONLYREMEDY OF THE USER OR BUYER, AND THE ONLYLIABILITY OF TENNANT AND SELLER FOR ANY ANDALL CLAIMS, LOSSES, INJURIES, OR DAMAGES(INCLUDING CLAIMS BASED ON BREACH OFWARRANTY, CONTRACT, NEGLIGENCE, STRICTLIABILITY, OR OTHERWISE) SHALL BE REPLACEMENTOF THE PRODUCT OR, AT THE ELECTION OF TENNANTOR SELLER, RETURN OF THE PURCHASE PRICE.No representative of Tennant has authority to give anyother warranty or assume other liability.The presence of a Tennant employee during the applicati<strong>on</strong>of Tennant’s Specialty Surface <str<strong>on</strong>g>Coating</str<strong>on</strong>g>s does not extend oralter the warranty or limitati<strong>on</strong>s in any manner whatsoever.Eco-HTS100 © Tennant Company 03/17/10 Page 4 of 445 of 57